SIBRAPE CLARIPUR SG20 User manual

CHLORINE GENERATOR

CLARIPUR SG20 E SG35

USER’S GUIDE

English 1Español 23

2

User’s Guide

User’s Guide

3

Important Warnings and Safety Precautions........................................................................4

Introduction..............................................................................................................................6

Technical features Chlorine Generator CLARIPUR SG20.....................................................7

Technical features Chlorine Generator CLARIPUR SG35.....................................................7

Installation Instructions.........................................................................................................8

Spare parts...........................................................................................................................11

Dimensions............................................................................................................................12

Indication Display.................................................................................................................13

Settings.................................................................................................................................15

Features................................................................................................................................15

Pool Water Chemistry, Conditions and Precautions...........................................................16

Cleaning the Blades with Acid.............................................................................................19

Unit of Measurement - Temperature..................................................................................19

Technical Assistance............................................................................................................20

Contacts...............................................................................................................................20

Warranty Terms....................................................................................................................21

Table Of Contents

4

User’s Guide

Important Warnings and Safety Precautions

Incorrect installation of this equipment could result in serious personal injuries or

even death.

Installers, pool operators and pool owners should read these warnings and all

instructions contained in this manual before installing, operating or servicing

equipment.

Claripur SIBRAPE Chlorine Generators are intended for use in commercial and

residential swimming pools.

Most countries have local regulations governing the construction, installation and

operation of residential and/or public swimming pools, spas and hot tubs.

It is important to follow these regulations according to the country of installation.

IMPORTANT WARNING

Attention installer! This installation and user manual contains important information

about installing, operating and using this product safely.

This manual must be handed over to the owner of the equipment.

Before installing this product, read and follow all warnings and instructions in this

manual. Failure to follow warnings and instructions could result in serious injury,

death, property damage, and loss of warranty.

Danger! Water temperature above 98,6ºF can be dangerous to health. Prolonged

immersion in hot water can induce hyperthermia. Hyperthermia occurs when the core

body temperature reaches a level above the core body temperature of 98,6ºF. The effects

of hyperthermia include: (1) Ignorance of danger imminent; (2) lack of heat perception;

(3) Failure to recognize the need to get out of the water; (4) Physical inability to leave

the water; (5) Fetal harm in pregnant women; (6) Unconsciousness resulting in risk of

drowning. The use of alcohol, drugs or medication can greatly increase the risk of fatal

hyperthermia in swimming pools, spas, hot tubs and hot tubs.

Do not allow children and/or untrained persons to operate this equipment.

When replacing a chlorine generator, check the power/flow of the equipment so

that they are compatible. Installing inadequate equipment can exceed the amount of

chlorine needed or fall short.

This equipment is intended for use in residential and/or commercial swimming pools,

so all regulations must be followed.

User’s Guide

5

RISK OF ELECTRIC SHOCK OR ELECTROCUTION

CHLORINE GENERATORS REQUIRE HIGH VOLTAGE AND CURRENT WHICH CAN CAUSE

ELECTRIC SHOCK, BURNS OR DEATH.

Always disconnect electrical power from the equipment before performing maintenance.

Failure to do so could result in accident, serious injury, or accidental death from electric

shock.

Pool, spa or hot tub Chlorine Generators must be installed by qualified professionals

in compliance with local electrical regulations and applicable ordinances. Incorrect

installation can create an electrical hazard which could result in death or serious injury

to pool users, installers or others due to electrical shock and could cause property

damage.

Failure to properly size the equipment, perform an improper installation, or use the

equipment in applications other than those for which the equipment is intended can

result in accidents, serious personal injuries, or death. These dangers may include, but

are not limited to, electric shock, fire, flood, serious injuries, property damage caused

by a structural failure of the equipment or other system component.

Never exceed the specifications of the Chlorine Generator, such as pressure, voltage,

current, etc.

DANGER OF SUCTION TRAP

Motor pumps move large volumes of water, generating high suction in the suction

devices, which can represent an extreme danger of accidental suction, of limbs and/

or hair if a correct dimensioning of the quantity and positioning of the bottom drains,

skimmer, devices of suction and piping.

FAILURE TO FOLLOW INSTALLATION, OPERATION AND SAFETY REGULATIONS AND

RECOMMENDATIONS MAY RESULT IN TRAPPED HAIR OR LIMBS WHICH CAN CAUSE

SERIOUS INJURIES OR DEATH. In case of doubt about the installation and/or operation

of the motor pump, consult a qualified pool professional service.

Motor pumps do not replace drains and their covers correctly installed and fixed. A

standard drain plug must be used to cover each drain. Swimming pools, spas and

hot tubs must use at least two drains and follow the proper regulations for design,

specification and installation.

Regularly inspect all drain covers for cracks, damage and advanced wear. If a cover is

loose, cracked, damaged, broken or missing, close the pool, spa or hot tub immediately,

turn off the pump, post a keep closed sign until an appropriate cover is properly installed.

Important Warnings and Safety Precautions

6

User’s Guide

Thank you for choosing a Sibrape product. To ensure correct and efficient use, it is essential to

read this manual completely for a good understanding of its operations, before putting it into

operation.

Our full line of pool products simplifies your routine so you can enjoy what really matters.

Comfort and well-being. Congratulations on the purchase of your Chlorine Generator, which

provides convenience in treatment and leaves the pool always ready for use in a very easy way.

The Chlorine Generator works together with filtration and produces chlorine automatically, from

salt, through an electrolysis process.

The Chlorine Generator is composed of a control panel that monitors and controls a cell that

must be installed in the filter return pipe, which can work in filtering or recirculating conditions

(according to daily recommendation). After installing the equipment, just add SALT (NaCl - Sodium

Chloride) with a high purity content, it is recommended that it has 99.8% purity, granules,

briquette or tablets. Non-iodized and without additives to have an automatically chlorinated

pool without complications.

WARNING: THE FORMATION OF CHLORINE GAS MAY OCCUR IN CASE OF IMPROPER

CONNECTION: To reduce the risk of personal injury, the Claripur Chlorine Generator

Power Source must be installed and connected to the side of the clock, controlled via an

electronic plug or stabilizer to that receives electrical energy when the pool pump is on.

Otherwise, harmful chlorine gas may form. The Chlorine Generator should never have

electrical power present when the pool pump is off and water is not flowing through

the unit.

WARNING: To reduce the risk of injury, service should only be performed by a qualified

pool professional.

WARNING: Never operate the Claripur Electronic Chlorine Generator without proper

flow or circulation of water. Formation of flammable gases will result in hazardous

conditions.

ATTENTION - The Claripur Electronic Chlorine Generator is for use in permanently

installed pools and can also be used in hot tubs and spas if applicable. Do not use in

demountable pools. A permanent pool is understood to be one that is built and cannot

be dismantled after use. A demountable pool is one that can be dismantled after use

and reassembled to regain its original integrity.

WARNING: When mixing acid with water, ALWAYS ADD ACID TO THE WATER. NEVER

ADD WATER TO THE ACID.

WARNING - Use of chemicals other than those recommended can be dangerous. Even

the proper use of recommended chemical agents can be dangerous. Follow Chemical

Agent Manufacturer’s Instructions.

Important Warnings and Safety Precautions

Introduction

User’s Guide

7

Technical Features Chlorine Generator CLARIPUR SG20

Technical Features Chlorine Generator CLARIPUR SG35

Feature Parameter:

Chlorine Generation 20g/H

Water Salinity: 2800 – 5000 ppm

Flow Detection: Turbine type sensor

Power Voltage: Full range 110~220VAC

Power: 120 W

Piping Diameter: 2“

Current in the cell: 5 A

Cell Voltage: 24V

Minimum Flow: 3 m3/H

Controller Protection Degree: IP 65

Feature Parâmetro:

Chlorine Generation 35g/H

Water Salinity: 2800 – 5000 ppm

Flow Detection: Turbine type sensor

Power Voltage: 220VAC

Power: 240 W

Piping Diameter: 2”

Current in the cell: 10 A

Cell Voltage: 24V

Minimum Flow: 3 m3/H

Controller Protection Degree: IP 65

8

User’s Guide

Inspection and Receipt

Check the product upon receipt, after removing the equipment from its packaging, check the shipping documents

and check whether any damage has occurred to the equipment, caused by loading and transport. If any irregularity

has been found, such as lack of components or damage to the equipment, immediately notify the person responsible

for the transport and Sibrape.

Electrical Installation

The electrical installation must be carried out by a qualified professional and in accordance with current local

legislation and Technical Standards. For Brazil, the Technical Standard ABNT NBR 5410 - Low voltage electrical

installations, establishes in detail the criteria that must be followed for installation, protecting the installation,

equipment, people and animals.

A well dimensioned project guarantees a perfect functioning of the equipment, protects the equipment and

increases its useful life.

The power supply to the equipment must be done through an exclusive circuit, independent of the others.

Chlorine generators must be installed inside a machine room and with sufficient area for ventilation.

The equipment’s power cables must be dimensioned by a qualified and qualified professional for this purpose.

CHECK THE CONNECTION VOLTAGE OF YOUR EQUIPMENT BEFORE CONNECTING POWER.

VERIFY THE CORRECT CONNECTION OF THE TERMINALS ON THE EQUIPMENT FOR THE AVAILABLE VOLTAGES

ACCORDING TO EACH PRODUCT.

It is mandatory to install devices that provide safety for the installation, equipment, people and animals, such as:

Contactor, Overload Relay, Surge Protection Devices, Phase Loss Relay, Residual Differential/Residual Differential

Switch and other necessary protections of according to the local standard.

The lack of electrical protection devices will result in the loss of the WARRANTY.

The warranty does not cover damage from electrical discharges, supply problems and natural phenomena.

Grounding: GROUNDING IS MANDATORY

For complete safety of the electrical installation, make sure that the motor is perfectly grounded, according to the

national technical standard. Use the existing terminal on the motor for grounding, connecting it to a wire of the

proper diameter as per the design and this wire to an appropriate iron/copper rod.

Installation Instructions

User’s Guide

9

The Chlorine Generator is installed after Residual Differential Device and Overload Protection Circuit Breaker.

There is no need to connect the Chlorine Generator together with the pump, as the Chlorine Generator has a flow

sensor that makes it turn on with the detection of the passage and water. For other installation methods, consult

technical support.

Cell controller (CPU)

1. Find a place free of water and with low humidity;

2. Fix the box using the side tabs;

3. Provide power point;

4. After fixed and energized, connect the Chlorine Generator to the CPU. To connect, just find the position

connector (there is only one way to fit it) and push the blue connector.

Installation Instructions

ELECTRICAL GENERAL BOARD

CIRCUIT BREAKER

CIRCUIT BREAKER

220V NETWORK

10

User’s Guide

Hydraulic Installation

The Chlorine Generator is installed after DR and Overload Protection Circuit Breaker. There is no need to connect

the Chlorine Generator together with the pump, as the Chlorine Generator has a flow sensor that makes it turn on

with the detection of the passage and water. For other installation methods, consult technical support.

Chlorine Generating Cell

1. Install after the filter and heating systems and before returning to the pool;

2. Section the pipe long enough to secure the equipment with the unions;

3. Glue the joints on the pipe;

4. Place the Chlorine Generator, observing the direction of the water flow;

5. Check that all the nuts are tightly screwed so that there are no leaks.

6. Always install the Chlorine Generator in the last portion of the return pipe, after electric, gas or solar

heaters.

7. After fixed and energized, connect the Chlorine Generator to the CPU. To connect, just find the position

blue connector (there is only one way to fit it).

Installation Instructions

FILTER

MOTOR PUMP

HEATING

CLARIPUR

RETURN

SUCTION

A A

B B

C C

D D

E E

F F

G G

H H

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

1:1

21/10/2021

GERADORDE CLORO

21/10/2021

SIBRAPE

CLEITON

CLEITON SENÃO ESPECIFICADO:

DIMENSÕESEM MILÍMETROS

ACABAM.SUPERFÍCIE:

TOLERÂNCIAS:

LINEAR:

ANGULAR:

REBARBARE

QUEBRAR

ARESTASAGUDAS

A2

NÃOMUDAR A ESCALA DO DESENHO

REVISÃO

NOTAS:

1.DIMENSÕES EM MILÍMETROS, SALVO INDICAÇÕES

CONTRÁRIAS;

2.VISTAS DE DESENHO DISTRIBUÍDAS

CONFORME1° DIEDRO.

002_G.C_2020_REV08_Montagem do conjunto G.C

Escala:

Quantidade:

Peso(Kg):

Estedesenho é de propriedade da Sibrape. A Reprodução, uso ou divulgação a terceiros não deve

serfeita sem prévia autorização .

Projeto:

Cliente:

TOLERÂNCIASNÃO INDICADA CONF.DIN MEDIO

1-6

+-0,1

6-30 30-100 100-300 300-1000 1000-2000 2000-4000

+-0,2 +-0,3 +-0,5 +-0,8 +-1 +-2

Desenho:

MATERIAL:

Data

Nome

Aprovado

Revisado

Desenhado

Arquivo:

PRODUTO FINAL

Created by Alice Design

from the Noun Project

Flow direction

Flow direction

Hydraulic installation diagram

Exit

The Chlorine Generator must be

installed with BY-PASS, this ensures

that the equipment receives the

ideal flow and can also be removed

for eventual maintenance and cell

cleaning.

User’s Guide

11

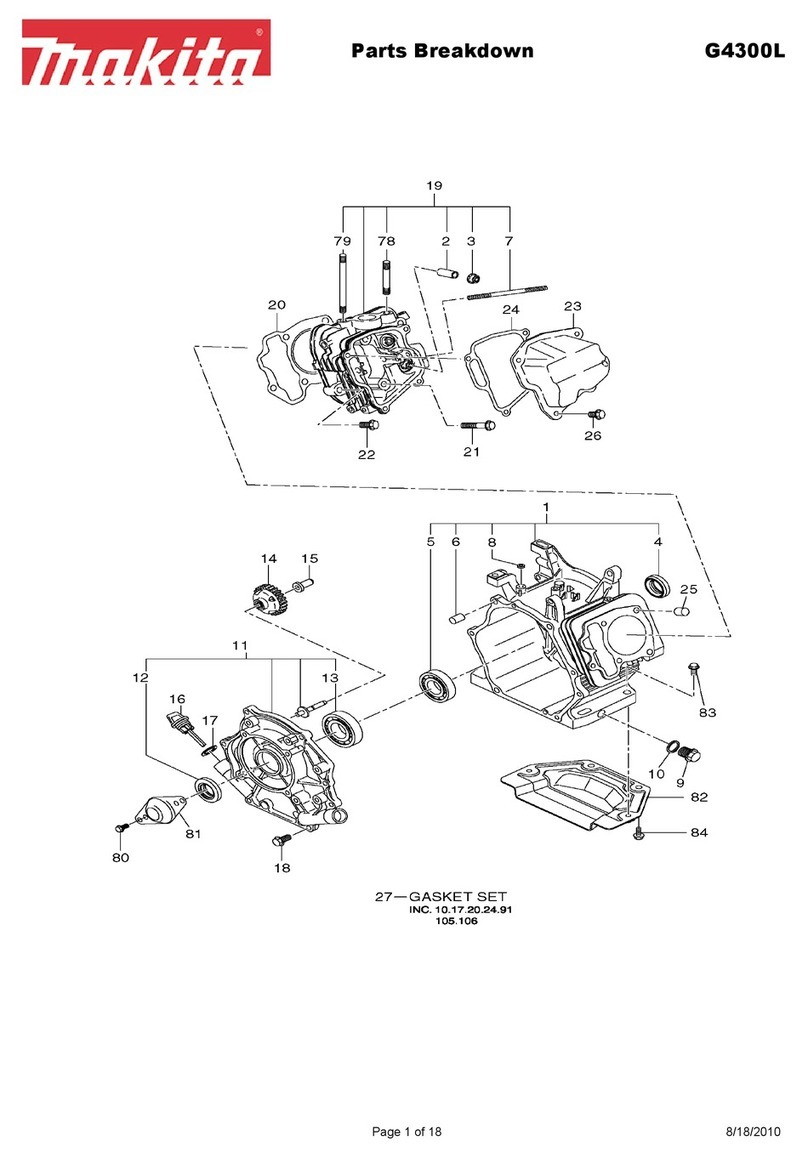

Spare parts

Chlorine Generator Parts

Item Code Description

01 028072506 KIT UNIAO PLATINUM 2 INC MX 005

02 08070183 CLARIPUR CELL NUT This is the code for the larger nut, which secures the

cover to the cell body

03 05130020 CHLORINE GENERATOR COMPLETE BLADES SG20 ENG/SPA

03 05130021 CHLORINE GENERATOR COMPLETE BLADES SG35 ENG/SPA

04 08070182 CELL BODY CHLORINE GENERATOR This is just the cell body, made of

polycarbonate

05 08070184 FLOW SENSOR KIT This item contains flow sensor with magnets, titanium

shaft and flow sensor holder

06 08290075 FLOW SENSOR WITH MAGNET This item contains the two parts of the flow

sensor already assembled with the magnets

07 05130016 COMPLETE CELL CHLORINE GENERATOR 20G This code contains every-

thing from the 20g cell, including the connections for the tubes

07 05130017 COMPLETE CELL CHLORINE GENERATOR 35G This code contains every-

thing in the 35g cell, including the connections for the tubes

- 05130014 CPU CHLORINE GENERATOR SG20 ENG/SPA

- 05130015 CPU CHLORINE GENERATOR SG35 ENG/SPA

Item

Código

Descrição

Detalhamento

01 28072505

KIT UNIAO PLATINUM/CLARIPUR 60MM

Esse item contem luva, porca e anel oring

02 08070183

PORCA DA CELULA CLARIPUR

Esse é o código da porca maior, que fixa a tampa ao corpo da célula

03 08110263

KIT TAMPA CELULA + ELETRONICA 15G RESINAGEM DUPLA

Esse item contem a tampa com nicho, prensa cabos/porca do prensa cabos, placas de titânio, toda a parte eletrônica e cabo com conector

04 08070182

CORPO DA CELULA GERADOR DE CLORO

Esse é apenas o corpo da célula, feito em policarbonato

05 08070184

KIT SENSOR DE FLUXO

Esse item contem sensor de fluxo com imãs, eixo de titânio e o suporte do sensor de fluxo

06 08290075

SENSOR DE FLUXO COM IMÃ

Esse item contem as duas partes do sensor de fluxo já montadas com os 4 imãs

08110262

CELULA COMPLETA GERADOR DE CLORO 15G

Esse código contem tudo da célula de 15g, inclusive as conexões para os tubos

A A

B B

C C

D D

E E

F F

G G

H H

J J

K K

L L

M M

N N

P P

R R

T T

24

24

23

23

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

1:1

25/10/2021

GERAADORDE CLORO

25/10/2021

SIBRAPE

CLEITON

CLEITON SENÃO ESPECIFICADO:

DIMENSÕESEM MILÍMETROS

ACABAM.SUPERFÍCIE:

TOLERÂNCIAS:

LINEAR:

ANGULAR:

REBARBARE

QUEBRAR

ARESTASAGUDAS

A0

NÃOMUDAR A ESCALA DO DESENHO REVISÃO

NOTAS:

1.DIMENSÕES EM MILÍMETROS, SALVO INDICAÇÕES

CONTRÁRIAS;

2.VISTAS DE DESENHO DISTRIBUÍDAS

CONFORME1° DIEDRO.

002_G.C_Montagemdo conjunto G.C_explosão

Escala:

Quantidade:

Peso(Kg):

Estedesenho é de propriedade da Sibrape. A Reprodução, uso ou divulgação a terceiros não deve

serfeita sem prévia autorização .

Projeto:

Cliente:

TOLERÂNCIASNÃO INDICADA CONF.DIN MEDIO

1-6

+-0,1

6-30 30-100 100-300 300-1000 1000-2000 2000-4000

+-0,2 +-0,3 +-0,5 +-0,8 +-1 +-2

Desenho:

MATERIAL:

Data

Nome

Aprovado

Revisado

Desenhado

Arquivo:

EXPLOSÃO E CÓDIGOS

1

7

3

4

1

6

5

2

12

User’s Guide

Dimensions

A A

B B

C C

D D

E E

F F

G G

H H

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

1:1

21/10/2021

GERADOR DE CLORO

21/10/2021

SIBRAPE

CLEITON

CLEITON SE NÃO ESPECIFICADO:

DIMENSÕES EM MILÍMETROS

ACABAM. SUPERFÍCIE:

TOLERÂNCIAS:

LINEAR:

ANGULAR:

REBARBAR E

QUEBRAR

ARESTAS AGUDAS

A2

NÃO MUDAR A ESCALA DO DESENHO

REVISÃO

NOTAS:

1. DIMENSÕES EM MILÍMETROS, SALVO INDICAÇÕES

CONTRÁRIAS;

2. VISTAS DE DESENHO DISTRIBUÍDAS

CONFORME 1° DIEDRO.

002_G.C_2020_REV 08_Montagem do conjunto G.C

Escala:

Quantidade:

Peso(Kg):

Este desenho é de propriedade da Sibrape. A Reprodução, uso ou divulgação a terceiros não deve

ser feita sem prévia autorização .

Projeto:

Cliente:

TOLERÂNCIAS NÃO INDICADA CONF.DIN MEDIO

1-6

+-0,1

6-30 30-100 100-300 300-1000 1000-2000 2000-4000

+-0,2 +-0,3 +-0,5 +-0,8 +-1 +-2

Desenho:

MATERIAL:

Data

Nome

Aprovado

Revisado

Desenhado

Arquivo:

PRODUTO FINAL

460,83 mm

460,83

154,48

A A

B B

C C

D D

E E

F F

G G

H H

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

2

1:1

26/10/2021

GERADOR DE CLORO

26/10/2021

SIBRAPE

CLEITON

CLEITON

SE NÃO ESPECIFICADO:

DIMENSÕES EM MILÍMETROS

ACABAM. SUPERFÍCIE:

TOLERÂNCIAS:

LINEAR:

ANGULAR:

REBARBAR E

QUEBRAR

ARESTAS AGUDAS

A2

NÃO MUDAR A ESCALA DO DESENHO

REVISÃO

NOTAS:

1. DIMENSÕES EM MILÍMETROS, SALVO INDICAÇÕES

CONTRÁRIAS;

2. VISTAS DE DESENHO DISTRIBUÍDAS

CONFORME 1° DIEDRO.

002_G.C_2020_REV 08_Montagem do conjunto G.C 02

Escala:

Quantidade:

Peso(Kg):

Este desenho é de propriedade da Sibrape. A Reprodução, uso ou divulgação a terceiros não deve

ser feita sem prévia autorização .

Projeto:

Cliente:

TOLERÂNCIAS NÃO INDICADA CONF.DIN MEDIO

1-6

+-0,1

6-30 30-100 100-300 300-1000 1000-2000 2000-4000

+-0,2 +-0,3 +-0,5 +-0,8 +-1 +-2

Desenho:

MATERIAL:

Data

Nome

Aprovado

Revisado

Desenhado

Arquivo:

DIMENSÕES EXTERNAS DA MONTAGEM

User’s Guide

13

LED indication

ACTIVE

The active LED remains lit while the equipment is producing chlorine.

FLOW

Indicates that the flow sensor has detected water passing through the pipeline.

TURBO/BOOST

indicates that the boost function is on, and will remain until it is turned off, or the 24H time expires

ERROR

• Blinking red – indicates low salt

• Solid red – Indicates an error that can be seen in the ERR menu by navigating the F key.

Dimensions

SALT CHLORINE GENERATOR

110-220VAC

50/60Hz

24VDC

5A

Erro

Error

Error

Turbo

Turbo

Boost

Fluxo

Flujo

Flow

Célula

Celda

Cell

Nunca conecte e descon ecte os cabos sem

desenergizar o equipamento.

Nunca conecte y desconecte cables sind esenergizar el equipo.

Never connect and disconnect cables without d e-energizing the equipment.

228,50

181,50

93,50

209,50

SALT CHLORINE GENERATOR

110-220VAC

50/60Hz

24VDC

5A

Erro

Error

Error

Turbo

Turbo

Boost

Fluxo

Flujo

Flow

Célula

Celda

Cell

Nunca conecte e desconecte os cabos sem

desenergizar o equipamento.

Nunca conecte y desconecte cables sin desenergizar el equipo.

Never connect and disconnect cables without de-energizing the equipment.

Indication Display

The Chlorine Generator works with two types of indication, LED indication and alphanumeric indication;

14

User’s Guide

Alphanumeric Indication

To switch between screens, simply press the F key quickly. It switches between menus:

•GENERATION

Indicates the percentage that is programmed for chlorine generation, which can be: 100%, 80%, 60%, 40% and

20%. And it is on this screen that the percentage of production is adjusted, using the keys.

•BOOST

The chlorine generator will produce 100% chlorine for 24 hours (as long as the pump maintains the water flow). On

this screen, it indicates the decreasing time, of 24 hours, for the end of the BOOST function.

•SALT

Indicates if the water has the ideal amount of salt for the equipment to have the best performance

possible.

Home Screen Indication when LOW level Indication when NORMAL level

Indication when HIGH level

SAL LOW – indicates when the salinity of the water is below 2800 PPM

SAL Normal – indicates when the salinity of the water is between 2800 to 5000 PPM

SAL HIGH - indicates when the salinity of the water is above 5000 PPM.

•ERROR

Indicates the error currently present, check the error indication table:

Indication Display

Adjust generation between

20% up to 100%

bst

ERR

sal

HIG

low nor

100 80

24

16

User’s Guide

15

Errors are indicated in sum, for example. If error 16 and error 2 occur, the display will indicate 18. If error 8 and

error 16 occur, the display will indicate 24, and so on.

Adjust chlorine production

The main indication of the equipment is the percentage of chlorine generation, which can be adjusted using the

keys found on the right of the display, indicated . The percentage can be set at: 100%, 80%, 60%, 40% and 20% of

full capacity.

BOOST - TURBO function

This function causes the Chlorine Generator to operate at 100% production for 24 hours. The time in this function

is counted by operating hours, not continuous hours. For example, if the generator runs 8 hours a day, it will

run at 100% for 3 days (24h/8h = 3). At the end of 24 hours, chlorine generation returns to the last programmed

percentage.

To activate the boost function, just press the (T) key to the left of the display. To monitor the time remaining for the

function to end, simply press the F key, the display will indicate “BST” and then the decreasing time from 24 to 0.

To return to the generation percentage indication, simply press the “F” button and with the arrows navigate to the

indication of % of generation.

The generation of chlorine in this equipment is constant, that is, it does not depend on the amount of salt in the

water. Just needing to be between 2800 and 5000 PPM.

Flow Sensor

The Chlorine Generator has a flow sensor that, only from a minimum flow of water, the generation is started. Thus,

even if the equipment is energized and the generation percentage is programmed, production will only start when

there is water flowing through the pipeline.

Indication Display

Settings

Features

ERROR INDICATION

CODE ERROR CAUSE

1 Short Circuit in Cell The cell may be short circuited.

Excess salt.

2 Open Cell

Electrical connection between controller and cell, broken.

Little salt in the water.

Disconnected cell.

4 Controller Overheating

Electronic controller is overheated.

Very hot environment.

Request a lot of power.

8Excessive Power

Requested

Need a lot of power in the cell.

Little salt in the water.

16 Problem With

Temperature Sensors

Problem with water temperature sensor.

Problem with CPU temperature sensor.

16

User’s Guide

Thermal protection

In order to protect and maintain product quality, the Sibrape Claripur Chlorine Generator monitors the water

temperature, so that, if the water reaches 64,4°F, the chlorine generation will change to 40% of its capacity and the

water reaches 57,2°F the generator will operate at 20% of its capacity.

It is important to note that this behavior can only be observed if the percentage programmed is higher than the

percentage of generation in thermal protection mode.

Operating in winter

Chlorine Generator can operate at temperatures up to 33,8°F. For this it modulates the power of the cell. Below

64,4°F it reduces the chlorine generation to 40%, and below 57,2°F it reduces it to 20% and maintains the chlorine

generation as long as there is enough water flow and enough salt.

This technology supports pools even on icy days.

Salt sensor

Sensor that assists in checking the status of the chlorine generation cell. He can assess whether the cell is in good

condition or not. Whenever a new chlorine generation cycle starts, the Salt Sensor checks the salinity of the water

and compares it with the cell, which can report problems in the cell.

Self cleaning

Every 5 hours of operation of the Chlorine Generator a self-cleaning procedure is performed. This procedure

ensures that the materials embedded in the generator blades are loosened, keeping the Chlorine Generator always

at maximum efficiency.

Ideal Chemical Conditions for Water

The following daily chemical conditions in pool water are recommended to help protect users, pool equipment and

any surfaces used in and around your pool.

These values are important for keeping pool equipment in proper operating condition, as well as preventing

corrosion, sludge or other problems. The Electronic Chlorine Generator is guaranteed to operate properly only if

these conditions are met.

Characteristics

Pool Water Chemistry, Conditions and Precautions

Pure chlorine: 2.0 - 4.0 ppm. Above 4.0 ppm can cause corrosion of metal components

Combined Chlorine

(Cloramines): None (superchlorination to remove all chloramines).

pH: 7.2 - 7.8 (USE MURIATIC ACID to lower the pH and Sodium Carbonate

to raise the pH).

Cyanuric Acid 30 - 50 ppm

Total Alkalinity: 80 - 120 ppm

Calcium Particles: 200 - 400 ppm

TDS (includes salt): 3000 min to 5700 to 6000 max ppm

Salt: 3000 - 4500 ppm (ideal 3500 ppm)

Metals (Copper, Iron,

Manganese): None

Nitrates: None

Phosphates: Less than 125 ppb

User’s Guide

17

Covered Pools

When using the Chlorine Generator in indoor pools and/or vinyl lines, less chlorine is required. It is recommended

to decrease chlorine production while the pool is covered.

What kind of salt to use

The purer the salt, the better the performance and duration of the Chlorine Generator. Use salt that is at least

99.8% pure NaCl, sodium chloride. The preferred and recommended salt is a granulated, evaporated, food grade,

non-iodized and additive-free salt. Consult your salt supplier.

How much salt to use?

Use Table 1 to determine how much salt you will need. Most pools contain salt, depending on the water source

and chemical used for cleaning. However, the pool owner should always test salt levels before adding salt. A hand

meter calibrated for NaCl (salt) can be used to determine salt levels in pool water. After turning on the CLARIPUR,

it will analyze the water through the salt sensor, and it will only start to produce chlorine, after the salt sensor

detects enough salt. If the amount of salt is low, the error LED will start flashing, informing the amount of salt is

low. This light indicates the salt status of the pool.

• 3500 ppm of salt is recommended to optimize water conditions.

• Low salt concentration below 2800 ppm will be indicated on the flashing error LED.

• High salt concentrations above 5000 ppm can cause excessive corrosion or deterioration of pool equipment and

any surfaces used in and around the pool.

Note: Salt measurements will vary between measurement devices (salt measuring strips, electronic testers, and

grinding). The salt sensor reading is accurate to +/- 500 ppm.

How to Add Salt to the Pool

1.Check the salt level in the pool before adding salt.

2.Determine the amount of salt from Table 1 below.

3.Slowly add salt to the outer perimeter of the pool for an even distribution. To prevent filter clogging or damage to

pool equipment and surrounding surfaces, do not add salt through the skimmer or tank.

4.Clean the bottom of the pool and allow the water to circulate for 24 hours to completely dissolve the salt.

5.After 24 hours, verify the correct salt reading through the Chlorine Generator indicators and with a separate

reliable test method.

6.Turn on the Chlorine Generator and set the appropriate cleaning output level to maintain free chlorine levels in

the pool water (between 2.0 - 4.0 ppm are recommended values).

Table 1 helps in calculating the amount of salt to add to the water. If the water has 0 salt or already has some

amount of salt present. The PPM line indicates the presence of salt in the water, and the amounts in KG are the

amount of salt to add to the water so that it reaches 3500PPM at the end. For example: If you have a 20,000 L

swimming pool and after taking the measurement you found that it already has 2000PPM of salt, just go to the

2000PPM column and go to the 20,000L line, that’s it, the amount of salt to be put in the pool is 30Kg .

Pool Water Chemistry, Conditions and Precautions

18

User’s Guide

Pool Water Chemistry, Conditions and Precautions

Table 1 - Volume of salt per amount of water

PPM > 0 250 500 750 1000 1250 1500 1750 2000 2250 2500 3000

Liters \/ salt needed in pound

12000 92,59 85,98 79,36 72,75 66,13 59,52 52,91 46,29 39,68 33,06 26,45 13,22

14000 108,02 101,41 92,59 85,98 77,16 70,54 61,72 55,11 46,29 39,68 30,86 15,43

16000 123,45 114,64 105,82 97,00 88,18 79,36 70,54 28 52,91 44,09 35,27 17,63

18000 138,89 130,07 119,05 110,23 99,20 90,38 79,36 70,54 59,52 50,70 39,68 19,84

20000 154,32 143,3 132,27 121,25 110,23 99,20 88,18 77,16 66,13 55,11 44,09 22,04

22000 169,75 158,73 145,50 134,48 121,25 110,23 97,00 85,98 72,75 61,72 48,50 24,25

24000 185,18 171,96 158,73 145,50 132,27 119,05 105,82 92,59 79,36 66,13 52,91 26,45

26000 200,62 187,39 171,96 158,73 143,3 130,07 114,64 101,41 85,98 72,75 57,32 28,66

28000 216,05 200,62 185,18 169,75 154,32 145,50 123,45 108,02 92,59 77,16 61,72 30,86

30000 231,48 216,05 198,41 182,98 165,34 149,91 132,27 116,84 99,20 83,77 66,13 33,06

35000 271,16 251,32 231,48 211,64 194,00 174,16 154,32 134,48 116,84 97,00 77,16 39,68

40000 308,64 286,60 264,55 242,50 220,46 198,41 176,37 154,32 132,27 110,23 88,18 44,09

45000 348,33 321,87 297,62 273,37 249,12 222,66 198,41 174,16 149,91 123,45 99,20 50,70

50000 385,80 359,35 330,69 304,23 275,57 249,12 220,46 194,00 165,34 138,89 110,23 55,11

55000 425,49 394,62 363,76 332,89 304,23 273,37 242,50 211,64 182,98 152,11 121,25 61,72

60000 462,97 429,90 396,83 363,76 330,69 297,62 264,55 231,48 198,41 165,34 132,27 66,13

65000 502,65 465,17 429,90 394,62 359,35 321,87 286,60 251,32 216,05 178,57 143,3 72,75

70000 540,13 502,65 462,97 425,49 385,80 348,33 308,64 271,16 231,48 194,00 154,32 77,16

75000 579,81 537,92 496,04 454,15 414,46 372,58 330,69 288,80 249,12 200,62 165,34 83,77

80000 617,29 573,20 529,10 485,01 440,92 396,83 352,74 308,64 264,55 220,46 176,37 88,18

85000 656,97 608,47 562,17 515,88 469,58 421,08 374,78 328,48 282,19 233,69 187,39 94,79

90000 694,45 645,95 595,24 546,74 496,04 447,53 396,83 348,33 297,62 249,12 198,41 99,20

95000 734,13 681,22 628,31 575,40 524,7 471,78 418,87 365,96 315,26 262,35 209,43 105,82

100000 771,61 716,50 661,38 606,27 551,15 496,04 440,92 385,80 330,69 275,57 220,46 110,23

User’s Guide

19

Cleaning the Blades with Acid

Unit of Measurement - Temperature

If the Chlorine Generator blades show a tendency to “scale”, it is recommended that every (2) two months the

Chlorine Generator blades are removed and inspected for scale formation and/or traces on the blades. Some filters

allow traces to pass through the Chlorine Generator, possibly settling between the Chlorine Generator blades. A

small amount of “scaling” is normal. If, when looking through the Chlorine Generator, it is observed that there is

excessive formation of “scales” between the blades or that there is the presence of traces, the Chlorine Generator

must be cleaned as follows:

BEFORE ANY MAINTENANCE, TURN OFF THE POWER TO THE EQUIPMENT AND DISCONNECT THE CELL CABLE

FROM THE CONTROLLER.

1. Use a water jet for cleaning. If the blades cannot reasonably be cleaned in this manner, acid cleaning will be

necessary.

2. To clean the blades with acid:

3. Disassemble the cell by opening the large nut and removing the blades from the body.

4. Mix (1) a quart of muriatic acid with 4 liters of tap water in a plastic bucket.

5. Soak the Chlorine Generator blades far enough to cover the entire blade. Be careful not to let the entire blade

holder submerge. Try not to splash acid out of the Bucket. If acid splashes out, rinse with water.

6. Wait until the solution starts to bubble to start cleaning. A foaming action will start, this is caused by scale

(calcium carbonate) being dissolved from the blades. If a rigorous foaming action does not start, the blades do not

need to be cleaned. Otherwise, leave the slides immersed in the solution until it stops foaming. However, do not

leave acid in the Chlorine Generator for more than 30 minutes. Excessive acid cleaning will damage the blades.

7. Remove the Chlorine Generator from the bucket and place it in an empty one. Rinse with clean water and check.

If deposits are still visible, repeat the acid cleaning process if necessary.

8. Rinse it again with clean water and check.

9. If the acid washing procedure is necessary, it is recommended to carry out the CALCIUM HARDNESS WATER test

on a sample of the pool water to be analyzed by a specialized professional or with specific pool kits available on the

market. The ideal range is 200 to 400 ppm).

10. Check the Chlorine Generator blades every two months and clean only if necessary.

11. Reassemble the cells in the body and reconnect the communication cable and then reconnect the electrical

power.

For any queries, please contact the Technical Assistance department.

The chlorine generator has a screen that allows the customer to select which temperature unit they are most used

to using between Celsius, Kelvin and Fahrenheit. Below is a brief step-by-step guide for changing the temperature

unit?

a.Press the “F” button for 3 seconds, the display should indicate “Cod” and the number “0” will flash. This indicates

that the screen is free to change;

b.Press the “/\” arrow until the number 12 appears and then the “T” button. “tmp” should appear on the display;

c.Press the “T” key again, the equipment will enable the edition of the temperature unit;

d.Use the “/\” and “\/” arrows to select between C, F, H (Celsius, Fahrenheit and Kelvin, respectively).

e.To save the selection, press “T” and then the “F” key, the display should indicate SAU.

20

User’s Guide

Company Data:

CORPORATE NAME - SIBRAPE IND. E COM. DE EQUIP. AQUA. E DE FILTRAGEM LTDA.

CNPJ - 29.596.862/0001-00

Address:

1150, Dr. Elpídio de Almeida Campos St. | Distrito Industrial Prefeito Luiz Roberto Jabali

Ribeirão Preto/SP | ZIP Code: 14072-105

Service and contact channels:

Tel. Brasil: +55 (16) 2101-7000

www.sibrape.com.br

Facebook.com/Sibrape

Instagram.com/Sibrape

Youtube.com/PiscinaSibrape

SIBRAPE customer service:

0800 727 3737

Technical Assistance

Contacts

Make sure that the dealer gives you the product manual and that you are aware of the conditions of installation, use

and maintenance of the equipment.

All reseller stores are trained and able to provide technical assistance.

Before requesting technical assistance from the retail store, make sure that all possibilities (problems / possible

causes / solutions) described on page 09 of your manual have been checked.

When asking for technical assistance, always have the sales invoice at hand.

Always demand original parts, remembering that the warranty for parts and labor for repairs carried out will be

90 days.

Manual and information subject to change without notice.

This manual suits for next models

1

Table of contents

Languages:

Popular Portable Generator manuals by other brands

Briggs & Stratton

Briggs & Stratton Elite 030208 owner's manual

Sole Diesel

Sole Diesel G-20T-15 instruction manual

Fischer Panda

Fischer Panda 22-4 HD PVMV-N manual

Craftsman

Craftsman 580.329100 owner's manual

Nidec

Nidec LEROY-SOMER LSA 52.2 MHV Installation and Maintenance

VOLTCRAFT

VOLTCRAFT FG-1302 user manual