Installation and Programming Manual ii

Contents

Chapter 1: Theory of Operation 1

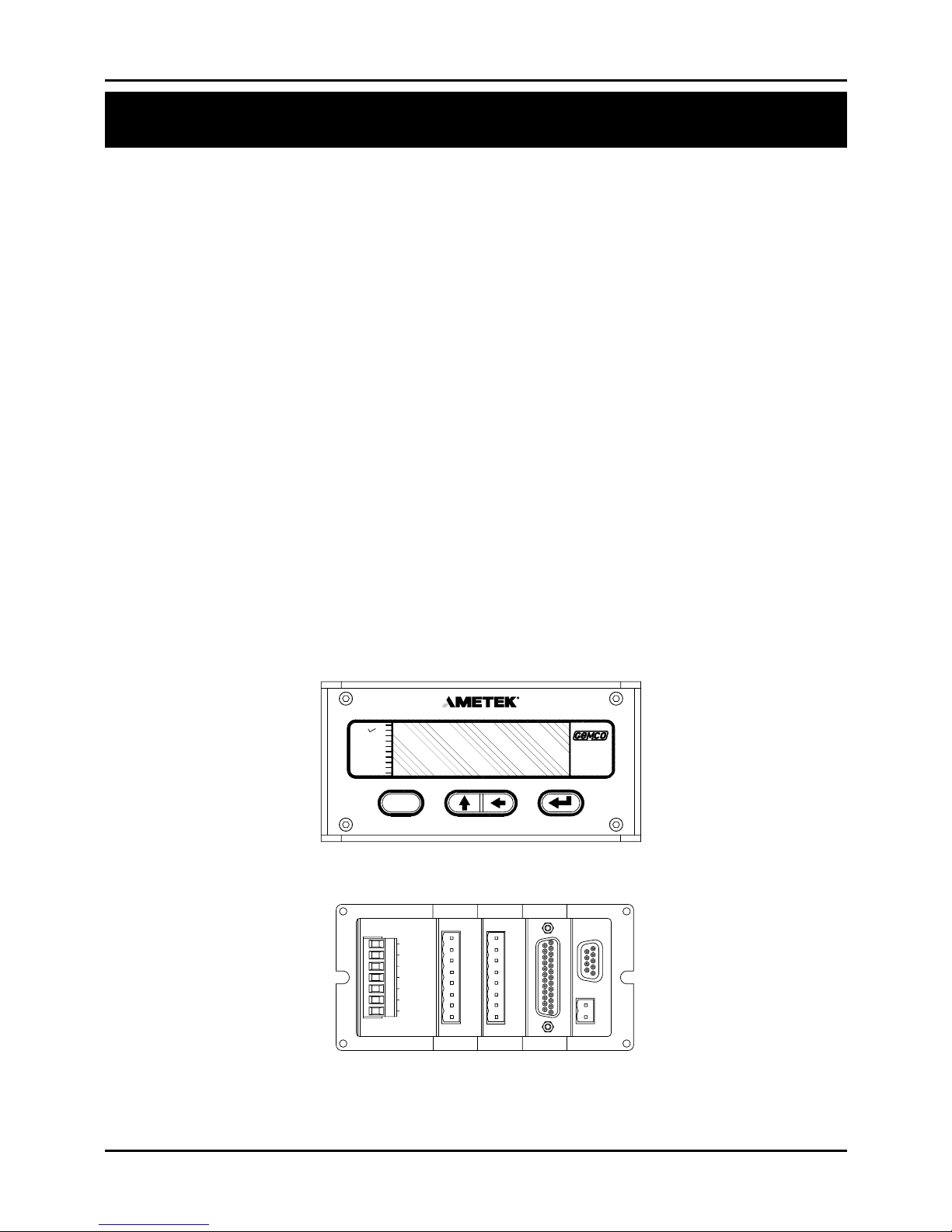

Chapter 2: Hardware Overview 2

2.1 tandard Modules ..................................................................................................................... 3

Controller (FMMP01) ......................................................................................................... 3

Power upply (FMP 01) .................................................................................................... 3

2.2 Input/Output Module ............................................................................................................... 3

Resolver (FMIR01) ............................................................................................................. 3

Variable Pulse (FMIP01)..................................................................................................... 4

LDT Input (FMIP020) ........................................................................................................ 4

Digital Output (FMOD01) .................................................................................................. 4

Analog Output (FMOA01).................................................................................................. 4

Relay Output (FMOR01) .................................................................................................... 5

2.3 tatus LEDs Defi ned ................................................................................................................ 5

Chapter 3: Mounting and Wiring 7

Things to Consider ..............................................................................................................7

3.1 Mounting ................................................................................................................................. 7

Interface Module ................................................................................................................. 7

Cabling ................................................................................................................................ 8

3.2 Wiring ..................................................................................................................................... 10

Controller Module (FMMP01).......................................................................................... 10

Relay Output Module (FMOR01)..................................................................................... 10

Power upply Module (FMP 01)..................................................................................... 11

Resolver Module (FMIR01).............................................................................................. 12

Variable Pulse LDT Module (FMIP01)............................................................................. 12

LDT Input (FMIP02) ........................................................................................................ 13

Digital Output (FMOD01) ................................................................................................ 13

Analog Output (FMOA01)................................................................................................ 14

Chapter 4: Programming 21

Before You tart ................................................................................................................21

Programming Keys Defi ned .............................................................................................. 22

4.1 Resolver Input Confi guration Functions................................................................................. 23

cale Factor (300) ............................................................................................................. 23

Turns Counting (301) ........................................................................................................ 23

Turns Counting Wrap Around (308) ................................................................................. 24

Position Offset (302) ......................................................................................................... 24

Programming cale Factor (300) ...................................................................................... 24

Display Power-Up (305) ................................................................................................... 26

Resolver Reset-to-Preset (307) ......................................................................................... 26

Spec Tech Industrial Electric

Spec Tech Industrial Electric