Huawei PDU8000 Series User manual

HUAWEI TECHNOLOGIES CO., LTD.

PDU8000 UPS Modular Input Power

Distribution Cabinet (Single Cabinet)

V1.0

Quick Guide

Issue: 04

Part Number: 31507772

Date: 2020-09-11

1

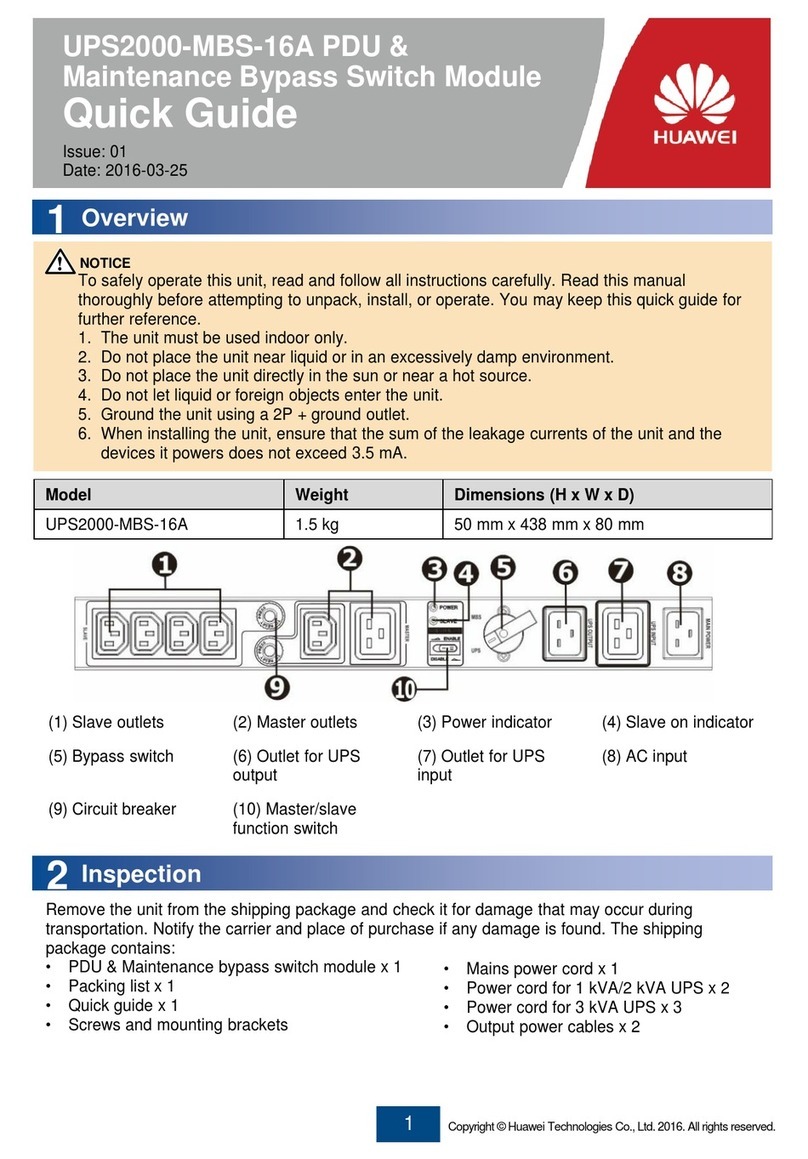

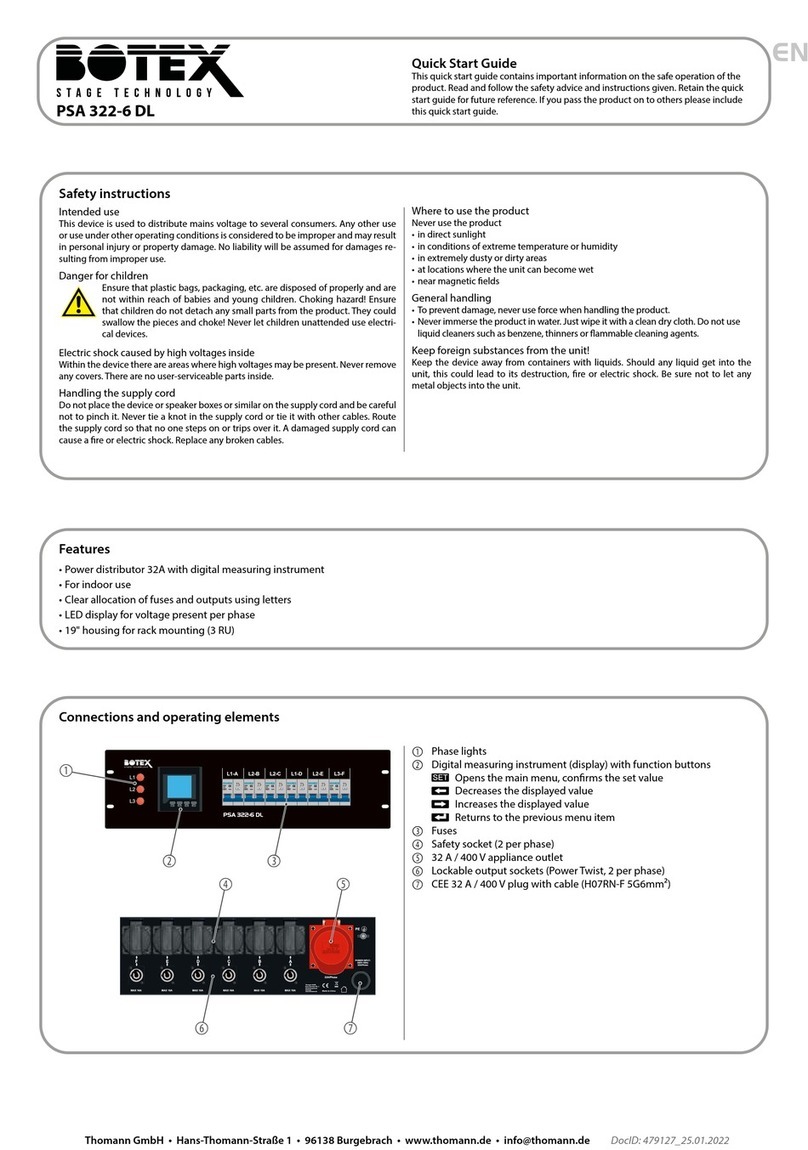

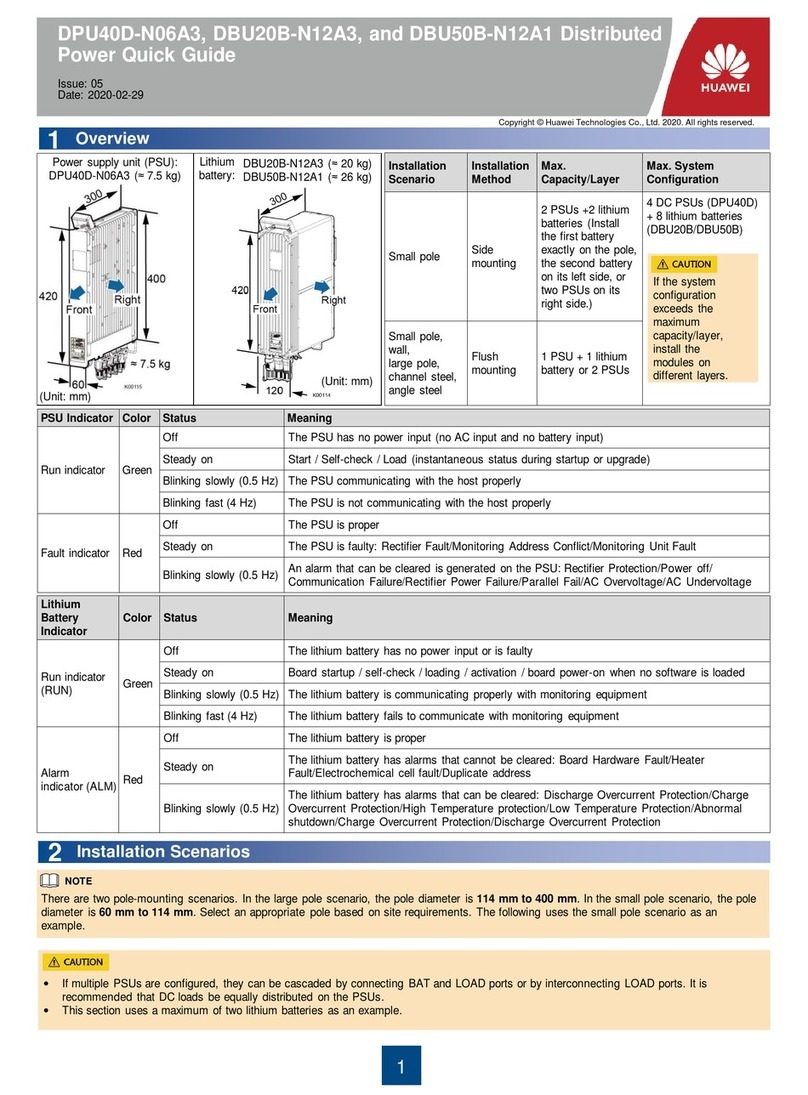

UPS modular input PDC

(single cabinet)

Indicator and electric

meter module

Input ATS module

UPS input module

Air conditioner load

output module

Maintenance bypass module

Copyright © Huawei Technologies Co., Ltd. 2020. All rights reserved.

The model number is in the PDU8000-XXXXACV4-UC format which is described as follows:

Figures in this quick guide are for reference only. The actual product appearance prevails.

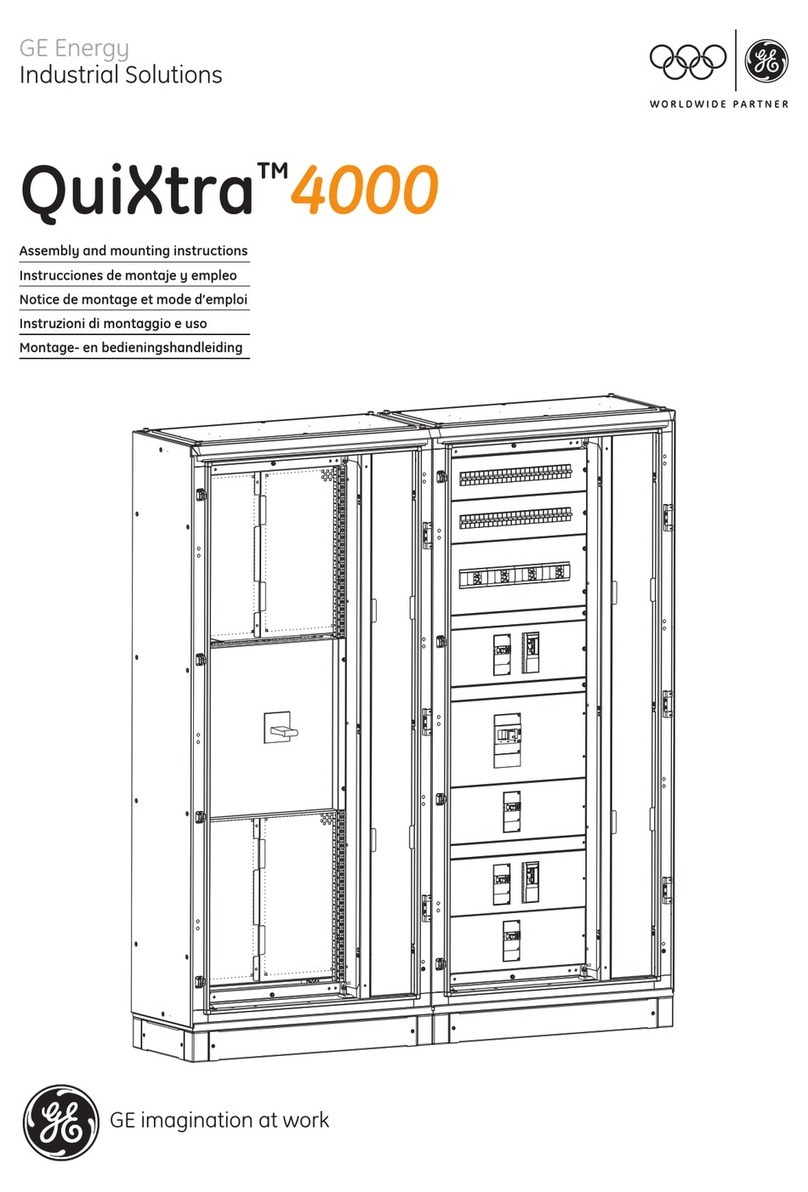

1Overview

Product Appearance

PDU8000 XXXX AC V4 UC

PDC PDC capacity Alternating current Rated: 380 V/400 V/415 V UPS PDC

Dimensions (H x W x

D): 2000 mm x 800

mm x 850 mm

2

ATS (8D) Appearance

(

1) 8D controller

(

2) Motor/Manual

selection lever

(

3) Electric operation

mechanism

(

4) Locking latch

(

5) Handle for manual

operation

(

6) Transfer switch

(

7) Input II

(

8) Input I

(

9) Alarm ID description

Cable Holes

Bottom cable

holes for power

cables

Signal

cable

outlet

Top cable

holes for

power cables

3

2Installation Preparations

Technical Documents

2.1

1. This guide describes how to install a UPS modular input PDC (single cabinet). Before

installation, read through the

User Manual

to understand the product information and

safety precautions.

2. Use insulated tools during installation and operation.

3. Only engineers certified by the manufacturer or its agents are allowed to perform PDU8000

installation, commissioning, and maintenance. Otherwise, personal injury or equipment

damage may occur, and the resulting PDU8000 faults are beyond the warranty scope.

4. Sections and steps marked as optional in this document can be performed selectively based

on the actual configuration.

Technical

Document

Function

Obtaining Method (Remarks)

Schematic diagram

Describes the control relationship of

circuit breakers for the PDC.

Delivered with the PDC

PD510

(

1) Current display

(

2) Voltage and frequency display

(

3) Power and power factor display

(

4) Maximum and average value

display

(

5) Harmonic display

(

6) Data display mode

4

Preparing Tools

2.2

Firestop putty

Protective gloves Insulated gloves

Hammer drill

Heat gun

Protective shoes

Insulation tape

Phase sequence

meter

Level

Solid wrench

Wire stripper

Phillips screwdriver

Cable tie

Flat-head

screwdriver

Rubber mallet

Electrician's knife

Multimeter

Electric hydraulic pliersCrimping tool

Adjustable wrench

Measuring tape

Step ladder (2 m)

Socket wrench set

Diagonal pliers

Insulated torque

wrench

Pallet truck

Cable cutter

This table may not list some tools required at specific sites. Onsite installation personnel and

technical support personnel should prepare tools based on site requirements.

Prepare firestop putty for sealing cable holes after cable connection. Huawei does not provide

the firestop putty. The customer needs to purchase it.

5

Unpacking

3.2

Unpacking and Accepting Goods

3.1

1. After the equipment is delivered to the installation site, representatives from the customer

and Huawei unpack and inspect the equipment together.

2. If any damage is found, report it to the carrier immediately.

1. Check whether the tiltwatch indicator on the carton has turned red. If yes, record the

information and contact the equipment carrier and the local Huawei office immediately.

2. Visually inspect the equipment appearance to check whether the equipment is paint-peeling,

misshapen, scratched, or soaked. If yes, record the information and contact the equipment

carrier and the local Huawei office immediately.

3. Check against the packing list that the equipment and fittings are correct and complete. If

some fittings are missing or do not comply with the models in the packing list, record the

information and contact the local Huawei office immediately.

4Installing the PDC

Transporting the PDC

1. Move the PDC to the specified installation position using a forklift.

2. Cut off and remove the binding straps, as shown in the figure.

3. Remove the packing materials and cushion foam, as shown in the figure.

4. Remove the plastic bag, take out the fitting box, and put it away.

3Acceptance Guide

1. Each PDC weighs about 350 kg to 480 kg. Take protective measures during movement to

prevent personal injury.

2. Move the cabinet with caution to avoid bumping or toppling, which may damage the

equipment.

6

1. Open the front and rear doors of the PDC,

and remove one ground cable from the

front and rear doors respectively.

2. Remove the screws from the front and rear

door sills and buckles.

3. Remove the front and rear door sills and

buckles by pulling them upwards in a tilted

way.

4. Remove the two L-shaped brackets from

the PDC front and rear, and remove the

bolts from the pallet under the PDC.

5. Move the PDC away from the pallet using

a forklift.

6. Reinstall the front and rear door sills and

buckles.

7. Reinstall the front and rear ground cables.

8. Adjust the PDC leveling feet using an

adjustable wrench to ensure that all

castors touch the ground.

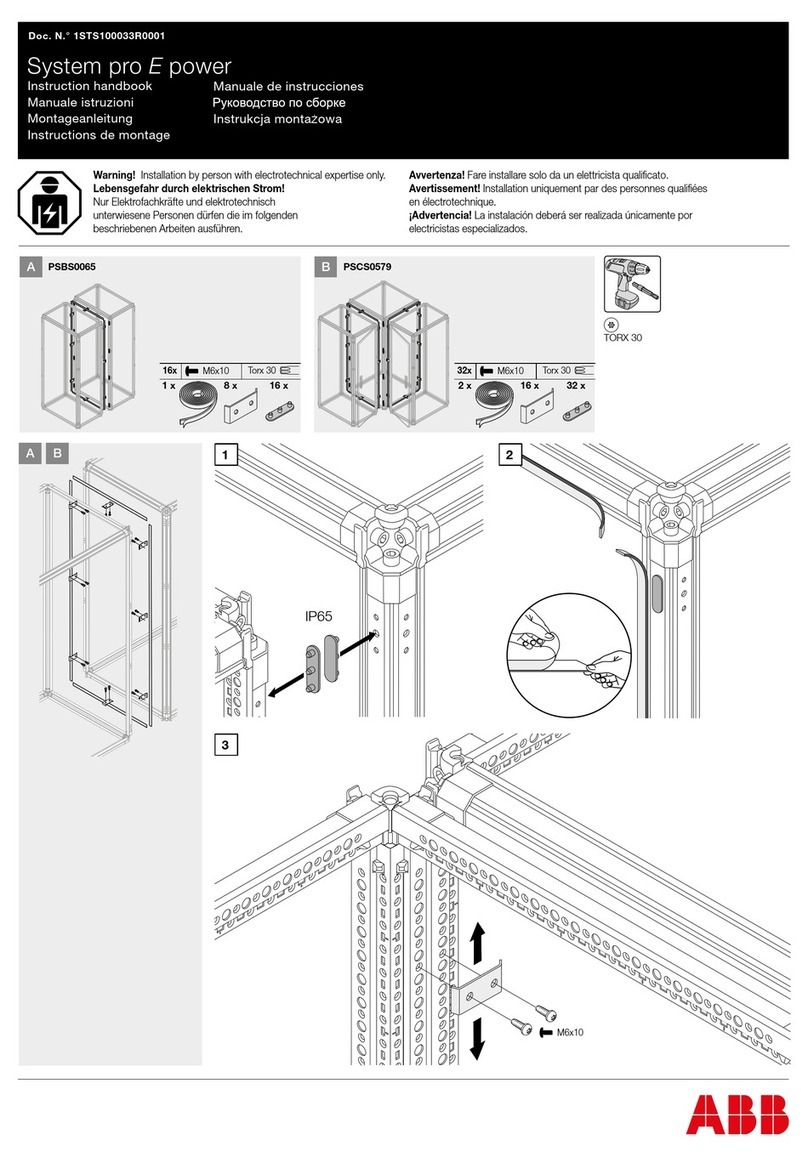

Securing the Cabinet to the Floor

1. Mark the mounting holes for PDC

bolts using a marker based on the

marking-off template, as shown in

the figure.

2. Use a hammer drill to drill holes to

depths of 52 mm to 60 mm at the

positions for installing expansion

bolts.

7

Put away the removed expansion bolt for securing the PDC.

(

1

) M12 expansion bolt

(

2) Spring washer

(

3) Flat washer

(

4) Expansion sleeve

8. Level the PDC using a level and an adjustable

wrench, as shown by (1) in the figure.

6. Align the PDC mounting holes with the

expansion bolt holes.

7. Adjust the leveling feet of the PDC using

an adjustable wrench until the leveling feet

touch the floor.

Do not remove the leveling feet as the

reinstallation can be difficult when you need

to use them.

3. Partially tighten the expansion bolt and vertically insert it into the hole. Knock the expansion

bolt using a rubber mallet until the expansion sleeve is fully inserted into the hole.

4. Rotate the expansion bolt clockwise using a wrench until the expansion sleeve fully expands.

5. Rotate the expansion bolt counterclockwise to remove it together with the spring washer and

flat washer.

1. Wrench a leveling foot clockwise to elevate

the cabinet, or wrench a leveling foot

counterclockwise to lower the cabinet. The

cabinet feet can be adjusted within a range

of 0–8 mm.

2. To prevent cabinet tilting, adjust all the

feet at the four corners instead of one foot.

3. Use a measuring tape when leveling the

cabinet to ensure that the height between

the cabinet top and the ground is 2000±3

mm.

8

9. Secure the PDC to a torque of

45 N·m using a socket wrench.

In the cabinet combination scenario,

the expansion bolts need to be

partially tightened.

Channel Steel Installation

1. Determine the cabinet installation

positions on the channel steels

based on the marking-off template,

as shown in the figure.

1. Huawei does not provide

channel steel or expansion bolts

used for securing channel steel.

It is recommended that the

customer purchase at least 50

mm wide channel steel.

2. Ensure that the distance

between the outer surfaces of

channel steels is 800 mm, and

that the surfaces are flush.

2. Drill mounting holes on the

channel steels using a hammer

drill.

3. Place the cabinet on the

channel steel using a forklift

and align the holes.

4. Adjust the leveling feet of the

PDC using an adjustable wrench

until the leveling feet touch the

channel steel.

In the channel steel installation

scenario, the four leveling feet

need to firmly touch the channel

steel to support the weight of the

cabinet, as shown in the figure.

5. Level the PDC using a level and an adjustable wrench.

Use a measuring tape when leveling the cabinet to ensure that the height between the cabinet

top and the channel steel is 2000±3 mm.

In the cabinet combination scenario, the expansion bolts need to be partially tightened.

6. Use a socket wrench to secure the PDCs.

The PDC side panel at the

combination side needs to be

removed only when a

combination copper bar needs to

be installed.

Combining Cabinets

1. Remove the screws for

combining cabinets at the

cabinet top and put the

screws aside, as shown in the

figure.

2. (Optional) Remove panels at

the PDC sides to be combined.

3. Pull a rope at the front and rear

of the PDC top and bottom

respectively to align the PDCs.

4. Level adjacent PDCs using a level and an

adjustable wrench.

5. Remove the cabinet connecting kit and

screws from the side beam, and combine

the cabinets using the screws.

The method for combining three or four cabinets is the same as that for combining two cabinets.

Here, combining two cabinets is used as an example.

9

Other manuals for PDU8000 Series

29

Table of contents

Other Huawei Power Distribution Unit manuals

Huawei

Huawei PDU8000 Series User manual

Huawei

Huawei PDU8000 Series User manual

Huawei

Huawei PDU8000 Series User manual

Huawei

Huawei PDC-0038V4ACIOA User manual

Huawei

Huawei PDU8000 Series User manual

Huawei

Huawei DPU40D-N06A3 User manual

Huawei

Huawei PDU8000 Series User manual

Huawei

Huawei PDC-0038V4ACIOA User manual

Huawei

Huawei PDU8000 Series User manual

Huawei

Huawei PDU8000 Series User manual