3

airframe. For reference, we performed all of our flight-testing with

our Waco models using .90, 1.00, and 1.20 4-stroke engines. The

.90 flies the airplane beautifully, as does the 1.00 engine. The 1.20

is close to over-powering the airplane but works fine with throttle

management. SIG's flying field is grass and all three of these

engines allowed easy take-offs.

This assembly manual depicts the installation of a Saito 1.00

4-stroke engine, mounted in the inverted position. This installation

has been completely tested and has demonstrated excellent

starting and running results along with great idle characteristics.

The Saito 1.00 engine provides the SIG Waco SRE with very good

power margins and excellent reliability. The installation of this

engine in our Waco will also show that the entire manifold and

muffler system can be kept within the confines of the cowl, with no

need for openings. Cooling airflow through the cowl and around

the engine has been completely tested on this design and found to

be excellent.

The only cowl openings required for this particular engine

installation were two small elliptical openings to clear the valve

boxes and a small diameter hole for the needle valve extension.

We really like this installation because it is practical and also

preserves the nice cowl and fuselage lines of the model. Take a

look at the Engine Installation section of this manual for more

complete details.

For reference, the practical maximum usable inside diameter of the

cowl is 7-1/2”. With the cowl fully in place on the fuselage, the

distance from the front face of the firewall to the rear face of the

spinner backplate is 5-7/16”.

Last, we strongly suggest that you take the time to carefully

break-in new engines. A good running, well broken-in engine

almost always minimizes engine related problems at the flying

field.

COVERING MATERIAL:

The SIG Waco SRE ARF model has been professionally covered

with SIG AeroKote®covering film. This high quality polyester film

has been expertly applied, using a scale color scheme, based on

the beautiful NC1252W full-scale Waco SRE.

The SIG Waco SRE ARF kits are built and covered in a part of the

world that is typically humid. When the individual covered parts are

removed from their plastic bags, some wrinkling may occur over a

24 to 48 hour period of time. This is especially possible if you live

in a drier climate. This phenomenon is perfectly normal and DOES

NOT mean that your model has a defect. Such wrinkles are a

result of the wood itself losing moisture and dimensionally

shrinking in the process. This is the nature of wood, especially

softer types, such as balsawood.

Some modelers may feel that the covering on the ARF model

should be perfect and that they should not be expected to re-shrink

wrinkles. This is not realistic, because any covering material -

regardless of brand - that has been hand applied over wood, is

indeed subject to the possibility of wrinkling.

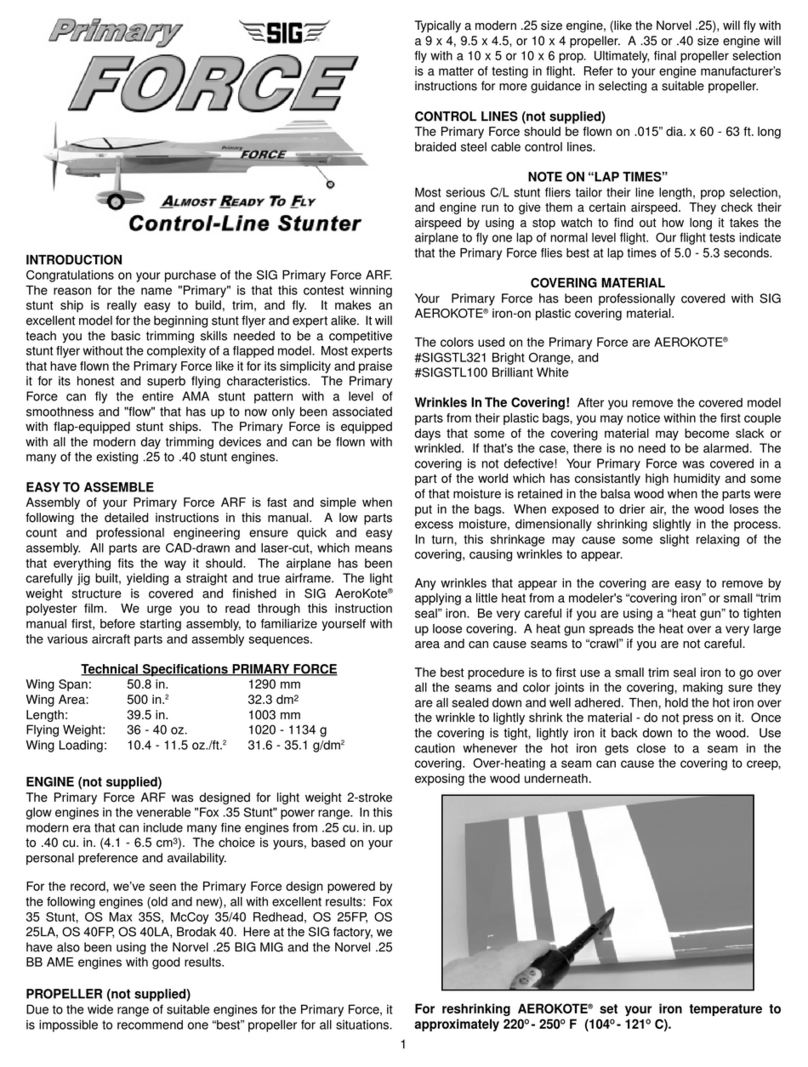

The requirement is to therefore re-shrink the covering as needed.

This is not difficult to do and can be done using normal hobby-type

covering tools, such as a heat iron, a trim seal tool and a hobby-

type heat gun. Carefully note that we do not recommend the use

of a heat gun around any areas where two pieces of covering

material have been seamed together. This is because a heat gun

generates a great deal of broadcast type heat that in turn can

loosen seams, often causing the seams to "creep". If you must use

a heat gun around or near such seams, we suggest that you

protect them first. To do this, soak a few paper towels in cool tap

water and arrange the wet towels directly onto and over the

seamed area. You can then use your heat gun to carefully shrink

these areas.

When using a hobby-type heat iron, we always suggest that the

surface of the shoe be covered with a soft cloth. This helps

prevent scratching or hazing the surface of the covering material.

For years we have used old cotton T-shirt cloth for this purpose and

it has worked quite well for us. There are also commercially avail-

able "covering socks" that fit onto most covering iron shoes.

However, these can vary in quality, so choose one that feels the

softest. Also note that the temperatures required to shrink and

seal AeroKote®(275O- 325OF) are definitely high enough to melt

and/or distort some plastic parts. Exercise common sense when

working with high heat sources around the plastic parts on your

model!

For reference, the SIG Waco SRE ARF model was covered using

the following AeroKote®colors and part numbers:

Cub Yellow Opaque SIGSTL331

Black Opaque SIGSTL201

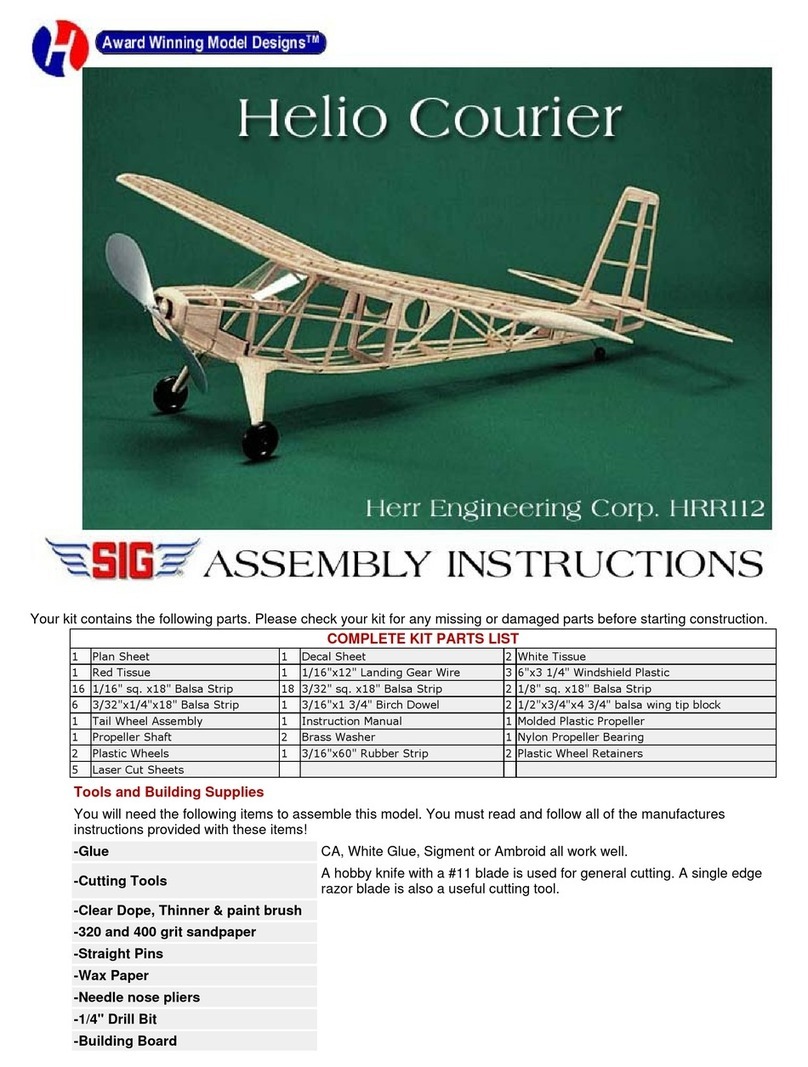

COMPLETE KIT PARTS LIST:

The following is a complete list of all parts contained in this kit.

Before beginning assembly, we suggest that you take the time to

inventory the parts in your kit, using the provided check-off boxes

(❑). Note that the CA type hinges for the ailerons, rudder, and

elevators are in place in each of these parts but are not yet glued

in place. Also note that the nuts and bolts required to mount your

engine to the motor mounts are not included in this kit and must be

purchased separately.

Important Note: Each Waco SRE ARF kit has been inspected

and inventoried on three separate occasions before leaving the

factory. Therefore, be assured that your kit has been checked

and was shipped with all of the listed parts included. Missing

part claims made after the assembly of the model begins

cannot be honored. Also, please be aware that the various

parts listed below may sometimes be packaged in a different

order than shown. Just be sure to check each parts bag to

make sure that you have received these parts.