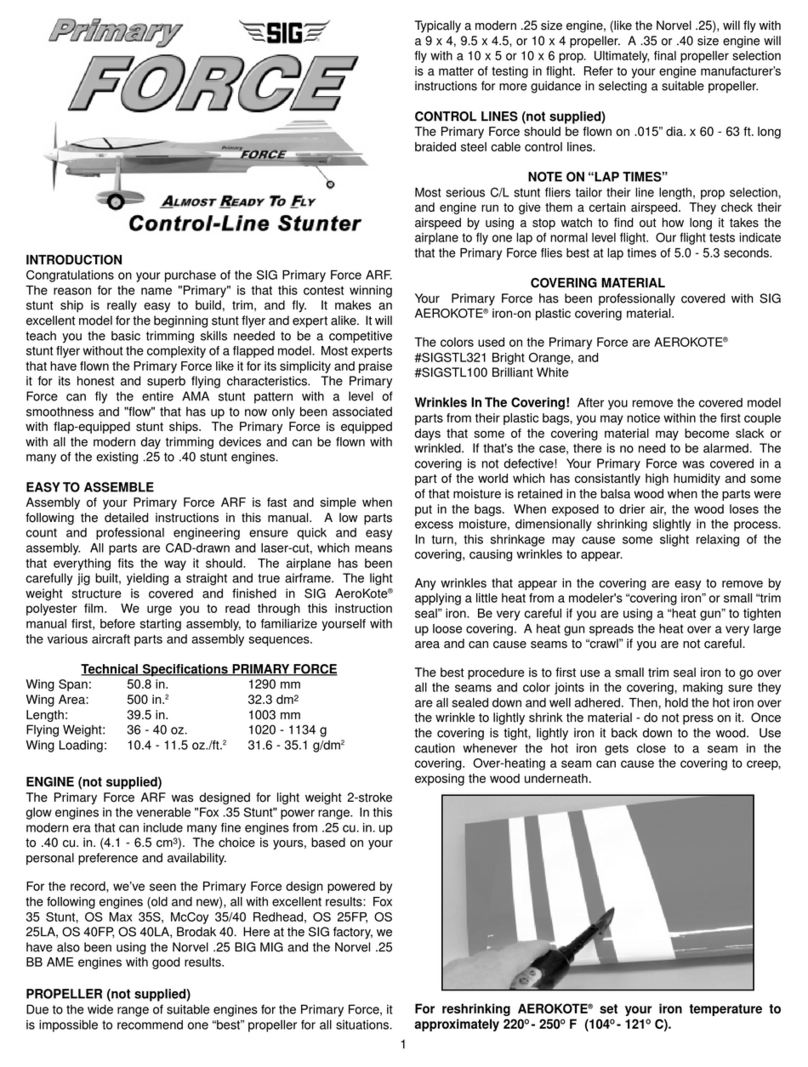

Caution When Using Heat Guns: You can also use a hobby-type

heat gun to shrink the covering, but you must be careful around

seams or color joints. Getting too much heat on the seams may

cause them to "creep" or come loose. You must also be careful

when using a heat gun when working around the windshield and

side windows - heat will distort the clear plastic material.

Recommended Temperatures:

To adhere the covering - 220°F - 250°F (104°C - 121°C)

To shrink the covering - 300°F - 320°F (149°C - 160°C)

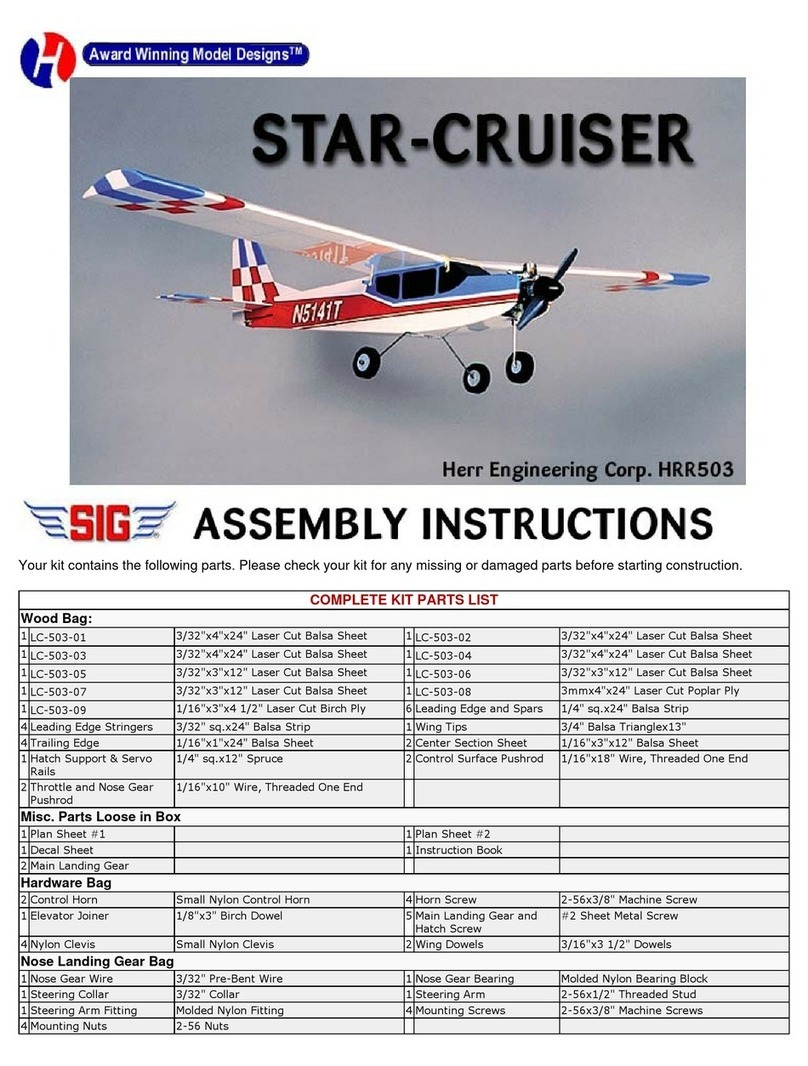

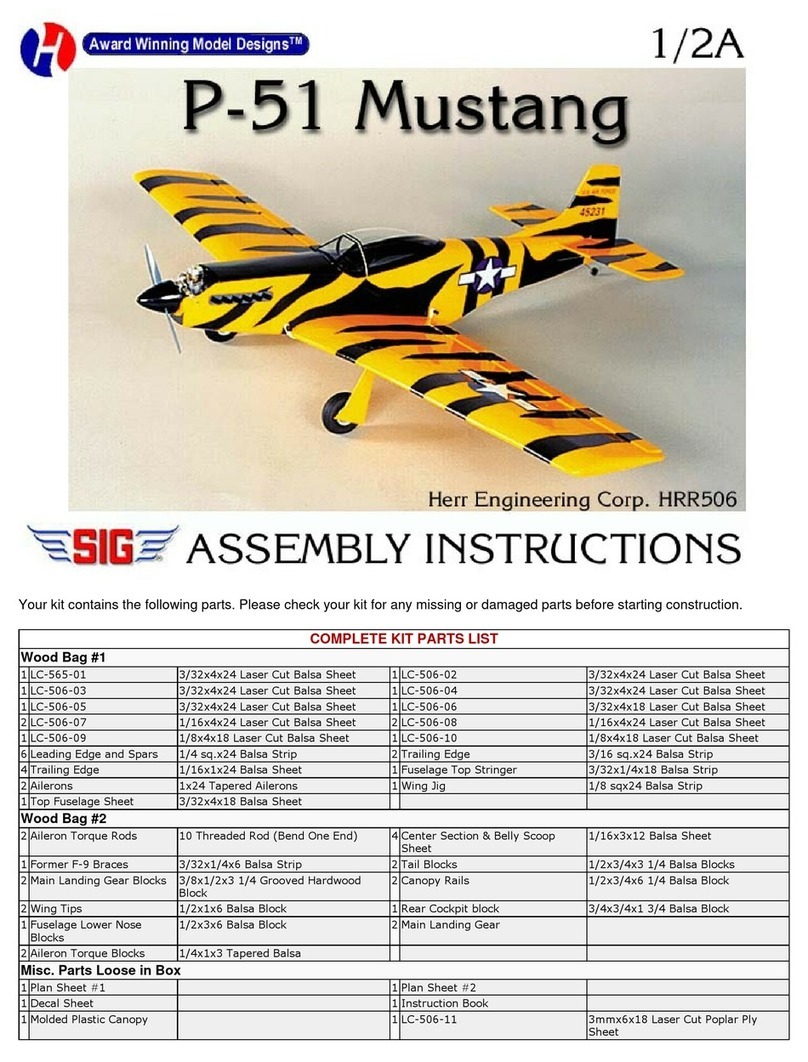

ASSEMBLY MANUAL Pages 3-4 - Replace the COMPLETE

KITS PART LIST with the following.

COMPLETE KIT PARTS LIST:

The following is a complete list of all parts contained in this kit.

Before beginning assembly, we suggest that you take the time to

inventory the parts in your kit, using the provided check-off boxes

(❑). note that the bolts and nuts required to mount your engine to

the motor mounts are not included in this kit and must be

purchased separately.

❑1 Bag (1) Right Wing Panel, covered

(1) Right Aileron, covered and hinged

(1) Right Flap, covered and hinged

❑1 Bag (1) Left Wing Panel, covered

(1) Left Aileron, covered and hinged

(1) Left Flap, covered and hinged

❑1 Bag (1) Fuselage, covered

(1) Molded Clear Plastic Windshield, with screws

❑1 Bag (1) Stabilizer & Elevator Assembly, covered and hinged

❑1 Bag (1) Fin & Rudder Assembly, covered and hinged

❑1 Bag (1) Fiberglass Cowling, painted white

(4) M3 x 10mm PWA Mounting Screws (taped inside

cowling)

❑1 Bag (1) Right Fiberglass Wheel Pant, painted red/white

(1) Left Fiberglass Wheel Pant, painted red/white

(2) M3 Blind Mounting Nuts installed in each wheel pant

❑1 Bag (1) Molded Clear Plastic Side Windows

❑1 Bag 3" Dia.White Spinner Assembly

❑ (1) Spinner Cone

❑ (1) Spinner Backplate

❑ (1) Prop Adapter Ring Set

❑ (4) M2 x 10mm Phillips Head Mounting Screws

❑1 Bag Engine Mount Assembly

❑ (1) Right Engine Mount

❑ (1) Left Engine Mount

❑ (4) M4 x 25mm PWA Mounting Bolts

❑ (4) M4 Flat Washers

❑ (4) M4 Split-Ring Lock Washers

❑ (4) M4 Blind Mounting Nuts

❑1 Bag Fuel Tank Assembly

❑ (1) 450cc (15.2 oz.) Fuel Tank

❑ (1) Fuel Tubing for inside fuel tank

❑ (1) Rubber Stopper (for glow engines only)

❑ (1) Front Clamp

❑ (1) Rear Clamp, threaded

❑ (1) M3 x 18mm Clamp Compression Bolt

❑ (3) AluminumTank Tubes - 40mm, 50mm, 60mm long

❑ (1) Metal Clunk Pick-Up Weight

❑ (1) 2-piece "Fuel Dot" assembly

❑1 Bag (1) Formed Aluminum Main Landing Gear, painted

white

❑1 Bag ❑ (2) 3-1/2" dia. (90mm) Main Wheels

❑ (2) M5 x 50mm Socket-Head Bolts for Axles

❑ (4) M5 Hex Nuts

❑ (2) M5 Split-Ring Lock Washers

❑ (2) M5 Plastic Spacer Sleeves

❑ (4) M4 x 20mm PWA Mounting Bolts for Landing Gear

❑ (4) M4 Split Ring Lock Washers

❑ (4) M3 x 12mm PWA bolts for Wheel Pants

❑ (4) M3 Split-Ring Lock Washers

❑1 Bag Tailwheel Assembly

❑ (1) Main Leaf-Spring, w/ Steering Arm & Tailwheel

❑ (1) Secondary Tailwheel Leaf-Spring

❑ (1) 3-Arm Rudder Steering Horn, Metal

❑ (2) M2 x 10mm PWA Mounting Screws for Rudder

Steering Horn

❑ (3) M3 x 15mm PWA Mounting Screws for Tailwheel

Assembly

❑ (2) Coil Steering Springs

❑1 Bag ❑ (1) Right Wing Strut, aluminum, painted white

❑ (1) Left Wing Strut, aluminum, painted white

❑ (4) M3 x 20mm Socket-Head Mounting Bolts

❑ (4) M3 Flat Washers

❑ (4) M3 Split-Ring Lock Washers

❑1 Bag ❑ (1) Aluminum Main Wing Joiner

❑ (1) Aluminum Tube Rear Wing Locator

❑1 Bag ❑ (4) Balsa Tail Fairings, covered

❑ (1) 5/16" x 3/4" x 5" Balsa Block for FuelTank Retainer

❑ (1) 1/8" plywood Fuel Tank Rear Former

❑1 Bag ❑ (1) Right Aileron Servo Hatch, covered

❑ (1) Left Aileron Servo Hatch, covered

❑ (1) Right Flap Servo Hatch, covered

❑ (1) Left Flap Servo Hatch, covered

❑ (8) 3/8" x 3/4"sq. Hardwood Servo Mounting Blocks

❑ (24) M2.6 x 8mm PWA Hatch Mounting Screws

❑ (2) 1/4-20 x 1-1/2" Nylon Wing Mounting Bolts

❑1 Bag ❑ (2) Plastic-coated Steel Pull-Pull Cables

❑ (7) Nylon Control Horns; ail(2),flaps(2),elev(1),rud(2)

❑ (1) Nylon Control Horn Base, for elevator

❑ (8) M3 x 12mm PWA Mounting Screws; for ail(4) &

flap(4) control horns

❑ (4) M2 x 20mm Mounting Bolts; for rud(2) & elev(2)

control horns

❑ (4) M2 Hex Nuts; for rudder & elevator control horns

❑ (4) Brass Pull-Pull Swage Tubes

❑ (4) Brass Pull-Pull Fittings w/ R/C Links and Hex Nuts

❑1 Bag ❑ (1) 5mm dia. x 19-3/4" Outer Throttle Pushrod Tube

❑ (2) 3mm dia. x 23-1/2" Inner Throttle Pushrod Tube

❑ (2) M2 x 22mm Threaded Studs with Metal R/C Links

❑ (5) 4-40 Pushrods, threaded both ends; ail(2), flap(2),

elev(1)

❑ (10) 4-40 R/C Links, for pushrods; ail(4), flap(4),

elev(2)

❑ (10) 4-40 nuts for pushrods; ail(4), flap(4), elev(2)

MISCELLANEOUS:

❑ (1) Printed Instrument Panel

❑ (1) Decal Sheet

ASSEMBLY MANUAL Pages 4-8 - Replace the entire section

titled WINGS with the following:

WINGS:

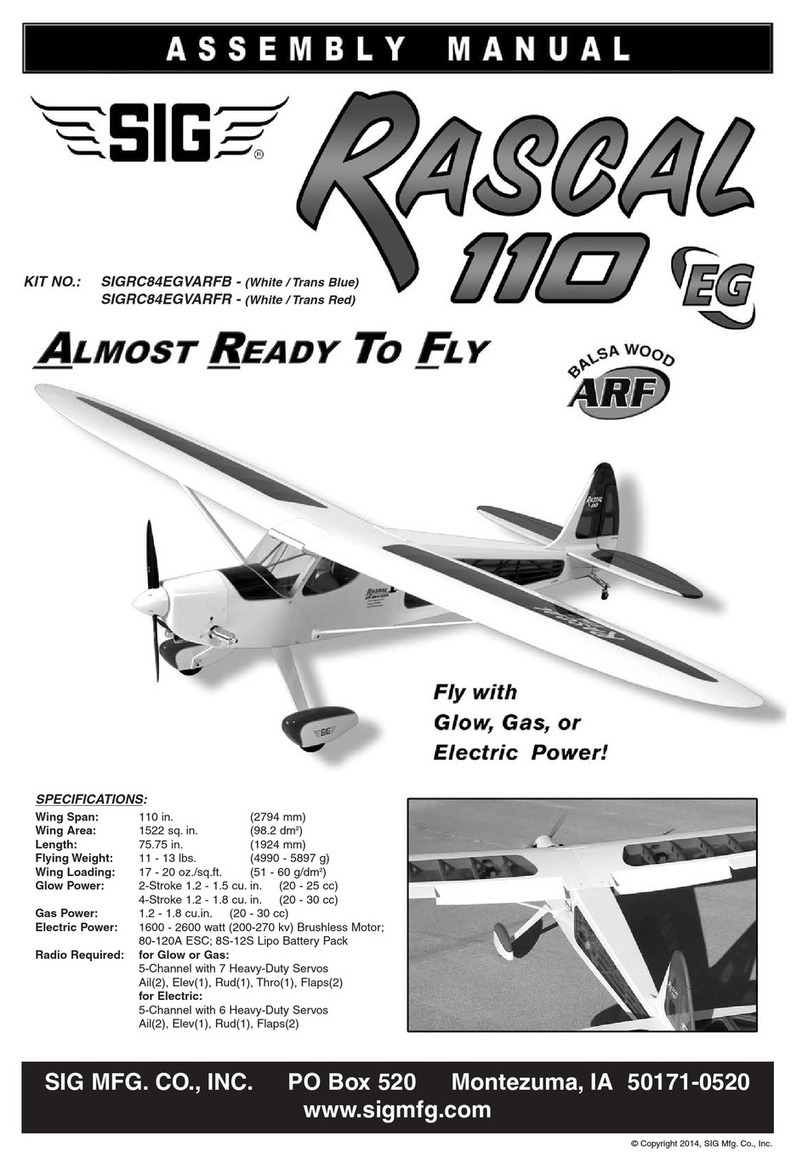

The Rascal 110 is designed with a permanent 2-piece wing

system, where the right and left wing panels will remain separate

for ease of transport and storage. You will join the right and left

wing panels at the flying field with the strong aluminum blade Main

Wing Joiner at the spar box location, and an aluminum Rear Wing

Joiner tube in the rear. This joiner system has proven itself to be

very tough and easy to use. This wing system is further

augmented in strength with the functional wing struts.

2