Shunyata Research HYDRA TRITON v2 User manual

USER GUIDE

Visit us online: shunyata.com

© Copyright 2015 — All Rights Reserved

THANK YOU!

Congratulations on your purchase of the Shunyata Research HYDRA TRITON v2. The HYDRA power distributors

are used by many of the finest recording studios, mastering engineers, recording artists and electronics

manufacturers worldwide.

Chances are that some of the music you listen to and the equipment that you own was produced using the

HYDRA TRITON as part of a reference system.

Thank you for choosing us to be a part of your system.

Caelin Gabriel

President

IMPORTANT SAFETY INFORMATION

WARNING: POTENTIALLY LETHAL VOLTAGES INSIDE!

THERE ARE NO USER SERVICEABLE PARTS INSIDE. REFER ALL SERVICE ISSUES TO SHUNYATA RESEARCH SERVICE

DEPARTMENT (or an Authorized Distributor).

CHECK VOLTAGE RATING

Verify the maximum voltage rating listed on the side of the box and on the unit before applying power.

WATER

This unit is NOT water proof. Do NOT submerge unit in water or any other fluid. Do NOT operate unit in an

environment of water condensation. Do NOT operate unit with standing water on the floor.

INPUT POWER REQUIREMENTS

This unit requires a properly installed AC Mains power connection. Ensure that the AC polarity is correct and

that a safety ground is present. Do NOT operate this unit with a cable that has the ground pin disconnected.

Do NOT operate this unit with a cheater plug that disables the safety ground connection. ONLY operate this

unit with an AC outlet that has a safety ground properly connected.

READ ALL WARNINGS and INSTRUCTIONS BEFORE OPERATING THIS UNIT

Shunyata Research

USER GUIDE HYDRA TRITON v2

p2

WARNING

Risk of electric shock.

DO NOT OPEN.

To reduce the risk of electric shock do not remove cover or back.

No user serviceable parts inside. Refer servicing to qualified service personnel.

© Copyright 2015 — All Rights ReservedShunyata Research p3

USER GUIDE HYDRA TRITON v2

UNPACKING

KEEP PACKING MATERIALS

Keep all the packing materials. If you need to ship the unit, you must use the original boxes and protective

inserts. Shipping without the original materials will void the warranty and you may not be entitled to claim

shipping insurance losses if the unit was improperly packed!

If your packing materials are missing or damaged contact Shunyata Research Customer Service to arrange for

replacements.

DO NOT plug in the unit until you have read the complete instructions!

WHAT’S IN THE BOX

HYDRA TRITON v2

Certified Warranty Card

PRODUCT INFORMATION

The HYDRA TRITON v2 is our highest performing, reference power distributor. It contains patented and

proprietary technologies that deliver state-of-the-art performance for home entertainment systems. The

HYDRA TRITON is also used by many of the most renowned recording studios worldwide. Many of the audio

industries most prestigious equipment manufacturers and top reviewers use the HYDRA TRITON as their

reference power distribution system.

DISTRIBUTED POWER CONDITIONING

Shunyata Research pioneered the concept of Distributed Power Conditioning to solve the problems associated

with power line noise in complex home entertainment systems. Home entertainment systems can be very

complex involving many components located in multiple locations. These systems may use several dedicated

power lines making it almost impossible to effectively reduce power line noise with a single box power

conditioner solution. Shunyata Research solves this problem by intercepting noise at multiple locations in the

entertainment system using a variety of products.

First, the HYDRA power distributors supply power to multiple components while

intercepting noise from the power line and reducing component-to-component noise.

Shunyata Research’s “noise reduction” power cables intercept noise generated by a

component’s power supply before the noise has the opportunity to propagate through

the power grid.

The VENOM DEFENDER is a unique “pocket power conditioner” that is designed for

single components that are remotely located. It provides surge protection and noise

reduction without the cost and complexity of a full size power distributor.

Example: A SONOS single-box audio component supplying music to a den or bedroom.

DTCD™ DESIGNED (Dynamic Transient Current Delivery)

The TRITON v2 was designed using the DTCD™ measurement analyzer. DTCD™ Analysis is a technique that

measures instantaneous current through low impedance electrical conductors and contacts. We use it to

optimize the design, specification and construction of parts and materials to ensure maximum current

delivery performance.

© Copyright 2015 — All Rights ReservedShunyata Research p4

CCI™ NOISE REDUCTION

Traditional power conditioners are designed to block noise coming in from outside the home but do not

address the noise that is generated by the electronic component’s themselves. In fact, most conditioners reflect

noise back into other components connected to the power conditioner. CCI™ (Component-to-Component

Interference) is one of the most significant but often overlooked aspects to power system performance.

The Shunyata Research designed CCI™ filter consists of a proprietary multi-stage filter that reduces RFI and

power supply generated interference.

NIC™ NOISE REDUCTION

NIC™ (Noise Isolation Chamber) is a patented technology that reduces high frequency power line noise. NICs™

use a non-reactive ferroelectric substance that actually absorbs high frequency noise. This allows HYDRA power

distributors to reduce noise without any of the negatives associated with conventional power conditioner

designs. ~ Patent US 8,658,892 ~

CopperCONN™ OUTLETS

All commercial grade connectors and virtually all audiophile grade connectors are made from brass or bronze

base metals. Some audiophile grade connectors may get a plating of nickel, silver, gold or rhodium that is

only a few millionths of an inch thick. The Shunyata Research CopperCONN™ is constructed using solid, high

purity, oxygen free copper as the base metal with a flash coating to protect the copper from oxidation.

The CopperCONN™ outlets and connectors are designed to provide superior grip strength and contact integrity.

This contributes to a measurable improvement in DTCD™ (Dynamic Transient Current Delivery) performance

and a correspondingly obvious difference in audible performance.

ZPP-DS Distribution Buss

The ZPP-DS significantly reduces the daisy-chained wires, terminal strips and terminal connectors found

within common power conditioners. The power outlets, electrical terminals and main electrical buss are all

unified into a single OFC copper buss that dramatically improves DTCD™.

CGS - CHASSIS GROUNDING SYSTEM

The TRITON v2 includes the exclusive Chassis Grounding System (CGS). This provides a central grounding

point for all electronic components in the system. The CGS normalizes voltage differentials between

component chassis’ which may reduce performance robbing ground loops. It also lowers chassis ground

noise using Shunyata Research’s patented NIC™ technology.

VTX™ CONDUCTORS

Shunyata Research’s exclusive VTX™ conductors are virtual tubes. The core of the conductor is completely

hollow, electrically, so that all of the current travels through the circumference of the conductor eliminating

skin effects and random eddy currents through the conductor. The VTX™ conductors are produced with

CDA-101 copper which is the highest purity copper available.

HYDRAULIC ELECTROMAGNETIC BREAKER

Common power conditioners use fuses or thermal breakers for over current protection. The problem is that

these devices cause voltage drops, increased contact impedance, thermal noise, excessive heat generation

and current limiting effects when heavily loaded.

The TRITON v2 uses a more advanced solution called a hydraulic electromagnetic breaker that can operate

right up the to the maximum current level without the limitations of fuses or thermal breakers.

ArNi CRYOGENIC TREATMENT

Shunyata Research operates its own cryogenic treatment plant. We have developed a proprietary ArNi Cryo

Treatment procedure that is more advanced than the conventional nitrogen based procedure. All the critical

connectors, conductors and contacts used in our power cables, signal cables and power distributors are

treated. This procedure noticeably enhances the performance of the treated parts.

USER GUIDE HYDRA TRITON v2

© Copyright 2015 — All Rights ReservedShunyata Research p5

USER GUIDE HYDRA TRITON v2

SHUNYATA FOOTER

Power distributors react very similar to amplifiers in relationship to floor borne vibration. We have tested

dozens of commercially available feet and determined that none of them were adequate for use with

our products. After researching multiple forms of energy dissipation methods, we developed a footer that

possesses the performance characteristics of an expensive after market isolator but also provides a good

grip on the shelf.

VIBRATION MANAGEMENT

The TRITON v2 chassis is made with heavy gauge steel and aluminum. Shunyata Research has developed

exclusive vibration absorbing AC outlet gaskets and chassis dampeners that measurably reduce resonant

vibration levels.

CONNECTIONS AND POWER UP

THE ELECTROMAGNETIC BREAKER

This is NOT a master ON/OFF switch. The breaker is designed to protect the

unit and the components in the event of an over-current event. You should

NOT use it as a master ON/OFF switch.

THE POWER CORD

The TRITON requires an IEC C19 terminated power cord. ONLY use a power

cord that is rated for 20-Amps of continuous current.

POWER UP SEQUENCE

Put the breaker in the OFF position.

Plug the C19 power cord into the unit’s inlet.

Ensure all electronic components are in the OFF position.

Plug each component into an available outlet.

Put the breaker in the ON position.

Turn each of the components on.

Wait approximately 5 seconds between each component.

IEC C19

OFF POSITION

ON POSITION

1

2

3

4

5

6

© Copyright 2015 — All Rights ReservedShunyata Research p6

POWER DOWN AND DISCONNECTION

WARNING: DO NOT PULL THE PLUG

DO NOT ever pull the unit’s power cord from the wall outlet while the system is operating. This unit carries

very high currents and pulling the cord may cause a large arc that will damage the power cord contact, the

wall outlet and potentially the unit’s inlet.

To remove the unit from the system, reverse the previous procedure.

• Turn OFF each connected component.

• Turn the unit’s Electromagnetic Breaker to the OFF position.

• Unplug each of the power cords attached to the unit.

• Unplug the unit’s power cord from the wall outlet.

CGS CHASSIS GROUNDING SYSTEM

The TRITON v2 includes the exclusive Chassis Grounding System (CGS) featuring Shunyata Research’s patented

NIC™ noise reduction technology. It provides a central grounding point for all electronic components in

the system which may reduce performance robbing ground loops. (Refer to the CGS Application Guide for

more information)

PERFORMANCE OPTIMIZATION

OUTLET ZONES

An AC duplex consists of two outlets. Each duplex has a dedicated CCI™ filter that reduces noise from the

components that are connected. For best performance, if there are four components or less, connect each

component to a separate duplex. If there are more than four components, group the components by

function. For example: Connect a DAC and transport to Zone 1 and the preamp to Zone 2.

BURN-IN

The power distributor is constructed using massive wiring and heavy duty contacts throughout. For best

performance allow at least 200 hours of continuous operation. For accelerated burn-in we recommend the

use of a fan or high-intensity lamp. Rotate the fan to each of the outlets since each outlet needs to burn-in.

MOUNTING PLATFORMS

Ideally the HYDRA TRITON v2 should be placed on a proper shelf, amp stand or solid platform. A heavy plank

of wood or a granite slab works well also.

CONES AND FOOTERS

The HYDRA TRITON v2 uses Shunyata Research’s isolation footer. It was designed specifically to reduce vibration

from the underlying platform. Some customers report that hard metallic footers offer improved performance

— such as Shunyata Research’s optional SSF stainless steel feet. You may wish to experiment with other more

expensive products (e.g. Stillpoints™).

USER GUIDE HYDRA TRITON v2

Chassis Ground System

© Copyright 2015 — All Rights ReservedShunyata Research p7

USER GUIDE HYDRA TRITON v2

AC WALL OUTLETS

We strongly recommend that you replace the wall outlet with a high quality commercial grade unit. The

standard wall outlet is not adequate for high current applications. There are many audiophile grade outlets

that are plated with a variety of metals including silver, gold, rhodium and others. Our experience is that these

do not offer significant improvement over a quality commercial grade outlet. We recommend the Hubbell

model 5362 or Shunyata Research’s SR-Z1 derivative of it.

OTHER POWER COMPONENTS

We DO NOT recommend using the HYDRA TRITON v2 with other power distributors, conditioners or

regenerators. Connecting multiple power components in series usually delivers unpredictable or poor results.

Conditioners and regenerators can be highly reactive and may degrade the DTCDTM and the CCI™ advantages

built into the HYDRA TRITON v2. If extra outlets are needed, use the VENOM PS8 which was designed

specifically to expand the outlet capacity of the TRITON without performance compromises.

CONTACT ENHANCEMENT FLUIDS

Contact fluids, pastes and gels are NOT recommended for use with this unit. Many of these types of products

leave a residue that can contaminate or damage the contact metals over a period of time. The products

labeled as silver bearing grease or silver impregnated silicon are particularly harmful. Some of these are

difficult or impossible to remove. Damage caused by these products will void your warranty! Never attempt

to clean the contacts inside the outlets. If you wish to clean the external contacts of a power cord, use CAIG

DeoxIT®and DeoxIT®GOLD.

THE HYDRA REFERENCE STACK

The HYDRA REFERENCE STACK is a modular three component

system that represents our highest performing power distribution

system. It consists of the TRITON, TYPHON and DPC-6. The TRITON

provides power distribution for 8 components while the TYPHON

extends the noise reduction capabilities of the TRITON. The

HYDRA DPC-6 is desirable if the system has computer or music

server audio components.

The TRITON may be used as a standalone power distributor. The

TYPHON and DPC-6 are optional and may be added later to extend

the power system capabilities.

© Copyright 2015 — All Rights ReservedShunyata Research p8

HYDRA TRITON v2 PRODUCT SPECIFICATIONS

USER GUIDE HYDRA TRITON v2

MAXIMUM VOLTAGE

• Max Voltage (US): 125VAC unregulated

• Max Voltage (Asia): 230VAC unregulated

• Max Voltage (Euro): 240VAC unregulated

CURRENT RATINGS

• Max continuous current: 20 Amps (US)

• Max continuous current: 16 Amps (EU, AU, UK)

• Instantaneous peak current:

>200 Amps @ 8.33ms

SURGE SUPPRESSION

• Max surge current: 40,000 Amps @ 8/50 µs

NOISE REDUCTION TECHNOLOGY

• NIC™ (Noise Isolation Chambers)

• Surge Module

• CCI™ Noise Filters (4)

OVER-CURRENT PROTECTION

• Hydraulic electromagnetic breaker

OUTLETS

• US Version: 8 NEMA 5-20R

• AS Version: 8 NEMA 5-20R

• EU Version: 8 EU1-16R

INPUT CONNECTORS

• IEC-C20

WIRING SYSTEM

• Dual 11 AWG VTX™ Conductors

• ZPP-DS Copper Buss System

• CDA-101 Copper

• Shunyata’s ArNi Cryogenic Treatment

CONSTRUCTION

• 16 Gauge Powder Coated Steel Chassis

• Anodized Aluminum Faceplate

• Vibration Dampening (internal)

• AC Outlet Dampening Gaskets

• Shunyata’s Isolation Footer

DIMENSIONS

Width: 17-1/4 in (43.8 cm)

Depth: 17-1/8 in (43.5 cm)

Height: 6 in (15.3 cm)

Weight: 40 lb. (18.2 kg)

SHUNYATA RESEARCH INC.

26273 Twelve Trees Ln. NW, Suite D

Poulsbo, WA 98370

shunyata.com

Phone: 360.598.9935

Fax: 360.598.9936

Email: [email protected]

Table of contents

Popular Power Distribution Unit manuals by other brands

hager

hager orion plus Mounting instructions

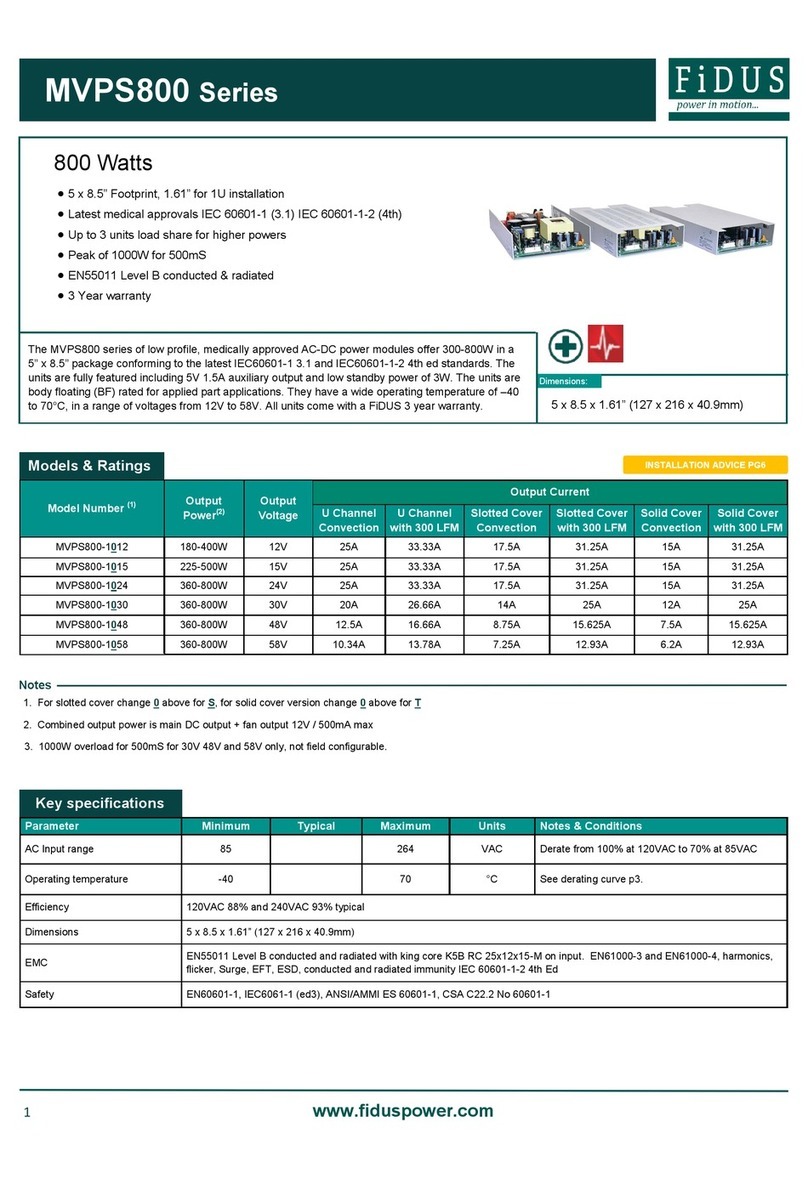

FiDUS

FiDUS MVPS800 Series quick start guide

GÜDE

GÜDE Expert Power Control 8031 Series manual

Huawei

Huawei PDU8000 Series quick guide

Sonorous

Sonorous Energy Saver-ES-05 operating instructions

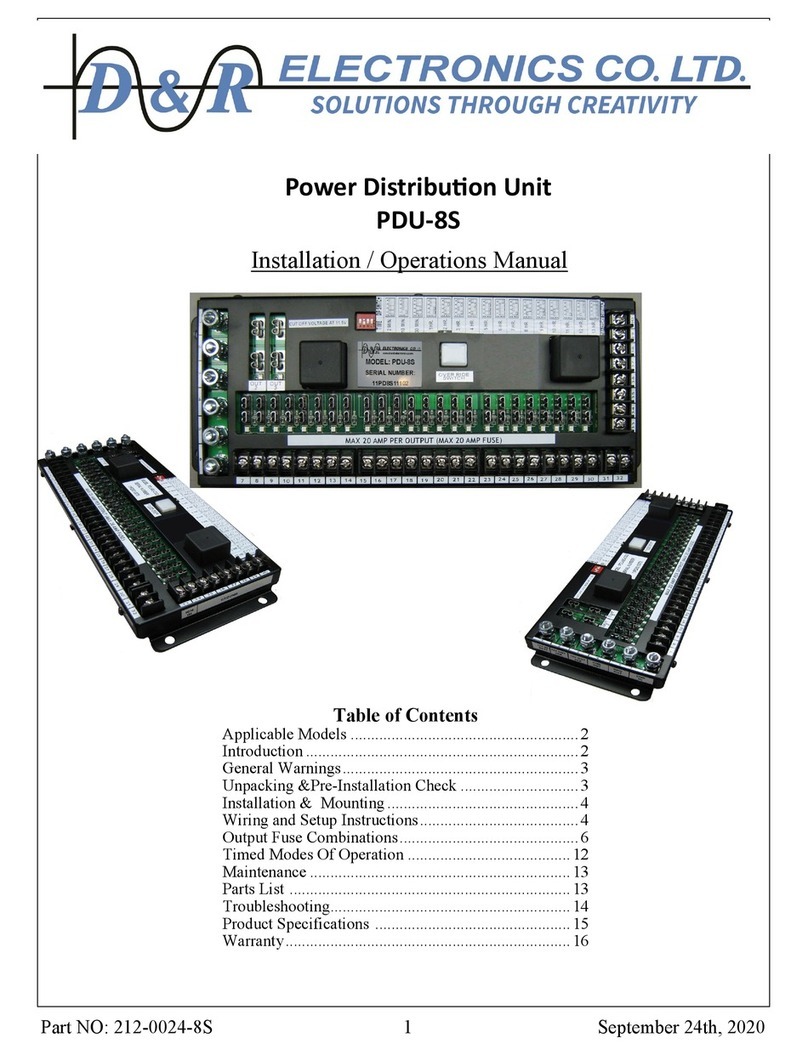

D&R ELECTRONICS

D&R ELECTRONICS PDU-8S Installation & operation manual

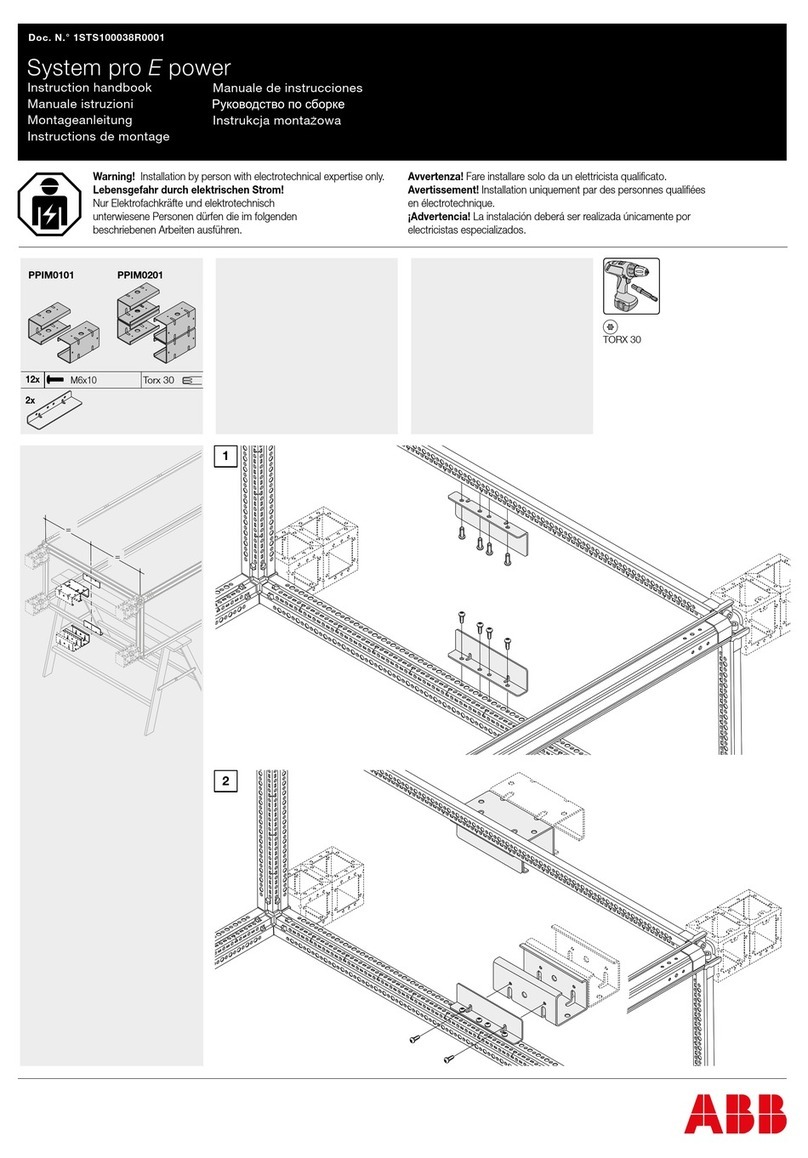

ABB

ABB Relion 611 Series Technical manual

Schulte Elektrotechnik

Schulte Elektrotechnik EVOline Port 1129 Operating and assembly instructions

A-Neutronics

A-Neutronics MS-1917-LCD instruction manual

MGE UPS Systems

MGE UPS Systems Comet EXtreme Series Startup guide

Behringer

Behringer POWERLIGHT PL2000 user manual

Botex

Botex BO-6-PW user manual