3

Building Technologies A6V10403182_a_en

Fire Safety & Security Products 30.09.2014

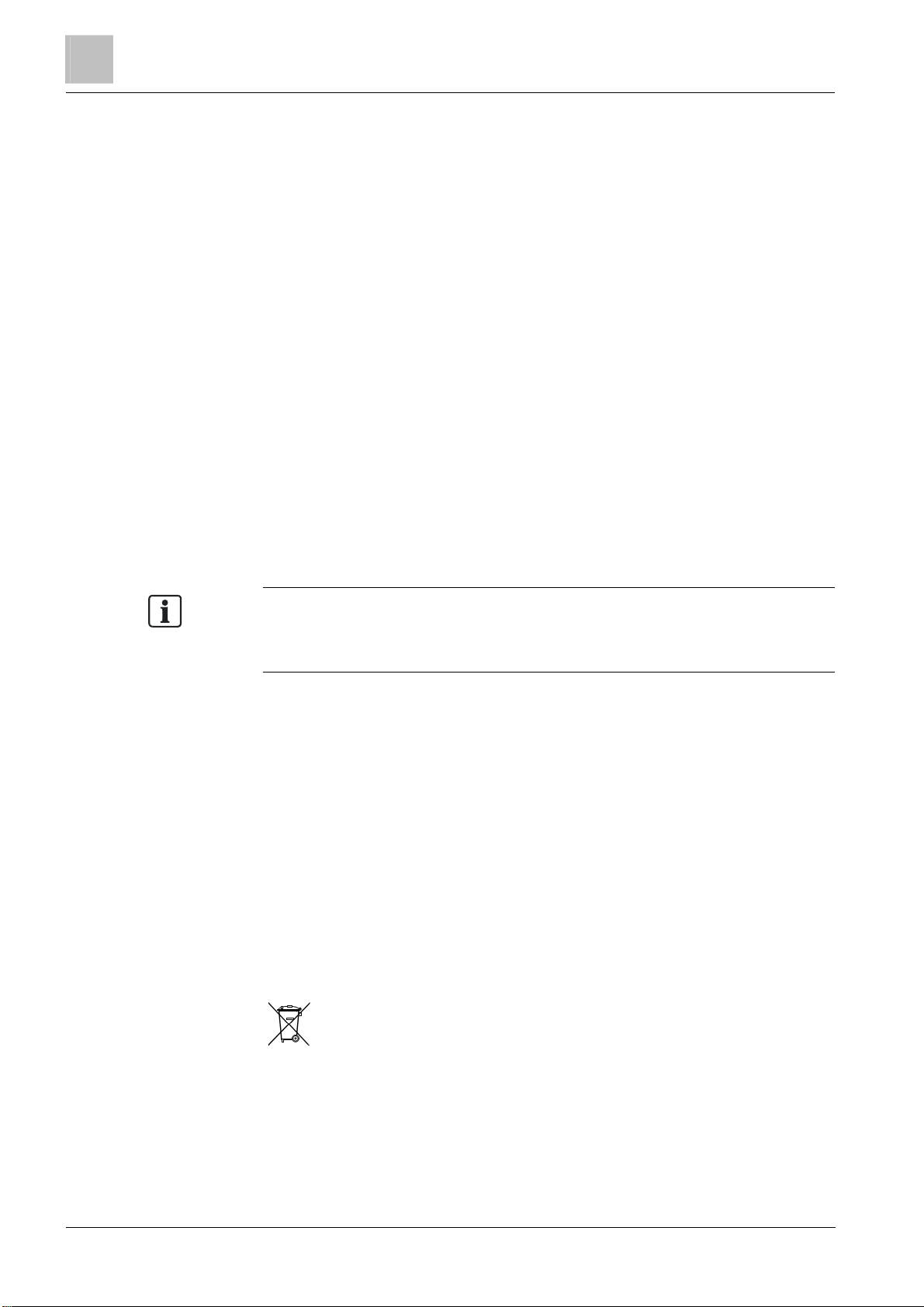

Table of contents

About this document.........................................................................................................5

1Safety regulations..............................................................................................8

1.1Country-specific standards...................................................................................8

1.2Assembly and installation.....................................................................................8

1.3Disposal and recycling .........................................................................................8

1.4Modifications to the system design and the products..........................................9

1.5Data privacy and protection .................................................................................9

2Introduction ......................................................................................................10

2.1Firewall application examples ............................................................................10

2.2What's new.........................................................................................................13

3Structure and functions...................................................................................14

3.1NK8237 hardware ..............................................................................................14

3.1.1Front panel..........................................................................................14

3.1.2Internal DIP switches..........................................................................15

3.1.3Internal jumpers..................................................................................16

3.1.4Ethernet interfaces..............................................................................16

3.1.5USB interface......................................................................................17

3.1.6SD card...............................................................................................17

4Hardware installation.......................................................................................19

4.1NK8237 hardware installation ............................................................................19

5Software installation........................................................................................23

5.1Installation checklist ...........................................................................................23

5.2Composer tool....................................................................................................23

5.3Launching Composer.........................................................................................23

5.4NK823x Web Server...........................................................................................25

5.5NW8202 IP configuration download tool............................................................26

5.5.1NW8202 hardware requirements........................................................26

5.5.2NW8202 software requirements.........................................................27

5.5.3NW8202 installation............................................................................27

5.6NW8204 maintenance and diagnostic tool.........................................................27

5.6.1NW8204 hardware requirements........................................................27

5.6.2NW8204 software requirements.........................................................27

5.6.3NW8204 installation............................................................................27

5.7Secure communication for web services............................................................28

6Configuration....................................................................................................30

6.1Configuration checklist.......................................................................................30

6.2Configuring IP settings via the NK823x Web Server .........................................30

6.3Configuring IP settings via NW8202 ..................................................................31

6.4Creating the NK8237 firewall project..................................................................33

6.5Configuring the Ethernet connections................................................................35

6.6Configuring the firewall.......................................................................................35