SIEB & MEYER CNC 61.00 Guide

:

CNC 61.00 Hardware Description CNC 0610510/12

Title

CNC 61.00

CNC 0610510/12

Hardware Description

SIEB & MEYER AG

Auf dem Schmaarkamp 21 * D-21339 Lüneburg * (Germany)

Telephone +049 - 4131 - 203 - 0 * Telefax: +049 - 4131 - 203 - 2000

E-Mail: [email protected]

Internet: http://www.sieb-meyer.com

:

CNC 0610510/12 CNC 61.00

Copyright

Translation of the original instructions, Copyright © 2009 SIEB & MEYER AG.

All rights reserved.

This manual or extracts thereof may only be copied with the explicit authorization by SIEB & MEYER AG.

Trademarks

All product, font and company names mentioned in this manual may be trademarks or registered trademarks

of their respective companies.

Identification Key

061-CNC_tec_610510/12/R006-SM-EN-hg/tm/ac/she/sü/uh

January 14, 2009

:Content

CNC 61 Hardware Description CNC 0610510/12 3

Content

1 Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety Instruction and Application Advice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2 Appropriate Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Transport and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.9 Guarantee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Unit Assembly Complying EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Emission of Line and Field Interferences According to Category C3 . . . . . . . . . . . . . . . . . . . . . 15

4 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Automation System CNC 61.00. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Hardware Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Performance Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.4 View of the Device 0610510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.5 View of the Device 0610512. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Module Type 0610510 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.2 Module Type 0610512 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3 Connections for Module Type 0610510 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.4 Connections for Module Type 0610512 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.5 Type Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.6 Module designation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 Supply Voltage 230 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Supply Voltage 400 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 Functional Description of the Connectors/Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1 Front Panel 0610512 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.2 Pin Assignment and Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.2 X1 - Connection of Motor Measuring System (Feedback) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2.2.1 Resolver Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.2.2.2 Hall Effect Sensor Evaluation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.2.2.3 Optical or Magnetical Length Measuring System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2.3 X2 - COM, Connection for Terminal or Programming Device. . . . . . . . . . . . . . . . . . . . . . . . . . .44

8.2.4 X3 - ENCO, Angle Pulse Output/SSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

8.2.5 Angle Pulse Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8.2.5.1 X4 - ENC1, Angle Pulse Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2.5.2 X5 - ENC2 - Angle Pulse Input/SSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2.6 X6 - SIO, I/O Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2.7 Connection to the Bus System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

8.2.7.1 X7 - MODLINK, ETHERNET, CAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2.7.2 X8 - MODLINK, CAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2.7.3 X9 - CAN, Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

8.2.8 X20 - Motor Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

8.2.9 X30 - Power Supply, X31/X32 Ballast Resistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

8.2.9.1 Connection Example for Three-Phase Supply with/without Transformer. . . . . . . . . . . . . . . . . . 49

8.2.9.2 Connection Example for Single-Phase Supply up to max. 230 VAC . . . . . . . . . . . . . . . . . . . . . 50

8.2.10 Inputs and Outputs of the Logic Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Content :

4 Hardware Description CNC 0610510/12 CNC 61

8.2.10.1 X50 - Internal Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2.10.2 X51 - Internal Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2.11 X52 - 24 V Supply/Thermal Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Wiring of 24 V (internal/external) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

8.3 Error Indications FC0 to FC3 ( Red Flashing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

8.3.1 Status Indications FC0 to FC3 (green and red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.3.2 Indication of Malfunctions - RIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.3.3 Status of Controller - RON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.3.4 Operation Indication - CNC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.3.5 Indication "Remote Control“ - REM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.3.6 Status Indication/Error Messages of Bus Systems - STX/SRX/SRR . . . . . . . . . . . . . . . . . . . . . 57

8.3.7 Test Pins - MP/GND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.3.8 Coding Selector - ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8.4 Layout Plan of the Output Stage 036050001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.5 Layput Plan of the Output Stage 036050001.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9 General Information Regarding the Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

9.2 Difficulties of Ground Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.3 Motor Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.4 Cables for the Rotor Position Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.5 Cables for External Ballast Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

10 Option Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.1 Option Module 061020043X. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

10.1.1 Two Serial Interfaces with RS232/RS485 Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.1.2 X10 - PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.1.2.1 Bus Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.1.2.2 Assignment of the Module Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

10.1.3 X13/X14 - Two Active Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

10.1.4 X13/X14 - Two Passive Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

10.1.5 X13/X14 - Two Analog Inputs (12 bits). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.1.6 Battery-buffered RAM and Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

10.2 Option Module 061020044X. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

10.2.1 X17/X18 - Analog Output 1/2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.2.2 X19 - Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

10.2.3 X10 - PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.2.3.1 Bus Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.2.3.2 Assignment of the Module Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

10.3 Option Module 061020045X. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

10.3.1 X11/X12 - INTERBUS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.3.1.1 Meaning of the ID code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.3.2 X13/X14 - Two Active Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

10.3.3 X13/X14 - Two Passive Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

10.3.4 Two Serial Interfaces with RS232/RS485 Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10.3.5 X13/X14 - Two Analog Inputs (12 bits). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10.3.6 Battery-buffered RAM and Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

11 Electric Performance Dimensioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.1 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

11.1.1 Output Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.1.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.1.3 Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11.2 Power Consumption of a Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

12 Appendix: Manufacturers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

12.1 PHOENIX Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.1.1 Order Key for PHOENIX Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

12.1.2 Overvoltage Protection FLASHTRAB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

12.1.3 Shield Terminal Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

12.2 SIBA fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

12.3 TOSHIBA - Fiber Optic Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Content :

6 Hardware Description CNC 0610510/12 CNC 61

:Symbols

Symbols 7

1Symbols

The following table explains the symbols used in this manual for describing purpo-

ses. Technical symbols and signs are supposed to be known and therefore not ex-

plained.

Symbol Meaning

Warning: danger

Warning: electrostatically sensitice devices (ESD)

Warning: dangerous voltage

Warning: hot surfaces

LIndicates general notes, to which special attention should be paid to.

1Indicates measures or steps to be taken by the user.

D

LEDs indicating the module status

LED on

ELED off

FLED flashes

Earthing

PE-connector (protective earth connector)

Ground (GND)

7

7

Symbols :

8 Symbols

:Safety Instruction and Application Advice

Safety Instruction and Application Advice 9

2 Safety Instruction and Application Advice

2.1 General Information

According to Low-Voltage Directive 2006/95/EC

Machine Guideline 2006/42/EC

Electromagnetic Compatibility 89/336/EEC

Warning

In principle, the complete installation, the initial operation and the

maintenance must only be carried out by specialized staff!

Specialized staff, according to this fundamental safety instruction,

are persons, familiar with the installation, mounting, initial and per-

manent operation of the product and, are qualified appropriately for

the work. The standards DIN VDE 0100 and DIN VDE 0110 and

also the legal national rules for prevention of accidents must be paid

attention to.

Warning

During operation the devices can have hot surfaces according to

their protection system.

When ferrite rings are used temperatures may reach values over

80°C. Only use wires suitable for temperatures over 80°C. This

meets the flammability class UL 94V-0, RTI 105°C.

Consider the corresponding notes in the manual.

Warning

Subjects can be damaged and persons be injured

Xwhen covers are removed illegally,

Xduring any improper use,

Xwhen either the installation or the operation is incorrect.

Warning

Consult SIEB & MEYER before carrying out any modifications

within the unit.

Warning

Incorrect or insufficient connection of the system to ground may

cause dangerous currents.

Safety Instruction and Application Advice :

10 Safety Instruction and Application Advice

2.2 Appropriate Use

Definition of the concepts acc. to IEC / EN 61800 - 3.

Before initial operation, make sure that the machine will not expose danger (e.g. un-

controlled moves). The conformity according to the safety standard EN 60204-1 and

EN 61800-5-1 must have been proven.

The manufacturer of the system or the machine has to meet the requirements of the

legal values regarding the Electromagnetic Compatibility (EMC). SIEB & MEYER´s

units can be operated in industrial areas, provided that the attached EMC information

has been taken into consideration.

SIEB & MEYER takes care in its own EMC laboratory over their products to meet the

respective standards, when they are installed properly.

Deviations of the construction and the installation, described in the documentation

and in the manual "Unit Assembly Complying EMC" require new measurements of

the system or machine by the machine manufacturer to meet the statutory require-

ments.

Appropriate proceedings according to the EMC Product Standard (PDS) DIN/EN 61

800-3 ensure the use in industrial areas.

XProducts, not equipped with an AC supply line filter must be operated with a se-

ries connected mains filter! Detailed information can be found in the chapter

"Unit Assembly Complying EMC".

If using the drive systems in residential areas, in business and commercial areas as

well as in small trade, the user has to take additional and larger filter measurements.

SIEB & MEYER products meet the requirements of the Low-Voltage Directive 2006/

95/EC.The coordinated standards of the series IEC / EN 50178 andIEC / EN 60 204-

1in combination with IEC / EN 60 947 and IEC / EN 61800-5-1 are strictly used for

the products.

Technical data and the connection specification can be found in the respective prod-

uct documents.

2.3 Transport and Storage

Make sure, that the unit is correctly used. The following points must especially be tak-

en into consideration:

XProtection against mechanical damage (transport, handling, etc.)!

XProtection against dirt and humidity!

XDry and well-ventilated storage area!

XNo storage in the open!

XStorage temperature between -25°C to +55°C (-13°F to +131°F)! Shortly it may

be +70°C (+158°F).

XProtection against contact with electronic components (electrostatic discharge)!

XNo modification of insulating distances!

:Safety Instruction and Application Advice

Safety Instruction and Application Advice 11

2.4 Installation

The drive components are designed for fulfilling the degree of pollution 2 according

to IEC 61800-1 / DIN EN 50178.

XThe units can be loaded to their maximum up to a height of 1,000 m M.S.L

(3,281 ft M.S.L.)

XFor an operation in areas higher than 1,000 m M.S.L. (3,281 ft M.S.L.) the ca-

pacity must be reduced by 15 % per 1,000 m (3,281 ft.)

XThe ambient air must not contain aggressive, electrically conductive or flamma-

ble substances and must not contain any amount of dust.

XThe maximum relative humidity is approx. 95 % (no condensation).

XThe admissible ambient temperature during operation is between +5°C and

+40°C (+41°F and +104°F).

XAt temperatures higher than 40°C (104°F) the capacity must be reduced by -1.5

% per 1°C. Annotation: F = C × 9/5+ 32; C = (F- 32) × 5/9

XMake sure that the fans installed in the units have sufficient space to take in and

exhaust the cooling air! In addition pay attention to the direction of air flow

through internally installed fans!

XDo not touch electronic components.

2.5 Electrical Connection

The electrical installation must be carried out according to the relevant electrical

codes (e.g. appropriate wire gauges, fuse protection and connections of ground con-

ductors must be considered).

Recommendations for the installation according to the EMC (e.g. shields, connection

to earth and line installations) can be found in the technical documents of the unit

(only for machine manufacturers). The manufacturer of the system or machine has

to meet the requirements of the legislation regarding the EMC.

XAll work at and within the units must only be carried out, when the units are

turned off, the mains supply is cut and the DC bus is completely discharged!

XThe mains supply must be protected via an overload release with restricted guid-

ance for each mains phase.

XThe mains line should only be connected, when the work is completed!

XBefore turning on the unit the first time, make sure that the connected machine

will not have runaway axes!

XAfter turning off the unit hazardous voltages may still exist for up to 3 minutes in

the power supply (due to capacitors).

XCapacitive loads must not be connected to the output phases of the servo am-

plifiers and frequency converters.

XPrevent cable loops. Therefore, the units must only be connected to earth at the

provided PE connection for the mains supply line and the racks only at the pro-

vided earth screw.

SIEB & MEYER products contain electrostatically sensitive

components that may easily be damaged by improper han-

dling.

The valid rules for prevention of accidents (e.g. VBG 1 and

VBG 4) should be paid attention to, when working at current-

carrying units.

Safety Instruction and Application Advice :

12 Safety Instruction and Application Advice

In general, the operation can be made with residual current operated devices. Nev-

ertheless, like all clocked units of the power electronics, also SIEB & MEYER´s prod-

ucts can lead leakage currents via the earth system. Depending on the sensitivity of

the residual current operated device and the installation type, the operation along

with the device may arise problems. The following points should be taken into con-

sideration:

XUse shortest motor leads possible.

XDo not connect additional consumers to the same residual current operated de-

vice.

XUse a residual current operated device with high response threshold for the sep-

arate power supply, e.g. 300 mA.

2.6 Operation

Systems, into which servo amplifiers and frequency converters are mounted, possi-

bly must be equipped with additional protective devices according to the valid safety

instructions (e.g. law about technical material, rules for prevention of accidents,

etc.).

All doors and covers must be closed during the operation.

2.7 Maintenance

The unit, especially the fan, must be checked regularly for cleanness and function

depending on the ambient pollution.

2.8 Disposal

XSIEB & MEYER products fulfill the requirements covered in the Directive

2002/95/EC on the restriction of the use of hazardous substances in electrical

and electronic equipment (RoHS Directive).

Make sure that the country-specific waste and disposal laws and statutes are con-

sidered for the disposal of packing material and irreparable devices.

Warning

In order to ensure a trouble-free operation of the installation, the fix-

ing all front panels and housing parts must always be tightened!

:Safety Instruction and Application Advice

Safety Instruction and Application Advice 13

2.9 Guarantee

The guarantee is only granted when the points 2.1 to 2.7 are taken into consider-

ation.

This Safety Instruction and Application Advice does not assure any features.

Warning

A first programming carried out by SIEB & MEYER does not release

the user from his duty to check programmed values for their correct-

ness!

These safety instructions must be kept!

Safety Instruction and Application Advice :

14 Safety Instruction and Application Advice

:Unit Assembly Complying EMC

EMC 15

3 Unit Assembly Complying EMC

The manual “Unit Assembly Complying EMC“ is available in German and English

and comprises

Xthe EMC guidelines

XInformation regarding the professional grounding and wiring

XSafety-Relevant Aspects

XExtracts from the EMC product standard

XPossibilities for the connection to different supply system types

Availability:

XHard copy version directly from SIEB & MEYER

XPDF file on CD-ROM directly from SIEB & MEYER

XPDF file in the Internet under www.sieb-meyer.de

3.1 Emission of Line and Field Interferences

According to Category C3

According to the EMC product standard DIN EN 61800-3, chapter 6 (emission of line

interferences), this device meets the restrictions towards interference values of the

category C3. More detailed information on the installation and the use of line filters

can be found in the manuals “Unit Assembly Complying EMC“.

Warning

The EC guidelines for the electromagnetic compatibility (EMC) must

be taken into consideration for the initial operation of all SIEB & MEY-

ER units!

Warning

This type of PDS is not intended for use in a public mains which sup-

plies residential areas. If this device is operated in such mains, high-

frequency interferences may occur.

Unit Assembly Complying EMC :

16 EMC

:General Information

CNC 61.00 Hardware Description CNC 0610510/12 17

4 General Information

This manual describes the digital servo amplifier with integrated control functions of

the series CNC 61.00, product line 0610510/12. The following information is provid-

ed:

XSafety Instruction and Application Advice

XUnit assembly complying EMC

XPossible connection possibilities

XTechnical data, dimensional drawings, type plate

XDescription of the device (general information, scope of supply, block diagram)

XMounting (fixing of the back planes, replacement of modules)

XGeneral information regarding the wiring (cables and line cross-sections)

XExternal protection, ballast circuit

XWiring examples

XBack planes and pin assignment

XStatus and error messages

Information for initial operation, parameterization and programming of the CNC

61.00 can be downloaded from our website.

This manual is available in German and English as PDF file on CD ROM and printed

version or it can be downloaded from the Internet. The PDF files can be printed on

standard printers.

This manual has the following demands on the trained staff of machine manufactur-

ers:

Transport →only by skilled employees familiar with

handling electrostatically sensitive

components.

Installation →only by experts with electrotechnical

experience

Initial Operation →only by experts with experience in the

fields of electrical engineering / drive

technology

General Information :

18 Hardware Description CNC 0610510/12 CNC 61.00

:Automation System CNC 61.00

CNC 61.00 Hardware Description CNC 0610510/12 19

5 Automation System CNC 61.00

The CNC 61.00 is a digital control for high-dynamic servo drives. Synchronous and

asynchronous AC servo motors can be driven.

The power and the control components of the CNC 61.00 form a compact unit. The

fields of application are, among others,

Xpositioning applications

Xvariable speed applications

Xtorque control

Xpress functions

Xnut setting functions

Xelectronic shafts

Xelectronic gears

Xdisk cam functions

Apart from the drive functions, the CNC 61.00 provides PLC functions and the pos-

sibility to control dialogs via a control terminal.

The CNC 61.00 can be used independently or can be connected with a higher-rank-

ing control (e.g. PLC, industrial PC, etc.). If several CNC 61.00 modules are net-

worked, they can communicate with each other. Thus, the CNC 61.00 can be used

for applications depending on each other such as electronic shafts, "flying shears",

etc.

Complex control applications can be executed with the CNC 61.00. The large pro-

gram memory permits programming and execution of extensive processes.

The CNC 61.00 of the series 61.05 is only available as compact unit.

5.1 Hardware Design

The CNC 61.00 combines servo and control functions in one module. The hardware

consists of the following components:

Xdigital speed and position controller with a sampling time of 500 :s

Xpowerful output stages for various motor types and performance ranges

Xevaluation of either resolver, Hall effect sensors, incremental encoders or sine/

cosine encoders

Xserial interface with a level according to RS232/485

Xeight galvanically separated inputs and outputs

Xadditional analog input

Xtwo angle pulse inputs and one angle pulse output (also usable for SSI encod-

ers)

XSIEB & MEYER IO interface for further 128 digital inputs/outputs

Xoptional MODLINK interface

Xoptional CAN bus

Xoptional Ethernet interface

Automation System CNC 61.00 :

20 Hardware Description CNC 0610510/12 CNC 61.00

The CNC 61.00 can be expanded by supplementary plug-in modules:

Xtwo analog inputs, 12 bits

Xtwo analog outputs, 12 bits

XINTERBUS interface

XPROFIBUS interface

Xtwo serial interfaces

Xconnection of two active/passive transducers

Xbattery-buffered RAM expansion and real-time clock

Due to the digitization, nearly all parameters can be adjusted via the software.

Possible arising errors are indicated as error code by LEDs on the front panel. Eval-

uated errors are, among others, overvoltage, undervoltage, tracking error, limit

switch and emergency stop.

5.2 Programming

Executable programs (application program) are created with the CNC 61.00 system

software on a PC.

Machine functions are programmed in application programs consisting of command

sequences that specify, for example, movement, PLC functions or reactions to user

inputs. The CNC 61.00 executes programmed commands while the application pro-

gram is running.

The commands have a uniform structure and permit compact programming. The

user will only need some commands due to the sophisticated command repertoire.

For parameterizing nut setting and pressing processes in a comfortable way, special

software interfaces are available.

5.3 Performance Features

Emphasis is put on the following performance features of the SIEB & MEYER auto-

mation system CNC 61.00:

Xsingle-phase power supply for lower motor powers in the 230 VACversion

Xgalvanic separation between control and power components

Xextensive protective functions for motor and CNC module, such as evalu-

ation of the thermal contact, I2t, etc.)

Xoutput for collective fault messages

Xshort circuit-proof (phase to phase, phase to ground)

Xoptimum evaluation of the encoder signals

Xhighly constant running, even at low speeds

Xhigh dynamics

Xself-controlled resolver adaptation and adjustment of up to 1.024 angle

pulses (version with resolver evaluation)

This manual suits for next models

2

Table of contents

Popular Controllers manuals by other brands

Johnson Controls

Johnson Controls SE-ZEC510-1 Installation, operation and maintenance manual

Ropex

Ropex CIRUS UPT-6010 operating instructions

Contemporary Research

Contemporary Research ICC-PSC2 Product View

Brunswick

Brunswick GS-X Pinsetter Operation manual

Azbil

Azbil BH-101G0W0000 Specifications & instructions

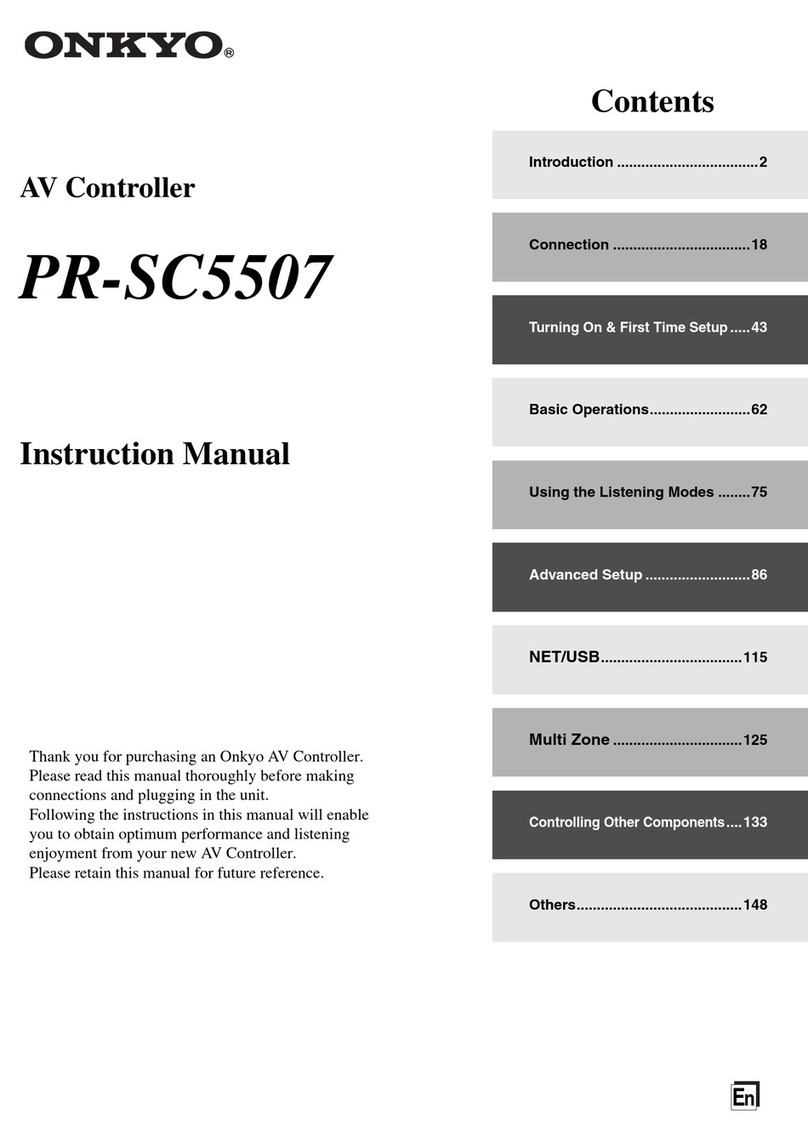

Onkyo

Onkyo PR-SC5507 instruction manual