1Working air port (2)

2Exhaust air port (3)

3Compressed air port (1)

Fig. 5 View from beneath

5.2.2 Product Variants

Characteristic Type code Description

Basic function VEAA Piezo proportional-pressure

regulator

L In-line valveValve type

B Sub-base valve

Valve function 3 3/3-way valve, normally closed

D2 0…2bar

D9 0…6bar

Pressure range

D11 0…10bar

F Flange/sub-basePneumatic connection

Q4 Push-in connector 4mm

V1 Voltage variant 0…10V

V2 Voltage variant 0…5V

Setpoint value input

A4 Current variant 4…20mA

V1 Voltage variant 0…10V

V2 Voltage variant 1…5V

Actual value output

A4 Current variant 4…20mA

Nominal operating voltage 1 24VDC

Electrical connection R1 M8 plug, 4-pin

Tab. 3 Product Variants

6 Transport and storage

– Store the product in a dry, UV- and corrosion-protected environment.

– Ensure short storage times.

7 Mechanical installation

1. Make sure there is sufficient space for the connecting cable and tubing con-

nections.

ÄThis will prevent kinks from forming in the connecting cables and the

tubing.

2. Place the valve as close to the consumer as possible.

ÄThis leads to improved control precision and shorter response times.

Options for mounting the valve:

– Mounting the in-line valve via 3lateral through-holes

– Mounting the in-line valve to H-rails using H-rail mounting VAME-P7-T

è 1.1 Further applicable documents

– Mounting the in-line valve to the mounting plate VAME-P6-Y

è 1.1 Further applicable documents

– Mounting the sub-base valve via 2through-holes using the sub-base

VABM-... è 1.1 Further applicable documents

8 Installation

8.1 Pneumatic Installation (In-line Valve)

1. Attach the tubing to the following connections:

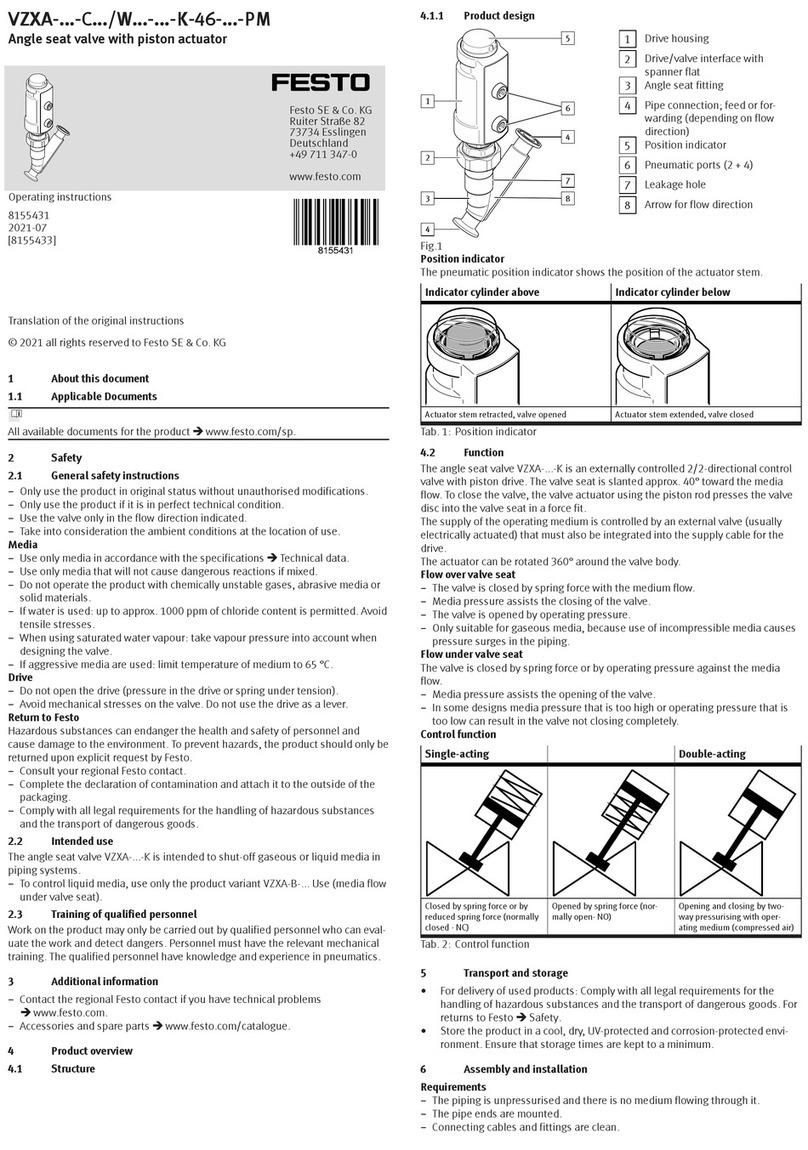

– Compressed air port (1) è Fig.3

– Working air port (2) è Fig.2

2. Fit a silencer at the exhaust port (3) or provide for ducted exhaust air è Fig.3.

–

Operating medium

NOTICE!

Pay attention to compressed air quality.

Damage to property or loss of function from lubricated compressed air.

• Operate product only with unlubricated compressed air.

• Observe the requirements for compressed air quality èTechnical data.

8.2 Electrical Installation

WARNING!

Risk of injury due to electric shock.

• For the electric power supply, use only PELV circuits that ensure a reliable

electric disconnection from the mains network.

• Observe IEC60204-1/EN60204-1.

WARNING!

Risk of Injury due to Electric Shock.

If the housing is damaged (forexample due to cracks), protection against danger-

ous voltage is no longer guaranteed.

• Do not start the device.

• Immediately shut down the device.

1. If a screened cable is used: earth the shield at the cable end farther away

from the valve.

2. Install electrical connecting cable without squeezing, kinking or stretching.

3. Screw electrical connecting cable onto the M8 plug connector. Tightening

torque: maximum 0.3Nm

Connection Pin Allocation Wire colour1)

(NEBU-M8...)

1 + 24V DC BN

2 Setpoint value (+) WH

3 GND BU

4 Actual value (+) BK

1) in accordance with IEC 757

Tab. 4 Pin allocation for plug M8, 4-pin

9 Commissioning

1. Check the operating conditions and limit values èTechnical data.

2. Switch on compressed air supply.

3. Check pneumatic connection points for tightness.

4. Connect valve to a setpoint signal.

5. Switch on operating voltage.

10 Cleaning

1. Switch off the following energy sources to clean the outside:

– Compressed air

– Operating voltage

2. Clean the outside of the product with a soft cloth. Do not use aggressive

cleaning agents.

11 Malfunctions

11.1 Diagnostics

LED

indicator

Status and meaning

LED lights up green:

– The operating voltage is present and within the permissible range.

– No error is present.

– The setpoint signal is in the permissible range (0…10.8V or 2.5…20.5mA).

LED flashes red:

–The operating voltage is above the permissible range (>29V).

LED flashes alternately red and green:

–The setpoint signal is above the permissible range (>10.8V or >20.5mA).

–The setpoint signal is below the permissible range (<2.5mA)

LED is off:

– No operating voltage applied.

–The operating voltage is below the permissible range (<19V).

Tab. 5 LED

11.2 Fault clearance

Fault description Cause Remedy

Operating voltage not applied Check the operating voltage

connection.

No setpoint voltage Check the controller and con-

nection.

Valve does not respond.

No/insufficient compressed air

supply

Check compressed air supply.

Flow rate is too low. Restriction of the flow cross

section due to connection tech-

nology (swivel fittings).

Use alternative connection

technology.