Sideshift SS Series User manual

BOW & STERN

THRUSTER

INSTALLATION MANUAL

SS/ST/WB/230/240/340/350 SERIES

VOLUME 2.7, JULY 2023

Sideshift Inc. 130 Industrial Ave, Unit 303, Carleton Place, ON, Canada K7C 3T2

1.877.325.4787 +613.686.6011 INFO@SIDESHIFT.CO

SIDESHIFT INSTALLATION GUIDE V2.7

1

INTRODUCTION

Thank you for your purchase of a Sideshift thruster system.

Sideshift thrusters are designed for easy installation by anyone with basic mechanical

and electrical skills.

This manual explains everything you need to know about installing your Sideshift

thruster.

We also provide unlimited telephone support at

1.877.325.4787. or +1.613.686.6011

See our website for helpful installation videos at

Installation - Sideshift Bow Thrusters and Stern Thrusters

This manual explains the different types of thrusters, the parts, tools and procedures

required to install them, the electrical system that supplies power to the thruster

motors, as well as maintenance and troubleshooting procedures.

We recommend that you familiarize yourself with the entire manual before starting

your installation.

SIDESHIFT INSTALLATION GUIDE V2.7

2

Safety warnings

WARNING: Ensure thruster battery switch and main ignition are turned off

when conducting maintenance and repair of the thruster.

WARNING: Use extreme caution when swimmers are in the area of the thruster.

Turn off ignition and avoid contact with thruster props when boat is

stationary.

WARNING: For optimal thruster performance and to prevent overheating

operate the Sideshift thruster in short bursts of 3-5 seconds at a

time as a standard practice. Never run for more than 30 seconds at

a time.

WARNING: When operating out-of-water do not run thruster for longer than

5 seconds to prevent overheating.

WARNING: If conducting an in-water installation, use a cordless drill only, as a

corded drill can present an electrocution hazard.

SIDESHIFT INSTALLATION GUIDE V2.7

3

MODEL TYPES

There are two basic types of Sideshift thruster systems covered in this manual:

fixed-mount bow thrusters and fixed-mount stern thrusters.

Electrical connections and controls for both types are similar, however placement

and mechanical attachment details vary between the two types of thrusters.

Our SS/ST series thrusters do not retract or deploy. They are permanently fixed to

the boat and rise out of the water when the boat planes, creating no drag. They also

work well on displacement type hulls and will create no noticeable drag, nor will they

affect handling.

Bow Thruster Models

Model

Suitable Boat Length

V DC

Max

Current

HP

Props

SS230

20-35 ft. (6.1 –10.7 m)

12

300 A

2.5 HP

Single prop

SS340

30-45 ft. (9.1 –13.7 m)

12

550 A

5.0 HP

Dual prop

SS350

40-60 ft. (12 –18.3 m)

24

400 A

7.5 HP

Dual Prop

Transom-Mount Stern Thruster Models

Model

Suitable Boat Length

V DC

Max

Current

HP

Props

ST/WB230

20-30 ft. (6.1 –9.14 m)

12

300 A

2.5 HP

Single prop

ST340

20-45 ft. (6.1 –13.7 m)

12

550 A

5.0 HP

Dual Prop

ST350

40-60 ft. (12.2 –18.3 m)

24

400 A

7.5 HP

Dual Prop

Outboard/Outdrive-Mounted Stern

Thruster Models

Model

Suitable Boat Length

V DC

Max

Current

HP

Props

ST230

20-30 ft. (6.1 –9.14 m)

12

300 A

2.5 HP

Single prop

ST230-Dual

30-40 ft. (9.14 –12.2m)

12

500 A

5 HP

Dual prop

ST240-Dual

35-50 ft. (10.7 –15.24m)

24

400 A

7.5 HP

Dual prop

SIDESHIFT INSTALLATION GUIDE V2.7

4

PARTS AND TOOLS

Bow Thruster Parts

Item

Photo

Purpose

Bow cover

Secures thruster base to hull.

Covers and protects through-hull

connections

Bow thruster base with

motor

Propeller and motor

Clamp Strap

Secures thruster base to hull.

SIDESHIFT INSTALLATION GUIDE V2.7

5

Center Bolt

Attaches clamp strap to thruster

Lock Nut (1)

Locks center bolt in place

Threaded hull insert and

bolts (2)

Secures clamp strap assembly to

hull.

Hull insert epoxy kit

Cements threaded hull inserts in

place

SIDESHIFT INSTALLATION GUIDE V2.7

6

Top through bolt

assembly

Secures top of upper section

Side screws (2)

Secures upper section cowling

SIDESHIFT INSTALLATION GUIDE V2.7

7

Stern Thruster Parts

Item

Photo

Purpose

Stern thruster base with

motor

L Bracket

Attaches stern thruster to

transom

Swim Platform Extension

Bracket

Attaches stern thruster to

underside of swim platform

SIDESHIFT INSTALLATION GUIDE V2.7

8

Common Parts

Item

Photo

Purpose

Joystick (single)

Controls bow or stern thruster.

Joystick (Dual)

Dual control for bow and stern

thruster.

Motor Controller

Switching solenoid for turning

thruster on and off.

SIDESHIFT INSTALLATION GUIDE V2.7

9

Threadlocker/Anti-seize

Prevents screw and bolt threads

from seizing, facilitating easier

assembly and disassembly.

Heat shrink tubes

(sufficient for all cables

attached to motor

controller. Cut to size)

Provides waterproofing for cable

at battery terminals.

Battery terminal

protectors

Protects terminals from moisture

and prevents shorts.

Terminal lugs and cable

lug crimper

Assortment of terminal lugs for

connecting thruster cables to

batteries, motor controller and

battery switch. Lug crimper also

included.

SIDESHIFT INSTALLATION GUIDE V2.7

10

Part

Image

Purpose

Wireless Key

Fob

Allows wireless

remote operation

of thrusters. Works

with all thruster

models.

Battery Switch

On/Off switch for

thruster batteries

Fuse/Voltage

Indicator

Fuse/Digital

voltage indicator

Wireless

Receiver

Wireless receiver

module connects to

motor controller to

receive control

signal from

joystick/wireless

remote

SIDESHIFT INSTALLATION GUIDE V2.7

11

Required Tools

•Cordless DC drill

•Water-proof angle drill (optional, for in-water installations)

•Heat gun

•3/8” drive torque wrench

•#2 Phillips screwdriver

•Wire stripper

•Wire crimper

•7/8” socket

•SAE wrench set 3/8” to 3/4”

•Pliers

•1½” joist drill bit

•½” 13 mm drill bit

•Drill bits up to ½”

•3/16” hex socket driver

•Caulking gun

•Hacksaw

•2 ½” hole saw

SIDESHIFT INSTALLATION GUIDE V2.7

12

ELECTRICAL COMPONENTS

Battery Requirements

The batteries supplying the thruster must be cranking type (NOT deep

cycle) capable of supplying the required minimum CCA (Cold Crank Amps),

outlined in the table below. Insufficient battery capacity will lead to poor

performance and possible damage to the thruster motor.

ST/SS Model

Qty

Voltage

Min. Total CCA (A)

230

1x12v

12

850

340 & 230-Dual

2x12v

12 V

1700

240 & 350

2x12v

24 V

850 at 24v

Warning: It is essential that the cold cranking ampere (CCA)

requirements are met as outlined in the table above.

Ensure batteries are load tested and properly charged at all

times to avoid performance problems and thruster motor

damage due to low voltage

Batteries must be installed as close to the motor controller as possible for optimum

performance. In ventilated areas, you can install either AGM or sealed lead acid

starting-type batteries.

BATTERY CAPACITY AND AGE

Under normal circumstances with new and fully charged batteries, you can expect

around 50 thruster cycles before the battery must be recharged.

It is advisable to recharge batteries after each use if possible, to extend the life of

the battery.

As batteries age and with repeated charge cycles, the battery slowly loses its ability

to hold a charge. The deeper the discharge before recharging, the shorter the life of

the battery. Over time it will be able to supply fewer thruster cycles before it

requires recharging and eventually will lack the capacity to allow proper thruster

performance.

Capacity reduces to the point that performance is poor or few thrust cycles are

available before recharging, and the batteries must be replaced.

SIDESHIFT INSTALLATION GUIDE V2.7

13

BATTERY STORAGE

Over time, batteries self-discharge, even when disconnected. Some new batteries

may have a self-discharge of 1-2% per month, but depending on the type and age

of the battery, it can rise to 6% per month or more.

If the battery is coated with moist dirt and corrosion by-products, discharge rates

can be even higher. Make sure the battery is clean and free of dirt and corrosion on

and around the terminals.

If the battery is a flooded type, top up the electrolyte, ensuring that it is above the

plates and below the vent cap well.

Fully charge the battery before storage, and store in a cool, dry place. Cooler

batteries will self-discharge at a lower rate than warm batteries.

Check the terminal voltage of the battery periodically. When the terminal voltage

drops below 12.4 volts (75% capacity), charge it until fully charged. More frequent

charging is preferred if convenient. It is recommended to charge the battery every

three months.

Note that as charge capacity decreases, the freezing point of the electrolyte

increases. This is important because the electrolyte must not be allowed to freeze.

At 62% capacity, the freezing point is -26.5°C/-16°F; at 85% capacity, it is -52°C/-

62°F.

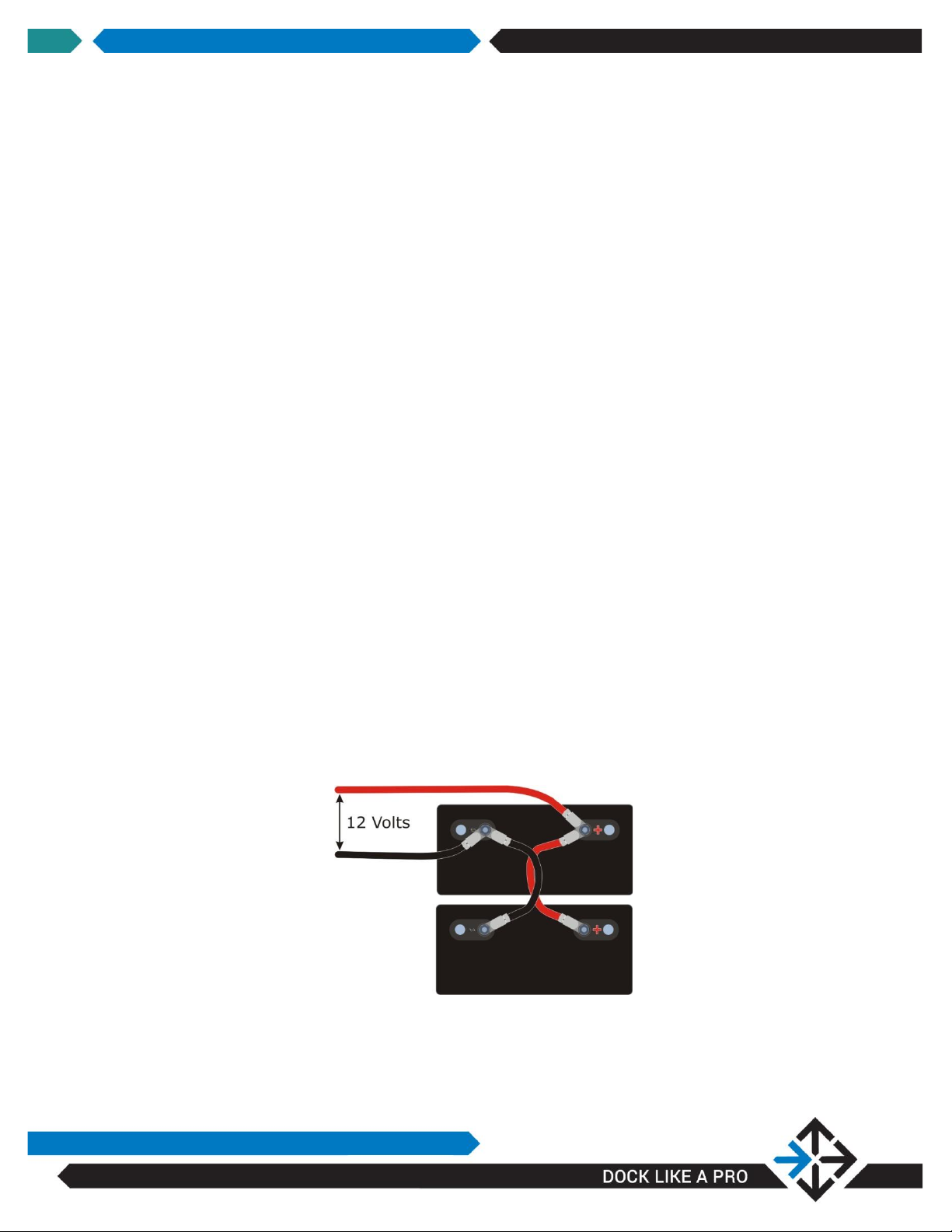

CONNECTING 12V BATTERIES IN PARALLEL TO BOOST CCA

You can double the CCA supplied from a single battery by connecting a second

battery in parallel to the first. You may prefer this alternative to buying a larger

single battery with the required CCA rating.

Figure 1: Two batteries in parallel, doubling CCA

SIDESHIFT INSTALLATION GUIDE V2.7

14

If you use a parallel configuration, the two batteries must be identical: same rating

and same manufacturer and ideally new batteries, or at least operated as a pair for

their entire service life. Each battery must be charged separately before installing to

ensure they start at the same charge level. Batteries which are dissimilar in any way

may not charge and discharge equally, leaving one battery undercharged.

To connect two batteries in parallel, prepare two shunt cables of the same gauge

used to connect the batteries to the motor controller. Connect the positive post of

one battery to the positive post of the other and the negative post of one battery to

the negative post of the other.

One post will share two compression terminals: the shunt and the cable to the motor

controller.

24 VOLT BATTERIES

24 volt batteries are less common than 12 volt batteries. You may find it more

convenient and less expensive to use two 12V batteries in series.

Figure 2: Two 12 V batteries in series, providing 24 V

To connect two batteries in series, connect the negative post of one battery to the

positive post of another using a short piece of battery cable of the same gauge used

to connect the batteries to the motor controller. The two remaining posts are each

connected to the motor controller using two battery cables, supplying 24V.

WINDLASS BATTERIES

It is possible to share an existing battery bank with a windlass, providing it has

sufficient capacity to meet both windlass and thruster usage, and is close enough to

the bow to supply the bow thruster. It is not recommended to power the stern

thruster from the windlass batteries due to the need for longer cable runs. Supplying

both bow and stern thrusters from a single battery is not recommended. The more

deeply discharged a battery becomes before it is recharged, the fewer charge cycles

it can provide in its lifetime, so if both thruster and windlass are used to a point

SIDESHIFT INSTALLATION GUIDE V2.7

15

where battery capacity drops below 75% before recharge, it is probably less

expensive to provide a separate battery bank dedicated to the thruster.

The cable gauge, CCA and circuit protection already in place for the windlass must

be compatible with the thruster in order for this approach to work. We do not

recommend using windlass batteries for our SS340 or SS350 bow

thrusters. See table below:

Thruster

Cable AWG

CCA

Circuit Protection

SS230

1/0

850 or greater

300 A peak

Table 1: Shared Battery Requirements

Cable and Terminal Requirements

Due to the high current load drawn by the motors, it is essential that the correct

type of cable and connectors are used, and that maximum cable length guidelines

are observed according to the gauge and thruster model. These guidelines are

summarized in the table below. The table assumes cables from the thruster to the

controller have not been shortened.

Cable must be high quality tin coated copper, marine grade cable. Cable ends must

be fitted with high grade cast copper, tin coated terminals and sealed with double

wall heat shrink tubing for moisture protection.

Recommended cable gauge for connecting motor controller to thruster battery bank,

fuse and battery switch:

Thruster Series

Cable AWG

230

1/0

340 & 230-Dual

2/0

240 & 350

2/0

SIDESHIFT INSTALLATION GUIDE V2.7

16

INSTALLATION OVERVIEW

Thruster installation involves three main phases: thruster mounting, joystick and

electrical installation.

There are differences between installing a bow thruster and a stern thruster,

although they share many common elements. Instructions for each type of

installation are covered separately below.

Electrical installation and joystick installation are similar for bow and stern thrusters.

Each is covered in a separate section.

Note that if you are installing both a bow and stern thruster, each thruster must

have a separate electrical installation, including batteries, motor controller and

joystick receiver. They can share a dual joystick which has two joysticks on a single

console, or use two separate single joysticks.

SIDESHIFT INSTALLATION GUIDE V2.7

17

INSTALLATION INSTRUCTIONS

–BOW THRUSTER

Bow thrusters can be installed with the boat in water or on land, although land-

based installation is easier.

In order to obtain the strongest possible epoxy bond(when not using through-bolt

hardware), installation should be performed when the hull is dry, clean and the

epoxy and hull surface temperature is between 70°F/21°C and 75°F/24°C .

View installation procedures on-line at Installation - Sideshift Bow Thrusters and

Stern Thrusters.

Bow Thruster Placement

The bow thruster is located on the center line, with the top of the propeller at least 5

inches (12 cm) below the shallowest waterline. The cables pass through the hull

above the waterline.

Figure 3: Bow Sideshift thruster placement

SIDESHIFT INSTALLATION GUIDE V2.7

18

Step-By-Step Instructions: Bow Thruster

STEP 1: DETERMINE WATERLINE

The propeller must be at least 5 inches (12 cm) below the shallowest

waterline and ideally out of the water when planing, so determining the

waterline is a crucial first step to installation.

Figure 4: Top of propeller 5" (12 cm) below water line

SIDESHIFT INSTALLATION GUIDE V2.7

19

NOTE: Be sure to determine the waterline with an empty boat to ensure

thruster placement will keep the propeller a minimum of 5” (12 cm)

below the waterline in the worst case scenario.

The water stain on the hull is a good indication of typical waterline over a

range of conditions. Use the lowest indication of waterline if a water

mark is visible.

If no water stain is visible, the waterline must be marked while the boat

is in the water. With the boat completely unloaded (fuel tanks empty but

standard equipment in place), mark the waterline near the bow of the

boat with a grease pencil.

STEP 2: POSITION CLAMP STRAP

Dry fit the clamp strap such that the holes at the end of each flange are between 2”

and 6” (5 and 15.25 cm) above the waterline. Mark the position on the bow with

tape. Duct tape works well.

Verify that drilling the hole locations selected in step a. above will not damage

anything on the inside of the boat, for example a water tank or wiring etc. If in

doubt, contact the boat manufacturer.

WARNING: Verify that the proposed location to drill the anchor holes and cable

holes as determined above will not interfere or damage anything on

the inside of the hull.

Remove the two-sided tape backing on clamp strap.

Reposition the clamp strap at the location marked above and fasten in place using

the attached two-sided tape.

This manual suits for next models

18

Table of contents

Other Sideshift Outboard Motor manuals

Popular Outboard Motor manuals by other brands

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS Side-Power SH 700/ 412 TC Installation and user manual

Yamaha

Yamaha T9.9W Service manual

Torqeedo

Torqeedo Travel 401 S operating manual

Sleipner

Sleipner VECTOR FINS VF650 installation guide

Vetus

Vetus BOW3512F Installation and user manual

MotorGuide

MotorGuide R5 Series manual