Showa Denki MAA1050-Y005E User manual

MAA1050-Y005E

Blower Operating

Instructions

Axial Flow/Mixed Flow Type Blower

- 1 -

Blower Operating Instructions

Introduction

Thank you for purchasing Showa Denki’s blower.

These Operating Instructions provide explanations on items for operation, maintenance, etc., of the

blower.

To ensure this blower exhibits its full performance and can be used safely without failures for a long

period of time, read these Operating Instructions carefully. Please keep these Operating Instructions at

hand for your later reference.

These Operating Instructions describe the following types of blowers.

Axial flow type blower

Mixed flow type blower

•Only the main body of the V-belt drive blower

(Motor base and belt guard are standard accessories.)

(Motor pulley and V-belt are optional.)

•M specification of the V-belt drive blower (blower in which a motor, pulley and V-belt are

incorporated)

•Only the main body of the motor shaft direct-coupling blower (impeller is an accessory)

(These Operating Instructions do not describe the assembly method because it requires

professional skills.)

•M specification of the motor shaft direct-coupling blower (blower in which a motor is

incorporated)

Symbols used in this description

The marks used in these Operating Instructions have the following meanings:

Warning This mark indicates that incorrect operation may lead to accidents

resulting in death or serious injury.

Caution This mark indicates that incorrect operation may lead to injury or

physical damage.

This mark indicates an operation that must not be performed.

This mark indicates an operation that should be performed carefully.

This mark indicates an operation that must always be performed.

- 2 -

Contents

Page

1. Safety Precautions ......................................................................................................................- 3 -

2. Overview of the Product..............................................................................................................- 6 -

2.1 Types and meanings of model symbols ..............................................................................- 6 -

2.2 Structure of the product and names of parts.......................................................................- 7 -

3. Reception of the Product.............................................................................................................- 8 -

3.1 Unloading and checking the product at the time of reception .............................................- 8 -

3.2 Movement and transportation..............................................................................................- 8 -

3.3 Storage before installation...................................................................................................- 8 -

4. Installation...................................................................................................................................- 8 -

4.1 Installation ...........................................................................................................................- 8 -

4.2 Duct connection ..................................................................................................................- 9 -

4.3 Installation of the motor (when the blower adopts the specification of V-belt drive main

body only)..........................................................................................................................- 10 -

4.4 Test operation ...................................................................................................................- 12 -

5. Operation ..................................................................................................................................- 13 -

5.1 Operation, Maintenance and Inspection............................................................................- 13 -

5.2 Replenishment of lubricating oil (grease) (V-belt drive only).............................................- 14 -

5.3 Cleaning of a blower and the impeller...............................................................................- 14 -

5.4 Management of belts.........................................................................................................- 16 -

5.5 Restart of operation after suspension or stoppage ...........................................................- 16 -

6. About the rotary sound of the bearing.......................................................................................- 17 -

7. Warranty....................................................................................................................................- 17 -

8. Malfunction Causes and Measures...........................................................................................- 18 -

- 3 -

1. Safety Precautions

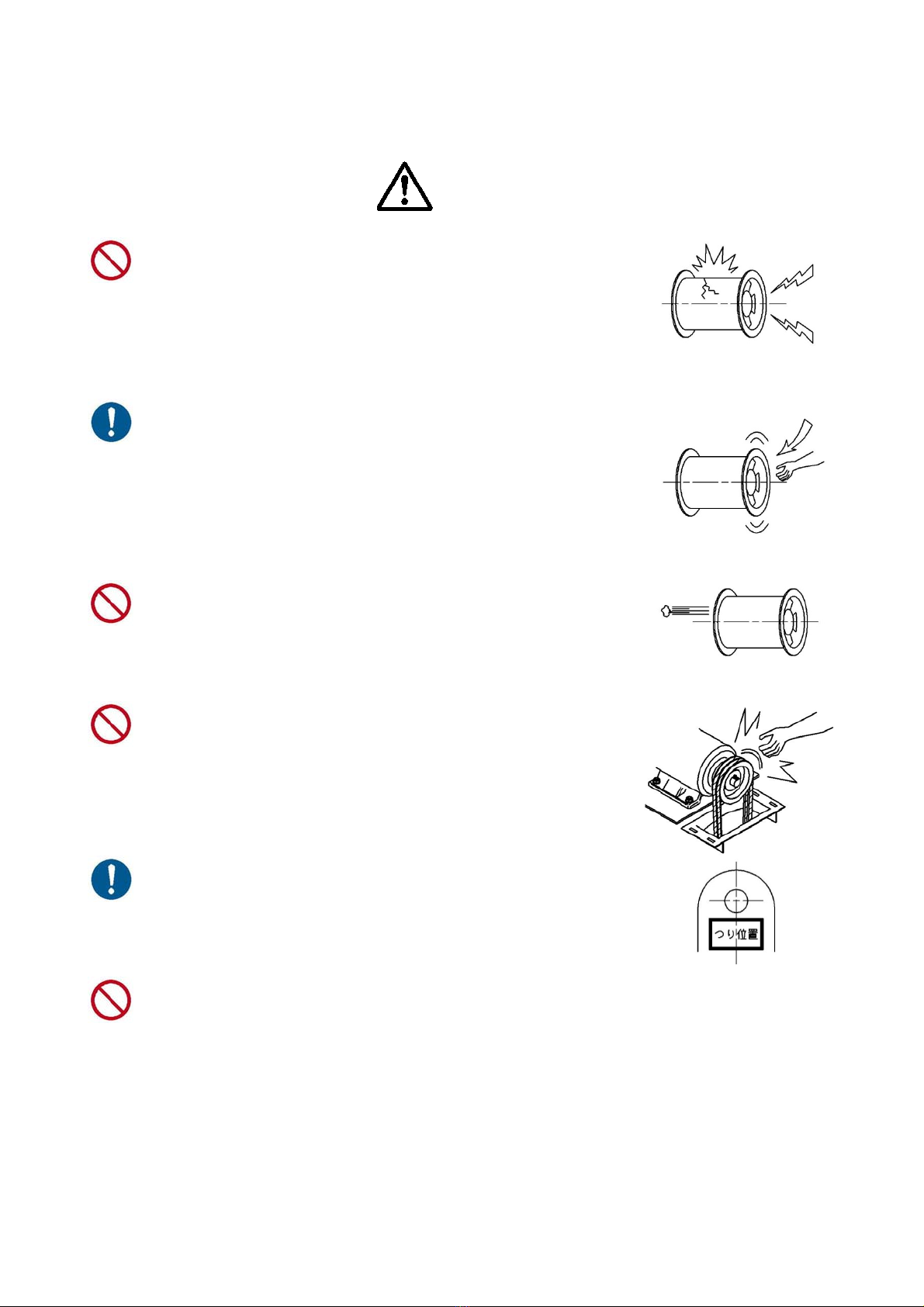

Warning

Intake of hazardous gas and installation in a hazardous

location are strictly prohibited.

This blower does not have an explosion-proof structure.

Intake of flammable gas or operating the blower in a location

with an explosive atmosphere may lead to explosion due to

a spark caused by static electricity or contact with an electric

device, metal, etc.

Attaching a metallic wire net to the intake

port/discharge port of the blower or duct.

If a duct is not attached to the intake port/discharge port of

the blower or if the tip opens even after the duct is attached,

make sure to attach a metallic wire net.

If a metallic wire net is not attached, part of the human body

or objects may be taken in or something taken in before may

rush out. This may cause a serious accident.

Keep your face away from around the discharge port.

Small dust, etc., taken in by the blower may rush out of the

discharge port at a high speed. If such dust enters the eye,

accidents such as loss of eyesight may occur. Make sure to

keep your face away from around the discharge port.

Operation with the guard removed is strictly prohibited.

Operation with the belt guard removed may cause your

hand or clothes to be caught, leading to an accident causing

injury or death.

When hoisting the blower, always use the hoisting

holes indicated as pull-up positions.

Using positions other than those specified to hoist the

blower may lead to an accident causing it to deform, turn

over, or fall.

Do not increase speed by changing a pulley or by using an inverter.

The increase of centrifugal force applied to the rotator or force applied by air flow pressure

may cause damage to the impeller or burnout due to overload of the motor.

- 4 -

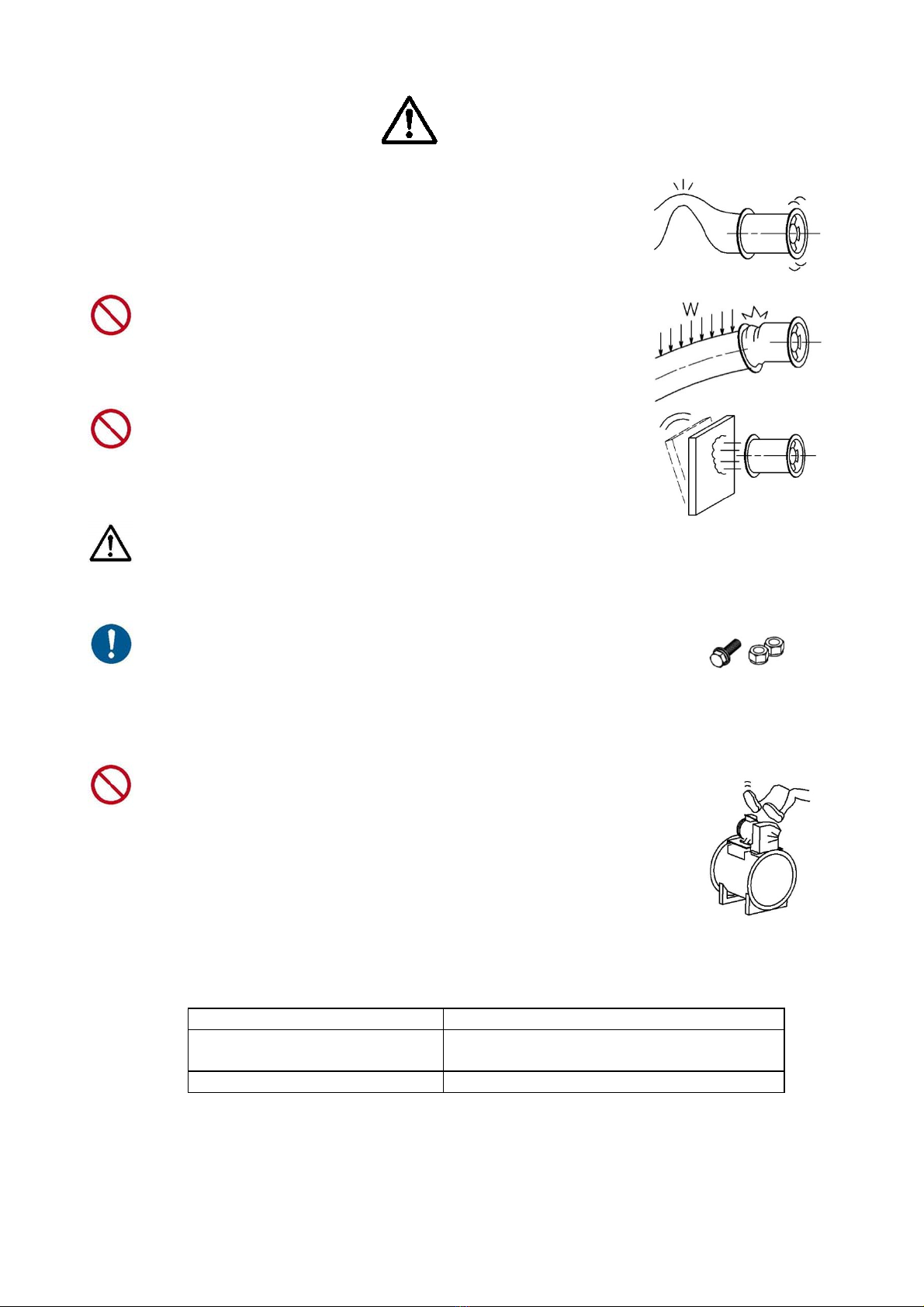

Caution

When installing piping, minimize the resistance to ducts,

pipes, etc., for air to flow smoothly. If the blower is operated

with the duct closed, it may enter stall operation status,

which may cause the impeller blade to generate abnormal

vibration, leading to an impeller damage accident.

Do not transfer the load of the duct to the blower.

Otherwise, deformation of the blower may cause contact

with the rotator, leading to an accident resulting in fire or

damage.

Remove the items that may turn over or fall due to vibration

or air flow pressure from around the blower and duct.

Otherwise, an accident may occur.

The wiring of the blower must be installed by a qualified

electrical engineer, as per the electrical equipment technical

standards and the extension rules. (Also refer to the

Operating Instructions of the motor.)

Before starting test operation, confirm that nothing is left in

the connected duct or casing or near the intake

port/discharge port, e.g., remaining materials, bolts, nuts,

tools, etc. Operating the blower with foreign material

remaining may cause an accident due to intake or rush-out,

or an accident resulting in damage.

Do not step on the blower. Otherwise, the blower may

deform or be damaged or a worker may fall.

The structure of the blower differs depending on the intake temperature. Operating the blower at a

temperature outside the range shown in the table below may cause deterioration of the belt, failure of

the bearing, and/or damage of the impeller.

Intake air temperature (°C) Blower specification

-10 or more to 50 or less Standard type (V-belt drive blower, motor

shaft direct-coupling)

50 or more to 150 or less Heat-proof type (V-belt drive blower only)

Relative humidity of 90% or less

- 5 -

The blower cannot take in solid material, dust or liquid.

Intake of them may cause an accident resulting in damage.

In the case of deceleration by an inverter, etc., a resonance between the main body and a duct

around it may cause an increase in vibration or generation of sound at a specific frequency

(rotation speed). In such a case, use the blower at a frequency other than that frequency. The

shipment inspection of this blower is performed only at the rated rotation speed*. This does

not mean that operation of the blower is guaranteed at frequencies other than that frequency.

* Operation inspection of special order products, parts, etc., may not be performed in some cases.

Precautions for the use of an inverter to operate the blower

(1) The standard motor may not be used for the operation in some cases as shown below.

•In the case that the insulation deteriorates due to surge voltage caused by the use of

a 400-V class motor whose insulation is not reinforced

•In the case of no margin for temperature rise in the motor

•In the case of no margin for allowable load GD2 of the motor

(2) At factory shipment, the setting of a commercial inverter is not suitable for the blower.

Change the following values at least.

•Base frequency: Adjust to the rated frequency of the blower (50 Hz or 60

Hz).

•Highest frequency: Adjust to the rated frequency of the blower.

•Maximum output voltage: Adjust to the rated voltage of the motor.

•Upper-limit frequency: Adjust to the rated frequency of the blower.

•Lower-limit frequency: 25 to 30 Hz (based on the cooling characteristics of the

motor).

•V/f characteristics: Change to square reduction torque.

(3) Other precautions

•The standard blower cannot be operated at an increased speed.

•Vibrations of components (belt, casing, etc.) making up the blower may increase at a

specific frequency. If the increase in vibration cannot be eliminated even after other

set values are changed, a resonance point may be causing it. In such a case, set a

jump frequency to prevent the increase in frequency.

•If the blower is installed on a vibration isolation table (rubber, spring, etc.), a

decrease in frequency may become a resonance frequency. In such a case, set the

jump frequency to prevent this symptom (otherwise, the blower and motor are

individually affected).

•If the carrier frequency is set higher, current leakage may increase, and the earth

leakage breaker may be activated.

•Do not use the inverter output power for applications other than electric motors.

- 6 -

2. Overview of the Product

2.1 Types and meanings of model symbols

Types and meanings of model symbols used for standard specifications are as shown in the

table below.

The model is indicated on the product nameplate (nameplate) affixed to the side face of the

blower main body (casing).

AV-5KM

Blank - Main body only

M - With a motor

Blank - Motor shaft direct-coupling

V - V belt drive

A - Axial flow type blower

MFT - Mixed flow type blower

Symbol of axial flow

Bore diameter

3 - Ø300

4 - Ø400

5 - Ø500

6 - Ø600

7 - Ø700

8 - Ø800

9 - Ø900

10 - Ø1000

|

|

|

- 7 -

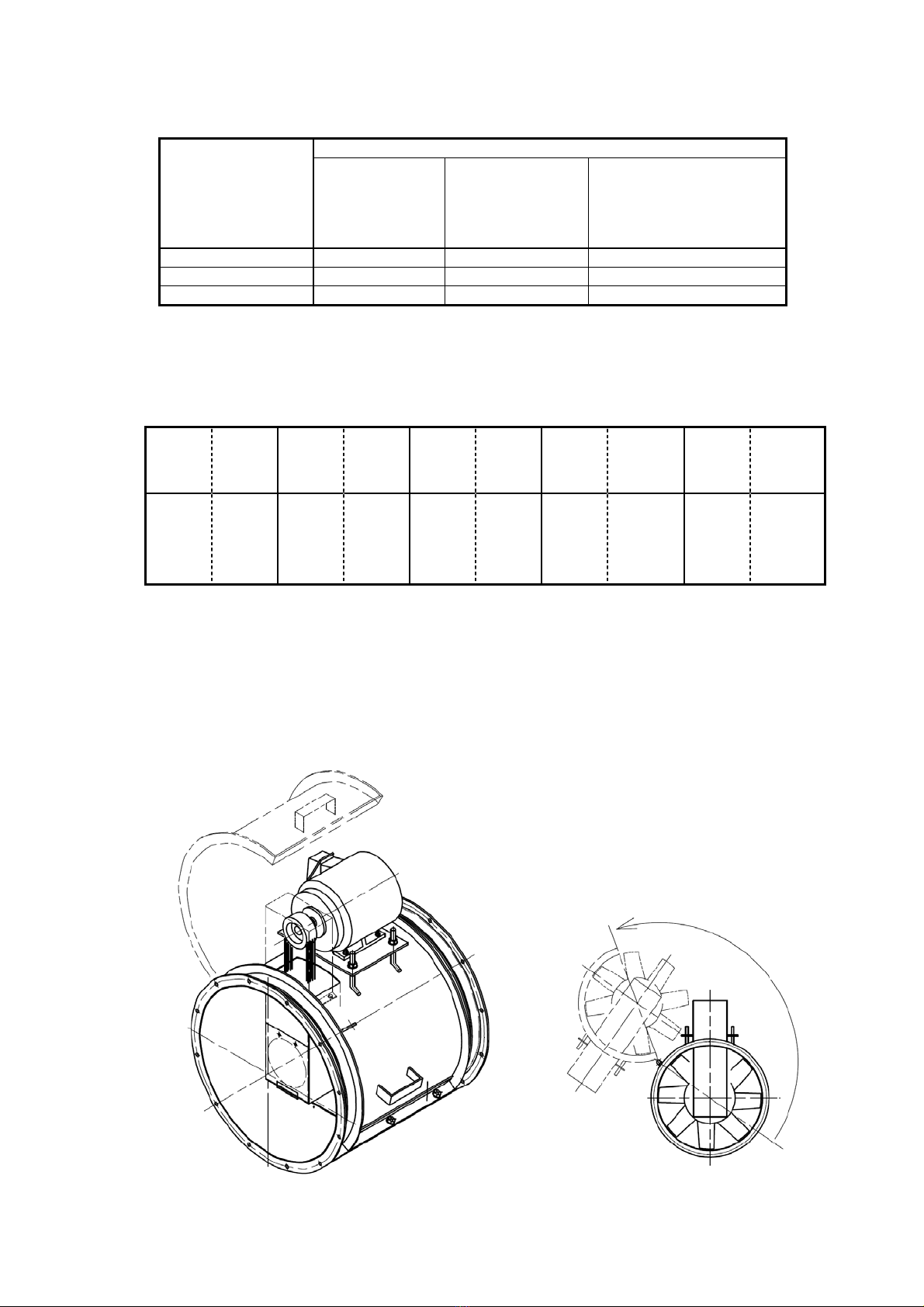

2.2 Structure of the product and names of parts

2.2.1 Disassembling parts drawing

Note 1) The disassembling structure drawing above shows a typical example of the product

of normal temperature specification. Some product may differ from that shown in

the drawing.

Note 2) In the case of the specification of main body only, none of the motor, pulley on the

motor side and V-belt are attached to the blower.

V-belt drive

Motor shaft

direct-coupling

Normal temperature

specification

Difference in the structure based on

temperature specification

Heat-proof specification

V-belt

Pulley on the motor side

Moto

r

Motor base

Casing

A

xis

Bearing

A

xial flow impelle

r

Holde

r

Holder

Belt guard

Pulley on the fan

side

Mixed flow impeller

Mixed flow

intake cone

- 8 -

3. Reception of the Product

3.1 Unloading and checking the product at the time of reception

Although we test and inspect carefully in order to ship an accepted product, please check the

following points upon reception of the delivered product.

•Is it the exact blower that you ordered?

•Is the blower free from abnormality due to

transport, such as damage and deformation?

•Are all the set items enclosed?

•Are the bolts and nuts tightened without

looseness?

3.2 Movement and transportation

When hoisting the blower for movement or transportation, always use the hoisting holes

indicated as hoisting positions.

Avoid hoisting the blower by using only one point. It is dangerous. The hoisting operation

should be performed by a qualified person.

3.3 Storage before installation

To store the blower before it is installed, cover the overall blower with a weatherproof sheet, etc.,

even if the blower is stored indoors. (Rotate the impeller about 10 times manually once in a

month to prevent corrosion of the bearing etc. (this is also required for the blower adopting

outdoor specifications). When rotating the impeller manually, carefully prevent the hand from

being caught.

4. Installation

4.1 Installation

4.1.1 Selection of installation location

Install the blower in a location as shown below.

•A location at a normal temperature without dew condensation (at a temperature of 10 to

40 °C with a relative humidity of 90% or less)

•A location where daily inspection and maintenance can easily be performed

•An indoor location where the blower is not exposed to rainwater

•A stable location where the blower is free from vibration

•A location without hazardous chemicals

4.1.2 Base and installation

•The standard type blower should be installed horizontally. (The specification of vertical

type requires a special order product.)

•As a rough indication, the appropriate amount of concrete for the foundation is 3 times of

the mass of the blower.

•To use a mount, install the blower on the horizontal surface with a strong structure.

•If a gap is found between the blower and the foundation surface, fill the gap by inserting a

liner plate (steel plate to fill a gap), confirm that the blower does not rattle, and then tighten

the foundation bolts.

•Securely tighten the bolts and nuts.

•Remove the retaining parts used in transportation, e.g., bolts for retaining

vibration-proofing (flexible) joints, fixing fittings of the vibration-proofing base, etc.

- 9 -

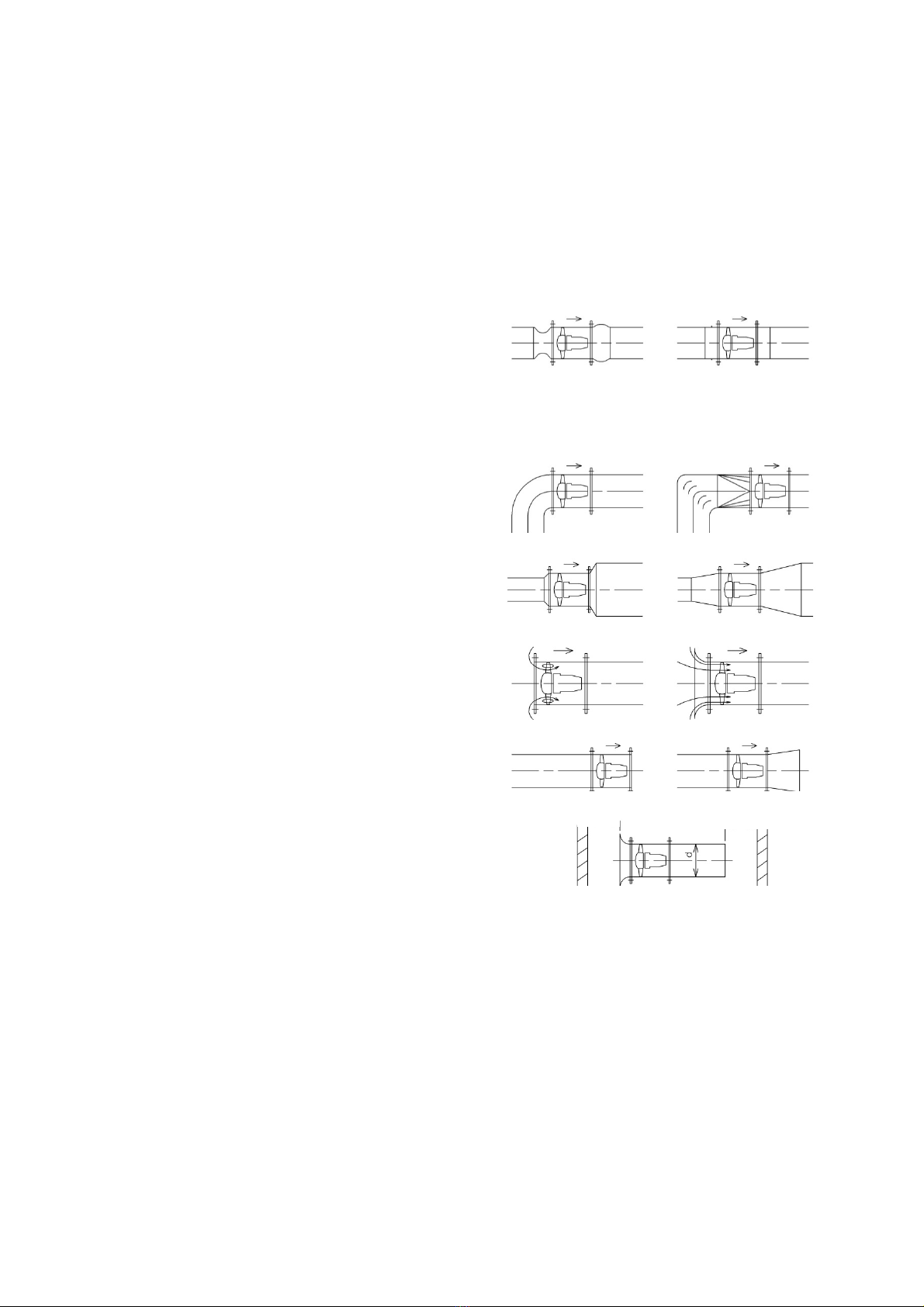

4.2 Duct connection

•Install a removable duct for maintenance and inspection and an inspection hole in front of and

behind the fan.

(Secure a space for inspection with the duct removed.)

•Attach a metal wire net to each of the openings of the intake duct and discharge duct as a

safety measure.

(The metal wire net is an optional accessory.)

•If the duct is installed inappropriately, increase in resistance may cause not only a lack of air

flow but also stalled operation status, leading to accident resulting in damage to the product.

When installing the duct, pay attention to the following points:

(1) When using a flexible joint, apply

appropriate tension to it.

Keep the length to the minimum

necessary by putting in a reinforcing ring

to prevent shrinkage on the negative

pressure side in particular.

× 〇

(2) When using an elbow with a small

curvature, attach a corner vane to it.

× 〇

(3) Prevent sudden expansion and sudden

reduction.

× 〇

(4) When the intake port is open, attach an

intake bellmouth to retain the

performance.

× 〇

(5) When the discharge port is open, attach a

diffuser to retain the performance.

× 〇

(6) Prevent installing the blower with the

intake port/discharge port close to the

wall.

d or more d or more

- 10 -

4.3 Installation of the motor (when the blower adopts the specification of

V-belt drive main body only)

4.3.1 Assembly

For the names of parts, refer to the disassembling

structure drawing in page 6.

•Prepare the motor, pulley on the motor side, and

V-belt that are required.

•Exactly “center” the pulley on the fan side and pulley

on the motor side as shown in the drawing at right.

Operating the blower with them not centered exactly

causes abnormal vibration of bearing and/or

significant reduction in the durability of V-belt, pulley

and bearing.

•Adjust the tension of the belt as follows: Neglecting

the tension adjustment causes a failure.

When adjusting the tension of the belt, use

adjustment nuts to fix the motor base.

•Procedure for tensing the belt

Step 1. Span calculation

First calculate the span (ℓ) of the V belt.

The span of the V belt is part of the connection

of the V belt with the motor pulley and the fan

pulley.

Step 2. Calculation of deflection

When a deflection load is applied, calculate the

deflection (δ) by the formula at right.

Step 3. Measurement of deflection load

Apply a deflection load (P) to the center of the

belt span. When the deflection of δmm is the

value calculated in Step 2, read the value of the

deflection load.

It is convenient to use a tension meter etc., for

measurement of deflection load.

X

Pulley on the

fan side

V belt

X≒0

A

djustment nuts

Pulley on the

motor side

ℓ

δD

d

P

C

(D-d)2

=C2 -

4

ℓ:span (mm)

C:distance from shaft (mm)

D:big pulley diameter (mm)

d:small pulley diameter (mm)

ℓ

Span

δ = 0.016 ×ℓ

δ: Deflection (mm)

ℓ: Span (mm)

Deflection

- 11 -

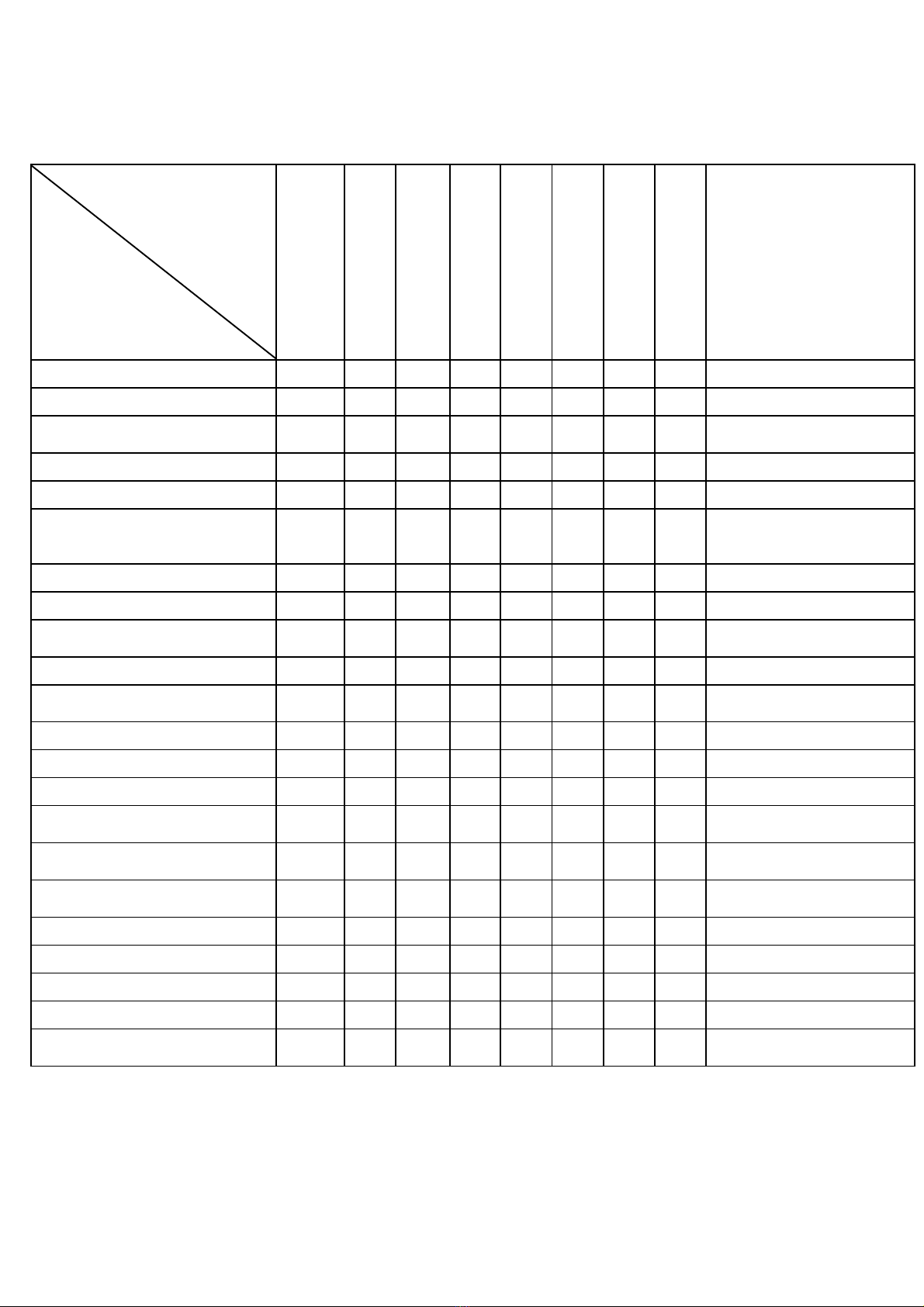

Step 4. Tension adjustment

Adjust the tension of the belt in such a manner that the read value of the deflection load

matches that shown in the following table.

Table of deflection load

Types of

belts

Range of small

pulley diameter

(mm)

Deflection load P (N/belt)

Minimum value When a new belt

is stretched

When a belt is

stretched again

M type 38 to 50 4.9 6.9 6.9

A type

65 to 80

81 to 90

91 to 105

106 or more

7.8

8.8

10.8

11.8

11.8

13.7

16.7

17.6

9.8

11.8

13.7

15.7

B type

115 to 135

136 to 160

161 or more

13.7

17.6

18.6

20.6

26.5

28.4

17.6

22.5

24.5

3V type

67 to 90

91 to 115

116 to 150

151 to 300

17.6

19.6

22.5

25.5

24.5

28.4

33.3

38.2

21.6

25.5

29.4

33.3

5V type

180 to 230

231 to 310

311 to 400

57.8

69.6

82.3

85.3

103.9

121.5

74.5

90.2

105.8

(Note) The range of small diameter of 3V/5V type is indicated in nominal diameter.

•A lack or excess of belt tension causes abnormal phenomena. The following table

indicates how to distinguish a lack of belt tension and an excess of belt tension from each

other.

Abnormal phenomena of belt

Phenomena caused by a lack of tension Phenomena caused by an excess of tension

•Slip

•Heat generation

•Overturn

•Vibration

•Aging of rubber resulting in cracks

•Wear of side face

•Reduction of lifetime due to deformation of

the belt on the pulley

•Heat generation

•Heat generation of bearing

•When a belt gets used to the pulley 20 to 30 hours after it enters the field operation phase,

perform a fine adjustment of the belt once again.

•When using multiple belts stretched, make them matched set for the number of belts to be

used (make the belts the same length).

•When the tension of the belts has completely been adjusted, make sure to attach the belt

guard to ensure the safety.

Correct Deformation

- 12 -

4.3.2 Electric wiring

•The electric wiring of the blower must be installed by a qualified electrical engineer, as per

the “electrical equipment technical standards” and the “extension rules.”

•Confirm the power supply specified on the product nameplate affixed to the side surface of

the main body and then use the power supply for this blower. Using a power supply other

than that specified on the nameplate to operate this blower is dangerous and may cause a

failure.

•Select an earth leakage breaker or breaker of the power supply appropriate for the current

at the time of startup.

•Ground the blower to prevent electric shocks.

•Also read the Operating Instructions of the electric motor.

•Install electric wiring to rotate the blower in the correct direction. (For details, see Section

4.4.)

4.4 Test operation

Before starting up the blower for test operation, make sure to perform the following inspection

to confirm that the condition is normal.

•Confirm that materials, bolts, nuts, tools, etc., used in construction works are not left inside

the duct or casing, or near the intake port/discharge port.

•Confirm that the blower installed is free from rattling and that all the bolts and nuts are

tightened without omission.

•Confirm that the protective parts used in transport have been removed.

•Confirm that a metallic wire net has been attached with the intake port/discharge port open.

•Check the electric wiring.

•Confirm that the items above are normal, turn on the switch once, and then turn it off

(inching) immediately to check for abnormal vibration or contact sound. At the same time,

visually confirm the rotation direction. (Affix a seal to the main body to indicate the rotation

direction.) If the blower rotates in the reverse direction, it makes the air flow in the reverse

direction.

•If the rotation direction is reversed, turn off the source power supply, switch two of the three

power cables with each other while the other cable remains connected, and then confirm

the rotation direction. Since different motor rotation directions and motor installation

directions are available for the blower, the wiring method may differ from the indication on

the motor terminal box. Also, since the colors of cables and phase of the power supply may

differ depending on the power company, reverse rotation may occur even if cables of the

same color are connected. When the power is initially supplied, make sure to confirm the

rotation direction.

•If no abnormality is found during inching, rotate the blower continuously to check for

abnormal noise. In addition, measure and record vibration values and current values, and

confirm that they are in the normal ranges.

•Before starting the formal operation, replenish the blower with the specified grease that

came with the blower. (See Section 5.2.)

•When using an air flow adjustment damper, open it fully at first, and then gradually throttle it

to reduce the degree of opening. If a change is detected in the course of throttling the

damper, e.g., sudden noise, increase in vibration, decrease in pressure, etc., degree of

opening to the fully closed side is not allowed so as to prevent stalling. When an axial flow

type blower is used, the range of air flow adjustment by a damper is limited and a judgment

must be made taking into account the above-mentioned consideration. It is recommended

to change the rotation speed for air flow adjustment.

- 13 -

5. Operation

5.1 Operation, Maintenance and Inspection

After starting to operate the blower, perform the maintenance and inspection regularly. If daily

inspection is performed on the following items from the beginning of the operation and the results

are recorded, abnormalities can be detected early to prevent problems. During the maintenance

and inspection, an experienced worker or trained worker should secure the safety. Inspect the

motor based on the operating instructions of the motor.

Inspection item

Recommended inspection cycle

Inspection contents

3 months 6 months 12 months

Condition inspection

Abnormal

noise

Blower

■

□

□

Check for abnormal noise due to rattles.

Check for metal contact noise.

Check for other noise considered to be

abnormal.

Motor

■ □ □

Check the grease.

Check for loose bolts.

Check the bearings for abnormal noise.

Vibration

■ □ □ Check the vibration value and any

changes to it.

Temperature

■ □ □ Check the temperature near the bearing

and any changes to it.

Electrical

section

□ ■ □ Check the current value and voltage

value, and any changes to them.

Component

inspection

V-belt

■ □ □ Check the tension.

Check for wear or cracks.

Pulley □ □ ■ Check for wear or cracks.

Coupling

Rubber bushing

□ ■ □ Check for hardening.

Check for wear or cracks.

Anti-vibration

rubber

□ ■ □ Check for hardening.

Check for wear or cracks.

Shaft seal □ □ ■ Check for cracks or damage.

Packing □ □ ■ Check for damage or hardening.

5.1.1 Abnormal noise

If an abnormal noise is heard, immediately stop the operation to perform inspection.

Possible types and causes of abnormal noise are as follows:

•Bearing sound

Abnormal lubricating oil (shortage/deterioration of lubricating oil, mixture of foreign materials,

deterioration due to injection of different type of oil)

Abnormality and lifetime of bearing

•Contact sound

Deformation/damage of Impeller/casing

Intake of foreign materials

Rattling due to looseness of bolts

•Chattering noise

See “Vibration” in the following section.

Pulsing sound (unstable fluid sound)

Excessively throttled air flow

Excessively large resistance of the device

- 14 -

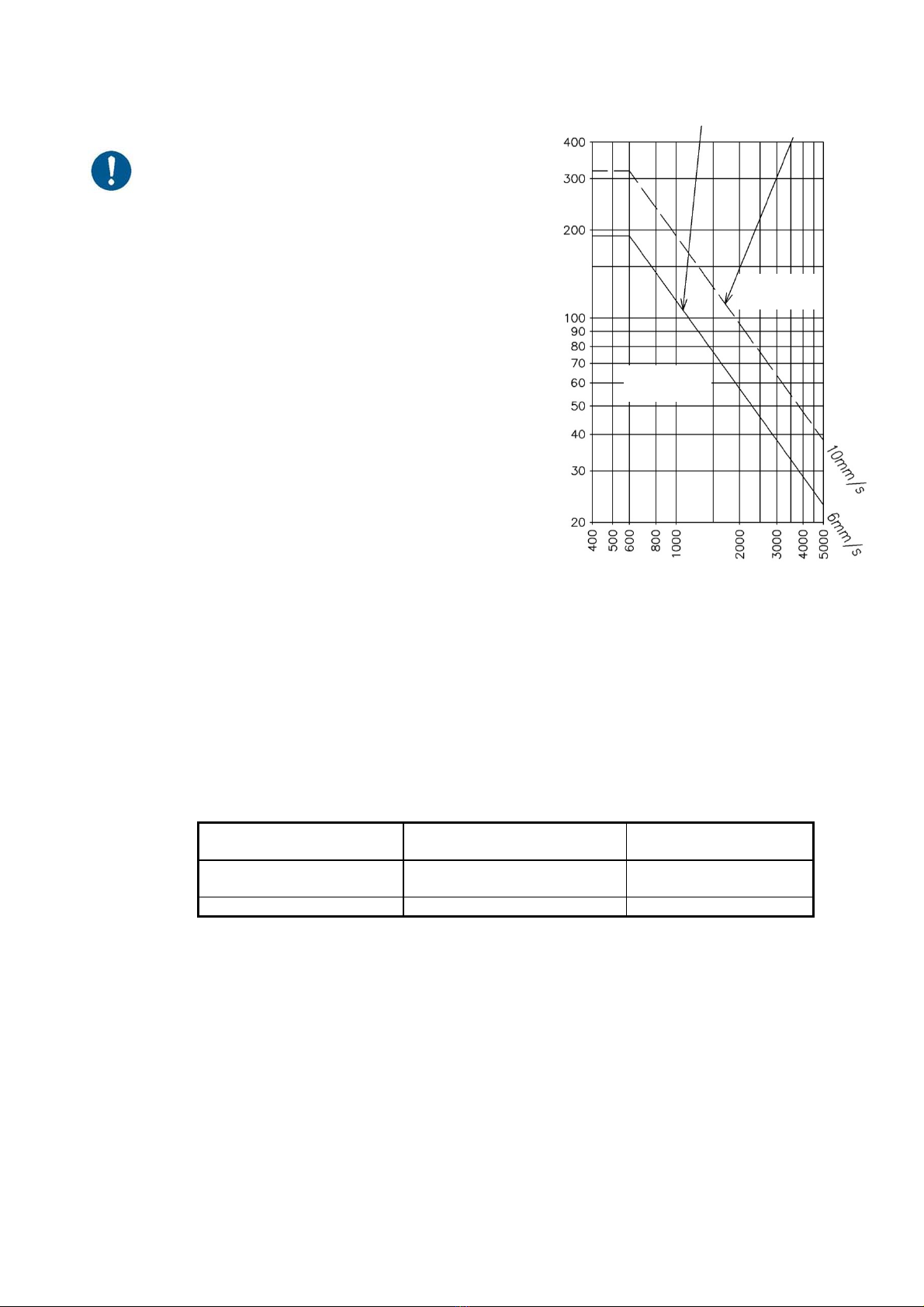

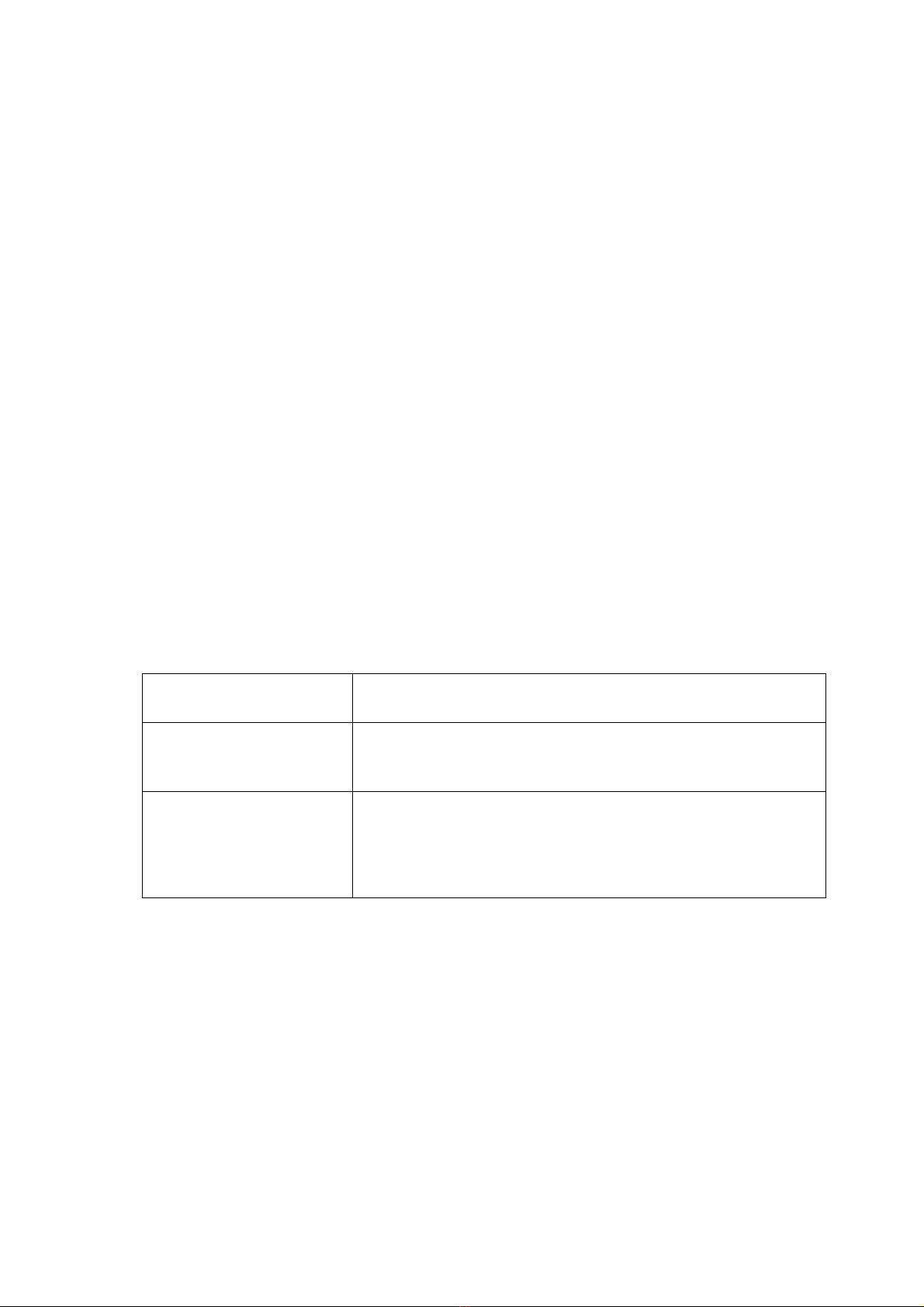

5.1.2 Vibration

If vibration exceeds the allowable value, stop

the operation and perform the inspection.

Possible causes of vibration are as follows:

•Unbalance of the impeller due to adhesion of dust to it

•Deformation/damage of Impeller/casing

•Abnormal axis or bearing

•Rattling due to looseness of bolts

•Stall operation or variation of flow

•Transmission/resonance of vibration

•generated from the duct/mount

•Lack of rigidity of duct or mount

5.2 Replenishment of lubricating oil (grease) (V-belt drive only)

Regularly replenish the bearing with lubricating oil (grease) is also necessary to use the blower

safely for a long period of time. Even if high quality grease is used, its lubricating function reduces

due to deterioration or hardening of the grease itself as the period of use lapses. Therefore,

replenish the blower with the appropriate amount of new grease at the appropriate time.

•When replenishing, select the grease from the following table.

Table of brands of specified grease

Temperature specification

of blower Grease manufacturer Product name of grease

(brand)

Normal temperature

specification Showa Shell Sekiyu K.K. Albania S3

Heat-proof specification Dow Corning Toray Co., Ltd. SH44M

(Remarks) A label indicating the “type of grease and interval for replenishment” is

affixed to the product.

The brands above are standard grease for the standard type of bearing

“pillow block bearing” used in this product.

For special specification products, refer to the separate reference materials.

•If a foreign material mixes with grease, it causes damage to the bearing. Store grease in a

closed container. Prevent grease of a type from mixing with that of a different type.

•Prevent decreasing the number of replenishments by increasing the amount of grease for a

replenishment.

•Be sure to confirm safety, and then replenish the bearing with grease during operation.

•For interval for replenishment and the replenishment amount, use the table below as a rough

indication.

Acceptable

Unacceptable

Vibration allowance value

Vibration allowance value

with antivibration

equipment

Tot

al

am

plit

ude

(

μ

m)

Rotation speed (min

-

1

)

Vibration allowance value graphic

- 15 -

Rough indication of interval for replenishment of grease

Temperature of

handled gas

ºC

Environmental conditions

Quite clean

(normal

environment)

Much refuse (flour

mill, sawmill, dust

collector, etc.)

Large volume of dust, high

humidity, or much spray or

water (refuse disposal

facility, processed marine

product factory, etc.)

50 or less 6 months 3 months 1 month

50 to 80 3 months 2 months 1 month

80 to 150 2 months 1 month 1 week

*1 The bearing must not be directly affected by water or refuse.

*2 If the temperature exceeds 80°C, reduce the interval for replenishment by 1/1.5 each

time the temperature increases by 10°C.

Rough indication of the replenishment amount of grease

Bearing

type

Repleni

shment

amount

(g)

Bearing

type

Repleni

shment

amount

(g)

Bearing

type

Repleni

shment

amount

(g)

Bearing

type

Replenis

hment

amount

(g)

Bearing

type

Replenis

hment

amount

(g)

UC203

204

205

206

207

1.2

1.2

1.3

2.3

3.5

UC208

209

210

211

212

4.3

4.9

5.6

8.0

9.8

UC213

214

215

216

12

15

16

19

UC307

308

309

310

311

5.4

6.7

8.4

12

17

UC312

313

314

315

316

20

27

32

38

45

(If a grease gun, which is our standard tool that comes with the product, is used, the

replenishment amount is approx. 0.5 g each time the lever is operated.)

5.3 Cleaning of a blower and the impeller

When an ACT type blower is used in a way similar to painting booth and this, please check

cleaning regularly by all means because an alien substance attaches to a blower part and an

impeller. In addition, the ACT type blower becomes the structure that internal check is easy to

make like a figure.

Open

- 16 -

5.4 Management of belts

For the belt, perform the tension management and visual inspection regularly according to the

description in section 4.3.1. If the blower has a belt driving system, powder dust is generated

from the belt. In particular, the amount of powder dust may be a little larger for approx. 2 months

after the start of operation. Unusually much powder dust may be generated due to abnormal

wear of the belt caused by inappropriate tension or inaccurate centering. In such a case, perform

an inspection.

5.5 Restart of operation after suspension or stoppage

In the case of suspension of the operation, take care about the storage environment even if the

period of storage is short. To prevent rust of the bearing, etc. during the suspension period,

rotate the impeller approx. 10 times manually or perform no-load running for approx. 5 minutes

once in a month. Before the restart of operation, make sure to perform an inspection similar to

that for test operation. In particular, check for materials adhering to the impeller or for corrosion

on it.

6. About the rotary sound of the bearing

The blower of the high-speed rotary or high temperature specifications of this blower chooses the

bearing of the C3 skimmer.

Therefore "a ball omission sound" may occur at the time of driving, but is not the abnormality of

the bearing.

When a rolling body enters the no load zone at the load zone, I come to be able to carry out a free

activity and begin to roll by gravity, and "a ball omission sound" is a sound when it collides in a

retainer and the orbit.

I show the example of the typical driving sound of the bearing.

Expression of the

sound Characteristic

With ticktacks

Clangor

It attract attention in low speed.

It is consecutive sounds at a high-speed turn

Metallic sound

It change by a change of the rotary speed with a cylinder

Roller bearing and sound like a metallic sound mainly

when

it is big.

It stay temporarily when I supply grease.

- 17 -

7. Warranty

Scope of warranty

Repair service is provided free of charge for a failure during the warranty period, as long as the

blower has been used in compliance with these Operating Instructions, labels attached to the

body, and other instructions.

In the case that this product is incorporated into other equipment used by the customer, the

warranty does not cover costs for removal from such equipment, reattachment to such

equipment, costs of other incidental work, costs of transportation etc., resulting opportunity loss

incurred by the customer, lost operation, or any other indirect loss or damage suffered by the

customer.

•For requests for repair service, please contact our nearest branch or sales office.

Warranty period

One (1) year from the date of delivery of the product.

Even during the warranty period, only charged service is provided in principle, if any of the

following applies:

•Failure or damage due to incorrect use that is not compliant with these Operating Instructions,

labels attached to the body, or other instructions, and/or unauthorized repair or modification

•Failure or damage due to transportation, dropping, etc. after the purchase

•Failure or damage due to fire, earthquake, storm, flood, lightening or other natural disasters,

environmental factors such as salt damage and public pollution, abnormal voltage, use of a

power supply (voltage or frequency) other than that specified, or the like

•Failure or damage due to repair or modification (including punching, etc. in the product) not

conducted by our company

•Failure or damage due to the use of parts other than those designated by our company

•Failure or damage due to the entry of foreign material

•Discoloration, scratching, natural consumption of consumable parts or other defects due to

use or deterioration over time

•Failure or damage caused by neglecting the maintenance and inspection described in the

Operating Instructions

We will not compensate for any loss or damage resulting from defects that occur during the

use of this product.

[Notices]

(1) The descriptions in these Operating Instructions are subject to change without prior

notification in the future.

(2) We have made all possible efforts to prepare these Operating Instructions. However, if you

have any questions about them or find any inquiries, errors, omissions, etc., please contact

our nearest branch or sales office.

(3) If the power supply frequency changes due to a change in the location where the blower is

used, it may not be used as it is. We will consider a measure in each case where it is

required. In such a case, please contact our nearest branch or sales office.

(4) At the time of inquiry, please describe the product type and the manufacturing number

indicated on the product nameplate.

- 18 -

8. Malfunction Causes and Measures

Fan malfunction causes and measures

Malfunction status

Malfunction cause

Overs and shorts of quantity

of wind, the static pressure

Excess/short of motor

Bearing overheat/burnout

Abnormal vibration

Peculiar noise

Corrosion and wear

Abnormal contact

Motor not activated

Measures

Defective installation

○○○○○Re-installation

Poor foundation ○○○Renovation

Contact with the rotator? ○○○○○○Processing of contact part,

and re-installation

Defective duct/duct joint ○○○○○○Renovation

Defective lubricating oil ○Replenishment

Inappropriate oil quality,

contamination, excessive

amount of oil

○Replacement or recycling

Inappropriate material ○○○Replacement

Unbalanced impeller ○○○○Correction

Deformation or damage of

impeller ○Repair or replacement

Wear or corrosion of impeller ○○

Repair or replacement

Operation at a dangerous speed ○○○○

Renovation or remodeling

of operation point

Abnormal bearing of the motor ○○○Replacement

Wrong rotation direction ○○○○○Change

Malfunction of the motor ○○○○○Repair or replacement

Intake of light gas ○

Renovation/replacement of

impeller

Intake of heavy gas ○○

Renovation/replacement of

impeller

Mixture of foreign object or

adhesion of scale ○○○○○○○Cleaning

Surging operation ○○○Change of operation point

Resistance to the pipe system ○○Renovation

Failure of damper ○○○○○Repair

Accumulation in the drain ○○○○○Draining

There is less pressure loss than

a plan ○○

Damper adjustment,

change of the rotary speed

Note on your purchased blower

Fan identification information that you may need when making an inquiry of us.

TYPE SERIAL NO.

Date of

Purchase Year/Month/Day Date of start

of operation Year/Month/Day

Supplier

TEL: Person in charge:

Table of contents

Other Showa Denki Blower manuals