Sidamo TM 200 B User manual

User’s manual TM200B

ORIGINAL USER’S MANUAL

TM 200 B

BENCH GRINDER-WIRE WHEEL

User’s manual TM200B

2

CONTENTS

1.

INTRODUCTION ............................................................................................................................................................................................................ 3

2.

WARNING SIGNS ........................................................................................................................................................................................................ 3

2.1.

WARNING SIGNS RELATED TO T E SAFETY OF T E MAC INE ............................................................................................................. 3

2.2.

WARNING SIGNS USED IN T IS MANUAL....................................................................................................................................................... 3

3.

SAFETY INSTRUCTIONS ............................................................................................................................................................................................ 4

3.1.

GENERAL SAFETY INSTRUCTIONS....................................................................................................................................................................... 4

3.2.

PARTICULAR SAFETY INSTRUCTION .................................................................................................................................................................. 5

3.3.

PROTECTION OF T E OPERATOR ......................................................................................................................................................................... 5

4.

DESCRIPTION AND OPERATING ............................................................................................................................................................................. 6

4.1.

PURPOSE OF T E MAC INE .................................................................................................................................................................................. 6

4.2.

SPECIFICATIONS .......................................................................................................................................................................................................... 6

4.3.

MAC INE OVERVIEW ................................................................................................................................................................................................ 6

5.

INSTALLATION .............................................................................................................................................................................................................. 7

5.1.

PACKING ..................................................................................................................................................................................................... 7

5.2.

TRANSPORT AND ANDLING ........................................................................................................................................................... 7

5.3.

INSTALLING T E MAC INE................................................................................................................................................................. 7

5.4.

ELECTRICAL CONNECTION .................................................................................................................................................................. 8

5.5.

DRY TEST AND INITIAL INSPECTION PRIOR TO USING T E EQUIPMENT FOR T E FIRST TIME ............................ 8

6.

OPERATING T E GRINDER ....................................................................................................................................................................................... 9

6.1.

ASSEMBLYING .......................................................................................................................................................................................... 9

6.2.

GRINDING/BRUS ING PROCEDURE ........................................................................................................................................... 10

7.

MAINTENANCE ......................................................................................................................................................................................................... 11

7.1.

ADJUSTMENTS ..................................................................................................................................................................................... 11

7.2.

PROTECTIVE S IELD ........................................................................................................................................................................... 11

7.3.

CLEANING ................................................................................................................................................................................................ 11

7.4.

LUBRICATING ......................................................................................................................................................................................... 11

7.5.

REPLACING T E W EEL ................................................................................................................................................................... 12

7.6.

REPLACING T E WIRE W EEL ...................................................................................................................................................... 13

8.

ACCESSORIES AND CONSUMABLE PARTS ..................................................................................................................................................... 14

8.1.

BASE S2 ....................................................................................................................................................................................................................... 14

8.2.

BASE S2ASP .............................................................................................................................................................................................................. 14

8.3.

DRILL S ARPENER .................................................................................................................................................................................................. 14

8.4.

W EELS AND WIRE W EELS ............................................................................................................................................................................ 15

9.

SPARE PARTS ........................................................................................................................................................................................................... 16

10.

ELECTRICAL CIRCUIT ............................................................................................................................................................................................. 18

11.

NOISE LEVEL ............................................................................................................................................................................................................. 19

12.

VIBRATIONS LEVEL ................................................................................................................................................................................................. 19

13.

PROTECTION OF T E ENVIRONMENT .............................................................................................................................................................. 19

14.

GUARANTEE ............................................................................................................................................................................................................. 19

15.

DECLARATION OF CONFORMITY ....................................................................................................................................................................... 20

User’s manual TM200B

3

1. INTRODUCTION

For safety reasons, please carefully read these instructions, prior to using this machine.

Serious injuries to persons or damages to the machine may be caused by the non-observance of these instructions.

This manual is intended to be used by operators, setters

and service engineers.

This manual is an important part of your equipment. It

provides rules and guidance to help you safely operating this

machine. You must read this manual and make sure of the

correct procedures and functions before operating the

machine. For your own safety, you must read these

precautions carefully and follow the instructions described

below.

These instructions must be followed anytime when

operating and servicing the machine. Serious injury and/or

failure of the machine may occur if operators fail in

observing safety guidance and instructions and operate the

machine in a wrong and different way from the one

described in this manual.

Please keep the manual with the machine or in a safe place

to make it available anytime. Make sure any person involved

in operating this machine can consult this manual. In case

this manual is damaged or lost, please contact us or your

dealer to be provided with a new manual.

Always use genuine SIDAMO parts and components.

Replacing SIDAMO parts and components by improper

parts may damage the machine and cause serious injuries

to operators.

This manual describes the safety instructions to be applied

by the operator. Both the employer and operators are

responsible, according to the article L.4122-1 of Labour

Laws, to take care of their health and safety and of the

health and safety of any other person involved by any action

or omission related to instructions given to them.

The employer is in charge of performing the assessment of

all particular risks related to the activity of his/her company.

e/she must train workers to operating the machine and

to the prevention of risks and provide with appropriate

information and instructions all workers in charge of

operating or servicing working equipments.

2. WARNING SIGNS

2.1. WARNING SIGNS RELATED TO T E SAFETY OF T E MAC INE

Meaning of the safety signs attached to the machine (they must remain clean and replace them immediately in case they are

peeled off or illegible) :

Always wear protective goggles

Always wear ear protection

Carefully read the User’s Manual

Do not wear loose clothes, loose sleeves, jewels,

bracelets, watches, rings, …

Wear protective hair covering to protect long hair.

Always wear protective gloves

Always wear safety shoes

Always wear a breathing apparatus

2.2. WARNING SIGNS USED IN T IS MANUAL

Straight hazard for human persons and the

machine

The machine and its vicinity may be damaged

Note

Technical ability level : operator, user

Technical ability level : setter, service

Wear protective gloves to perform tool changing

and cleaning

Technical ability level : maintenance agent

Only low voltage qualified and authorized workers should be allowed to perform interventions on the

electrical circuit.

User’s manual TM200B

4

3. SAFETY INSTRUCTIONS

3.1. GENERAL SAFETY INSTRUCTIONS

Always follow the basic safety instructions to reduce risks of fire, electric shock, mechanical crash and injury for any

person using power tools.

This manual considers only reasonably predictable

behaviours.

Our machines are designed keeping first in mind the safety

of operators.

We accept no responsibility for any damage cause by the

lack of experience, any improper use of the machine and/or

the machine being damaged and/or instructions provided

by this manual not being followed.

Accidents always happen following an improper use or

because the User’s Manual was not read and understood.

We remind you that in case changes are performed on the

machine, we will be freed from our obligations.

Before starting operating the machine, always check that

guards are in place and in working condition.

Make sure moving parts run correctly, that no element is

damaged and that the machine runs correctly when it is

commissioned.

Only authorized and qualified workers should be allowed to

repair or replace faulty parts.

Keep the vicinity of the machine tidy. Put everything in order.

Make sure the operator can see the entire working area

from the working station.

Untidy working areas and benches are hazardous and can

cause serious injuries.

Never use the machine outdoor ; never expose it to rain and

damp, or to an atmosphere containing flammable fluids.

Provide good lighting conditions to the machine.

No worker under the age of eighteen is allowed to operate

the machine.

Keep children, animals and unauthorized persons away from

the working area. They are not allowed to touch either tools

or electric cables.

Never leave a running machine unattended. Always switch

the machine off. Never leave the machine until it comes to a

full stop.

Never force a tool. It will do the job better and be

safer if it used at the rate it was designed for.

Do not force small tools perform a machining that should be

done by a larger tool.

Use the right tool and do not use tools for a job they were

not designed for.

Never damage electric cables.

Never pull the power cable to unplug the machine.

Keep the main power cable away from heat sources, greasy

parts and/or sharp edges.

Never use the power cable in wet conditions and protect it

from any damage.

Regularly check the condition of the power cable. In case it

is damaged, have it repaired by an authorized repairer.

Faulty switches should be replaced by an authorized

company.

Never try to run the machine in case the main switch is out

of work.

Do not overestimate your strength.

Do not overreach. Never lose balance.

Always be aware. Use common sense and do not run the

machine when you are tired.

Always use both hands to run the machine.

Use only recommended accessories. Using accessories

different from the ones recommended in this manual may

be hazardous.

The user is responsible for the machine and must make

sure that :

The bench grinder is used only by qualified,

authorized and trained workers.

Safety instructions are followed.

Users have read and understood the safety

instructions.

Users have read and understood the User’s

Manual.

Responsibilities for servicing and possibly repairing

have been correctly assigned and followed.

Failures and faults have immediately been

communicated to an authorized repairer or to your

dealer.

The bench grinder is used for applications

described in this manual.

Do not use the machine for any application other

than that it was designed for. Any other use is

hazardous.

Never remove or bypass mechanical and/or

electrical protections.

Never try to modify or retrofit the machine.

SIDAMO accepts no responsibility for any damage caused to

persons, animals or objects, and resulting from the non-

observance of the safety instructions described in this

manual.

User’s manual TM200B

5

3.2. PARTICULAR SAFETY INSTRUCTION

Protective devices were designed to protect the operator, as far as possible, when machining a material hazardous for

health or in case dusts are produced. In these cases, always use a dust collection system (optional S2ASP).

This bench grinder was not designed to machine materials producing flammable or explosive dusts, e.g. aluminium,

magnesium and their alloys.

Prior to starting grinding, please wait until the wheels have

reached their maximum speed.

Adjust the protective shield and the spark screen to protect

the operator from spark emissions.

Always wear compulsory convenient PPEs.

Always hold the part to grind, using both hands.

Never hit the wheel or the wire wheel with the part to grind.

Instead, apply a progressive force.

Regularly cool down the part to grind, using a water tank.

Never attempt to touch rotating wheels.

Always wait until all evidence of rotation has ceased, prior to

starting any intervention on the grinder.

Prior to any servicing or maintenance, always switch off and

unplug the grinder.

When continuously operating the grinder, do not touch the

surface of the grinder, as there is a risk of burn.

Never use additional accessories to perform tasks they

were not designed for.

Using improper tools is hazardous.

Never install a wire wheel instead of a wheel, and vice versa.

Never use damaged wheels and wire wheel.

Prior to installing a new wheel, check its condition (See

section 7.5 « Replacing a wheel »).

Always use only wheels and wire wheel s recommended by

SIDAMO. The speed indicated on the wheels must be higher

or equal to the speed indicated on the tool plate.

The wheels and the wire wheel should be always perfectly

clean.

Never attempt to clean rotating wheels and wire wheel.

When cleaning, always using protective goggles and gloves.

Use a brush and a clean and dry cloth.

Never immerse the grinder into water. Never wash it using

water under pressure as water can get into electric parts.

Never use solvent or aggressive detergents.

Store the grinder in a cool place, out of the reach of

children.

azards :

Mechanical hazards :

Risk of being entangled when the operator

performs manual machining close to the wheel or

the wire wheel.

Risk of being caught when the operator performs

manual machining between the wheel and other

parts of the grinder, especially when he gets close

to the work piece-holder of between the wheel and

the work piece.

Risk of friction or abrasion when the operator

unintentionally touches the rotating wheel or wire

wheel.

Materials and products :

Risk of breathing poisonous dusts produced by the

wheel or the wire wheel for operators or other

persons authorized to stand by the grinder when

machining or brushing.

The machine falls or rolls over :

Risk of injury for the operator in case the grinder or

the base is not correctly fixed.

3.3. PROTECTION OF T E OPERATOR

To ensure operator’s safety, make sure that the protective shield and the wheel and wire wheel guards are in place and

in good condition. Make sure that non-working parts are protected by a guard.

This machine was designed to be operated by only one

operator.

The operator should wear adapted Personal Protective

Equipments, such as :

Protective goggles.

Ear protections.

Safety shoes.

Protective gloves.

Breathing protection.

The operator should wear tight clothes and should wear

protective a hair covering to protect long hair, if necessary.

For example, the operator should never wear :

Loose clothes or sleeves.

Bracelets, watch, ring, jewels.

Any other object subjected to be caught or

entangled by moving parts of the machine.

User’s manual TM200B

6

4. DESCRIPTION AND OPERATING

4.1. PURPOSE OF T E MAC INE

The bench grinder TM200B is designed to be installed on a

bench or a base to perform tangential grinding (i.e. grinding

of the surface of a work piece using the periphery of the

wheel).

When operating and maintenance are correct, the grinder

can provide many years of safe and consistent work.

To do so, please thoroughly examine the different functions

of the machine.

4.2. SPECIFICATIONS

Cast iron body

Self-lubricated sealed ball bearing assembly

Main switch with under-voltage switch-off oil

Polycarbonate protective shields

Automatic internal thermal protection of the motor

Stamped steel housings fitted with a dust

extraction outlet

Safety and conformity :

-gap between the wheel and the housing less

than 5 mm

-spark screen and tool-holder adjustment to 2

mm from the wheel

Wheel

(mm)

Wire wheel

(mm)

Wheel

grain

Type

of

brush wire

Power

(kW) Main power

Rotating

speed

(tr/mn)

Weight

(kg)

Dimensions

(W x x D)

(mm)

TM 200 B 200 x 30 x 32 200 x 25 x 32 AA 60 M Brassed

iron 0,9 1-phase 230 V 2800 27,5 570 x 330 x 265

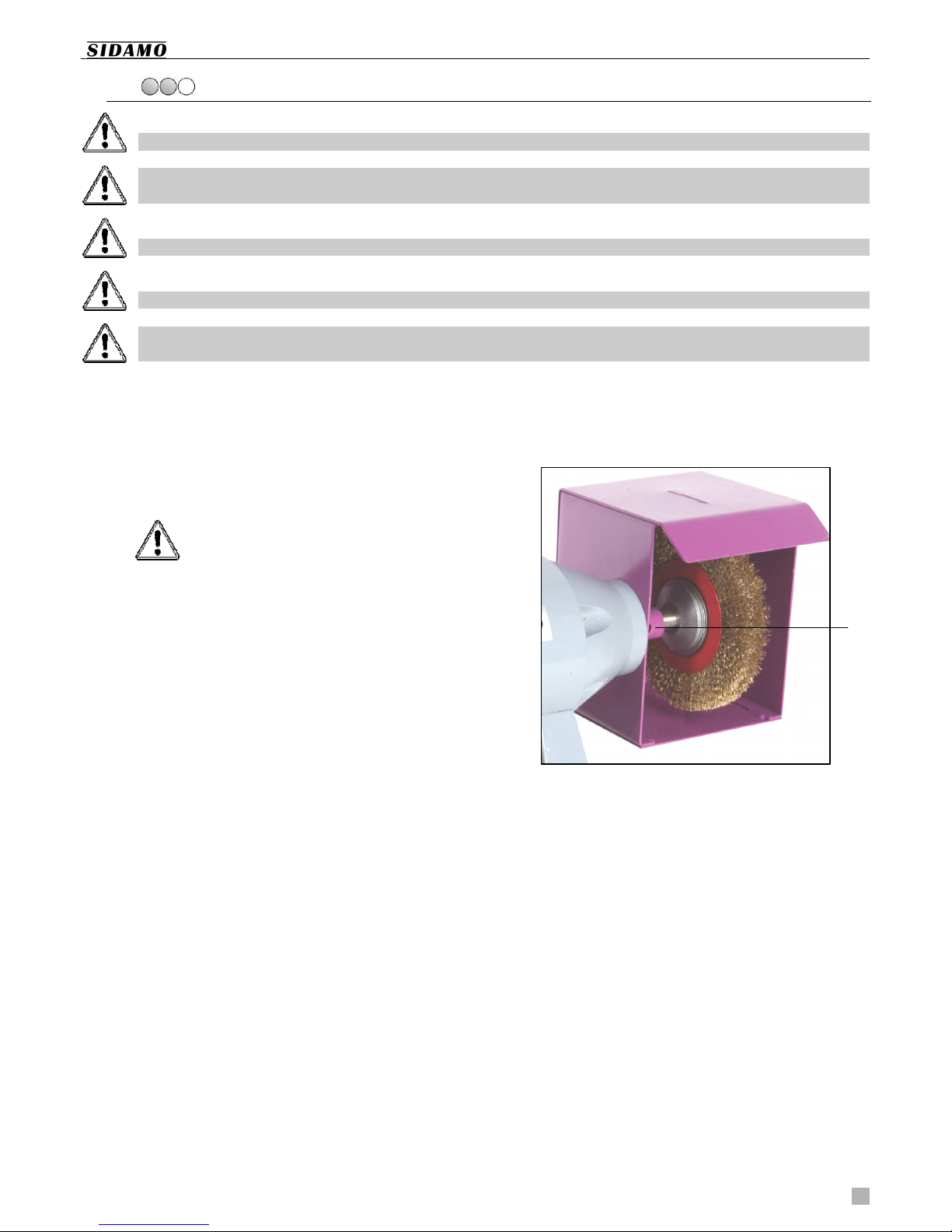

4.3. MAC INE OVERVIEW

Figure 1

1. Wire wheel protective guard

2. Wire wheel

3. Adjustable spark screen

4. Protective shield

5. Wheel protective guard

6. Wheel AA 60 M

7. Tool-holder

8. Base

9. « ON/OFF » switch

10. Fixing holes

1

2

10

9

8

3

4

5

6

7

User’s manual TM200B

7

5. INSTALLATION

5.1. PACKING

The packing may include a desiccant bag. Discard it and keep out of reach of children.

The bench grinder comes packed into a cardboard packing.

When unpacking, take each part of the grinder out and

check its condition prior to assemblying.

Keep the manual for further reference.

In case the product is not in perfect condition or if some

parts are damaged or missing, please contact your dealer.

5.2. TRANSPORT AND ANDLING

Considering both weight (27,5 kg) and dimensions of the

machine, only one person is required to handle the machine.

5.3. INSTALLING T E MAC INE

Fix the grinder to a convenient support or to a bench, using fixing holes in the base.

Connect a dust extraction adapted to extraction outlets, if required.

Position the grinder on the working station. Mind the height : the working station should be as comfortable as possible.

The recommended height is 70 to 80 cm from the ground level.

Vicinity of the equipment :

Main power should comply with the specifications

of the machine.

Ambient temperature : between +5°C and +35°C.

Relative umidity : not over 90%.

Sufficient ventilation of the workshop.

Good lighting conditions in the working area : 300

lux.

Procedure :

1. Fix the support or the bench to the ground.

2. If necessary, fill the support with sand to reduce

vibrations and stabilize the assembly.

3. Fix the grinder to the support or the bench, using 4

screws (M6) through the holes (10 fig.1). Tighten

them firmly, using appropriate nuts.

Optional S2 or S2ASP base to be ordered to the dealer.

Do not apply excessive tightening torque when installing the grinder on an uneven surface. There is a risk of breakage.

User’s manual TM200B

8

5.4. ELECTRICAL CONNECTION

Only low voltage trained and authorized technicians should be allowed to perform interventions on the electric circuit.

POWER

Make sure the voltage of the motor matches the voltage of

the main power.

Perform the connection, using the power cable.

The power socket must match the plug of the grinder.

The machine is connected to a power system. This system

must be connected to earth, according to in-force safety

regulations.

We remind the user that a magneto thermal breaker must

be installed before the electrical circuit to protect all

conductive devices against short-circuits and overloads.

This protection should always be selected according to the

electrical specifications of the machine, as stated on the

rate plate :

Voltage : one-phase 230 V

Frequency : 50 z

Rate : 3,9 A

Main motor power : 0,9 kW

Power connections and extensions must be protected

against splashes and should be fitted onto dry surfaces.

Regularly inspect condition of the power chord, of the switch

and of the cable duct.

Operating the grinder, using a damaged power chord, is strictly prohibited.

Always use a cable winder with both section and length adapted to the power of the machine. Unwind completely the

cable.

Never pull the cable to unplug the grinder. Always use the plug.

Make sure that direction of both wheel and wire wheel rotations match the arrow displayed by the wheel and the wire

wheel housings. The guarantee does not cover damages resulting from a poor connection.

5.5. DRY TEST AND INITIAL INSPECTION PRIOR TO USING T E EQUIPMENT FOR T E FIRST TIME

Make sure all protections are in place and in

working condition.

Make sure moving parts correctly run and that no

part is damaged.

Check condition of the wheel and the wire wheel.

Make sure the grinder is correctly fixed to the

bench or to its support and that the support is

correctly fixed to the ground.

Perform a dry test : the machine should run

correctly.

User’s manual TM200B

9

6. OPERATING T E GRINDER

Always follow safety instructions related to bench grinders.

Prior to starting the grinder, make sure you are familiar with control devices.

Make sure the tightening torque applied to the fixing nuts of wheels is correct. Check the condition of the wheels before

using them (See section 7.5 « Replacing a wheel»).

Prior to any servicing or maintenance, always unplug the grinder.

Always wear convenient Personal Protective Equipments.

When continuously operating the grinder, be careful with the surface of the grinder, because of the risk of burn.

6.1. ASSEMBLYING

Wheel side :

1. Fix the spark screen (8) to the wheel guards (1 and

6) and adjust it so that the distance from the

periphery of the wheel is max. 5 mm.

2. Fix the transparent protection shield (7) to the

spark screen (8) and adjust it so that the operator

is protected.

3. Fix the tool-holder (10) to the wheel guards (1 and

6) and adjust it so that the distance from the

periphery of the wheel is max. 2 mm.

4. Because of wear, the wheel diameter

decreases and these distances increase.

As the wheel wears out, the spark screen and the tool-holder should be regularly adjusted to maintain the distance from

the periphery of the wheel.

User’s manual TM200B

10

6.2. GRINDING/BRUS ING PROCEDURE

Always keep your hands away from the grinding area when the grinder is operated.

During the grinding, there is a risk of projection of sparks and debris.

Use extreme care when performing a manual grinding/brushing : risk of contact with the wheel and the wire wheel (risk

of entanglement, burn, pinching, abrasion or crushing).

In case of important vibrations, identify the unbalanced wheel or wire wheel and correct its balance using an appropriate

balancing device.

Always use tool-holders only in horizontal position.

Keep the screen perfectly clean.

Do not apply excessive force on tools. Performances of tools are not increased when one applies a great force, but the

lifespan of tools and of the machine will be reduced.

Operating cycle

Grinding instructions :

1. Adjust the protective shield, the spark screen and

the tool-holder to prevent any contact with the

wheel.

2. Always wear protective equipments.

3. Always wear protective goggles.

4. Insert the plug of the grinder into the main power

socket.

5. Press « I » on the main switch to operate the

engine. The wheels then reach their max. speed.

Wheel side

6. Gradually take the workpiece to grind closer to the

wheel, leaning on the tool-holder.

7. Always use both hands to hold the work

piece. Cool it down, from time to time, using a

water tank.

The wheel has a fine grain (AA 60 M) to perform

finishing machining and dry sharpening of tools

(plane blades, scissors, pairs of secateurs,…), made

from hard and hardened metals.

Wire wheel side

6. Firmly hold the work piece to brush with

your hands, then apply a progressive force, but do

not exert an excessive force in order to let the

motor run at its rating speed. Cool the workpiece

down, from time to time, using a water tank.

Brassed iron, wavy wire wheels are adapted to

pickling, cleaning, rust removing, polishing of work

pieces made from ferrous/no ferrous metal, wood,

plastics.

Let the wheel and the wire wheel reach their maximal speed, prior to starting grinding.

Do not brake or block the wheel or the wire wheel by pressing too much.

Stopping the grinder :

Press « 0 » on the main switch to stop the grinder.

Several seconds are required to completely stop

the wheels.

Wait until all evidence of rotation has ceased prior to starting any intervention on the grinder.

User’s manual TM200B

11

7. MAINTENANCE

Disconnect the machine, prior to performing any maintenance or servicing operation.

Always wear gloves and protective goggles and always use a brush and a clean and dry cloth to perform cleaning.

Never use solvent or aggressive detergents.

Never used compressed air to remove chips.

Never immerse the grinder into water and never wash it using a water jet.

Please read below the most frequent maintenance

interventions : daily, weekly, monthly and 6-month

interventions.

Non-observance of instructions leads to an early wear and

reduces the performances of the machine.

7.1. ADJUSTMENTS

Regularly control distances in relation with the wear of the

wheel :

Spark screens at max. 5 mm from the peripheral

surface of the wheel.

Tool-holders at max. 2 mm from the peripheral

surface of the wheel.

7.2. PROTECTIVE S IELD

Regularly check the cleanliness of the protective

shield. Replace it as soon as it is damaged.

Maximum lifespan of a protective shield : 2 years.

7.3. CLEANING

Regularly clean the grinder, particularly inside the

wheel guard to prevent heaps of dust and abrasive

grit from building up.

7.4. LUBRICATING

Motor ball bearings are life-long lubricated and

require no servicing.

User’s manual TM200B

12

7.5. REPLACING T E W EEL

Always unplug the grinder prior to replacing the wheel.

Never install a wire wheel in the wheel guard or a wire wheel guard instead of the wheel guard.

When replacing the wheel, always use a wheel with the same weight and the same dimensions.

Replace a wheel as soon as its diameter gets down to 140 mm.

Never install/use a wheel when its diameter is less than 140 mm.

Never use a worn out or a damaged wheel.

Use only wheels recommended by SIDAMO with a speed higher or equal to the speed indicated on the tool plate.

Regularly control the condition of your grinder, particularly the distance between the tool-holder and the wheel, the

conditions of the wheels and the condition of the main power.

Checking the condition of a new wheel :

Prior to installing a new wheel, perform a sound test to

control its general condition :

1. To perform this test, the wheels should be perfectly

dry and clean. Otherwise the sound emitted could

be lower.

2. Using a non-metal tool (the wooden handle of a

screwdriver or a wooden mallet), slightly tap on the

side of the wheel : a slight tap on a sound wheel

gives a clear and nice sound.

3. On the opposite, when the sound is dull and broken,

do not use the wheel.

Use extreme care when handling wheels. In case a wheel has received a shock or has dropped on the floor, do not use it

(in any case, refer to the Instruction Sheet that comes with the wheel).

We recommend the use of vitrified wheels. Various qualities are available.

Please refer to the table about wheels or, for more information, to the packing of the wheel.

Procedure :

1. Make sure the machine is not connected to power.

2. Remove the spark screen (8 fig.2) and the tool-

holder (10 fig.2).

3. Remove the screws and remove the wheel outer

guard (1 fig.2).

4. old the drive shaft in position, using an open-end

wrench fitted at the end of the shaft.

5. Remove the wheel nut (2 fig.2) using an open-end

wrench.

6. The left nut is a left-hand nut. To unscrew,

use clockwise direction.

7. Remove the outer flange of the wheel guard (3

fig.2).

8. Replace the used wheel (5 fig.2) by a new one

(make sure both flanges and the shaft are clean

prior to installing a new wheel).

9. Make sure the hole of the wheel matches the

wheel-holder shaft. If necessary, use reduction

rings.

10. Reassemble the outer flange of the wheel housing.

11. Tighten firmly the fixing nut, but do not apply

excessive torque, because its own inertia tends to

tighten it.

12. Reassemble the outer guard of the wheel.

13. Make sure the side distance between the wheel

and the guard is less than 10 mm.

14. Reassemble all others parts, first removed.

User’s manual TM200B

13

7.6. REPLACING T E WIRE W EEL

Always switch off the equipment prior to performing this operation.

Never install a wheel in the wire wheel guard or a wheel guard instead of the wire wheel guard.

Always use similar models of wire wheels (same weight and same dimensions).

Never use a worn out or a damaged wire wheel.

Use only wire wheels recommended by SIDAMO with a speed higher or equal to the speed indicated on the tool plate.

Regularly control the condition of your grinder, particularly the conditions of the wheels and the condition of the main

power.

Procedure :

1. Make sure the equipment is switched off.

2. Block the driving shaft by matching, on the left side

of the wire wheel, the hole of the driving shaft with

the hole of the wire wheel guard (A).

3. Unscrew the wire wheel nut (18 fig.2) using an

open-end wrench.

4. The right nut is a right-hand nut. To

unscrew it, use anticlockwise direction.

5. Remove the outer flange of the wire wheel (3 fig.2).

6. Replace the used wire wheel (17 fig.2) with a new

one (make sure flanges and fitting shafts are clean

prior to fitting a wire wheel).

7. The hole of the wire wheel should perfectly fit the

shaft of the wire wheel-holder. If necessary, use

reduction bushes.

8. Fit the outer flange of the wire wheel.

9. Tighten the fixing nut, but do not apply excessive

torque. Because of its own inertia, this nut will tend

to self tighten.

A

User’s manual TM200B

14

8. ACCESSORIES AND CONSUMABLE PARTS

8.1. BASE S2

The bench grinder is designed to be fitted on a base S2

(optional).

Suction eight x Width x Depth

(mm)

Weight

(kg) Reference

S2 Not

included 845 x 360 x 360 13 20198075

8.2. BASE S2ASP

The grinder is fitted with two outlets to extract dusts.

It is possible to connect a base with a S2 ASP dust

extraction system.

Suction Power

(kW) Main power

Rotating

speed

(tr/min)

Air flow

(m³/h)

Depression

(mm 2O)

Noise

level

(dB)

eight x Width x Depth

(mm)

Weight

(kg) Reference

S2 ASP

included 0,15 1-phase

230 V 2800 290 95 75 845 x 360 x 360 25 20113033

8.3. DRILL S ARPENER

Additional drill sharpener, designed to be installed on

the bench, next to the grinder :

Sharpening of drills from Ø 3 mm to Ø 18 mm.

Angle adjustment range : from 41° to 88°.

Reference

Drill sharpener 20198072

User’s manual TM200B

15

8.4. W EELS AND WIRE W EELS

Genuine wheel/wire wheel :

Wheel AA 60 M : Ø 200 x 30 x 32 mm

(Reference : 10505063)

Brassed iron wire wheel : Ø 200 x 30 x 32 mm

(Reference : 10306012)

Available range of wheels/wire wheels :

Quality Description Application

A 24 R Fine grain grey corundum Dry deburring of ferrous metals,

removing rapidly large stock allowances

A 36 R Coarse grain grey corundum Dry deburring of ferrous metals,

removing rapidly large stock allowances

A 60 M Fine grain grey premium corundum

Finishing and sharpening of ferrous and

hardened metals (axes, sickles, drills,

burins, blades)

AA 60 M Fine grain white premium corundum Dry sharpening of hardened steels

(knives, scissors)

C 120 J Very fine green silicon carbide Dry sharpening of carbide and very hard

and hardened metals

Brassed

iron wavy

wire wheel

Better resistance of the wire to

deformation, because of the tension

force, lifespan is 30% longer than with

a steel wire

Pickling, cleaning, rust removing,

polishing of work pieces made from

ferrous/no ferrous metal, wood,

plastics

Stainless

steel wavy

wire wheel

To grind stainless steel and other non-

ferrous materials. No surface

blackening

Pickling, cleaning, rust removing,

polishing of work pieces made from

ferrous/no ferrous metal, wood,

plastics

User’s manual TM200B

16

9. SPARE PARTS

EXPLODED VIEW

Figure 2

User’s manual TM200B

17

PART LIST

N° Description Quantity Note

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Left outer wheel guard

Wheel fixing nut

Flange

Washer

Wheel AA 60 M (Ø 200 x 30 x 32)

Left inner wheel guard

Protective shield

Spark screen/Shield-holder

Screws/Shield fixation

Tool-holder

Screws/Tool-holder fixation

Motor flange

Stator

Bearing

Rotor

Wire wheel guard

Wire wheel (Ø 200 x 25 x 32)

Wire wheel fixing nut

Switch

Power cable

Base

Plate

Electric plug

Capacitor

1

1

4

4

1

1

2

2

1

1

2

2

1

2

1

1

1

1

1

1

1

1

1

1

N° 1 + 6

N° 7 + 8 + 9

N° 20 + 23

User’s manual TM200B

18

10. ELECTRICAL CIRCUIT

ELECTRICAL DIAGRAM

User’s manual TM200B

19

11. NOISE LEVEL

All data related to the noise level of this machine, when

operating, depend on the type of material ground and on the

type of wheel used. That is why measurement data are only

relative.

The risk of hearing damage, for the operator, is related to

the noise exposure time.

The operator must wear soundproof headphones or any

convenient PPE when sound power is over 85 dB(A) at the

working place.

Equivalent, continuous, sound pressure level at the

working station :

LpA = 84,1 dB(A)

Sound power level :

LwA = 97,1 dB(A)

Calculating the sound pressure was performed considering

factors such as : reverberation of the test place, absorption

of noise at the ground level and other noises that can

interfere with the measures. The result is only an estimation

: nevertheless, one may say that, considering the values

obtained, the uncertainty would be about 3 dB(A).

The values given are those of emissions and do not

necessarily mean any safe working values. Although there is

a correlation between levels of emission and levels of

exposure, these values cannot be used with certainty to

determine whether additional measures are necessary.

Factors influencing actual levels of exposure are : the

properties of the working area, other noise sources, etc., i.e.

the number of machines and the type of processes used in

the vicinity of the machine. Also the highest acceptable

levels of exposure may vary in different countries. owever

this information should help the machine user evaluating the

risk and the risk rate in a better manner.

12. VIBRATIONS LEVEL

All data related to vibrations produced by this machine, while

machining, depend on the type of material ground and on

the type of wheel used. That is why measurement data are

only relative.

Average value of hand/arm vibrations :

Aw(8) < 2,5 m/s²

13. PROTECTION OF T E ENVIRONMENT

This machine is made from various materials that can be

recycled. This sign indicates that used equipment should be

discarded separately from other types of wastes.

Recycling these equipments will be best performed, in

compliance with the WEEE Directive 2012/19/EU on

waste electrical and electronic equipment.

ousehold users should contact their dealer or their local

government office for details of where and how they can

take this item for environmentally safe recycling.

Thank you for helping us protecting our environment.

14. GUARANTEE

Only authorized After-Sales Services are allowed to carry a

Guarantee. The Guarantee for this equipment is for 3 years,

starting from the date of purchase by the user.

As the invoice acts as a proof of valid Guarantee, we

recommend keeping it.

The purpose of the Guarantee is only to repair or replace,

free of charge, faulty parts, following an expertise performed

by the manufacturer.

The Guarantee will not cover any damage caused by the

user or a repairer non-authorized by the company SIDAMO.

The Guarantee will not cover any consequential or

subsequent damage, direct or indirect, material or

immaterial, caused to persons or things and resulting from

a failure or a shutdown of the equipment.

The Guarantee will not cover damages caused by :

Abnormal use.

Inappropriate operating.

Electrical modification.

A fault when transporting, handling or servicing.

The use of non-genuine parts or accessories.

Interventions performed by non-authorized persons.

The absence of any protection or device designed

to protect the operator.

The Guarantee of your machine is excluded in case on the

non-observance of above instructions.

The Buyer is responsible for the Goods during the transport.

Therefore the Buyer may exercise all judicial and

administrative remedies against the carrier, in the correct

form and within the legally required time.

User’s manual TM200B

20

15. DECLARATION OF CONFORMITY

« ORIGINALE » DECLARATION OF CONFORMITY

The undersigned (Manufacturer/Importer) :

SIDAMO

Z.I. DES GAILLETROUS – 41260 LA C AUSSÉE-SAINT-VICTOR - FRANCE

Declares that the new product described hereafter :

Description : BENC GRINDER-WIRE W EEL

Brand : SIDAMO

Model : TM 200 B

Reference : 20113104

Serial N° :

Complies with the essential safety requirements that apply to it :

Machinery Directive 2006/42/EC

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

WEEE Directive 2012/19/EU

Ro S-2 Directive 2011/65/EU

REAC 1907/2006

Noise Directive 2003/10/EC

Vibration Directive 2002/44/EC

La Chaussée-Saint-Victor

Date :

JÉRÔME GERMAIN

Executive Officer

Person entitled to create the technical file :

M. GERMAIN – SIDAMO – Z.I. DES GAILLETROUS – 41260 LA C AUSSÉE-SAINT-VICTOR

Z.I. DES GAILLETROUS – 41260 LA C AUSSÉE-SAINT-VICTOR

Tel : 33 2 54 90 28 28 – Fax : 33 897 656 510 – Mail : si[email protected] – www.sidamo.com

Certified company ISO 9001 – ISO 14001

USER SERVICE

Tel : 33 2 54 74 02 16

It is SIDAMO’s policy to continuously develop and improve our products, and therefore we reserve the right to modify or

change the details at our discretion and without notice. Information, photos, exploded views and diagrams contained in this

document are not contractual.

Edition novembre 2017

User’s Manual TM200B

Table of contents