SICK LSI 101 Parts list manual

TECHNICAL DESCRIPTION

Laser Scanner Interface

LSI 101

Certification

2 8 008 310

Technical Description

©SICK AG . Safety Systems .Germany .All rights reserved

3

SICK LSI Technical Description - 06/98

Table of Contents

1 Approvals and Certificates .................................................................. 4

2 Conditions of Use.................................................................................... 5

3 How the LSI Works ................................................................................. 6

4 Fields of Application - What the LSI Can Do................................ 7

Area protection ............................................................................. 7

Vehicle protection ........................................................................ 7

5 LSI System Planning .............................................................................. 8

5.1 General planning information ................................................ 8

Sensors: .......................................................................................... 8

Monitoring areas: ........................................................................ 8

5.2 Mobile protection: For on-board

vehicle use ..................................................................................... 9

6 Supply Package .....................................................................................10

7 Mounting the LSI ................................................................................... 11

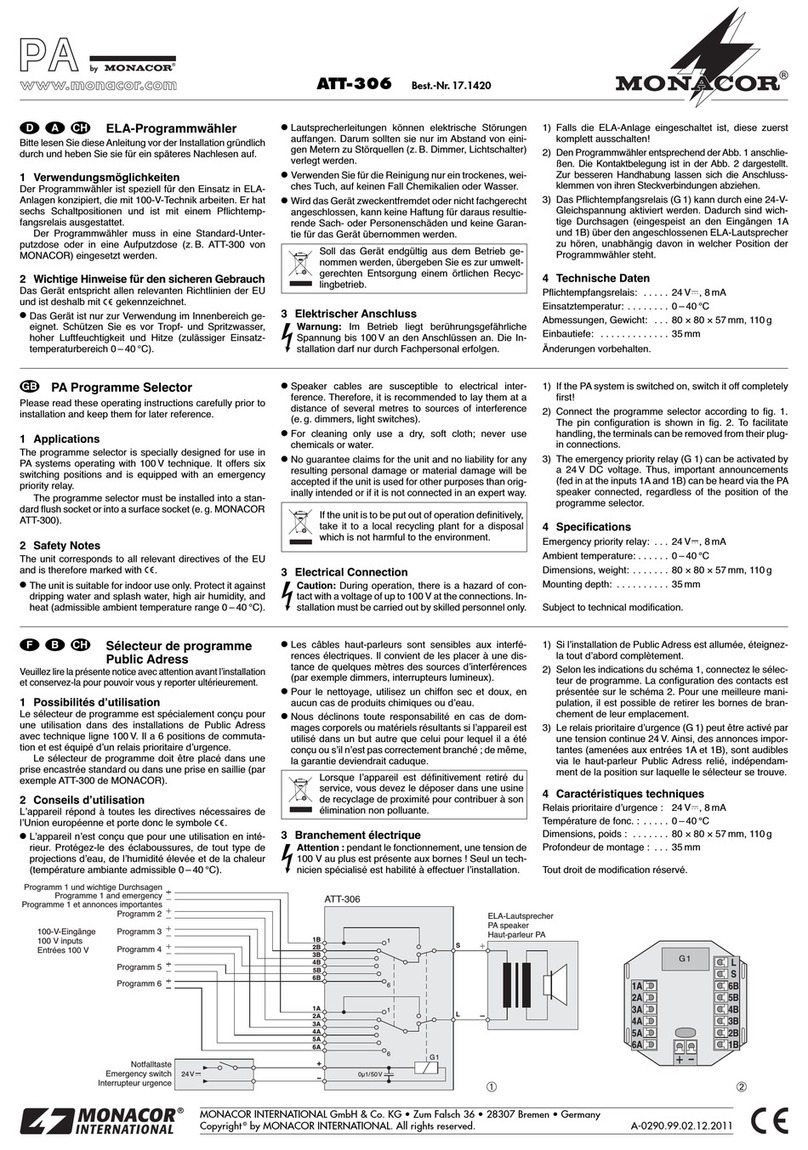

8 Connecting Up the LSI ........................................................................ 12

8.1 Wiring up the LSI and PLS .....................................................12

8.2 Connecting the LSI to the ..........................................................

controller and power ...............................................................13

8.3 Connecting the LSI to a PC...................................................16

9 Programming the LSI - User Software.......................................... 17

9.1 Installing the PLS/LSI user software ................................ 17

System requirements .............................................................. 17

9.2 What To Do .................................................................................. 18

Essential steps ........................................................................... 18

Other options ..............................................................................18

9.3 Entry: The initial configuration .............................................19

Configure hardware ................................................................. 20

Define monitoring areas ........................................................ 22

Define monitoring cases ....................................................... 23

Send configuration to LSI...................................................... 25

Edit monitoring area ................................................................ 26

Define rectangular field: ......................................................... 27

Define segmented field: ........................................................ 28

Send monitoring area to LSI ................................................ 29

9.4 Expand configuration ............................................................. 30

Log on additional sensors .................................................... 30

Define additional monitoring areas .................................... 31

Define additional monitoring cases ...................................31

Change inputs and outputs .................................................. 33

Change address........................................................................ 34

Change application variant ................................................... 34

Change restart behavior ........................................................ 35

Configure incremental sensors ........................................... 35

9.5 Edit/dimension fields ............................................................. 36

Convert fields ............................................................................. 36

Change scale of segmented field....................................... 37

9.6 Teach-in protective field ....................................................... 39

9.7 Adapt protective fields to speed........................................41

9.8 Simulate monitoring cases .................................................. 45

9.9 Monitor protective fields ....................................................... 46

9.10 Monitor inputs and outputs ..................................................47

9.11 Check settings .......................................................................... 48

9.12 Receive and store configuration ....................................... 49

9.13 Change password .................................................................... 50

9.14 Change screen view ................................................................51

9.15 Interrogate fault memory (system diagnosis) ............. 53

Initial fault diagnosis ................................................................ 53

Interrogate LSI fault memory ............................................... 53

Interrogate sensor fault memory ....................................... 54

Deconfigure sensor ................................................................. 55

10 Care and Maintenance ...................................................................... 56

10.1 LEDs on the LSI........................................................................ 56

10.2 LSI fault table .............................................................................. 57

10.3 SICK Service / Hotline ............................................................ 57

11 Appendix ................................................................................................... 61

11.1 Application examples .............................................................. 61

For area protection ...................................................................61

For vehicle protection ............................................................. 63

11.2 Startup testing and restart .................................................. 66

Performing startup testing .................................................... 66

Restart after intrusion into protective field ...................... 67

11.3 Technical data ........................................................................... 68

11.4 Accessories ................................................................................ 69

For mounting .............................................................................. 69

For connection to controller and PLS ............................... 69

Power supply units ................................................................... 69

User documentation................................................................ 69

11.5 Standards and regulations................................................... 69

11.6 Connection diagram ................................................................70

11.7 Dimensional drawing ............................................................... 71

12 Glossary ....................................................................................................72

This technical description contains all the information necessary

for project planning setting up the LSI. You will find in it the

information you need for mechanical mounting, electrical

installation and programming of the LSI.

The description covers the following LSI types:

LSI 101-11X (certified for personal protection to

IEC/EN 61496-1)

The last digit of the type designation (X: 2 to 4)

corresponds to the maximum number of sensors allowed

Also refer to the technical description of the PLS laser scanner,

which contains additional essential information on planning and

installing the LSI system

Along with this technical description you are also provided with

an instruction manual, containing important information for day-

to-day use of the LSI.

Keep the technical description and the instruction manual

readily to hand at all times.

Essential sections you should read:

Conditions of Use: ................................... Section 2

Supply package,

Mounting and connecting up the LSI:.... Sections 6 to 8

Entry into the user software ................ Sections 9.1 to 9.3

4SICK LSI Technical Description - 06/98

1 Approvals and Certificates

5

SICK LSI Technical Description - 06/98

2 Conditions of Use

The LSI is a device designed to protect people and property. It is

intended to monitor hazardous areas in enclosed spaces in

conjunction with one or more PLS laser scanners.

Observe the instructions relating to permitted use. SICK cannot

be held liable for damage arising from use of the LSI other than

stipulated.

•Be sure to follow the instructions given in the technical

description of the PLS laser scanner! It contains important

information on safe operation of the LSI system.

•Install the LSI in a dry location and protect the unit against

dirt and damage (IP 54 switch cabinet).

•Route all wires and connecting cables such that they are

protected against damage.

•Ensure that the connected controller and all other devices

also have the necessary safety integrity. Make sure that the

controller guarantees prompt switching between the

monitoring cases. Note that there may already be someone

in the protective field when the switch occurs. Safe

protection is guaranteed only by prompt switching (that is,

before the danger arises for the person at this point).

•Make sure that the input circuitry matches the expected

ambient conditions, in order to prevent interference and

resulting errors in monitoring case switching.

•Make sure that the response time of the LSI system is

adequate in every monitoring case to protect the hazardous

area (the response time of the LSI depends on the multiple

evaluation, and is pre-set in the PLS/LSI user software).

•Make sure that no obstacles in the monitoring area can

obstruct the fields of vision of the connected PLS units or

cause shadows.

Where there are unavoidable areas of shadow, check

whether they present any risk. Take precautions as

necessary.

•Keep the monitoring area free of smoke, fog, steam and

other air pollution. The functioning of the LSI system may

otherwise be impaired, and error shutdowns may occur.

•In mounting, installation and use of the LSI, observe the

standards and regulations applicable in your country. The

appendix presents a summary of the most important

regulations.

•For programming of the monitoring areas and monitoring

cases, take note of the description of the PLS/LSI user

software in section 9. This describes how to connect the LSI

to a PC and how to work with the user software.

•If you deploy the LSI for vehicle protection, note that it can

only be used on vehicles with an electric motor.

When using the LSI on materials handling equipment in

narrow aisles be sure to follow the instructions given in the

technical description of the relevant PLS.

If using the LSI with PLS type 101-316, note that the

response time of the LSI is not programmable, but is fixed at

270 ms.

•The LSI must be disposed of in a proper and environmentally

friendly manner at the end of its useful service life.

6SICK LSI Technical Description - 06/98

3 How the LSI Works

Principle of Operation

The SICK LSI (Laser Scanner Interface) is an electronic

component with which you can interconnect one or more PLS

laser scanners to form one system and control them flexibly

according to the specific application. The LSI system is thus able

to monitor complex hazardous areas on a machine or vehicle.

Sensors, monitoring areas and monitoring cases

The LSI receives from the machine controls system certain input

signals, e.g. input A = low, input B = high. These signals activate

in the LSI one of the monitoring cases you configure using the

PLS/LSI user software.

The definition of each individual monitoring case stipulates which

monitoring area (consisting of a protective field and warning

field) is to be monitored on which of the connected sensors.

The active sensor, e.g. sensor 1, transmits the space contour it

sees to the LSI. The LSI compares the data received from the

sensor with the contour of the defined monitoring area.

Evaluation of a monitoring case in the LSI (simplified block diagram)

As soon as the LSI detects an object in the monitoring area, it

switches off the output configured for that case. In the example,

there is an object in protective field 3 and the LSI shuts off the

defined output OSSD A. This output signal is transmitted to the

machine controls system where it triggers a response, e. g.

EMERGENCY STOP.

Based on the monitoring cases, the LSI system can react flexibly

to various input signals and view various monitoring areas on the

sensors, according to application requirements. Up to two

sensors can be active at any one time under the same input

conditions (simultaneous monitoring cases).

Sensor 3 Sensor 4Sensor 2

LSI

Input signals from

machine controls

system

(A = low, B = high)

Intrusion !

Shut-off signal to

machine controls system

e. g. EMERGENCY STOP

Defined

space contour

Object in area

Data

Sensor 1

Field 3

1

Inputs

A = low

B = high

Sensor

1

Field

3

Output

OSSD A

Monitoring case 2 active:

7

SICK LSI Technical Description - 06/98

PF1 PF2

WF2

WF1

active sensor inactive sensor

direction

PF1 PF2 PF3 PF4

PF1 PF2 PF3 PF4

Machining center with changing load positions

Driverless transport system with direction detector and speed-

sensitive protective field switchover

4 Fields of Application - What the LSI Can Do

These pages provide an overview of the key fields of application

of the LSI.

Area protection

On hazardous stationary machinery the LSI, in conjunction with

one or more PLS units, ensures that the machine (or its

hazardous movement) is shut down as soon as someone enters

the hazardous area. This is done by means of flexibly

programmable monitoring areas, each comprising a protective

field and a warning field, which are assigned to the connected

sensors for monitoring purposes. In the same way the LSI can

protect the interiors of large machines.

You can define various monitoring cases to match the active

protective fields to the situation on the machine and to monitor

different hazardous areas depending on the applicatio, such as

in different production phases.

Vehicle protection

You can deploy the LSI on vehicles, such as driverless transport

systems (DTS), forklifts and shunting cars, to safeguard a

vehicles path - on its way through a production hall for example.

The LSI with its connected sensors ensures that the vehicle

decelerates and stops if a person or obstacle is standing in the

way. You can protect both manually controlled vehicles and

driverless transport systems (DTS).

Several monitoring cases - defined by you - provide diverse

monitoring of various hazardous areas, such as when the vehicle

is moving forward and when reversing.

You can also record the speed of the vehicle by means of

incremental encoder, and so adapt monitoring areas of differing

sizes dynamically to the vehicle speed.

8SICK LSI Technical Description - 06/98

5 LSI System Planning

5.1 General planning information

Sensors:

You can connect up to four sensors to the LSI. All connected

sensors must be of the same type (e.g. four PLS 101-312).

These are currently types PLS 1XX-3XX, or any type for which

this is expressly permitted in the technical description.

Monitoring areas:

You can define up to eight monitoring areas. Each monitoring

area consists of a protective field and a warning field.

To define the size of the monitoring area, follow the instructions

given in the technical description of the PLS. It gives

dimensioned examples for static and dynamic applications.

For the PLS system with LSI, the minimum response time is 190

ms (except if you combine the LSI with PLS type 101-316 for

vehicle protection, in which case note that the response time of

the LSI is not programmable, but is fixed at 270 ms).

Monitoring cases:

To view the monitoring areas on the connected sensors, you can

set up to 15 monitoring cases.

At each time point a maximum of two monitoring cases may be

active at any one time (simultaneous monitoring cases).

Safety and signaling outputs:

The LSI has two independent safety output pairs OSSD (output

load per OSSD channel max. 250 mA ≤100nF; restart effective

from 0.2 to 5 seconds).

If necessary, you can perform contactor monitoring on any of the

safety outputs (EDM, permitted tolerance max. 200 ms).

The warning field and signalling output load is 100 mA.

Inputs:

The LSI has the following inputs:

Four binary inputs (A to D) with a maximum of 80 ms time

difference (antivalent)

Two incremental encoder inputs (inputs C and D)

Two restart inputs

Two EDM inputs (contactor monitoring)

9

SICK LSI Technical Description - 06/98

Speed

Safety supplement

Vehicle braking distance

Protective field depth

Distance

The braking distance of the vehicle plus the safety supplement

produces the required protective field depth

5.2 Mobile protection: For on-board

vehicle use

With the aid of incremental sensors, you can adapt the size of

the monitored area to the speed of the vehicle.

Note:

The two incremental encoders must be mounted such that one

continues to work safely and fault-free in the event of failure of

the other. In this, failure of the incremental encoders must be

prevented by design, mechanical and electrical means.

Also make sure that the systematic influences (such as

temperature, shaft breakage, slip) are not able to influence the

speed recording of both incremental encoders at the same time.

The incremental encoders must meet the following

requirements:

Type: two-channel rotary encoder with 90° phase offset

Supply voltage: 24 V DC

Outputs: push/pull

Protection IP54 or higher

Shielded cable

Max. pulse frequency: 100 kHz

Determine the number of pulses each incremental encoder

delivers per centimetre covered by your vehicle, running in a

straight line. You will need these figures to configure using the

PLS/LSI user software (see section 9.7 and the calculation

example in the appendix, section 11.1).

Calculating the protective field depth on the vehicle:

When calculating the required protective field depth on a vehicle

you must take into account that the braking distance increase is

not linear, but quadratic, as the speed increases (see diagram).

Note:

For precise information on the required protective field depth

and on the necessary safety supplements refer to the technical

description of the PLS.

•Define the required speed range for your application.

•Calculate the longest braking distance for each speed range

(i.e. the braking distance for the upper speed limit).

•Add to that distance the necessary safety supplements (see

technical description of PLS).

This will give you the required protective field depth for each

speed range.

•Configure the protective fields using the PLS/LSI user

software, as described in section 9.7.

10 SICK LSI Technical Description - 06/98

6 Supply Package

You receive:

the LSI

a connection set as per order (see below)

(e.g. connection set A: one PLS supply plug, one PLS

interface plug, one screw-in interface connector for

connection of the PLS to the LSI)

a top-hat rail fixture (mounted)

2 brackets for wall mounting

instruction manual

technical description

Note:

The LSI is not supplied with user software.

The PLS/LSI user software as from version 03.20 is used to

program a single PLS or a LSI system. It is supplied with the PLS

(on a 3.5 floppy disk).

Available connection sets:

Connection set A

1 PLS supply plug

1 PLS interface plug

1 screw-in interface connector

for sensor connection to LSI

excluding cable 2 019 065

Connection set B

As connection set A, with 3 m cable 2 019 066

Connection set C

As connection set A, with 5 m cable 2 019 067

Connection set D

As connection set A, with 10 m cable 2 019 068

Connection set E

As connection set A, with 15 m cable 2 019 069

Connection set F

As connection set A, with 20 m cable 2 019 070

11

SICK LSI Technical Description - 06/98

7 Mounting the LSI

The LSI is shipped fitted with a top-hat rail fixture. A wall

mounting bracket is also supplied.

If you secure the LSI by the wall bracket, vibration problems can

be avoided.

Mounting the LSI on a top-hat rail:

•Mount the LSI as shown in the diagram, with a TS 35 top-hat

rail.

Mounting the LSI on a wall:

•Unscrew the top-hat rail fixture.

•Attach the supplied wall bracket to the LSI as shown in the

diagram.

•Mount the LSI on the wall using M6 screws.

108

86

13

min. 75 min. 75

Mounting the LSI with a top-hat rail (All dimensions in mm)

216

7

226

Mounting the LSI on a wall (all dimensions in mm)

12 SICK LSI Technical Description - 06/98

8 Connecting Up the LSI

8.1 Wiring up the LSI and PLS

Notes:

Also refer to the connection diagram in the appendix. For the

requirements to be met by the cables used, refer to section 4.3

of the instruction manual, under Cable requirements.

•Connect the LSI Power Out + and Power Out - terminals

to the power terminals on the PLS.

Use 4-pin socket connector strips.

•Connect the LSI communication terminals (e.g. Sensor 1)

to the PLS interface.

•Connect the LSI-termination shielding to the strain relief. The

PLS-termination shielding is not contacted. Follow the pin

assignment.

Connecting PLS to LSI

Pin assignment of the interface connector in RS422 mode

LSI

RXD–

RXD+

TXD+

TXD–

Enclosure

NC

NC

NC

NC

NC

1

2

3

4

5

6

7

8

9

Pin no.

Sensor

RXD–

RXD+

TXD+

TXD–

NC

NC

jumpered

NC

NC

1

2

3

4

5

6

7

8

9

Pin no.

LSI-termination shield

connected to strain relief (enclosure)

4321

SENSORSENSORSENSORSENSOR

Sub-D

plug

PLS To LSI

LSI To PLS

1

9

1

9

shielding open

Connect shielding

to strain relief

13

SICK LSI Technical Description - 06/98

8.2 Connecting the LSI to the

controller and power

Notes:

Lay all wires and connecting cables such that they are protected

against damage.

If you are using the PLS to protect hazardous areas: make sure

that the connected controller and all other devices also have the

necessary safety integrity.

Perform a function check of the connected input controller if you

have not executed a monitoring case switchover for a lengthy

period of time. For this check you have the following options:

Specific intrusion in the active protective field after

monitoring case switchover

(look out also for simultaneous monitoring cases!)

Monitoring by means of the I/O monitor (see section 9.10).

Also refer to the connection diagram in the appendix.

Label the connectors to avoid incorrect connection.

Connecting LSI inputs:

•Connect the inputs (A, B, C, D) of the LSI to the controller, as

shown in the connection sketch. Use 4-pin socket connector

strips (the WAGO connector supplied is an aid to wiring).

Notes:

Each input requires two signals, which must always be

inverse to each other (maximum permissible tolerance:

80 ms).

If using incremental encoders, inputs C and D are occupied

and unavailable for use.

Connecting LSI outputs:

•Connect the outputs to the controller, as shown in the

connection sketch.

Use 4-pin socket connector strips.

Notes:

Note that in safety-related controllers for K1 to K4 you must

use relays or (auxiliary) contactors with positively-driven

contacts, taking account of appropriate protective measures

(circuitry).

Connecting LSI inputs and outputs

INPUT

A

A2A1 B1

B2

WZ A

ERROR

OSSD A1

OSSD A2

RES A

EDM A

EDM B

RES B

WZ B

OSSD B1

OSSD B2

INPUT

C2C1 D1 D2

AB

B

24 V DC

K5K6K1K2K7K3K4

14 SICK LSI Technical Description - 06/98

Connecting LSI to power supply:

•Connect the LSI supply via a suitably rated fuse to the power

supply, e.g. a 24 V DC power supply unit (transformer,

regulated with safe isolation to EN 60742, see technical data

in appendix).

Use 3-pin socket connector strips.

Connecting restart buttons as required:

•Connect the restart buttons (normally open) to inputs

RES A and RES B.

Use 4-pin socket connector strips.

Notes:

Outside the switch cabinet Restart A and Restart B must be

routed in separate cables.

When fitting the restart button, note that the button must be

mounted such that, when the button is pressed, the hazardous

area is fully visible.

Connecting a contactor monitor as required:

•Connect the break contacts of the contactors to inputs

EDM A and EDM B, as shown in the diagram (K1 to K4

are contacts of the elements directly controlling hazardous

movement).

Use 4-pin socket connector strips.

Note:

Contactor monitoring is activated 200 ms after a switchover.

In the static state the outputs are tested cyclically every

5 seconds.

optic

electronic

++

__

+

_

+

_

+

_

_

24 V DC

POWER OUTPOWER OUT

LSI

POWER IN

Power

supply

Sensors

Si

Connecting LSI to power supply

Connecting restart buttons

INPUT

A2A1 B1 B2

RES A

EDM A

EDM B

RES B

WZ B

OSSD B1

OSSD B2

INPUT

C2C1 D1 D2

AB

B

24 V DC

INPUT

A

A2A1 B1

B2

WZ A

ERROR

OSSD A1

OSSD A2

RES A

EDM A

EDM B

RES B

WZ B

OSSD B1

OSSD B2

AB

B

24 V DC

K1

K2

K1K2

K3

K4

K3K4

Connecting a contactor monitor

15

SICK LSI Technical Description - 06/98

Connecting incremental encoders as required:

•Connect two incremental encoders to inputs Speed Input C

and Speed Input D.

Use 9-pin metallized sub-D plugs.

Notes:

If using incremental encoders, inputs C and D are occupied and

unavailable for you to use.

The incremental encoders must meet the following

requirements:

Type: two-channel rotary encoder with 90° phase offset

Supply voltage: 24 V DC

Outputs: push/pull

Protection IP54

Shielded cables

Max. pulse frequency 100 kHz

Make sure each incremental encoder delivers at least 50 pulses

per centimeter covered by your vehicle (for configuration of the

incremental sensors see section 9.7 and the calculation

example in the appendix).

•Connect the shielding to the strain relief, as shown in the

diagram. Follow the pin assignment.

Note:

You will find various examples of connection and configuration

options for the LSI in section 11.1.

Connecting incremental encoders

Pin assignment

1 +24V DC

2 +24V DC

3 GND

4 GND

5 n.c.

6 IN 0°

7 IN 90°

8 GND

9 n.c.

LSI To incremental encoders

1

9

Connect shielding

to strain relief

Shielding and pin assignment

SPEED INPUT

INPUT

OR

C2C1 D1 D2 C D

SPEED INPUT

Must remain

open !

Incremental encoders

16 SICK LSI Technical Description - 06/98

c

i

t

p

o

c

i

n

o

r

t

c

e

l

e

PLS

LSI

PC

Connecting LSI to a PC

Pin assignment of the interface connector in RS422 mode

NC

NC

PC

RXD–

RXD+

TXD+

TXD–

NC

NC

NC

NC

1

2

3

4

5

6

7

8

9

Pin no. 1

2

3

4

5

6

7

8

9

Pin no.

LSI-termination shield

connected to strain relief (enclosure)

LSI

RXD–

RXD+

TXD+

TXD–

Enclosure

NC

NC

jumpered

NC

8.3 Connecting the LSI to a PC

To configure your LSI system or change settings, you must

temporarily connect the PC to the LSI. For this, the LSI is fitted

with a switchable interface which permits you to connect the PC

and LSI quickly and easily.

•Connect the LSI RS 232 interface (COM port) to a free

serial port on the PC. Use a RS 232/RS 422 interface cable

(see appendix, Accessories).

You can now configure your LSI system.

Notes:

The LSI RS 232 interface is set up for connection to a PC. If

required, you can reprogram it as a RS 422 interface by

jumpering pins 7 and 8. The RS422 LED on the LSI then lights

up to indicate the fact.

The pin assignment of a RS 422 interface is not standardized.

Compare the pin assignment of the connecting cable with the

one on the PC (see diagram) and adapt it accordingly.

17

SICK LSI Technical Description - 06/98

9 Programming the LSI - User Software

9.1 Installing the PLS/LSI user

software

Note:

The PLS/LSI user software as from version 03.20 can be used

to program a single PLS or a LSI system. If you have already

installed the user software for a PLS application on your PC you

do not need to install new software. You can begin programming

immediately.

If you have older PLS/LSI user software installed on your PC

which you want to continue using, specify a different program

directory/folder when installing the new PLS/LSI software.

System requirements

min. 80486 processor

min.4MBRAM

min. 4 MB available hard disk capacity

MS-Windows(version 3.11 or higher) or Windows 95

Color monitor recommended (not monochrome monitor)

When installing your PLS/LSI user software you are guided by

the installation program. You only need to start the installation

program:

•Boot your PC.

•Insert the PLS/LSI program disk in your PCs floppy drive.

•Under MS-Windows:

Choose File-Run from the File Manager.

Under Windows 95:

Choose Run from the Start menu.

•Select and run Install.exe.

•As necessary, enter the program directory/folder where you

want the new PLS/LSI user software to be installed.

•Follow the on-screen instructions.

When the installation is finished a message box appears telling

you that the setup has been completed successfully.

The PLS/LSI user software is now installed. You can run it any

time by clicking on its icon.

18 SICK LSI Technical Description - 06/98

9.2 What To Do

Notes:

When the program starts you are automatically logged on as the

machine operator. As such, you can poll data but cannot

transmit any.

To be able to transmit configuration data and monitoring areas

to the LSI, you must log on as an Authorized Client. How to log

on is described in section 9.3.

Make sure that the LSI and all PLS units are correctly connected

as described in section 8.

On the status bar at the bottom of the screen there is a color

key for on-screen indication of protective fields and warning

fields.

Essential steps

In creating a new configuration you are guided by the PLS/LSI

user software. It guides you automatically through the following

steps:

•Configure hardware:

You log the sensors on and define whether you are using the

LSI for area protection or for protection on a vehicle. You

also define the inputs and outputs as well as the restart

behavior of the outputs.

•Define monitoring area:

You define the areas to be monitored by the LSI. If you wish,

you can also determine the shape and size of the protective

fields and warning fields here.

You can define up to eight monitoring areas.

•Define monitoring cases:

For each monitoring case (max. 15) you link a sensor to a

monitoring area and define the input conditions under which

the monitoring case is activated. Here you also determine

which output is to be switched in the event of intrusion into

the protective field.

You can also define a specific order of switching between

the monitoring cases.

•Send configuration to LSI:

You now transmit all the configuration settings you have

made to the LSI. You must be logged on as an Authorized

Client to be able to do this.

•Edit monitoring areas:

Here, if you wish, you have the chance to alter the shape and

size of the protective fields and warning fields.

•Send monitoring areas to LSI:

Finally you transmit the protective fields and warning fields to

the LSI. For this too, you must be logged on as an

Authorized Client.

When you have completed these steps the LSI system is ready

for operation.

Note:

Change the logon password, to protect your LSI system against

manipulation (see section 9.13).

Log the configuration data stored in the LSI, and back up the

configuration on the hard disk or on a floppy (see section 9.12).

Other options

In addition to the essential steps, you can use a number of other

options when configuring your LSI system.

Edit fields:

To edit the protective and warnings fields the PLS/LSI user

software provides you with a number of useful edit functions.

Teach-in and check protective field:

In the teach-in process the active sensor runs over the

space contour and the LSI generates a protective field on

that basis. You can influence the extent of the protective

field by running a target board over it, for example. You have

to check learned protective fields.

You can also edit a learned protective field subsequently, just

like any other segmented field (function not available for use

of LSI with PLS 101-316).

Adapt protective fields to speed:

When using the LSI on a vehicle, you can switch between

protective fields of different shapes and sizes depending on

the speed of the vehicle. In this way you can adapt the

monitoring area flexibly to the environment and speed of the

vehicle. You need to connect incremental sensors to the LSI

for this.

Simulate monitoring cases:

You can check the settings of the monitoring cases by

simulating the input conditions on PC. In this way you can

check whether sensors and fields are correctly assigned in

every monitoring case.

Monitor protective fields:

You can monitor the protective fields and warning fields in

operation using a connected PC. You can also store the

defined space contours of the sensors as a check.

Monitor inputs and outputs:

You can monitor and log the switching states of the LSI

inputs and outputs with the I/O monitor. You can save the

data obtained to an ASCII file for subsequent evaluation.

Check settings:

You can view, check and print all configuration settings in a

page view.

Receive and store configuration:

You can receive and print the configuration data stored in the

LSI. You can save any configuration to the hard disk or to a

floppy.

Change password:

To protect your LSI against manipulation, you should change

the logon password.

Change screen view:

You can zoom, unzoom or move the screen view, for

example.

Interrogate fault memory (system diagnosis):

For troubleshooting purposes you can interrogate the fault

memory of the LSI and the connected sensors.

19

SICK LSI Technical Description - 06/98

9.3 Entry: The initial configuration

The LSI is shipped with certain pre-configured settings. This

section describes how you can adapt those settings to your

application.

•Switch on your LSI system (it takes a few seconds to start

up).

•Start the user software.

The following dialog box appears:

•Click on Yes.

The PC receives the pre-configured settings and displays them

on-screen.

This dialog box appears.

To be able later to send the configuration and monitoring areas

to the LSI, you must log on as an Authorized Client.

•Choose Authorized Client from the category list.

•Enter the password SICK_PLS and click on Logon.

You are now logged on as an Authorized Client (see status bar

at bottom of screen).

Note:

Always log off when leaving your workstation! This will prevent

unauthorized persons from manipulating your LSI system.

20 SICK LSI Technical Description - 06/98

Configure hardware

You can edit the received configuration or create a new

configuration.

To create a new configuration:

•From the menu choose File - New and click on

LSI Configuration.

•Click on OK.

This dialog box appears. This is where you set the sensor type

you want to work with.

•Select your sensor type or have the sensor detected

automatically by clicking on Detect.

•Click on Continue.

The further steps and dialog boxes are the same as those

described below for Edit Configuration.

To edit the received configuration:

•From the menu choose LSI - Configuration - Edit.

•Or choose the Edit Configuration button from the toolbar.

This dialog box appears. This is where you set the address under

which the LSI and the sensors are to be addressed.

•Select whether you want to use a universal or single

address.

Universal address (zero):

This is the recommended setting. If you set Universal

address, the stored configuration can be transferred at a

later time to any other LSI.

Single address (between 5 and 126):

If you set Single address you assign the LSI the address

specified here for transferring the configuration. It is then

only possible to reload a configuration at a later time if the

address specified here and the one stored in the LSI match.

This makes sense when you want to ensure that a

configuration saved as a file can only be transmitted to

specific LSI units.

•Click on Continue.

This dialog box appears. This is where you set field of application

of your LSI system.

•Select whether you want to use the LSI for area protection or

vehicle protection (e.g. DTS - Driverless Transport Systems).

•Select the evaluation you want to use.

Standard:

Standard evaluation.

Pixel suppression:

With this setting objects detected by just one pixel per scan

are ignored. This can be useful in preventing error

shutdowns.

•Click on Continue.

Table of contents

Other SICK Recording Equipment manuals