SIG 3D MAYHEM ARF User manual

Note:

The large control throws used in 3D flying require a servo

with precise centering capability. The new digital type servos have

outstanding centering characteristics and are highly recommended

for serious 3D flying. You can not expect this airplane to give you

optimum 3D performance using non-ball-bearing standard servos.

SERVO CHORDS NEEDED:

Ailerons - one standard y-harness

and

two 6” or two 12” servo extension chords

(depending upon the length of the pigtail wires on

your particular servos)

Elevator - one 24” servo extension chord

HEAVY-DUTY SERVO ARMS:

Larger than stock size servo arms are needed to achieve the large

3D control throws. We recommend Du-Bro®"Super Strength"

Servo Arms, which are available to fit any brand of servo. They are

very strong and work well with this model.

ENGINE SELECTION:

Engine choices for the 3D MAYHEM are many. The MAYHEM has

been designed to perform well when using the recommended

engine sizes. Do not use an engine larger than recommended.

RECOMMENDED ENGINES:

.72 to .91 cu.in. 2-Stroke

.72 to 1.20 cu.in. 4-Stroke

Very Important: The 3D MAYHEM is designed for slow speed, high

torque aerobatics. It’s fantastic low speed maneuverability is the

result of light weight and very large control surfaces - which are

naturally prone to flutter if flown at excessive airspeeds. To avoid

problems, follow these carefully tested guidelines:

1) Do not use engines larger than recommended. Resist the

urge to overpower your 3D MAYHEM with larger engines, which

can cause balance and structural problems, and produce

excessive airspeed.

2) Do not use a propeller with more than 6 inch pitch. Keep the

airspeed of the MAYHEM down by using low pitch propellers.

3) Do not fly full throttle except during climbs of at least 10

degrees. Always throttle back when in a dive.

Ignoring these cautions will put your model at high risk for

catastrophic in-flight structural failure.

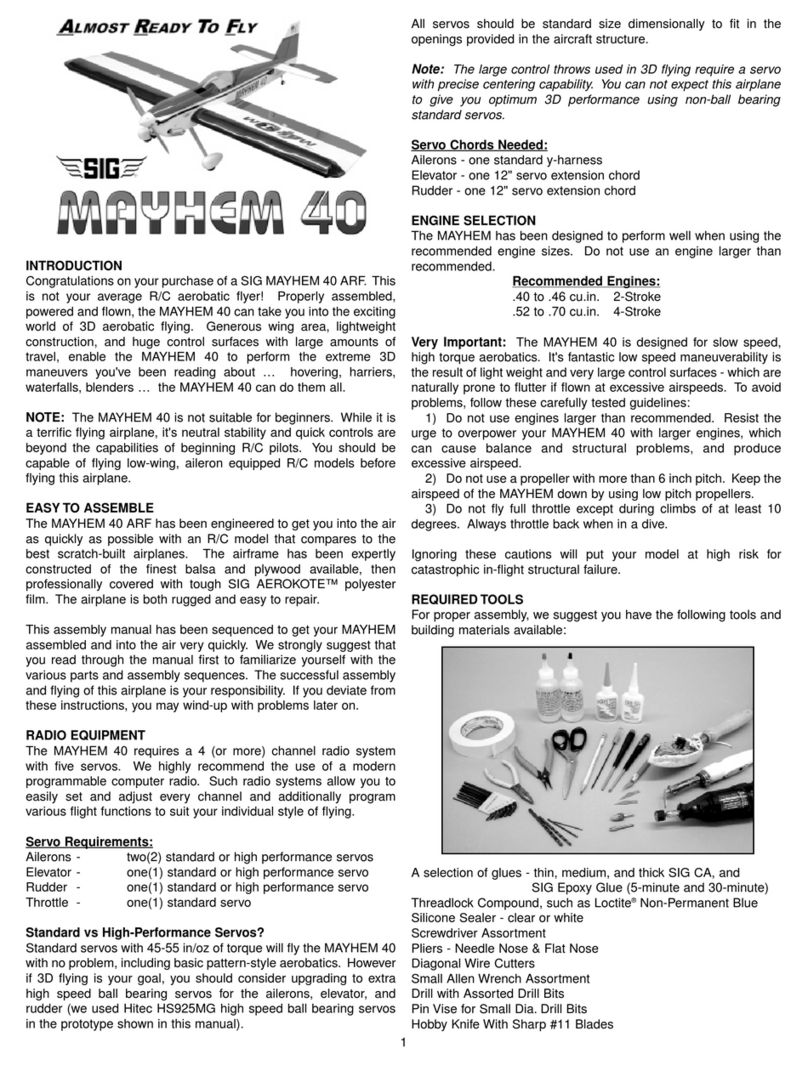

REQUIRED TOOLS:

For proper assembly, we suggest you have the following tools and

building materials available:

A selection of glues - thin, medium, and thick SIG CA, and

SIG Epoxy Glue (5-minute and 30-minute)

R

1

3D MAYHEM ARF ASSEMBLY MANUAL

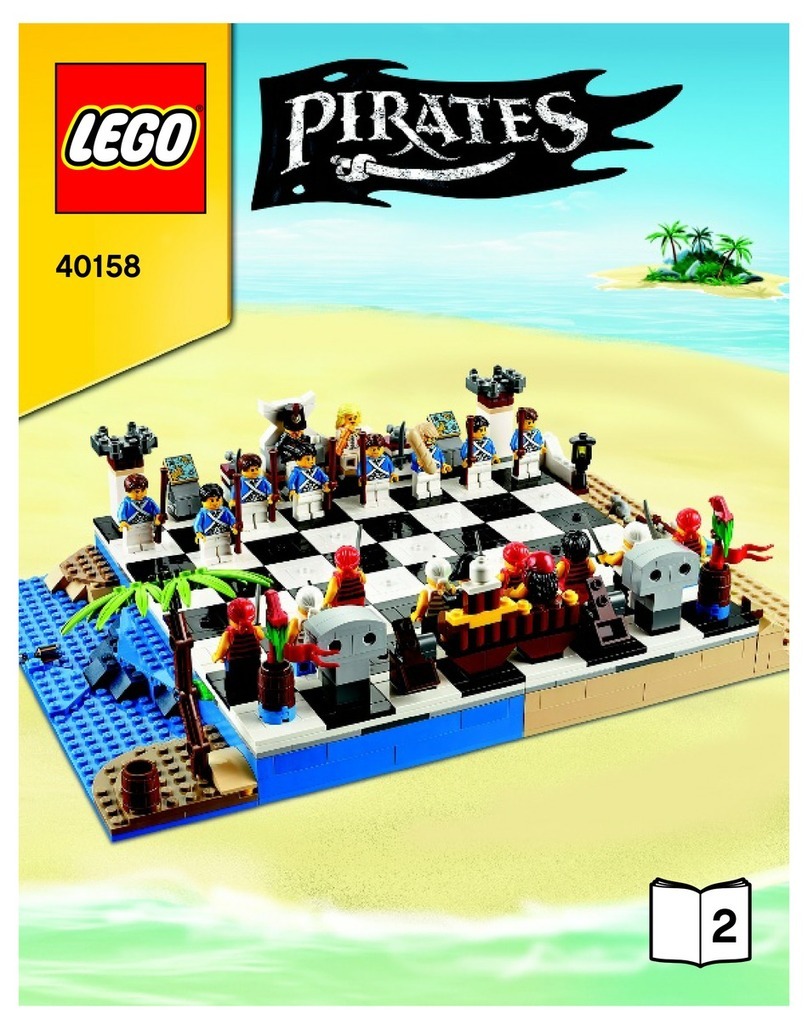

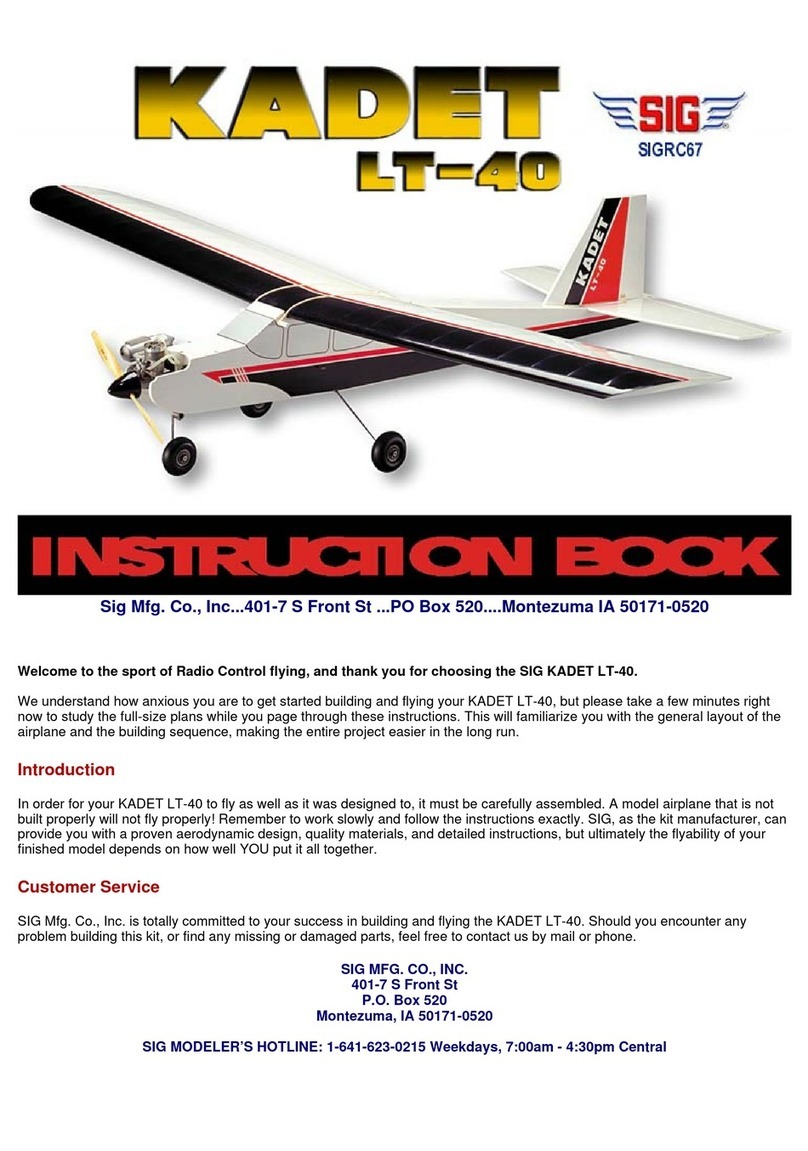

INTRODUCTION:

Congratulations on your purchase of a SIG 3D MAYHEM ARF.

This is not your average R/C aerobatic flyer! Properly assembled,

powered and flown, the 3D MAYHEM can take you into the

exciting world of 3D aerobatic flying. Generous wing area,

lightweight construction, and huge control surfaces with large

amounts of travel, enable the 3D MAYHEM to perform the extreme

3D maneuvers you've been reading about…hovering, harriers,

waterfalls, blenders…the 3D MAYHEM can do them all.

NOTE: The 3D MAYHEM is not suitable for beginners. While it is

a terrific flying airplane, it's neutral stability and quick controls are

beyond the capabilities of beginning R/C pilots. You should be

capable of flying low-wing, aileron equipped R/C models before

flying this airplane.

EASY TO ASSEMBLE:

The 3D MAYHEM ARF has been engineered to get you into the

air as quickly as possible with an R/C model that compares to the

best scratch-built airplanes. The airframe has been expertly

constructed of the finest balsa and plywood available, then

professionally covered with tough Oracover®polyester film. The

airplane is both rugged and easy to repair.

This assembly manual has been sequenced to get your MAYHEM

assembled and into the air very quickly. We strongly suggest that

you read through the manual first to familiarize yourself with the

various parts and assembly sequences. The successful assembly

and flying of this airplane is your responsibility. If you deviate from

these instructions, you may wind-up with problems later on.

RADIO EQUIPMENT:

We highly recommend the use of a modern programmable

computer radio. Such radio systems allow you to easily set and

adjust every channel and additionally program various flight

functions to suit your individual style of flying.

The 3D MAYHEM requires a 4 (or more) channel radio system with

five servos.

SERVO REQUIREMENTS:

Ailerons - two (2) ball bearing servos with 70+ in/oz of torque

Elevator - one (1) ball bearing servo with 70+ in/oz of torque

Rudder - one (1) ball bearing servo with 90+ in/oz of torque

Throttle - one (1) standard servo

All servos are standard size dimensionally.

Threadlock Compound, such as Loctite®Non-Permanent Blue

Silicone Sealer - clear or white

Screwdriver Assortment

Pliers - Needle Nose & Flat Nose

Diagonal Wire Cutters

Small Allen Wrench Assortment

Drill with Assorted Drill Bits

Pin Vise for Small Dia. Drill Bits

Hobby Knife With Sharp #11 Blades

Scissors

Covering Iron and Trim Seal Tool

Masking Tape

Paper Towels

Power Drill With Selection of Bits

Dremel®Tool with Selection of Sanding and Grinding Bits

Soldering Iron and Solder

Large Fuel Tubing

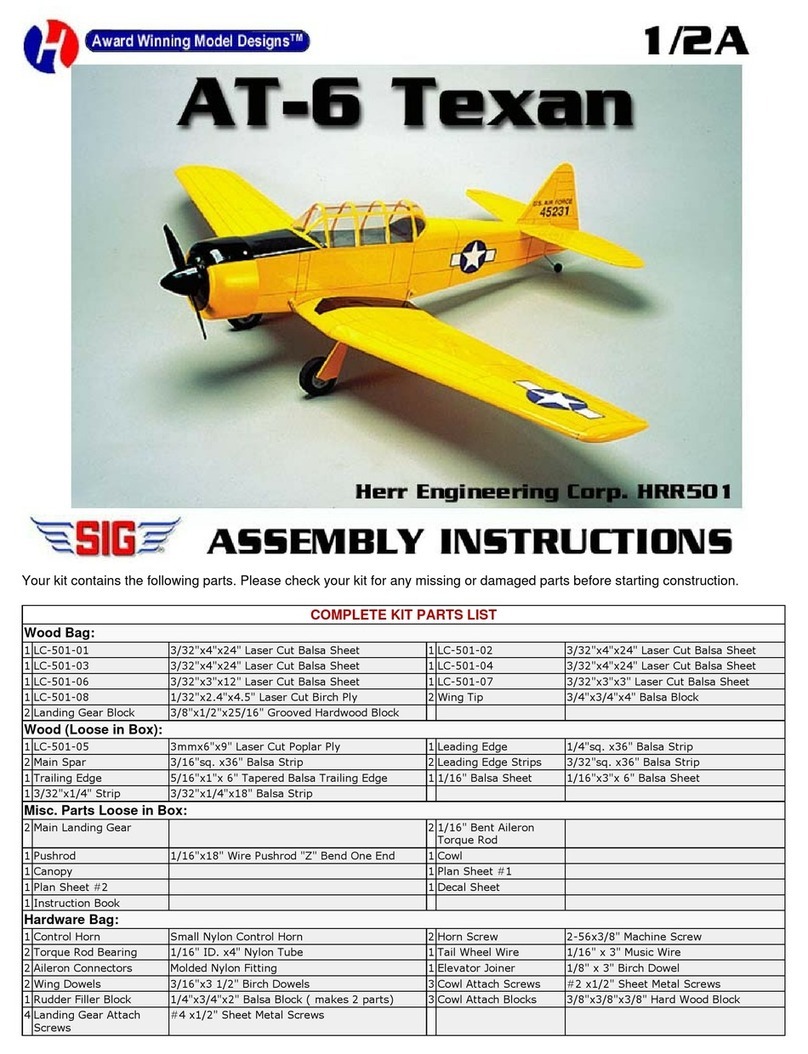

KIT CONTENTS INVENTORY:

The following is a complete list of all parts contained in this kit.

Before beginning assembly, we suggest that you take the time to

inventory the parts in your kit, using the check-off boxes (❑)

provided. Note that the CA type hinges for the ailerons, rudder,

and elevators are in place in each of these parts but are not yet

glued in place. Also, note that the nuts and bolts required to mount

your engine to the motor mounts are not included in this kit and

must be purchased separately.

Note: The “PWA” designation for some of the bolts and screws in

the following list means it has a “Phillips Washer Head”.

BASIC AIRCRAFT PARTS (covered with Oracover ):

1 bag ❑(1) Right Wing Panel & Right Aileron, with

❑(6) CA Hinges installed but not glued

1 bag ❑(1) Left Wing Panel & Left Aileron, with

❑(6) CA Hinges installed but not glued

1 bag ❑(1) Fin & Rudder Set, with

❑(3) CA Hinges installed but not glued

1 bag ❑(1) Stabilizer & Elevator Set, with

❑(6) CA Hinges installed but not glued

1 bag ❑(1) Fuselage, with

❑(1) Clear Plastic Canopy installed

❑(4) M2 x 8mm PWA Mounting Screws, for canopy

❑(2) 1/4-20 Blind Nuts installed, for wing attachment

❑(3) M4 Blind Nuts installed, for l.g. attachment

❑(1) Plastic Antenna Tube installed

1 bag ❑(1) Fuselage Bottom Fairing

OTHER PARTS:

1 bag ❑(1) Fiberglass Cowling, white

❑(4) M2.6 x 10mm PWA Mounting Screws

1 bag ❑(1) Right Fiberglass Wheel Pant, white

❑(1) Left Fiberglass Wheel Pant, white

1 bag Main Landing Gear Parts:

❑(1) Aluminum Landing Gear

❑(3) M4 x 15mm PWA Mounting Bolts

❑(2) M4 x 34mm PWA Axle Bolts

❑(2) M4 Lock Nuts

❑(4) M4 Hex Nuts

❑(2) 2-3/4" dia. Main Wheels

❑(4) M3 x 10mm PWA Mounting Bolts, for wheel pants

❑(4) M3 Split Lock Washers, for wheel pants

1 bag Tailwheel Assembly:

❑(1) Leaf-Spring with Steering Arm, Yoke, & Tailwheel

❑(3) 3mm x 10mm PWA Mounting Screws

❑(2) Coil Steering Springs

❑(1) Metal Rudder T-Horn

❑(2) 2mm x 9mm PWA Mounting Screws, for T-Horn

1 bag Fuel Tank Assembly:

❑(1) 450cc (15.2 oz.) Plastic Tank

❑(1) Rubber Stopper

❑(1) Metal Front Clamp

❑(1) Metal Rear Clamp

❑(1) M3 x 18mm Clamp Bolt

❑(1) Metal Clunk Pickup

❑(1) Fuel Pickup Tubing, for inside tank

❑(1) 3mm od x 40mm long Aluminum Tube

❑(1) 3mm od x 47mm long Aluminum Tube

❑(1) 3mm od x 60mm long Aluminum Tube

❑(1) .093" id x .195" od x 9" Fuel Tubing

❑(1) .093" id x .195" od x 9" Fuel Tubing

1 bag 2-3/4" Dia.White Spinner Assembly:

❑(1) Plastic Spinner Cone

❑(1) Plastic Spinner Backplate

❑(1) Plastic Prop Shaft Adapters

❑(4) Screws

1 bag ❑(2) Glassed-Filled Engine Mounts

❑(4) M4 x 25mm PWA Mounting Bolts

❑(4) M4 Blind Nuts

❑(4) M4 Flat Metal Washers

❑(4) M4 Split Lock Washers

1 bag Throttle Pushrod Assembly:

❑(1) 1/8”od x 15-3/4”Plastic Pushrod Tube

❑(1) 3/16”od x 13-3/4”Plastic Pushrod Sleeve

❑(1) Threaded Stud with Metal R/C Link, for servo end

❑(1) Threaded Stud with Nylon R/C Link, for eng. end

❑(2) Laser-Cut Plywood Pushrod Supports

1 bag Aileron & Elevator Pushrods:

❑(3) 4-40 x 3”Threaded Pushrods

❑(6) 4-40 Metal R/C Links

❑(6) 4-40 Hex Nuts

❑(6) Spring Keepers

1 bag Misc. Control System Parts:

❑(2) .023" dia. Steel Cables,

for pull-pull rudder linkage

❑(4) Rigging Couplers w/ R/C Link & Knurled Stop Nut,

for pull-pull rudder linkage

❑(4) 2mm od x 4mm Metal Tubes,

for pull-pull rudder linkage

❑(3) Right Control Horns,

for elevator(1), aileron(1), rudder(1)

❑(2) Left Control Horns,

for aileron(1), rudder(1)

❑(12) 2.6mm x 10mm Mounting Screws,

for aileron & elevator control horns

❑(4) M2.5 x 14mm Mounting Bolts,

for rudder control horns

❑(4) M2 Hex Nuts, for rudder control horns

❑(4) M2.5 Split Lock Washers,

for rudder control horns

1 bag Misc. Parts:

❑(1) Hardwood Front Wing Joiner

❑(2) 1/4-20 x 2" Nylon Wing Bolts

❑(2) Fiberglass Wing Bolt Guides

❑(1) Plywood Wing Bolt Plate

❑(1) 3/8" x 1/2" x 4" Balsa Stick,

for fuel tank rear support

MISCELLANEOUS:

❑1 EACH #SIGDKM279 3D MAYHEM Decal Sheet

❑1 EACH #SIGIB279 3D MAYHEM Assembly Manual

2

®

3

COVERING MATERIAL:

Your 3D MAYHEM ARF has been professionally covered with

premium Oracover®polyester film covering. The Oracover®colors

are #10 White, #23 Red, #52 Blue, and #71 Black. (Note: In the

United States, Oracover®is sold under the name of Hangar 9

Ultracoat®. The equivalent Ultracoat®colors are called #870 White,

#866 True Red, #885 Midnight Blue, and #874 Black).

You may notice that some wrinkles might develop in the covering

after removing the parts from their plastic bags. If that is the case,

there is no need to be alarmed. This is perfectly normal in low

humidity climates. Your model was built and covered in a part of

the world with relatively high humidity and therefore the wood was

likely carrying a fair amount of moisture. When exposed to drier air,

the wood typically loses this moisture, dimensionally "shrinking"

slightly in the process. In turn, this causes the wrinkles.

Any wrinkles that appear in the covering are easy to remove by

using a hobby-type heat iron. We suggest covering the iron's

shoe with a thin cotton cloth, such as an old T-shirt, to prevent

scratching the film. The iron should be set to about 280O- 300OF.

First, use the heated iron to go over all the seams and color joints

in the covering, making they are all sealed down and well adhered.

Then use the heated iron to lightly shrink the material - do not

press on it. Once the covering is tight, lightly iron the material back

down to the wood. You can also use a hobby-type heat gun to

re-shrink the covering, but you must be extra careful around the

seams. Re-heating seams may cause them to "creep", making

them unsightly.

MODELER’STIP: One of the most common problems associated

with shrinking any covering film is controlling the heat around

seams. Heat applied close to or directly onto seams reheats the

covering adhesive and the seam will often "crawl". This is easy to

control. Just tear a few paper towels into strips and soak them in

cool tap water. Lay the wet strips over any covering seam and use

your heat gun or iron as you normally would. The wet strips keep

the seam cool while the covering immediately next to it shrinks.

WARPS!

Light weight is a key ingrediant in the 3D MAYHEM’S flight profile.

Because of their light weight construction, the ailerons, elevators,

and rudder of the MAYHEM can become warped whenever the

covering material is heated for shrinking. Care must be used to

make sure that the control surfaces remain straight as the covering

cools. Avoid putting a twist in the part while taking out wrinkles.

If you find a warp in one of your parts, the warp can almost always

be removed by twisting the surface in the opposite direction and

holding it there while heat is applied to the covering material. After

the covering cools, release the control surface and recheck for the

warp. The amount of reverse twist and heat that you apply, will

determine where the control surface ends up after it cools.

Note: When trying to remove a warp, an extra set of hands are

needed. Have someone assist you. While one person holds the

reverse twist in the control surface, the other person applies the

heat by passing a covering iron over both sides of the part.

WING ASSEMBLY - OVERVIEW:

The wing of the MAYHEM comes in two pieces, a right wing panel

and a left wing panel, which will be permanently glued together to

make a strong one-piece wing.

For precise control of the ailerons, there is one aileron servo

mounted in each wing panel.

As received in the kit, the wing panels have the ailerons in place

but not yet permanently hinged. Hinging the ailerons will be done

later. For now, remove the ailerons from the wing panels and pull

out all the CA hinges and set them aside until called for.

To avoid unnecessary dents, dings, or scuffing of the airplane

parts, we suggest that you cover your workbench with a soft

household blanket or foam sheet while assemblying your model.

WING ASSEMBLY, PART I: Installing the aileron servos

For the following steps you will need these parts:

•1 - Right Wing Panel

•1 - Left Wing Panel

•2 - Aileron Servos (not supplied)

•2 - 6”or 12”Servo Extension Chords (not supplied)

[actual length you need depends upon the length of the

pigtail wires on your particular servo.For the Hitec®servos

shown in the pictures, we used 6”extension chords.]

•1 - ServoY-Harness Chord (not supplied)

❑1) Before installing the aileron servos in the wing, you must

attach a servo extension chord onto the end of the aileron servo

wire. The combined length required is approximately 21”.A6”or

12”extension chord will usually provide sufficient length. Plug the

extension chord onto the servo wire and secure well with tape.

Also, install the mounting grommets and eyelets onto the servo as

described in the instructions that came with your servos.

❑2) Inside the aileron servo bay opening, you will find a short

length of wood with a string tied to it. The string will be used to pull

the aileron servo wire through the wing panel to the center of the

wing. Gently break the wood piece loose from the wing structure,

and pull it and the string a few inches out of the servo bay

opening. Remove the wood from the string and disgard it. Tie the

end of the string securely to the end of the servo wire, as shown.

❑3) On the top of each wing panel, just inboard of the center

wing rib, you will find another opening. This is the exit hole for the

aileron servo wire. Inside this opening you will see another piece

of wood with a string tied to it. This is the other end of the string in

the aileron servo bay. Break the wood piece loose and carefully

pull the string and servo wire through the wing until the servo wire

emerges from the opening in the top of the wing.

Note: You may occasionally feel like the wire has become stuck

inside the wing. This is simply the plug on the end of the servo wire

4

hitting the side of the holes in the wing ribs. Gently work the string

back and forth from both ends until the plug fits through the hole.

Sometimes the servo plug comes through all the ribs the first time

without getting hung up, and other times it seems like it gets hung

up on every rib. Be patient and don’t try to force it. The holes in

the ribs are large enough to get any common servo plug through.

Sometimes it helps to hold the wing panel vertically (center end

down) and shake it slightly while pulling lightly on the string.

❑4) After you get the end of the servo wire all the way through

the wing, tape the loose end of the wire to the wing's top surface,

so that it won't fall back inside the wing.

❑5) Fit the servo into the plywood servo mount that is built into

the wing panel. Note that the servo should be positioned so that

its output arm is at the rear end, toward the trailing edge of the

wing. Take up any slack in the servo wire as you insert the servo

by pulling on the end of the cable where it exits the top of the wing.

Use a small drill bit to drill small pilot holes in the servo mount for

the servo mounting screws. Use the screws supplied with your

radio system to mount the servo securely in place on the servo

mount. Repeat this proceedure to mount the servo in the opposite

wing panel.

WING ASSEMBLY, PART II: Joining the wing panels:

For the following steps you will need these parts:

•1 - Right Wing Panel

•1 - Left Wing Panel

•1 - Hardwood Wing Joiner

❑1) Trial fit both wing panels onto the Hardwood Wing Joiner.

Check to see that the wing panels fit together in proper alignment,

and that both root ribs come into firm contact with each other. If

the Hardwood Wing Joiner requires a little trimming to achieve this

fit, do so now. When satisfied with the fit, take back apart.

❑2) Use Sig slow drying epoxy glue to permanently join the two

wing panels together. Apply the glue generously to the end ribs,

Work some glue into the joiner slots, and coat the joiner itself.

Carefully slide the wing panels together on the joiner. Press them

together tight. Wipe away any excess epoxy that oozes from the

joint with a paper towel or a rag dampened with rubbing alcohol.

Be careful that the leading and trailing edges of the two wing

panels are perfectly aligned and that there is no built in twist.

Secure the joint in perfect alignment with tape until the glue dries.

NOTE: It's very important to use plenty of epoxy when gluing the

wing panels together. The strength of your wing joint depends on

it! Don't worry if the excess glue oozes out and gets on the

covering material. With slow-drying epoxy, you will have plenty of

5

to clean up all the glue smears with a paper towel soaked in

rubbing alcohol. Also, if possible get someone to help you with this

proceedure. An extra set of hands makes the job much easier!

While one person is holding the wing panes tightly together, the

other person can wipe off the excess glue.

WING ASSEMBLY, PART III: Hinging the ailerons:

For the following steps you will need these parts:

•The wing assembly

•1 - Right Aileron

•1 - Left Aileron

•12 - CA Hinges (6 per aileron)

❑1) Start by reinserting the CA Hinges back into the six slots in

the trailing edge of the wing panel. Slide the hinges HALFWAY into

each hinge slot. DO NOT GLUE THE HINGES AT THIS TIME!

❑2) Now reinstall the aileron onto the exposed half of the hinges.

It's easiest to slip the aileron onto the hinges at angle, one hinge

at a time, instead of trying to push it straight onto all the hinges at

once. Start at the wingtip, inserting the end hinge into the end slot

in the aileron. Once you have that hinge started, move to the next

hinge and get it started into its slot. Move on down the line until

you have all six hinges started. Then you can finish

pushing the aileron up against the back of the wing. Don't be

overly concerned if the hinges don't end up perfectly straight or

perfectly centered in the slots - approximately halfway is good

enough. AGAIN, DO NOT GLUE THE HINGES IN AT THIS TIME!

❑3) To set the proper amount of gap between the aileron and the

wing, simply deflect the aileron to the maximum amount of travel

needed. This will automatically set the proper hinge gap! Keep in

mind that for best control response the gap should be kept as small

as possible, but big enough to allow full movement of the control

surface. Make sure everything is functioning properly before pro-

ceeding to the next step.

❑4) Flex the aileron downward, exposing the hinges between the

wing and aileron. Carefully place 3-4 drops of Thin CA glue

directly onto each hinge in the gap. You will notice that the glue is

quickly wicked into the slot as it penetrates both the wood and the

hinge. Turn the part over and apply 3-4 drops of glue to the other

side of each hinge. Keep a rag handy to wipe off any excess glue.

Note: For CA hinges, we always recommend using a fine-tip

applicator on your CA glue bottle, to better control the flow. Also,

if you get some glue smears on the plastic covering, don't worry

about them right now. Once the glue has had a chance to dry, you

can clean the glue smears off the covering with CA Debonder.

❑5) Allow at least 10 minutes before flexing the aileron. After suf-

ficient time has passed, flex the aileron up and down several times.

At first you might notice a little stiffness in the joint. This will go

away after the hinges have been flexed back and forth a few times.

Also, pull on the aileron at each hinge location to make sure all the

hinges are securely in place. Repeat this process to attach the

other aileron to the other wing.

WARNING: The CA hinges provided in this kit are made of a

special absorbant material that can only be glued with Thin CA

adhesive. Thin CA (any brand) is the ONLY type of glue that can

be used on these hinges - do not use epoxy or any other type of

glue! Also, never use CA Accelerator on CA Hinges!

It's critical that you only make one application of glue to each side

of a CA Hinge! If you apply additional glue after the first

application of glue is dry, the second application of glue will

merely puddle in the hinge gap and make the hinge too stiff to

operate. The excess glue could also weaken the hinge! When

properly glued, the part of the hinge that you can see in the hinge

gap should have a dry appearance, not wet. A dry appearance

indicates that almost all of the glue has properly soaked into the

hinge slot. A wet appearance indicates that excess glue is

puddled in the hinge gap. Three to four drops of Thin CA is the

right amount.

WING ASSEMBLY, PART IV:

Install Control Horns & Pushrods:

For the following steps you will need these parts:

•The wing assembly

•2 - 4-40 x 3”Threaded Pushrods

•4 - 4-40 Metal R/C Links

•4 - 4-40 Hex Nuts

•4 - Spring Keepers

•1 - Right Control Horn

•1 - Left Control Horn

•8 - 2.6mm x 10mm Mounting Screws

•2 - Aileron Servos (not supplied)

•2 - Heavy-Duty Servo Arms (not supplied)

❑1) Install heavy-duty servo output arms on the aileron servos.

For 3D flying, the servo arms should be at least 3/4”long to

provide full control surface travel. Install the arms on the servos

with the arms pointing towards the wing tips, not towards the

fuselage. Also make sure the arms are 90Oto the servo when the

transmitter’s aileron control stick and trim lever are both in neutral.

❑4) Each aileron pushrod consists of aThreaded Rod with a Hex

Nut, a R/C Link, and a Spring Keeper on each end.

Clip one end of the pushrod into the end hole of the servo arm.

Clip the other end of the pushrod into the middle hole of the

control horn. Adjust the overall length of the pushrod by screwing

the R/C links in or out as needed to get the aileron in neutral

position when the servo is in neutral position.

Because of the thickness of the MAYHEM airfoil, it is not easy to

determine exactly when the aileron is in neutral position. For this

reason we have supplied an Aileron Positioning Guide (APG). Cut

out the APG and use it to hold the aileron in true neutral position

when making your pushrod length adjustments.

❑5) Once you have the pushrod length properly adjusted, slide

the spring keepers up onto the R/C links, and then screw the hex

nuts up tight against the end of the R/C links. Put a drop of

Locktite®thread locking compound, or CA glue, on the hex nuts to

keep them from coming loose.

WING ASSEMBLY, PART V: Fitting the Wing to the Fuselage:

For the following steps you will need these parts:

•The wing assembly

•1 - Fuselage

•1 - Plywood Wing Bolt Plate

•2 - 1/4-20 x 2”Nylon Wing Bolts

•2 - Fiberglass Wing Bolt Guides

•1 - Fuselage Bottom Fairing

❑1) Trial fit the wing in place on the fuselage, using the two 1/4-

20 x 2”nylon bolts provided. The nylon wing bolts should pass

freely thru the holes near the trailing edge of the wing and thread

into the blind nuts that are pre-installed in the fuselage. Do not

overtighten the bolts - just snug them up enough to hold the wing

in place for the next step.

Note: If you have any difficulty mounting the wing to the fuselage,

find the cause of any binding now, and fix it before proceeding.

❑2) We need to draw guidelines on the ailerons to show where to

mount the control horns.

a. First draw a line paralell to the aileron hinge line, right at

the back edge of the aileron leading edge. Note: If you reflect light

off the aileron covering, you can clearly see the back edge of the

aileron leading edge. This piece is balsa wood. Right behind this

leading edge balsa is a piece of hardwood approximately 9/16”

wide. This hardwood piece is where the aileron control horn will be

mounted in the next step.

b. Use a straight edge to draw a second line on the aileron

which lines up with the last hole in the aileron servo arm. This line

should be 90Oto the leading edge of the aileron.

❑3) a. Locate the proper metal control horn for the aileron you

are working on (choose a control horn whose base will point the

same direction as the servo arm). Also locate four M2.6 x 10mm

Mounting Screws.

b. Set the control horn in place on the bottom of the aileron.

The front of the base of the control horn should be lined up with

line 2a, while the upright arm of the horn should be lined up with

line 2b. Once you have the horn properly located, mark the

location of the four control horn mounting holes onto the aileron.

c. Drill a 3/64”dia. (or #56 drill) pilot hole into the aileron at

each mark. Do not drill completely through the aileron! Mount the

control horn in place using the M2.6 x 10mm Mounting Screws.

d. Repeat this process to mount a control horn on the other

aileron.

6

IMPORTANT: After you finish mounting the control horns on

the ailerons for the first time, take them back off and set them

aside temporarily. Then put a few drops of Thin CA into each

of the screw holes in the aileron. The Thin CA will soak into

the threads in the wood, and when it dries the holding power

of the threads will be much stronger. Use Thin CA only, not

medium or thick CA. Let the Thin CA dry completely before

remounting the control horns onto the ailerons.

❑5) Now permanently glue the fuselage bottom fairing onto the

bottom of the wing with thick CA glue or epoxy. Let dry.

❑6) a. Bolt the wing back in place on the fuselage. Locate the

two Fiberglass Wing Bolt Guides and fit them into the wing bolt

holes in the bottom fairing. The guides should slip into the holes

and go all the way down against the surface of the wing and

around the head of the wing bolt. If the holes in the bottom fairing

are too small, enlarge them slightly until the guides slide in - but not

too much, you want a snug fit!

b. Once you have the wing bolt guides fitted in place, use a

little thin CA glue to adhere them to the bottom fairing. Let dry.

c. Use a sharp hobby knife to trim the excess wing bolt

guide off flush with the bottom fairing. Don’t try to take it all off with

one deep cut - cut off small pieces at a time. By working slowly and

carefully, you can get it trimmed off without gouging or cutting into

the bottom fairing.

d. With the wing removed from the fuselage, and the wing

bolts removed from the wing, put a few drops of thin CA glue in the

bottom of the wing bolt guides to bond them to the surface of the

wing. Don’t use too much.

7

❑2) Set the fuselage bottom fairing in place on the bottom of the

wing. Align it with the fuselage. Use a felt-tip pen to mark the

location of the bottom fairing on the wing surface. Mark both sides.

Then remove the fairing and wing from the fuselage.

❑3) Remove the covering material from the bottom of the wing

between the marked lines. Start by using a sharp hobby knife to

cut through the covering material along the marked lines. Be very

careful to cut the covering material only - not the balsa wood

structure underneath! Once you’ve cut through the covering

material, peel the unwanted covering off the wing.

❑4) Glue the plywood wing bolt plate in place on the bottom of

the wing, carefully aligning the two 1/4”holes in the plate with the

holes in the wing before the glue dries. Make sure there is no

excess glue inside the holes. If necessary, run a 1/4”dia. drill bit

through the holes after the glue is completely dry.

❑2) Bolt the engine mounts in place on the front of the firewall

using the M4 Mounting Bolts, Washers, and Blind Nuts provided.

The blind nuts go on the back of the firewall, inside the fuselage

(see building tip below). As you tighten the bolts the first time, the

prongs of the blind nuts will sink into the back of the firewall,

holding the blind nuts in place. After all the blind nuts are installed,

apply a little glue on the flanges of the blind nuts inside the

fuselage, to keep the blind nuts from ever coming loose. Be

careful not to get any glue in the threads of the blind nuts.

❑3) a. Move your engine forward or backward on the engine

mounts until you measure exactly 5-3/4" from the front face of the

prop drive washer to the front of the firewall. This is the distance

your engine needs to be from the firewall for proper cowl alignment

and prop clearance purposes. Accurately mark the engine's

mounting bolt hole locations onto the engine mounts. Then set the

engine aside.

b. Drill the four engine mounting holes completely through

the mounts. Be very careful to drill them perpendicular to the

mount. Use a drill press if available.

c. Mount your engine in place on the engine mounts. We

suggest using a little thread locking compound (Loctite®) on the

mounting bolts to keep them from coming loose.

Note: This kit DOES NOT contain bolts for mounting your engine

to the engine mounts. That’s because not all .72-1.20 size engines

use the same size. Some engines may need 8-32 size bolts, while

others may need 10-32. You will need to go to the hobby shop to

obtain the correct size mounting bolts for your engine.

FUSELAGE ASSEMBLY, PART I: Engine Mounting:

For the following steps you will need these parts:

•1 - Fuselage

•2 - Glassed-Filled Engine Mounts *

•4 - M4 x 25mm PWA Mounting Bolts

•4 - M4 Blind Nuts

•4 - M4 Flat Metal Washers

•4 - M4 Split Lock Washers

•Engine and suitable Mounting Bolts (not supplied)

* SAFETY: Size Limit on Glass-Filled Engine Mounts!

The glass-filled engine mounts provided in this kit are intended for

glow engines up to 1.20 cu.in., either 2-stroke or 4-stroke. Using

these mounts with larger engines is not recommended. Larger

engines should use an aluminum engine mount (not furnished).

❑1) Note that the horizontal and vertical thrust lines are scribed

into the front of the firewall. Also notice that the vertical thrust line

is slightly off center. This is to compensate for the 2Oright thrust

that is already built into the fuselage.

a. Draw two parallel vertical lines exactly 1-1/16”on each

side of the vertical thrust line.

b. Draw two parallel horizontal lines exactly 1-13/64”on

each side of the horizontal thrust line. (1-13/64”is just a thin

pencil line bigger than 1-3/16”)

c. The intersections of these four lines indicate where the

Blind Nuts need to be installed for the Engine Mounts. Use a 1/4"

dia. bit to drill four holes in the firewall for the M4 Blind Nuts.

NOTE: The 2-1/8”total vertical spacing between the blind nuts,

along with the slotted holes in the engine mounts, should allow the

engine mounts to accomodate any engine that has a crankcase

width between 1-9/16”to 2-1/8”. That should cover most engines

that will be used in the Mayhem. If the width of your engine’s

crankcase is less than 1-9/16”, or more than 2-1/8”, you will have

to plan accordingly and adjust the dimension in step 1a above.

8

BuildingTip: Inserting the blind nuts into the holes in the back

of the firewall, working through the belly of the fuselage, can be

a difficult job if you have big hands. A short stick and a little

piece of masking tape can make the job a lot easier. Simply

double back the tape and use it to hold

the blind nut on the end of the stick as

shown (a 1/4”sq.balsa stick is being use

in these pictures). This “handle” makes

it easy to insert and hold the blind nut in

the hole while you thread the mounting

bolt in from the front.

❑3) The entire main landing gear assembly is now mounted onto

the bottom of the fuselage using the three M4 x 15mm PWA

Mounting Bolts provided. Be sure to put a drop of thread locking

compound, such as Locktite®, on the threads of the bolts before

screwing them in.

FUSELAGE ASSEMBLY, PART III: Cowling and Spinner:

For the following steps you will need these parts:

•The fuselage assembly

•1 - Fiberglass Cowling

•4 - M2.6 x 10mm PWA Mounting Screws

•1 - 2-3/4”Spinner Assembly*

* The plastic spinner assembly included in this kit should work fine in most

cases. However with the Saito .91 engine and APC prop combination

shown in our photo model, we decided to use an aftermarket aluminum

spinner. The Saito's crankshaft was not long enough to go through

FUSELAGE ASSEMBLY, PART II: Main Landing Gear

For the following steps you will need these parts:

•The fuselage assembly

•1 - Aluminum Landing Gear

•3 - M4 x 15mm PWA Mounting Bolts

•2 - 2-3/4" dia. Main Wheels

•2 - M4 x 34mm PWA Axle Bolts

•2 - M4 Lock Nuts

•4 - M4 Hex Nuts

•1 - Right Fiberglass Wheel Pant

•1 - Left Fiberglass Wheel Pant

•4 - M3 x 10mm PWA Mounting Bolts

•4 - M3 Split Lock Washers

Note: When assembling the hardware in the following steps, we

recommend that you use a thread-locking compound, such as

Locktite®, to keep the parts from vibrating loose in flight. It only

takes a small drop, placed right in the threads of the mating parts,

to keep them tight and secure.

❑1) a. Insert one of the M4 x 34mm PWA Axle Bolts through the

hub of one of the 2-3/4”dia. Main Wheels. Slide the wheel all the

way up against the head of the bolt.

b. Next thread a M4 Hex Nut onto the threaded end of the

bolt, and run it all the way up to the wheel - but not too tight - the

wheel must turn freely.

c. Now thread another M4 Hex Nut up tight against the first

one. This extra hex nut serves as a spacer to keep the tire from

rubbing on the wheel pant after it is installed.

d. Finally, insert the threaded end of the axel bolt through

the aluminum landing gear leg and install an M4 Lock Nut. Tighten

securely.

e. Repeat this proceedure to install the other wheel onto the

opposite landing gear leg.

❑2) Mounts the Fiberglass Wheel Pants to the landing gear with

the M3 x 10mm PWA Mounting Bolts and M3 Split Lock Washers 9

IMPORTANT SAFETY ISSUE!

DO NOT DRILL AND TAP THE GLASS-FILLED ENGINE MOUNTS

FOR BOLTS, OR USE SELF-TAPPING SCREWS OR WOOD

SCREWS. THOSE METHODS WILL WEAKEN THE ENGINE

MOUNTS AND CAN LEAD TO ENGINE MOUNT FAILURE!

1) Use only Socket-Head Bolts with Aircraft Lock Nuts and Flat

Metal Washers to fasten your engine to the glass-filled engine

mounts, as shown in these instructions.

2) The holes you drill through the mounts must be big enough for the

engine mounting bolts to pass freely through. The bolts should not go

in tight. In the case of 8-32 mounting bolts, a 11/64" dia. drill bit will

provide proper clearance holes. For 10-32 bolts use a 13/64”drill bit.

provided. Tighten securely. Double check to make sure that the

wheels turn freely without obstruction.

❑4) Determine the location of the hole required in the cowling for

access to your engine's needle valve. Start with the engine and

cowling on the airplane and “eyeball”the approximate location of

where the needle valve will exit the cowling. Take your best guess

and mark that location on the cowl. Now make a small 1/16”dia.

hole at the marked location. Chances are that you are close to

the correct spot. Stick a piece of music wire into the hole, down to

the needle valve. Carefully observe if the hole needs to be

repositioned to straighten up the wire, as if it were the needle valve.

Make another mark on the cowl and open the hole just a little

towards the corrected position. In this manner, continue checking

and adjusting the exit hole until it aligns perfectly with the

carburetor/needle valve position. Then enlarge the hole enough to

insert and install the needle valve in the carb. Be sure the hole has

at least 3/32" clearance around the needle valve to avoid contact.

Tip: A handy tool to assit with cutting holes in the cowling is a

small penlight. The penlight can be used from the inside or outside

of the cowl to highlight and spot the required hole location.

❑5) Figure out what size and shape opening you will need in the

cowling to accomodate your engine’s muffler, and cut it out now.

Note:

As you can see in the photo, the cutout for the Saito .91

muffler in our photo model was a bit of a challenge. Thru visual trial

and error we determined that it would be best to install the muffler

level. The next step was to remove the cowling from the airplane

and permanently mount the “pipe” portion of the muffler assembly

on the engine in the level position. Then a cutout was made in the

cowling to clear the pipe, so that the cowling could be reinstalled on

the fuselage. Next the cutout was gradually enlarged until the

“chamber” portion of the muffler could be screwed onto the end of

the pipe. Undoubtably there are other ways this muffler installation

could be done. You may have other ideas.

❑6) Figure out how you are going to light your glow plug and

whether that will require an opening in your cowling.

Note: One option, that requires no cowling changes, would be to

use a “remote” glow plug wiring harness, (not supplied). Another

option, as shown here with our Saito .91 installation, was to use an

the spinner backplate, through the thick APC prop, and still have enough

threads sticking out in front of the prop to safely use the standard Saito

prop nut and washer. We found that a TrueTurn®aluminum spinner had a

thinner backplate and a different style prop nut, which took care of the

problem. Depending on your engine and prop combination, you might face

a similar situation. Another alternative to a whole new spinner would be to

find a prop nut that extends down into the prop hub, like some of the older

OS®4-stroke prop nuts.

❑1) Try fitting the Fiberglass Cowling over your engine and back

onto the fuselage. If you have a typical MAYHEM engine

installation (meaning a single-cylinder engine mounted inverted)

you will need to make an opening in the bottom of the cowling for

the engine cylinder to stick through. Watch carefully to see where

the head of the engine first hits the inside of the cowling and mark

that location with a pencil or felt tip marker. Remove the cowl, and

use a Dremel®Tool to make a small opening in the cowl at the point

of contact. Refit the cowl, checking the hole location and size,

adjust as needed and again use the Dremel®Tool to make the

opening bigger. Keep refitting, remarking and readjusting the hole

until the cowling can be slipped over the engine into correct

position on the fuselage. As a general rule, you should end up with

at least 3/16" clearance between the cowling and any engine part.

❑2) Once the cowling is in place without any part of the engine

contacting it, mount your spinner backplate and propeller on the

engine prop shaft. Tighten the prop assembly sufficiently to bring

the spinner backplate firmly in contact against the engine’s prop

mounting flange. Now check to see that you have at least a 1/16"

gap between the back of the spinner backplate and the front of the

cowling (1/16”to 1/8”is OK). Adjust the final location of the

cowling, making sure that the spinner backplate is centered on the

front and that the back edges are tight against the fuselage. Use

masking tape to temporarily hold the cowling in correct position on

the fuselage.

❑3) With the cowling securely taped in place, use a 3/64" (or

#56) dia.drill bit to drill pilot holes in the fuselage, centered in each

of the four pre-drilled mounting holes in the cowl. Mount the cowl

to the fuselage with the four M2.6 x 10mm PWA Screws provided.

10

FUSELAGE ASSEMBLY,PART IV:Install The Tail Surfaces:

For the following steps you will need these parts:

•The fuselage assembly

•1 - Stabilizer & Elevator Set

•1 - Fin & Rudder Set

•9 - CA Hinges (6 for elevators, 3 for rudder)

❑1) Six CA hinges have been factory installed, but not glued, in

the Stabilizer and Elevator set. Glue the hinges permanently in

place at this time, using the same proceedures used for gluing the

aileron hinges on page 5. Let dry 10 minutes before flexing the

hinges. Do not glue the Fin and Rudder hinges at this time!

❑2) Prepare the fuselage to receive the stabilizer and elevators

by extending the stabilizer cutout all the way to the back of the

fuselage. In other words, cut out the portion of the fuselage that is

directly behind the stabilizer slot, so that the stab and elevators can

then be slid in place from the back. This portion of the fuselage

was left in during manufacture of the airplane to lend support the

top of the fuselage during shipping and handling.

a. Start by drawing guidelines

on the rear of the fuselage to

indicate exactly where cuts should

be made to remove the unwanted

portion. The guidelines are simply

a straight extension of the top and

bottom edges of the stabilizer slot.

b. Use a hobby razor saw

and/or hobby knife to cut out

the unwanted portion of wood

between the lines.

c. Smooth the surfaces of the

fresh cuts with fine sandpaper,

and then fuel proof the exposed

wood with some thin CA glue.

❑3) Mount the wing to the fuselage, and then trial fit the

stabilizer/elevator assembly in place. Check the alignment of the

stab with the rest of the airplane. View the airplane from the top,

front and rear, making sure the stabilizer is not tilted or skewed

(see drawing on next page). Measure the distance from the wing

trailing edge back to the stab’s leading edge tip, and note the

distance. Then make the same measurement on the opposite side

of the airplane. The two measurements must be the same. Adjust

the stabilizer as needed until they are the same.

❑4) Once you have the stabilizer properly aligned, use a felt-tip

pen to mark the locaton of the fuselage sides on the bottom and

top of the stab. Take the stabilizer off the airplane and remove

the covering material between the lines, so there will be a good

extended glow plug battery ignitor (not supplied), and simply make

a small notch in the bottom rear edge of the cowling to let the

ignitor line up perfectly with the glow plug.

❑7) Next figure out how you are going to fuel and de-fuel your air-

plane, and whether that will require another opening in your cowl-

ing. If so, make the opening now.

Note: In our photo model we’ve installed a Du-Bro #334 Kwik-Fill

Fueling Valve, (not supplied), for this purpose. The best way to

mount the Du-Bro FuelingValve is directly on the MAYHEM firewall

with a SIG #SIGSH759 Fueling Valve Mounting Bracket, (not

supplied). Mount the bracket in a position that will put the fueling

valve close to the inside of the cowling, but not contacting it. Do

not mount the fueling valve directly onto the fiberglass cowling.

The repeated insertion of the fueling probe will ultimately cause

flex cracks around the fueling valve.

Make a 5/16” dia. hole in the cowling, directly over the fuel valve,

to allow the fueling probe to be inserted into the valve.

❑8)

The supplied plastic spinner is easy to assemble. If the diam-

eter of your engine’s prop shaft is smaller than the hole in the spin-

ner backplate, select a prop shaft adapter to fit. If your prop shaft

is larger than the hole in the backplate, the hole can be drilled larg-

er to fit, (use drill press). Install the backplate and your propeller

tightly onto your engine, using the engine's prop nut and washer.

Snap the spinner cone in place, and attach it to the backplate with

the four screws provided. Don't over-tighten the screws.

11

❑8) The fin can now be permanently glued in place on the

fuselage. Epoxy glue is recommended for this step for maximum

strength. Wipe any excess epoxy glue smears off the covering

material with a rag soaked in rubbing alcohol.

❑9) Attach the rudder onto the back of the fin and fuselage with

three CA hinges. After assembly and alignment, glue the hinges

permanently in place using the same proceedures you used for

gluing the aileron hinges and elevator hinges in previous steps. Let

dry 10 minutes before flexing the hinges.

FUSELAGE ASSEMBLY, PART VI: Install Tailwheel:

For the following steps you will need these parts:

•The fuselage assembly

•1 - Leaf-Spring with Steering Arm, Yoke, & Tailwheel

•3 - 3mm x 10mm PWA Mounting Screws

•2 - Coil Steering Springs

•1 - Metal Rudder T-Horn

•2 - 2mm x 9mm PWA Mounting Screws

❑1)

Mount the Metal Rudder T-Horn onto the bottom of the rudder

with two 2mm x 9mm PWA Mounting Screws, as shown here.

❑2) Hold the tailwheel leaf spring assembly in place on the

fuselage. Make sure it is lined up with the fuselage centerline, and

12

wood-to-wood joint between the stab and the fuselage in the

next step. Be very careful not to cut into the balsa wood when

removing the covering material.

❑5)

The stabilizer/elevator assembly can now be permanently

glued into the fuselage. Slow-drying epoxy glue is recommended for

this step, to allow you plenty of time to get the stab back in proper

alignment before the glue dries. Wipe any epoxy glue smears off the

covering material with a rag soaked in rubbing alcohol.

❑6) Seperate the Fin and Rudder from each other, and set the

Rudder and Hinges aside for now. Trial fit the fin alone in place on

the fuselage. There should be no gaps between the bottom of the

fin and the top of the fuselage. If there are any gaps, sand the

bottom of the fin to eliminate them.

❑7) Use a felt-tip pen to mark the locaton of the fin on the top of

the fuselage. Take the fin back off the airplane and remove the

covering material between the marked lines from the top of the

fuselage. This is to provide a strong wood-to-wood joint between

the bottom of the fin and the fuselage in the next step.

mounting bolt, nuts, and lock washers. Also, the control horns must

be positioned so they line up with an imaginary line from the control

horn, to the pull-pull cable exit hole, to the rudder servo arm.

❑3) The rudder pull-pull system can now be installed. From the

kit contents, locate the 2 Steel Cables, 4 Rigging Couplers with

Metal R/C Links and Knurled Stop Nuts, and 4 Metal Tubes.

Slide one of the metal tubes onto the end of one of the cables. Then

thread the cable through the small hole in the end of the rigging

coupler, giving yourself about 4" - 5" of cable past the hole to work

with. Loop the short end of the cable back through the metal tube.

Pull the tube up towards the rigging coupler, leaving the tube about

1/2" away from the coupler. Use pliers or a crimping tool to squeeze

the metal tube tightly over the cable, locking it in place. Cut off the

excess short end of the cable. Repeat this process to install a

rigging coupler on one end of the other piece of cable

.

that it is as far back as shown in the pictures. Use a fine felt-tip pen

to mark the locations of the 3 mounting holes onto the fuselage. Drill

pilot holes into the bottom of the fuselage with a 1/16" dia. drill bit.

❑3) Install the leaf-spring on the bottom of the fuselage with the

3mm x 10mm PWA Mounting Screws.

❑4) Install the 2 Coil Steering Springs, connecting the tailwheel

steering arm to the metal T-horn mounted on the bottom of the

rudder. A needle nose pliers works best for making the loops in

each end of the spring wires. It’s very important that both springs

be bent identically, resulting in the exact same overall length, so

that the tailwheel will be in neutral position when the rudder is

neutral. Also, the springs should be under a little tension when

they are installed, so that they remain tight at all times. However,

do not over stretch the springs. A little bit of tension is all you need.

RADIO INSTALLATION, PART I: Rudder:

For the following steps you will need these parts:

•The fuselage assembly

•1 - Right Control Horn

•1 - Left Control Horn

•4 - M2.5 x 14mm Mounting Bolts

•4 - M2 Hex Nuts

•4 - M2 Split Lock Washers

•2 - .023”dia. Steel Cables

•4 - Rigging Couplers w/ R/C Link and Knurled Stop Nut

•2 - 2mm od x 4mm Metal Tubes

•1 - Rudder Servo (not supplied)

❑1) Mount your rudder servo in the center of the plywood servo

tray in the fuselage, using the grommets and mounting screws that

came with the servo. Install a large heavy-duty 2-sided servo arm

on the rudder servo.

❑2) Mount the right and left metal control horns on each side of

the rudder, as shown. Note that the control horns should be

directly opposite each other, and that they share the same four

13

❑4) The finished ends of the two cables prepared in the last step,

are for hooking up to the rudder control horns. Feed the unfinished

bare ends of the cables into the pull-pull exits built into the rear of

the fuselage, one on each side. Pass the cable ends completely

through the rear of the fuselage and up to the rudder servo loca-

tion. Keep pulling the cables forward until you can

connect the R/C links to the rudder control horns.

❑5) Turn the fuselage upside down on your bench to make it eas-

ier to complete the pull-pull cable connections to the rudder servo

arm.

a. Temporarily plug your rudder servo into your receiver and

turn on the radio system. Make sure the rudder trim lever on the

transmitter is centered. Then center the servo arm on the rudder

servo. Temporarily tape the rudder in neutral alignment with the fin.

b. Examine the two remaining rigging couplers and center the

R/C links on the threaded portions of the couplers. Clip the R/C

links into the outermost holes at each end of the rudder servo arm.

d. Pick up the bare end of one of the pull-pull cables inside the

fuselage and lightly pull on it, while you look inside the fuselage to

make sure the cable is not caught on or twisted around anything.

Then slide one of the remaining metal tubes over the end of that

cable. Next, poke the end of the cable through the small hole in the

end of the appropriate rigging coupler on the rudder servo arm

(make sure you’re installing the left side cable in the left side

rigging coupler, and vice versa). Make a half loop back into and

through the metal tube. Pull the cable snug to remove any slack

(not too tight) as you slide the metal tube up close to the servo

arm. Crimp the tubing tightly over the cable, locking it in place. Cut

off the excess short end of the cable. Repeat the process to attach

the other pull-pull cable on the opposite side of the servo arm.

❑6)

Wi

th the rudder still taped in neutral position, adjust the

threaded R/C links until you get both pull-pull cables to

approximately the same mild tension - it’s not necessary to pull the

cables extremely tight. Remove the tape holding the rudder in

place, turn on the transmitter and test the movement and centering

of the rudder. Adjust as needed. When satisfied with the operation

of the pull-pull system, tighten the knurled stop nut on each rigging

coupler up against the end of the R/C link to lock the links in place.

14

RADIO INSTALLATION, PART II: Elevator:

For the following steps you will need these parts:

•The fuselage assembly

•1 - 4-40 x 3”Threaded Pushrod

•2 - 4-40 Metal R/C Links

•2 - 4-40 Hex Nuts

•2 - Spring Keepers

•1 - Right Control Horn

•4 - 2.6mm x 10mm Mounting Screws

•1 - Elevator Servo (not supplied)

•1 - 24”Servo Extension Chord (not supplied)

❑1) Plug a 24”long servo extension chord onto the end of the

elevator servo wire. Secure well with tape. Poke the free end of

the extended servo wire through the elevator servo mount in the

rear of the fuselage. Hold the fuselage vertically as you pass the

servo wire all the way forward to the radio compartment. Avoid

tangling the servo wire with the rudder pull-pull cables. Once you

have the wire completely inside, install the elevator servo in the

fuselage using the using the rubber grommets and screws that

came with the servo.

❑2) Mount the control horn on the bottom of the right elevator

using the four 2.6mm x 10mm mounting screws. Locate the horn

near the end of the elevator, directly in line with the elevator servo

(there is a plywood plate to mount the horn on, already built into

the bottom of the elevator, under the covering material). Hold the

control horn in place on the elevator, lined up with the elevator

servo arm. Also make sure the pivot holes in the control horn line

up with the hinge line. Mark the four control horn mounting holes

on the elevator with a felt-tip pen. Drill a 3.64”dia.(or #56 drill) pilot

hole for each screw, then screw the horn in place.

❑3) The elevator pushrod consists of aThreaded Rod with a Hex

Nut, a R/C Link, and a Spring Keeper on each end. Clip one end

of the pushrod into the elevator servo arm. Clip the other end of

the pushrod into the control horn. Adjust the overall length of the

pushrod by screwing the R/C links in or out as needed to get the

elevator in neutral position when the servo is neutral. Once you

have the pushrod length properly adjusted, slide the spring

keepers up onto the R/C links, and then screw the hex nuts up tight

against the end of the R/C links. Put a drop of Locktite®thread

locking compound, or CA glue, on the hex nuts to keep them from

coming loose.

IMPORTANT: After you finish mounting the control horn on

the elevator for the first time, take it back off and set it aside.

Then put a few drops of Thin CA into each of the four

mounting screw holes in the elevator. The Thin CA will soak

into the threads in the wood, and when it dries the holding

power of the threads will be much stronger. UseThin CA only,

not medium or thick CA. Let the Thin CA dry completely

before remounting the control horn onto the elevator.

RADIO INSTALLATION, PART III: Throttle Pushrod:

For the following steps you will need these parts:

•The fuselage assembly

•1 - 1/8”od x 15-3/4”Plastic Pushrod Tube

•1 - 3/16”od x 13-3/4”Plastic Pushrod Sleeve

•1 - Threaded Stud with Nylon R/C Link

•1 - Threaded Stud with Metal R/C Link

•2 - Laser-Cut Plywood Pushrod Supports

•1 - Throttle Servo (not supplied)

The following instructions describe installation of the throttle

pushrod materials that are included in this kit. This pushrod

system should work with most 4-stroke or 2-stroke single cylinder

glow engines, like the Saito .91 shown in the photos. There may

be some engine that require a different pushrod arrangement and

different materials (not supplied).

❑1) Mount your throttle servo in the plywood servo tray inside the

fuselage, using the rubber grommets and mounting screws that

came with the servo. If your engine’s throttle arm is on the right

side of the airplane (like our Saito .91), then you should mount the

throttle servo to the right of the rudder servo. If your throttle arm is

on the left, mount the servo on the left.

❑2) Drill a 3/16"-7/32”dia. hole through the firewall, aligned with

your engine's carburetor throttle arm. From the front, insert the

3/16" od x 13-3/4”long Plastic Pushrod Sleeve through the firewall

and into the fuselage, back to the throttle servo. Notice that there

is a slot cut in the first fuselage former behind the firewall for the

pushrod sleeve to go through. The slot keeps the pushrod sleeve

out of the area where the fuel tank will be mounted.

❑3) Inside the fuselage, slip the two Laser-Cut Plywood Pushrod

Supports over the end of the pushrod sleeve. The plywood

pushrod supports should be positioned wherever needed along the

pushrod sleeve to aim it directly at the throttle servo arm. Once

you’ve determined where to mount them, glue the plywood

pushrod supports to the fuselage.

Note: In the following photos of our Saito .91 installation, you will

see that we glued one plywood pushrod support to the 3rd

fuselage former, and the other pushrod support to the inside of the

fuselage about 2-1/2“ away from the servo.

❑4) Determine how long the pushrod sleeve needs to be to fit

your installation (we purposely provided it too long so it would

cover most situations). In most cases you will need to shorten the

pushrod sleeve a little bit. As a general rule, the ends of the

pushrod sleeve should be about 1-1/2”away from the servo arm

and the throttle arm. Use a sharp razor blade to cut the pushrod

sleeve to length. Remove the tube and sand its surface with 220

sandpaper to rough it a little. Reinstall the tube and glue it in place

to the firewall and the plywood pushrod supports. 15

❑5) Screw the Threaded Stud with Nylon R/C Link into one end

of the 1/8”od x 15-3/4”Plastic Pushrod Tube. Use a needle nose

pliers to grip the threaded stud so you can screw it in at least 1/8”.

❑6) At the firewall, insert the plain end of the plastic pushrod tube

inside the plastic pushrod sleeve. Push it in until the nylon R/C link

can be clipped to engine throttle arm. Then reach inside the

fuselage and operate the throttle pushrod tube from the servo end.

Make sure the pushrod can fully open and close the carburetor

without binding.

❑7) Finish the servo end of the throttle pushrod as follows:

a. Turn your radio on and make sure the throttle servo is

operating in the right direction for high and low throttle. Put the

throttle servo in high throttle position and turn off the radio.

b. Put the throttle pushrod in high throttle position.

c. Inside the fuselage, clip the Threaded Stud with Metal R/C

Link to the servo arm. Hold the threaded stud and the pushrod tube

together and mark the tube for cutting to length. Be sure to allow

for the 1/8”that the threaded stud will be screwed inside the end of

the pushrod tube. Cut off the excess pushrod tube with a sharp

razor knife.

d.

Unclip the R/C link from the servo arm, and screw the threaded

stud at least 1/8”inside the end of the pushrod tube, as you did the

other end in step 5. Then reattach the R/C link to the servo.

❑8) Turn your radio back on and check the operation of the

throttle. Adjust the overall length of the throttle pushrod by scewing

the R/C links in or out as needed to achieve full throttle control.

When finished, secure at least one of the R/C links to it’s threaded

stud with CA glue, so that the pushrod tube cannot rotate in flight

and change adjustment.

16

RADIO INSTALLATION, PART IV:Radio System:

With all the servos now installed, all that remains is the installation

of the receiver, battery pack, and switch.

RX BATTERY PACK: The single heaviest unit of the radio system

is the battery pack. This means that you can, if needed, locate the

battery pack wherever it is needed in the airplane to help achieve

the correct balance point. Be sure to wrap the battery pack in foam

rubber and use rubber bands or tie-wraps to secure it to the model

structure so that it can't move around in flight.

RECEIVER: Wrap the receiver in foam and use rubber bands or

tie-wraps to secure it in the fuselage. Notice that the MAYHEM has

a plastic tube already installed inside the fuselage for use as an

internal antenna mount. The plastic tube runs from the radio

compartment all the way back through the fuselage, with an exit

hole in the bottom of the fuse just ahead of the tailwheel assembly.

Slide your antenna into this tube when installing your receiver.

Note: Instead of trying to push the limp antenna wire all the way

through the plastic tube, its easier to run a long small diameter

music wire (not supplied) from the back of the airplane, into the

tube, and forward into the radio compartment. When the music

wire appears inside the fuselage, tape the end of your antenna to

it, and then slowly pull the antenna out to the back of the airplane.

SWITCH:

The radio on/off switch should be mounted on the

fuselage side opposite the engine exhaust. Cut a small rectangular

opening in the fuselage side for the switch toggle to poke through,

and drill two small holes for the switch mounting bolts.

SAFETY CHECK: The elevator and aileron pushrods have spring

keepers to prevent the R/C links from opening up in flight, while the

rudder and throttle R/C links do not. Take the time to fit each

rudder and throttle R/C link with a short length of silicone fuel

tubing to keep the links firmly closed. This common safety practice

has saved a lot of models! Also, make sure that you have secured

the servo arms to each servo with the retaining screws.

Turn the radio system on and check the functions of all the

controls. Make sure they are moving in the right direction!

Thousands of R/C airplanes have crashed over the years because

the servos were moving the wrong way! Also make sure all the

servos are centered and working perfectly, without any binding.

Correct any such problems now, before proceeding.

RADIO INSTALLATION, PART V: Set The Control Throws:

Use a ruler to accurately measure and adjust the travel of each

control surface to the amounts shown below. Keep in mind that

these settings are meant to serve as a starting point. As you gain

experience flying your MAYHEM, you may want to adjust the

throws to suit your flying style. All measurements should be taken

at the widest part of the elevators, ailerons, and rudder.

RADIO INSTALLATION, PART VI: Range Check:

Be sure to range check your radio installation on the ground,

before you attempt to fly your MAYHEM for the first time. With the

transmitter antenna collapsed, and the receiver and transmitter

turned on, you should be able to walk at least 100 ft.away from the

model and still have solid control. Have an assistant stand by the

airplane to watch the action of the control surfaces, while you walk

slowly away from the model, constantly working the controls as you

go. Your assistant should signal to you if the control surfaces

become erratic. If all is well out to 100 ft. or further, repeat the test

with the engine running, with the assistant holding the airplane. If

the control surfaces do not respond correctly, do not fly! Find and

correct the problem first. Look for loose servo connections or

broken wires, corroded wires, poor solder joints in your battery

pack, or a defective cell in the battery pack, or a damaged

receiver crystal from a previous crash. If you can’t find and fix the

problem, send the radio in to an approved service center.

NEVER FLY WITH A RADIO SYSTEM THAT ISN’T WORKING

100% CORRECTLY. THE PROBLEM WON’T GET BETTER IN

THE AIR, IT WILL GET WORSE!

Normal Control Throws

High Rate Low Rate

Elevator 1-3/4" up 1-1/4" up

1-3/4" down 1-1/4" down

Ailerons 1-1/2" up 1" up

1-1/2" down 1" down

Rudder 3" right 2" right

3" left 2" left

3D Control Throws

The 3D control throws are only meant for

extreme aerobatics. They are not meant for

normal flying. You should be competent and

comfortable flying your MAYHEM with normal

control throws before attempting 3D rates.

Elevator: 2-3/4" up

2-3/4" down

Ailerons: 2-1/4" up

2-1/4" down

Rudder: 4-1/2" right

4-1/2" left

Expo: Use -20% exponential travel on elevator,

ailerons, and rudder when using 3D rates.

17

❑4) A 3/8”x 1/2”x 4”balsa stick is provided to keep the fuel tank

in place. Install the balsa stick across the back of the tank, gluing

it to the front of the fuselage former. This will keep the tank from

sliding backwards in flight. If the tank ever has to be removed for

service, you can break the balsa stick loose and get the tank out.

DECAL APPLICATION:

The decals in this kit are made of sticky-back mylar with an

extremely aggressive adhesive. They are NOT water activated

transfers. These decals are not die-cut and need to be cut from

their sheets with a sharp hobby knife or scissors. Trim as close to

the image as possible.

Putting sticky-back decals on a model can be tricky! Especially

medium to large size ones like those in this kit. If you don't do it

right you will end up with unsightly air bubbles trapped underneath

the decal. The best method is to put large decals on “wet”.

You will need a "soapy water" mixture (water mixed with a very

small amount of dish soap, or SIG Pure Magic Model Airplane

Cleaner, or Fantastic®, Windex®, or 409®type cleaners all work

good). You will also need a supple squeegee, (the SIG 4" Epoxy

Spreader #SIGSH678 is perfect for this job), a couple clean soft

cloths (old tee shirts are great), a good straight edge, a ruler, and

a hobby knife with sharp #11 blades. We also suggest that you

have some trim tape handy for making temporary guidelines (1/8"

width or so is perfect) for help in aligning the decals.

First spray the surface of the model where the decal is to be placed

with a soapy water mixture. Then peel the backing sheet

completely off the decal, being careful not to let the sticky side

double over and adhere to itself. Place the decal onto the wet

surface of the model. Do not push down! The soapy water

solution will keep the decal from actually sticking to the model until

you have had time to shift it around into exact position. Once you

have it in position, squeegee the excess soapy water out from

under the decal. Mop up the water with a dry cloth. Squeegee

repeatedly to get as much of the water out from under the decal as

possible. After setting overnight, the decal will be solidly adhered

to the surface.

FUEL TANK INSTALLATION

❑1) Assemble the fuel tank as shown. We recommend that you

plumb your tank with a standard 2 tube setup, with or without the

optional aftermarket fueling valve (see page 11, step 7). One of

the tubes is the “vent”line, through which you will fuel and defuel

the tank. The other tube is the “fuel feed”line to the carburetor.

Note that the rubber stopper for the tank has two holes that go all

the way through it. Use these holes for the aluminum vent and fuel

feed tubes. Use the shortest of the three supplied aluminum tubes

for the fuel feed tube. Use the longest of the aluminum tubes for

the vent tube. Gently bend the vent tube upwards to 90O, so it will

be near the top of the tank. Adjust the length of the internal

silicone fuel tubing to allow free movement of the metal clunk

pick-up inside the tank. Install the stopper assembly into the neck

of the tank and secure by tightening the clamp bolt.

Be sure to label the "vent" and "carb" lines for later identification.

❑2) Trial fit the tank in place into the front of the fuselage to

familiarize yourself with how it mounts. The front of the tank should

fit through the hole in the firewall. The main body of the tank is

supported by the contoured hole in the fuselage former. Take the

tank back out of the fuselage.

❑3) Apply a bead of silicon adhesive around the neck of the tank,

where it will contact the inside of the firewall. Put another big blob

of silicone on the front of the tank just below the neck. Slide the

tank in place into the fuselage, pushing it in until the neck goes into

the hole in the firewall. Do not push it all the way up tight against

the firewall. Leave it about 1/8" short. The blob of silicone on the

front of the tank will act as a spacer and cushion between the tank

and the firewall after it dries. It will also keep the tank away from

the ends of the engine mounting bolts that may be protruding

slightly past the back of the firewall.

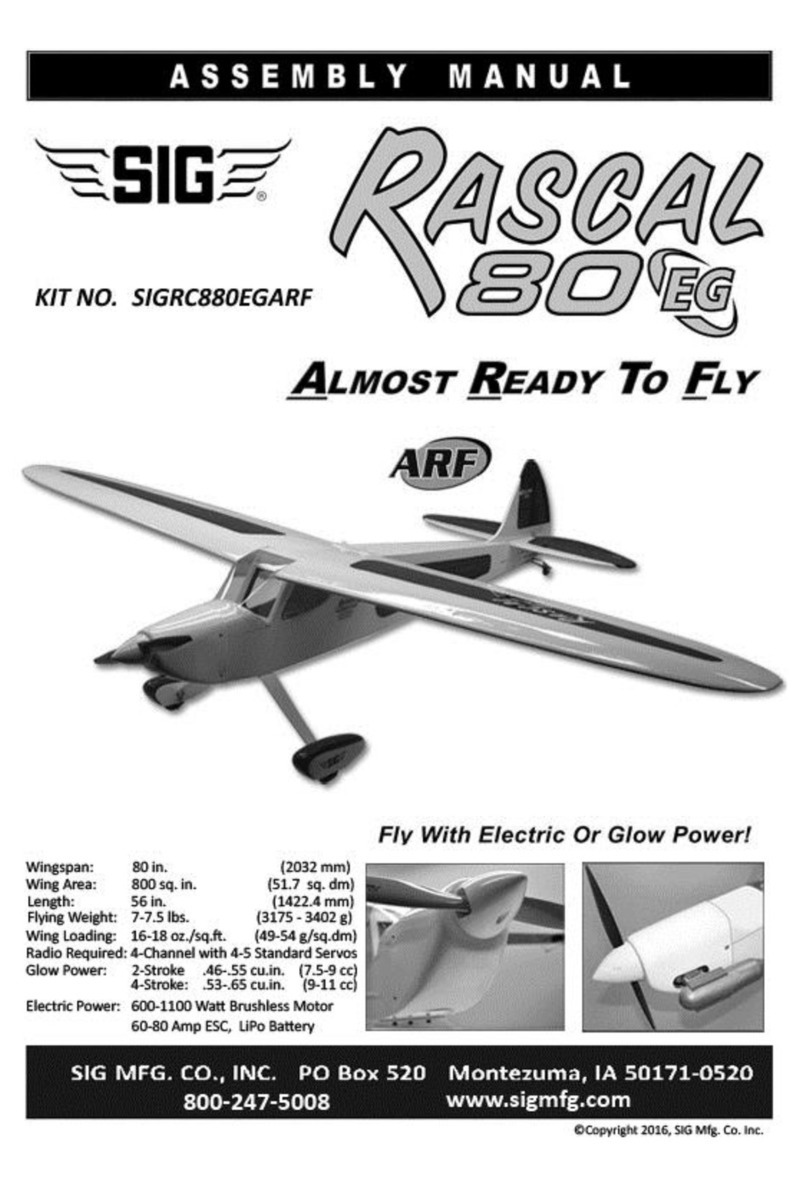

BALANCE POINTS REFERENCE CHART

* Percentage of Mean Aerodynamic Chord

% of distance aft of

MAC* wing leading edge

29% 4.785"

31% 5.115"

33% 5.445"

34% 5.610"

35% 5.775"

36% 5.940"

37% 6.105"

38% 6.270"

For initial test flying and familiarization purposes, we suggest

a starting balance point of 33% MAC, which is approximately

5-7/16" behind the leading edge of the wing.

As your experience with the MAYHEM increases, you can adjust

the balance point to suit yourself. In general, as the balance point

is moved aft, the airplane will become more responsive and less

stable in all axis. Some pilots like their models extremely reactive,

while others like to fly with more smoothness. If you never get into

3D flying, you will probably like the balance point at the intial

setting of 33%. In the end, the final balance point and control

throws you use will depend somewhat on how you like to fly.

The best means of shifting the CG fore or aft is by shifting the

locatoin of the battery pack. If is the heaviest movable component

in the airplane. Wherever you put the battery pack, make sure it

cannot move around in flight. Our MAYHEM prototypes, using

either the OS or Saito 1.20 4-strokes, required no additional nose

or tail weight to achieve different balance points. We shifted the

balance point by shifting the battery pack.

If moving your battery pack does not achieve the balance point you

want, and more weight is needed, consider using a larger (and

therefore heavier) battery pack. Try to avoid adding useless

weight. If you need more weight in the nose, try a heavier spinner

or replace the light wheels with heavier after-market wheels. If

your model is nose heavy and battery shifting does not work, you

can try adding lead stick-on weights in the rear of the fuselage.

After you’ve determined how much tail weight you need, the

weights can be placed inside the fuselage by simply removing the

elevator servo and placing the weights inside and securing them.

With the elevator servo back in place, the weights are hidden.

Lastly, the aerobatic performance of your MAYHEM will benefit

greatly if you balance the airplane laterally as well as fore and aft

(eliminate the "heavy wingtip" syndrome). Lateral balancing

requires that the model be suspended upside down, using

substantial chord or fishing line. Hang the model in level flight

attitude from the ceiling or a rafter, with one line looped over the

engine propeller shaft and another line looped over the tailwheel

bracket. The model should hang level in side view. With the model

secured in this way, level the wings and then slowly let go. Ideally

the wings should stay level when you put them there. If one wing

panel drops lower, it means that it is heavier than the other panel.

When flying the model, this imbalance can cause the airplane to

"pull" to the heavy side, especially in loops and up line maneuvers.

To make the airplane track true, the light wing panel needs weight

added so it will balance level with the other panel. Add stick-on

weights or push finishing nails into the light wingtip to achieve

balance. Always make sure the weights cannot come loose.

BALANCE THE MODEL

This is probably the single most important step in preparing your

MAYHEM for flight. The final placement of the longitudinal Center

of Gravity, or Balance Point, is extremely important and should be

approached with patience and care.

Completely assemble the model, including propeller, spinner, etc.

Do not leave anything off the airplane that will be on it in flight. DO

NOT fill the fuel tank for balancing purposes. Some people prefer

to balance their airplanes by lifting the model up by one finger at

each wingtip to find the spot where the model will sit perfectly level.

This has been done for years and is an acceptable way to balance

a model. However with an airplane as large as the MAYHEM, it is

virtually impossible to balance it by the wingtips by yourself. We

prefer to use a "balancing fixture" to check the model's balance

point right along each side of the fuselage. This method can be

done alone and is actually more precise than a fingertip balance.

You can make your own simple "balancing fixture" with a couple of

1/4" dia. dowels glued into a fairly substantial wood base, at

perpendicular 90Oangles. The dowels need to be the same length

and tall enough to accommodate the height of the assembled

airplane, as well as the width of the fuselage, plus about 1/2"

additional width. The tops of the dowels need to be padded to

avoid damage to the wing. We used 1/8" thick rubber sheet, cut to

1/4" diameter, glued in place, for the padding. There are also

commercial units available for balancing for those of you who don’t

want to make your own.

Set the model UPSIDE DOWN on the balancing fixture and shift it

back or forward until you find the exact spot where the model will

sit perfectly level. Carefully measure the distance of that spot from

the leading edge of the wing and compare with the balance chart.

IMPORTANT NOTE: Balanced means the airplane sets perfectly