Shundaiwa DGA20EM User manual

OWNER’S AND OPERATOR’S MANUAL

Vertical, Water-Cooled 4-Cycle Diesel Engine

DGA20EM

X753-008 33 0

X753801-490 0

CAUTION

Do not operate the Generator, or any other appliance, before you have read and understood

the instructions for use and keep near for ready use.

Introduction

Thank you for purchasing this Shindaiwa soundproof diesel engine generator.

This manual has been created to ensure safe usage of this generator. Be sure to read this manual

before operation. Improper operation/handling of this generator will result in an accident or

malfunction.

Handling/Operation of this generator can only be performed by persons who understand the

contents of this manual and can handle/operate the generator in a safe manner. Persons who

suffer from an illness, are taking medicine or not feeling way such that safe operation would be

negatively affected must not operate this generator.

Work performed using this generator and handling/operation of this generator must be in

accordance with corresponding laws and regulations based on such laws. Consult with the

authorized distributor where this generator was purchased if you have any inquiries regarding the

corresponding laws.

Always be sure to include this manual when loaning out this generator and instruct operating

personnel to read this manual before operation.

Store this manual in a specified location where it will be secure and available for consulting at any

time. Order another copy from the authorized distributor where this generator was purchased if this

manual becomes dusty, grimy or torn.

Consult with the authorized distributor where this generator was purchased if you have any

inquiries regarding any points related to this generator and manual.

When inquiring about this generator, be sure to provide the model name and serial number.

If disposing of this generator, do so in a manner that is in compliance with laws related to industrial

waste. Contact the authorized distributor where the generator was purchased if you have any

inquiries regarding proper disposal.

Caution notice ranks in this manual are classified as follows.

WARNING : Indicates a potentially hazardous situation which, if not

avoided, can result in death or serious injury

CAUTION : Indicates a potentially hazardous situation which, if not avoided,

can result in minor or moderate injury and property damage.

< Note > : Other types of cautions and indications.

Note that CAUTION items can also lead to major accidents under some circumstances if not

correctly followed.

All caution notices are important. Be sure to follow all of them.

Table of Contents

1. Safety Guidelines··························································································· 1

2. Specifications ······························································································· 5

2-1. Data········································································································ 5

2-2. Ambient Condition······················································································ 6

3. Use ·············································································································· 6

4. Parts ············································································································ 6

4-1. Outer and Main Components········································································ 6

4-2. Operation Panel ························································································ 7

4-3. Output Panel····························································································· 8

5. Equipment ···································································································· 9

5-1. Controller ································································································· 9

5-2. Switches ·································································································11

5-3. Voltage Regulator ·····················································································12

5-4. Fuel Line Changeover Valve (3-Way Valve) ····················································13

6. Transportation & Installation ··········································································14

6-1. How to transport ·······················································································14

6-2. Installation·······························································································15

7. Connecting load ···························································································16

7-1. Select Load Cable·····················································································16

7-2. Connecting Load Cable··············································································17

7-3. ELCB and Grounding·················································································18

8. Initialization and Pre-check ············································································21

8-1. Engine Oil ·······························································································21

8-2. Coolant / Water ························································································22

8-3. Fan Belt··································································································24

8-4. Fuel ·······································································································24

8-5. Fuel, Engine Oil and Coolant Leakage ··························································25

8-6. Battery····································································································26

9. Operation·····································································································27

9-1. Initialization and Preparation ·······································································27

9-2. Procedures during Operation·······································································29

9-3. Stopping ·································································································30

9-4. Protection Functions··················································································31

9-5. Connecting to External Fuel Tank·································································32

10. Check and Maintenance···············································································33

11. Long Term Storage ······················································································40

12. Troubleshooting··························································································41

13. Generator Circuit Diagram············································································45

14. Engine Circuit Diagram················································································46

1

WARNING : EXHAUST GAS POISONING

Do not operate the generator in poorly ventilated areas such as indoors or tunnels, as

the exhaust gas of the engine contains substances that are harmful to human health.

Do not direct exhaust fumes at bystanders or buildings.

WARNING : ELECTRIC SHOCK

Do not operate the equipment with any doors or covers open.

Always turn all the breakers OFF, place the Power Switch in the OFF position and stop

the engine before connecting / disconnecting the load cable to the output terminal or

receptacle.

Close the output terminal cover before operating.

Do not insert a pin, wire or other metal object into the electrical outlet.

Do not touch the generator if the generator or casing or your body becomes wet during

operation.

Do not touch internal electric parts while the generator is operating.

Always turn the Power Switch to the OFF position and stop the engine, then close and

lock OPERATION PANEL DOOR before checking or maintaining the engine or any

equipment.

WARNING : INJURY

Close all doors and lock them during operation.

Do not open the check door when the Power Switch is in the ON position. It will cause

injury by rotating parts such as cooling fans and fan belt.

Always turn the Power Switch to the OFF position and stop the engine, then close and lock

OPERATION PANEL DOOR before checking or maintaining the engine or any equipment.

Always be sure to use Lifting Hook when lifting up the generator. Using other parts

when lifting up the generator could cause the result of falling.

Do not attempt to lift the equipment with any additional weight such as optional fuel

tanks or trailers.

No persons should ever be under a lifted generator.

Always be sure to check that the breakers on load side and switches for any

equipment using the generator are at OFF before turning the breaker to ON. Also be

sure to advise personnel on the load side that power will be turned on or off before

operating the breaker.

Do not modify the equipment and do not operate with parts removed.

CAUTION : EYE/SKIN INJURY

Wear rubber gloves and other protective wear to protect eyes, skin and clothing from

the battery fluid which contains diluted sulfuric acid. If the battery fluid contacts eyes or

skin, wash out immediately with a sufficient amount of clean water. Be sure to receive

medical treatment, especially if the fluid contacts the eyes.

CAUTION : EXPLOSION

Never use or recharge the battery if the fluid level is below the minimum level.

Do not create sparks or bring flame near the battery as it generates flammable gas.

1 Safety Guidelines

2

CAUTION : FIRE

Do not carry flammable items (such as fuel, gas and paint) or items that are highly

combustible near the generator as the muffler, exhaust gas and other parts become

extremely hot.

Position this generator 3 ft. (1 m) or more from walls or other hindrances, and on a

level surface.

Do not connect the generator output to indoor wiring.

This generator uses diesel fuel. Always be sure to stop the engine and not bring flames

close when inspecting fuel or refueling. Wait until the engine has cooled before

performing such procedures.

If fuel spills, always be sure to wipe and drain off spilled fuel.

Do not operate the equipment with liquid accumulated in the spill containment.

If fuel or oil is leaking, repair the leaking location before operating.

Always be sure to wipe up any spilled fuel or oil.

Allow the generator to cool before covering with the protective cover.

Never allow flame to come close to the generator.

Always make sure that the engine is stopped when working on piping.

After working on the piping, check that there is no fuel leakage.

Absolutely never inspect or perform maintenance to the equipment near fire or other

open flame.

CAUTION : ELECTRIC SHOCK

Do not sprinkle water on equipment or used where exposed to rain.

CAUTION : BURNS

Do not touch the engine and surrounding components immediately after stopping the

engine as they are still extremely hot.

Do not open the radiator cap immediately after stopping the engine. Doing so will result

in hot steam gushing out.

Hot steam gushes out from the coolant sub-tank if the generator overheats. Do not

touch the coolant sub-tank.

Always be sure to stop the engine and allow the engine to cool when performing

inspection or maintenance of engine oil. Opening the oil level gauge or oil filler cap

during operation will result in hot oil gushing out.

3

CAUTION : INJURY

Always be sure to use Lifting Hook when lifting up the generator, and slowly lift it

straight up.

Personnel performing lifting work must wear protective gear such as helmets, safety

shoes and gloves.

Position the generator on a level stable surface so that it cannot slide or move in any

manner.

Before starting operation, always be sure to turn off all switches of equipment using the

generator and all breakers to OFF.

Do not move the generator during operation.

Do not operate the generator if it has been modified or any parts have been removed.

Securely fix the equipment with rope or similar item to avoid any unexpected move

when transporting by truck or other vehicle.

CAUTION : PROPERTY DAMAGE

Do not use the equipment for any improper applications. Improper usage can result in

an accident or malfunction.

If using this generator for medical equipment, check before use with the medical

equipment manufacturer, doctor, hospital or similar entity.

Check that the generator output setting, output terminal connection and load power

source are consistent.

Cable burnout can occur due to generated heat if the load current exceeds the

allowable current of the cable.

The voltage drop between cables is large if the cable is excessively long or thin,

resulting in decreased input voltage to equipment using the generator, thereby causing

decreased performance, faulty operation and malfunction.

4

Warning / Caution Label Locations

When warning / caution labels become unreadable or damaged,

place new labels at the appropriate locations as specified in the following figure.

When ordering the labels, use the following part numbers.

1. Injuries······································ (Part no.: X505-004630)

2. Caution (coolant)························ (Part no.: X505-004650)

3. Safety Precaution ······················· (Part no.: X505-004660)

4. Caution (Electric Shock)·············· (Part no.: X505-004640)

5

2-1. Data

Unit DGA20EM

Generator

Generating Method - Rotating Filed, Brushless 3-Phase

Synchronous Generator

Rated Output kVA 20

kW 16

Rated Voltage V 415

Rated Current A 27.8

Rated Frequency Hz 50

Rated Speed min-1 1500

Phase & Wiring - 3-Phase 4-Wire

Power Factor % 80

Insulation Class - F

Exciting Method - Self Excitation(Brushless)

Poles - 4

Engine

Method - Vertical, Water-cooled 4-Cycle, Diesel Engine

Model No. - Isuzu BV-4LE1

Cylinder-bore x stroke

mm 4 - 85 x 96

Continuous Rated

Output kW{PS}

19.1{26}

Speed min-1 1500

Displacement L 2.179

Combustion Method -

Swirl Chambered

Cooling Method - Water-cooling radiator

Lubricating - Trochoid pump, force-feed lubrication

Starting - Starter Motor

Fuel - Diesel

Oil - SAE Class CD or higher

Fuel Tank Capacity L 78

Lubricant Volume L 8.8(including filter 0.4 L)

Coolant Volume L 8.2(including sub-tank 0.9 L)

Starter Motor Cap. V-kW

12-2.0

Alternator Cap. V-A 12-20

Battery - 75D31R

Dimension

Length mm 1440

Width mm 780

Height mm 1140

Dry Weight kg 699

Installed Weight kg 789

2 Specifications

6

Engine Check Door Radiator Lug for rope Alternator

check

door

2-2. Ambient Condition

Be sure to use the equipment under the following ambient condition range. Otherwise

the condition may cause damage, insufficient output or durability shortage to the

equipment.

■Ambient: Temperature: from -15 to 40 degree Celsius

■Relative: Humidity: less than 80%

■Altitude: Less than 300m

Power Supply for submersible Pump, etc.

Power Supply for lightings, etc.

Power Supply for electric tools, home appliances

4-1. Outer and Main Components

3 Use

4 Parts (Components)

Lug for rope

Lifting Lug

Operation Panel Door

Output Terminal Cover

Fuel Inlet

Engine Check Door

Outer Fuel Outlet

Coolant Drain

Lug for Rope

Oil Drain Plug

Alternator Check Door

Sub Tank

Fuel Tank

Fuel Drain

Water Separator

Fuel Filter

Oil Gage

Outer Fuel Inlet

Oil Filter

Battery

Air Cleaner

Oil Filler

7

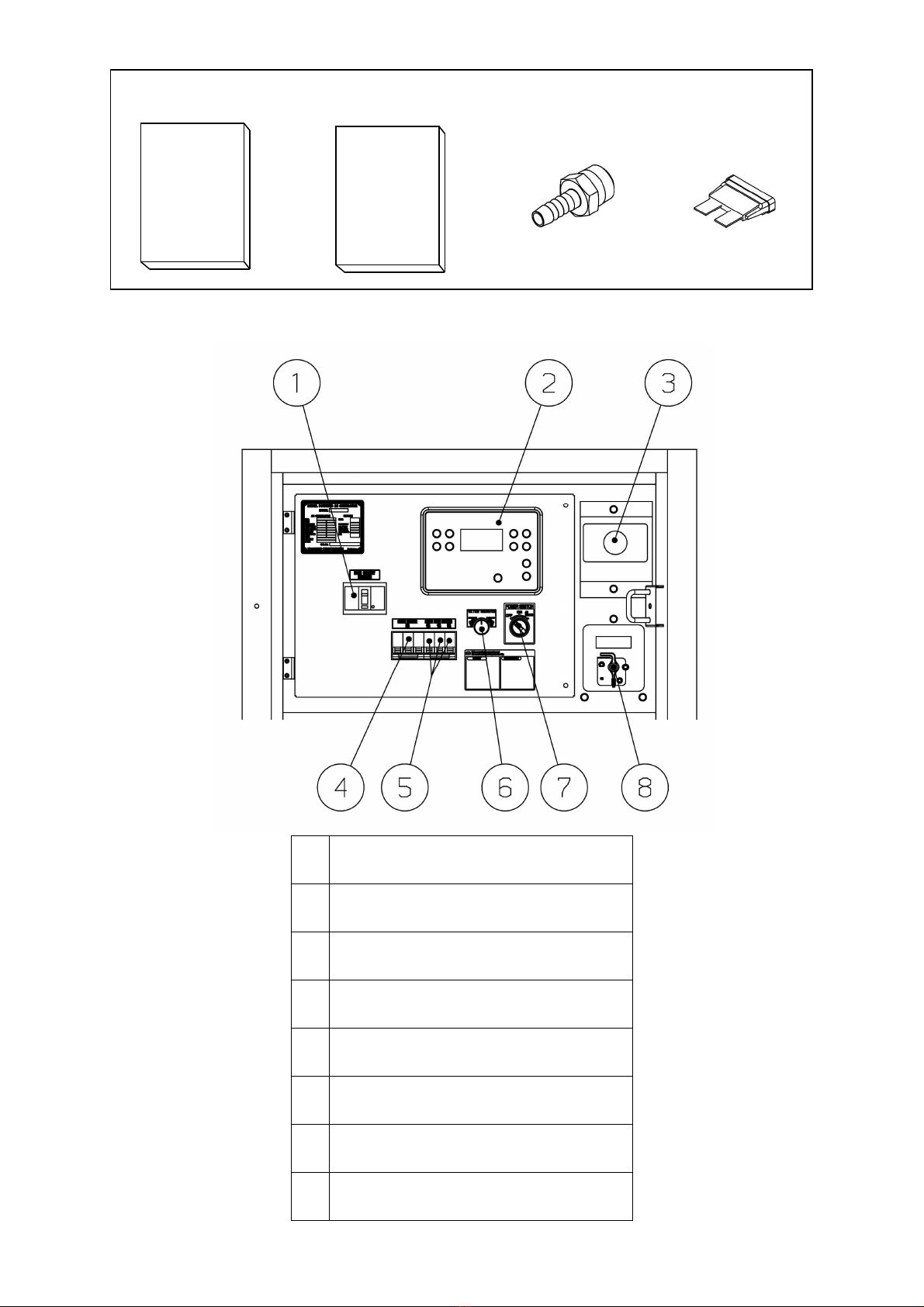

4-2. Operation Panel

1

Main Circuit Breaker

2

Controller

3

Emergency Stop Button

4

3-Phase Breaker

5

1-Phase Breaker

6

Voltage Regulator

7

Power Switch / Air Bleeding

8

Battery Isolator

Accessories

Nipple (2 pieces) Fuse (2 pieces)

Owner’s

Manual

User’s

Manual

For Engine

8

4-3. Output Panel (Side Door)

3-Phase ELCB

1-Phase ELCB

1-Phase

Receptacle

(15A)

3-Phase Receptacle

(20A)

Bonnet Grounding Terminal

Output Terminal Cover

9

5-1. Controller

This generator has a Controller which is used for starting or stopping the power generator

or the engine, for monitoring. If you turn the Power Switch to ON position, the status

Screen appears.

(1) Front panel elements

①STOP button

Press this button to initiate the stop sequence of the gen-set.

② START button

Press this button to initiate the start sequence of the engine.

③LEFT button

Use this button to move left or to change the mode. The button can change the mode

only if the main screen with the indicator of currently selected mode is displayed.

④RIGHT button

Use this button to move right or to change the mode. The button can change the mode

only if the main screen with the indicator of currently selected mode is displayed.

15

5 Equipment

1

2

3

4

5

6

7

8

9

10

11

12

13

14

10

⑤HORN RESET button

Use this button deactivate the horn output without acknowledging the alarms.

⑥FAULT RESET button

Use this button to acknowledge alarms and deactivate the horn output. Inactive alarm

will disappear immediately and status of active alarms will be changed to “confirmed”

so they will disappear as soon as their reasons dismiss.

⑦UP button

Use this button to move up or increase value.

⑧PAGE button

Use this button to switch over display pages.

⑨DOWN button

Use this button to move down or decrease value.

⑩ENTER button

Use this button to finish editing a setpoint or moving right in the history page.

⑪GCB button

No use.

⑫GENERATOR status indicator

There are two states – Gen-set OK (indicator is green) and Gen-set failure (indicator is

red). Green LED is on if the generator voltage is present and within limits. Red LED

starts flashing when gen-set failure occurs. After FAULT RESET button is pressed,

goes to steady light (if an alarm is still active) or is off (if no alarm is active).

⑬GCB on

No use.

⑭Load

No use.

⑮Operation Display

< Note>

The displayed information is structured into “pages” and “screens”. USE PAGE button to switch

over the pages.

11

3P Breaker 1P Breaker

5-2. Switches

(1)

Power Switch / Air Bleeding

This is the main Power Switch of the generator.

When the Power Switch turned to OFF position, the Controller is OFF.

When the Power Switch turned to AIR BLEEDING position,

automatically starts air-bleeding device.

(2) Emergency Stop Button

This button is used to stop the engine in emergency.

By inserting the button, the engine stops.

Be sure to restore the Power Switch to OFF and re-set

the button, turning clockwise after using the emergency stop button.

(3) Main Circuit Breaker

By turning this circuit breaker on the control panel to ON,

Power will be transferred to the output receptacles and to the

load side.

The breaker trips to OFF, either overload or short-circuit.

< Note >

Do not use ELCB as the ON/OFF switch to the load.

(4) 3-Phase Circuit Breaker

1-Phase Circuit Breaker

Each receptacle, 3-Phase and 1-Phase is

incorporated with circuit breaker respectively.

The breaker trips on overload or short-circuit on

to stop power transmission to load.

< Note >

Do not use this breaker as the ON/OFF switch to the load.

12

3P ELCB

(5) 3-Phase Earth Leakage Circuit Breaker (3P ELCB)

1-Phase Earth Leakage Circuit Breaker (1P ELCB)

Each receptacle, 3-Phase and 1-Phase is

incorporated with ELCB respectively.

When current leak occurs, it trips to stop

power transmission to load.

< Note >

Do not use this breaker as the ON/OFF switch to the load

(6) Battery Isolator

When turning the switch to OFF, the engine

electric circuit does not activate due to no

battery power.

5-3. Voltage Regulator

(1) Voltage Regulator

The dial adjusts generator output voltage.

By turning the dial clockwise, you can increase the voltage.

By turning the dial counter-clockwise, you can decrease the voltage.

OFF position ON position

1P ELCB

13

A side Lever Position

3-way Valve

B side Lever Position

5-4. Fuel Line Changeover Valve (3-way valve)

By switching the 3-way valve, you can use fuel from external fuel tank.

In this case, the built-in tank fuel cannot be used.

(1) Using fuel from built-in fuel tank

The lever for 3-way valve is set to

Awhen the equipment is shipped.

Outer fuel inlet and return are

closed with plugs (PT1/2).

Use fuel as they are.

< Note >

After having used the outer fuel and removed piping, be sure to set the lever to A position and

fix the plugs.

(2) Using fuel from external fuel tank

Connect hoses from the external fuel tank to the external fuel intake and the external fuel return

ports, and set the lever for 3-way valve to Bposition.

You can now supply the fuel from

the external gas tank.

For detailed instructions, refer to

『9-5.Connecting to External Fuel Tank』

CAUTION : Fire

Always stop the engine when performing any work on the fuel line.

Always wipe any drip of Diesel fuel or engine oil. Do not use this equipment,

when a leak is found. Repair the equipment before use.

Be sure to confirm that there is no leakage in the piping.

External Fuel Inlet

External Fuel Return

3-way Valve

14

Roping Lug

6-1. How to transport

WARNING : Injuries

When lifting the equipment, always use a lift hook.

Never use roping lug for lifting the unit, for it may cause equipment to drop.

(1) Lifting the equipment

Always use a Lift lug, when lifting

the equipment for transportation.

(2) Transporting the equipment

When transporting the equipment, make

sure that the equipment is secured properly

with ropes tied to the roping lugs through.

< Note >

Always use extreme care when loading, unloading, and transporting the equipment,

otherwise damages and malfunction of the equipment may bring.

6 Transportation and installation

Lifting Lug

15

6-2. Installation

WARNING : Suffocation from exhaust gas

Exhaust fumes from the engine contains many elements harmful to humans.

Do not operate this equipment in poorly ventilated area, such as inside a

room or in a tunnel

CAUTION : Suffocation from exhaust gas

Do not point the exhaust fume toward pedestrians or buildings.

CAUTION : Fire

Always operate this equipment on flat surface and, at least 1 meter away

from any objects (wall, box, etc.).

Temperature around muffler and exhaust can get extremely high. Keep

any inflammable items (such as fuel, gas, paint, etc.) away from the

equipment.

Always set the equipment on hard, flat surface.

Keep the equipment at least 1m from a wall or any obstacles, to allow workable

space to access the control panel and opening of the panel door.

< Note >

This equipment must be operated on hard and flat surface. Operating under any

other conditions may result in malfunctions.

Do not block the airflow from radiator vent or muffler exhaust. It may result in reduced

engine performance, overheating, or damage to the electrical parts.

Operating in dusty area or salty air (by the ocean), or any other particulate

environment may result in clogged radiator, which may cause overheating, other

malfunctions and insulation deterioration. Use extreme care, frequent checks and

maintenance.

16

7-1. Select Load Cable

Select the cable with proper gauge, based on its allowable amperage and the distance

between the generator and the machinery to be connected.

CAUTION : Damage to properties

If the load exceeds the allowable amperage, the damage to the cable may

be damaged in overheating.

If the cable is either too long or too small gauge, there will be greater

voltage drop between cables which brings voltage drop to loads. It may

result in reduced performance in the connected loads, malfunction, or

damages.

< Note >

It is recommended to select the proper gauge and length of cable, in

consideration of the maximum 5% marginal drop only for the rated voltage,

between the terminals of loads and generator via the cables.

Expedient Formula: the voltage drop of cables

3-Phase 3-Wire

1 Length (m)

Voltage Drop (V) = × × Current (A) × √3

58 Dia (mm2)

1-Phase 2-Wire

1 Length (m)

Voltage Drop (V) = × × Current (A) ×2

58 Dia (mm2)

7 Connecting Load

Table of contents

Popular Inverter manuals by other brands

Hitachi

Hitachi SJ-LW instruction manual

Mitsubishi Electric

Mitsubishi Electric FREQROL-K Series instruction manual

Robin America

Robin America RGX2900 parts manual

SunSynk

SunSynk SUN-8K-SG04LP3 user manual

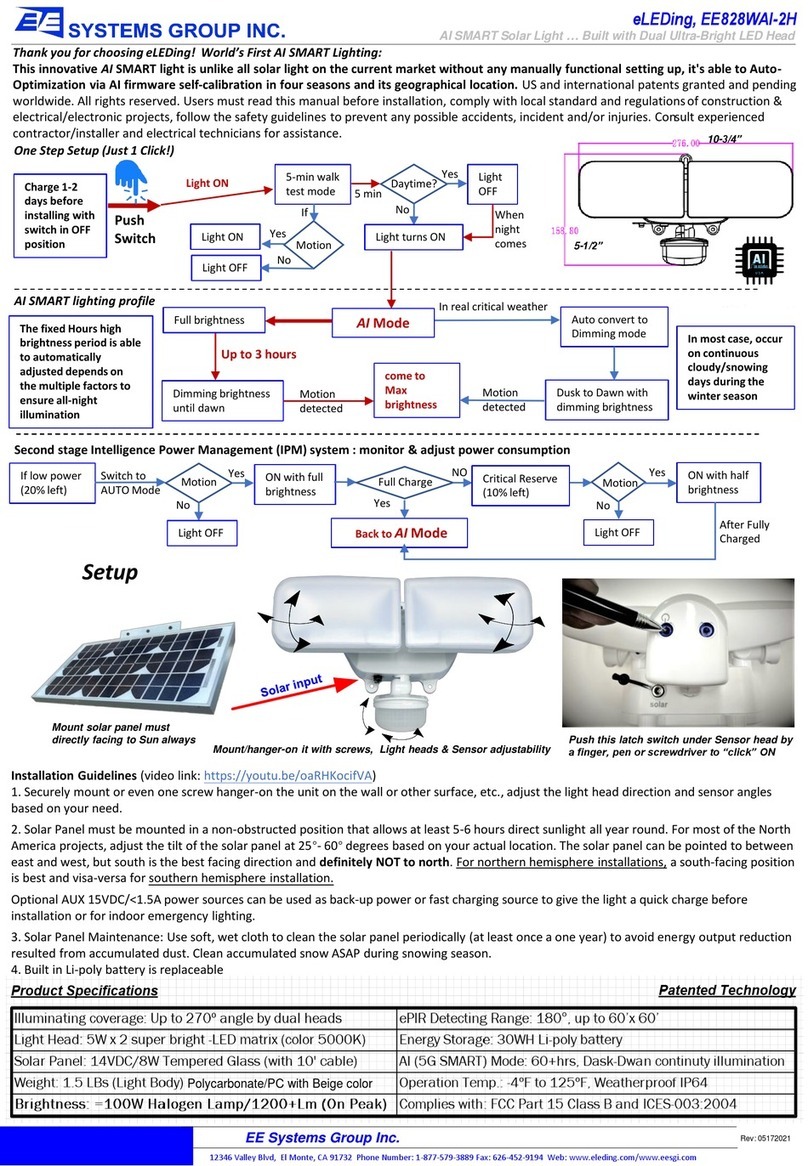

EE Systems Group

EE Systems Group eLEDing EE828WAI-2H quick start guide

Nothern Lights

Nothern Lights OM944T Operator's manual