SIGNAL INSTRUMENT 821S User manual

821S OPERATING MANUAL

Page 1 of 13

S\masters\manuals\821S

MODEL 821S

PRECISION GAS DIVIDER

OPERATING MANUAL

The SIGNAL INSTRUMENT Co. Ltd.

12 Doman Road, Camberley

Surrey, GU15 3DF

England

Tel: 01276 682841

Fax: 01276 691302

International

Tel: + 44 1276 682841

Fax: + 44 1276 691302

Part Number 821S/MAN

821S OPERATING MANUAL

Page 2 of 13

S\masters\manuals\821S

DOCUMENT HISTORY

ISSUE AMENDMENT DATE

1.00 First published

2.00 ECN 1000 April 23, 1994

821S OPERATING MANUAL

Page 3 of 13

S\masters\manuals\821S

CONTENTS

1 INTRODUCTION .……………………………………………………………………………....5

1.1 Description ……………………………………………………………………..5

1.2 Principle of Operation …………………………………………………………5

2 SPECIFICATION ………………………………………………………………………………..6

2.1 Safety …………………………………………………………………………...6

2.2 Power ……………………………………………………………………………6

2.3 Pneumatics ……………………………………………………………………..6

2.4 Ratios ……………………………………………………………………………6

2.5 Performance ……………………………………………………………………6

2.6 Remote Option …………………………………………………………………6

3 INSTALLATION ………………………………………………………………………………….7

3.1 Introduction ……………………………………………………………………..7

3.2 Location …………………………………………………………………………7

3.3 Mains Power Connection ……………………………………………………..7

3.4 Gas Connections ………………………………………………………………7

3.5 Gas Connections ………………………………………………………………8

3.6 Remote Control …………………………………………………………….…..8

4 OPERATION …………………………………………………………………………………….9

4.1 Installation ……………………………………………………………………...9

4.2 Local Operation ………………………………………………………………..9

4.3 Remote Operation ……………………………………………………………..9

4.4 Flow Control …………………………………………………………………..10

4.5 Viscosity Correction ………………………………………………………….10

4.6 Derived Correction Factors ………………………………………………….10

4.7 Gas Mixtures ………………………………………………………………….10

4.8 Experimental Derivation ……………………………………………………..10

4.9 Trace Gases …………………………………………………………………..11

5 CARE AND MAINTENANCE …………………………………………………………………12

5.1 Care ……………………………………………………………………………12

5.2 Routine Maintenance ………………………………………………………..12

5.3 Fault Finding ………………………………………………………………….12

5.4 Capillary Set Up Procedure …………………………………………………12

DIAGRAMS

Figure 1 Pipe Fitting Assembly …………………………………………………………………………8

821S OPERATING MANUAL

Page 4 of 13

S\masters\manuals\821S

©The Signal Instrument Co. Ltd., 1994

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system or

transmitted in any form or by any means – electronic, mechanical, photocopying, recording or

otherwise – without the prior written permission of The Signal Instrument Co. Ltd.

While we believe that the information and guidance given in this manual is correct, all parties

must rely upon their own skill and judgement when making use of it. The Signal Instrument Co.

Ltd. Will not assume any liability to anyone for any loss or damage caused by any error or

omission in the manual, whether such error or omission is the result of negligence or any other

cause. Any and all such liability is disclaimed.

821S OPERATING MANUAL

Page 5 of 13

S\masters\manuals\821S

1 INTRODUCTION

1.1 Description

1.1.1 The Signal Gas Divider Model 821 has been developed as a primary source of diluted

reference gas using a single reference gas and a diluent. Eleven fixed steps give

concentrations of 0% to 100% of reference gas in the diluent, in 10% steps.

1.1.2 Applications include linearity verification of correction of gas analysers in the automotive

or ambient air pollution industries. The savings in space and cost when using a single

reference gas source make the Model 821 an essential requirement for the modern

analytical laboratory.

1.1.3 An optional computer interface with an optically isolated four-line input, allows automatic

control of your test procedures.

1.2 Principle of Operation

1.2.1 A precision pressure regulator maintains equal pressures of both the reference gas and

the diluent. This is verified by a differential pressure gauge and is displayed on the front

panel.

1.2.2 The reference or SPAN gas is routed through up to ten identical capillaries depending on

the selected concentration. Those capillaries not carrying SPAN gas carry the diluent or

ZERO gas.

1.2.3 The down-stream side of all capillaries are coupled together ensuring equal pressure

differences across each one. A backpressure regulator in series with the output line

removes the effect of varying load pressures up to 10 psi (690 mbar. 69 kPa).

1.2.4 Because the ten capillaries are identical and the two pressures are identical, then the

flow rates through each capillary will be equal. (This is not valid for SPAN and ZERO

gases with differing viscosities).

1.2.5 The actual concentration is then given by the ratio of the number of capillaries carrying

SPAN gas to the total number of capillaries.

821S OPERATING MANUAL

Page 6 of 13

S\masters\manuals\821S

2 SPECIFICATION

2.1 Safety

2.1.1 The instrument has been constructed in accordance with prescribed safety standards.

All hazardous circuits are shielded within the instrument.

2.2 Power

2.2.1 Mains supply 240V ± 15% 50/60 Hz 100 VA

2.2.2 Fuse rating 2A quick blow 5 x 20 mm.

2.3 Pneumatics

2.3.1 All gases compatible with stainless steel, Viton and Kynar may be used.

2.3.2 Maximum pressure 50 psi (3.5 bar, 350 kPa) on any port.

2.3.3 Flow rate up to 5L/min with a downstream pressure 10 psi (690 mbar, 69 kPa). (May be

throttled down to achieve lower flow rates.)

2.4 Ratios

2.4.1. 0, 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90% and 100% selected by a front

panel switch. Actual selection indicated by LED indicators.

2.5 Performance

2.5.1 Accuracy ± 0.2% F.S.

2.5.2 Repeatability ± 0.1% F.S.

2.6 Remote Option

2.6.1 When fitted it provides a 4 line, optically isolated, TTL compatible remote control of ratio.

2.6.2 Isolation 50V DC max.

2.6.3 Input level 4-6 Volt at 5mA approx. each line.

2.6.4 Positive or Negative logic may be chosen by using a 0 volt or 5 volt common return.

2.6.5 Rear panel switch selects remote or local control of ratio.

2.6.6 15 way D plug is fitted to the rear panel.

821S OPERATING MANUAL

Page 7 of 13

S\masters\manuals\821S

THE GAS DIVIDER MUST NOT BE USED WITHOUT A SAFETY

EARTH CONNECTION

If hazardous gases are being used, ensure that the OUTPUT port is ALWAYS connected to a

safe vent, either via the equipment being calibrated, or directly from the divider.

3 INSTALLATION

3.1 Introduction

3.1.1 Installation requires the use of a tool set compatible with electrical and pneumatic skills.

A suitable set of tools for a minimum installation consists of an electrician’s flat bladed

screwdriver for the mains connections, a sharp knife for cutting PTFE tubing, and a 9/16”

(14.3mm) A/F spanner. Full installation of remote control will require the use of a

soldering iron plus solder, wire cutters, wire strippers, small pliers, and a working

knowledge of the equipment to be connected. Plumbing in stainless steel will require the

use of pipe cutters and benders. We, or our local agent, can offer an installation service

if you do not have the necessary skills.

3.1.2 The pneumatic and electrical connectors are found on the rear panel.

3.2 Location

3.2.1 The gas divider should be placed in a dry and sheltered location out of direct sunlight,

avoiding drafts, and protected from rain. All mains power connections must be protected

from water ingress.

3.3 Mains Power Connection

3.3.1 The gas divider is factory set for a particular mains voltage. Check that the voltage

quoted on the rear panel is compatible with your local supply. The divider is not

sensitive to mains frequency variations and may be used over the full 50 Hz to 60 Hz

range.

3.3.2 The gas divider is supplied with a 2m long mains lead with an IEC320 socket at one end

for connection to the analyser. The other end should be connected to a mains plug to

suit the local supply.

3.3.3 Standard Wiring

•Connect the BROWN wire to the LIVE (L) pin.

•Connect the BLUE wire to the NEUTRAL (N) pin.

•Connect the GREEN & YELLOW wire the EARTH (E) pin.

•If the plug has provision for a fuse, one of 2 or 3 Amp rating should be used.

3.4 Gas Connections

3.4.1 Before the gases are connected to the 821, switch the mains supply on and check that

the pressure difference meter reads zero (centre zero). If necessary use a screwdriver

to adjust the potentiometer mounted to the right of the meter to obtain a zero indication.

821S OPERATING MANUAL

Page 8 of 13

S\masters\manuals\821S

3.4.2 3.4.2 ¼” (6.35 mm) O.D. tube is

required for all connections; 0.060” (1.5

mm) wall PTFE tube is recommended.

Slide the nut and ferrule over the tube.

The tubing should be inserted into the

tube-fitting aperture and held firmly

against the end stop. The nut should be

rotated clockwise until it is “finger tight”.

Tighten the nut a further 1¼ turns with a

9/16” (14.3 mm) A/F spanner. When

connections are remade, it is only

necessary to tighten the nut slightly with

the spanner after making it “finger tight”.

3.5 Gas Connections

3.5.1 Connect the two gases to be used to the ZERO

and SPAN input ports. (0% will pass all ZERO

gas and 100% will pass all SPAN gas).

3.5.2 Connect the OUTPUT port to the instrument

under test.

3.5.3 Set the SPAN gas pressure to 25 psi (1.7 bar,

170 kPa) and the ZERO gas pressure to 35 psi

(2.4 bar, 240 kPa).

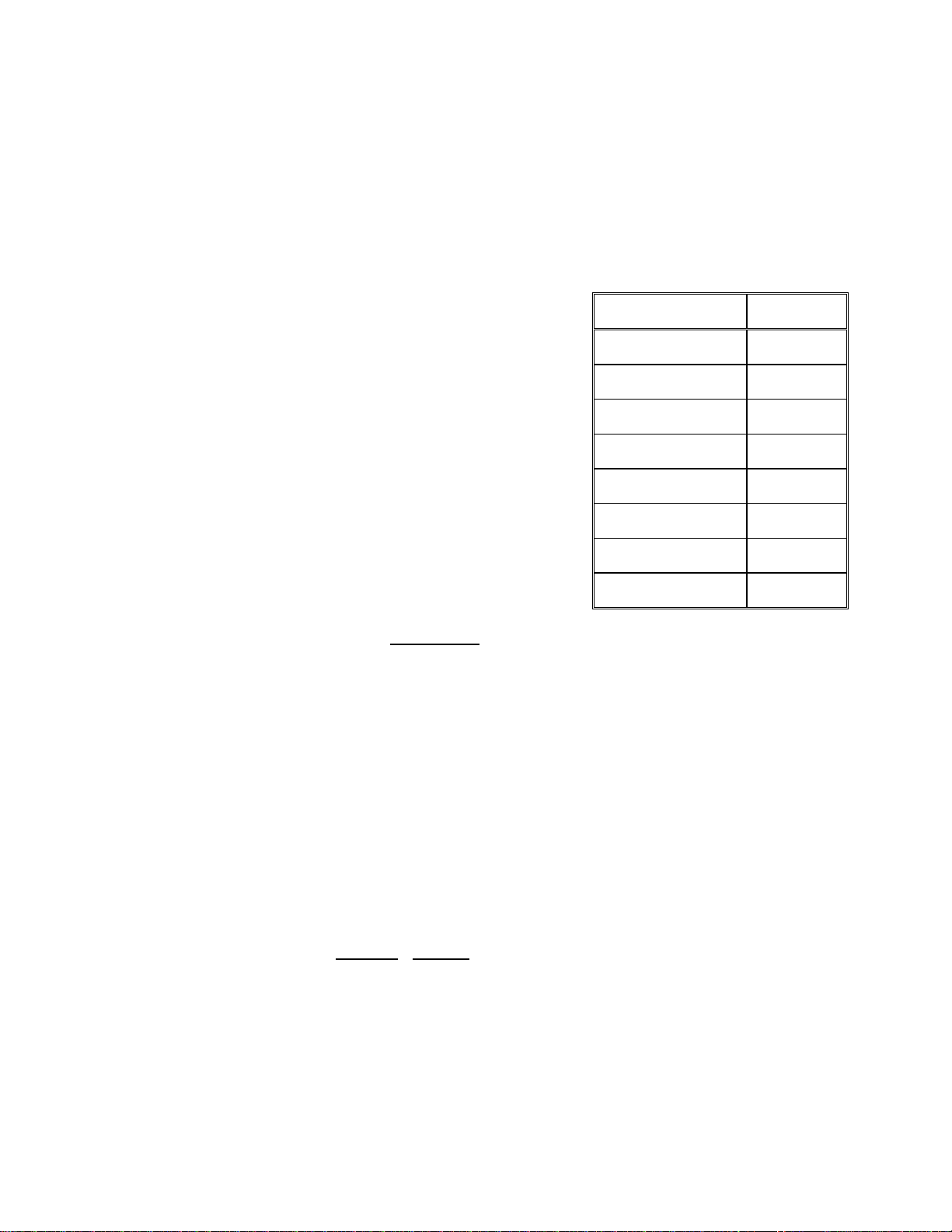

3.6 Remote Control

3.6.1 A 15 way ‘D’ socket should be connected to the

controller lead using the following connection

details. B(n) refers to the nth significant bit. The

truth table follows a BCD code in 10% steps.

Codes higher than 10 results in 100% SPAN gas.

Refer to section 4.3.

Figure 1 Tube Fitting Assembly

PIN CONNECTION

1 B(0) +ve

2 B(1) +ve

3 B(2) +ve

4 B(3) +ve

5 Not Used

6 Not Used

7 Not Used

8 Not Used

9 B(0) –ve

10 B(1) –ve

11 B(2) –ve

12 B(3) –ve

13 Not Used

14 Not Used

15 Not Used

821S OPERATING MANUAL

Page 9 of 13

S\masters\manuals\821S

4 OPERATION

4.1 Installation

4.1.1 Install the divider as detailed in the installation section. Set the input gas pressures to

25 psi (1.7 bar, 170 kPa) for the SPAN gas and 35 psi (2.4 bar, 240 kPa) for the ZERO

gas. Operate the mains switch (push button switch on the front panel) and the ‘Mains

On’ indicator will glow.

4.2 Local Operation

4.2.1 If the 821 is fitted with the remote

control option the rear panel switch

should be set to LOCAL.

4.2.2 Set the front panel rotary switch to

the required concentration of SPAN

gas in ZERO gas. The output stream

will then consist of the set

concentration.

4.2.3 If gases of different density or

viscosity are being mixed, correction

factors must be applied to predict the

actual concentrations delivered.

Refer to the section on correction

factors.

4.2.4 During the normal operation of the

821, the pressure difference meter

on the front panel should show

ZERO difference (centre zero) for all

ratios except 100%. If this is not the

case, check that the gas pressures

are set correctly and that they remain

stable for all positions of the ratio

switch. Alternatively, if pressure

meters are not available, check that

the flow rate remains constant for all

switch positions. If the air supplies

are correct and stable, a fault may be

indicated. Refer to the section on

Care and Maintenance.

4.3 Remote Operation

4.3.1 Set the rear panel switch to REMOTE.

4.3.2 The concentration will then be set in accordance with the following Truth Table. The

concentration indicator LEDs will show which ratio is currently selected and the position

of the rotary control will have no effect. A logic 1 is given when a 5V signal is applied

between B(n) +ve and B(n) –ve. Refer to section 3.6

B(3) B(2) B(1) B(0) %

Selected

0 0 0 0 0

0 0 0 1 10

0 0 1 0 20

0 0 1 1 30

0 1 0 0 40

0 1 0 1 50

0 1 1 0 60

0 1 1 1 70

1 0 0 0 80

1 0 0 1 90

1 0 1 0 100

1 0 1 1 100

1 1 0 0 100

1 1 0 1 100

1 1 1 0 100

1 1 1 1 100

821S OPERATING MANUAL

Page 10 of 13

S\masters\manuals\821S

4.4 Flow Control

4.4.1 The output flow can be reduced by inserting a restricting device (e.g. needle valve) in

series with the output line.

4.4.2 The pressure at the output port should not be allowed to rise to within 5 psi (340 mbar,

34 kPa) of the SPAN gas pressure otherwise incorrect operation may occur. This is

approximately equivalent to a lower flow limit of 2 L/min.

4.5 Viscosity Correction

4.5.1 Gases with a viscosity different to air will flow

through the precision capillaries at different

rates. When the SPAN and ZERO gases have

similar viscosities (but different to air) there is no

noticeable effect on the accuracy of the mixture.

When the SPAN and ZERO gases have

different densities or viscosities then correction

factors must be applied in order to predict the

actual concentration delivered.

Let Z = the correction factor for the ZERO Gas

Let P = the percentage selected

Let S = the correction factor for the SPAN Gas

Let A = the actual percentage obtained

Then

A= ___100·P·S___

100·Z-P·Z+P·S

4.6 Derived Correction Factors

4.6.1 The table contains experimentally derived factors for some of the more commonly used

gases. This list is continually being refined and increased. We may have already

established the correction factor for a gas not on the list.

4.7 Gas Mixtures

4.7.1 The correction factor for mixtures containing gases whose correction factors are known

may be determined by adding together the relevant percentages of each correction

factor e.g. a mixture containing 10% Carbon Dioxide and 90% Nitrogen would have a

correction factor of :-

10·0.96 + 90·1.03 =1.02

100 100

4.8 Experimental Derivation

4.8.1 The correction factor of a gas may be experimentally derived by analysing another

mixture of that gas with a gas of known correction factor.

4.8.2 Re-arranging the correction formula gives two further useful formulae.

GAS FACTOR

Air 1.00

Carbon Dioxide 0.96

Carbon Monoxide 1.01

Helium 1.50

Hydrogen 2.78

Nitrogen 1.03

Oxygen 0.92

Methane 1.18

821S OPERATING MANUAL

Page 11 of 13

S\masters\manuals\821S

Z=S·(100·P-P·A)

100·A-P·A

S=Z·(100·A-P·A)

100·P-P·A

4.8.3 Using the 821, a series of readings at 10% intervals may be obtained from a suitable

detector. After correcting for the detector offset, scale factor, and linearity, the results

can be inserted into one of the above formulae to determine the unknown correction

factor. Using the results obtained for 10% to 90% inclusive, an average correction factor

can be calculated which may then be used for future work involving that gas.

4.9 Trace Gases

4.9.1 For gases containing less than 2000 ppm of trace gas the effect on the correction factor

is usually negligible. The correction factor for higher concentrations will need to be

verified experimentally.

821S OPERATING MANUAL

Page 12 of 13

S\masters\manuals\821S

5 CARE AND MAINTENANCE

5.1 Care

5.1.1 The Model 821S Gas Divider has been designed for general use and requires minimal

maintenance. The Model 821S Gas Divider is also a precision instrument and will

reward you with years of trouble free service by being treated as such.

5.2 Routine Maintenance

5.2.1 Only the pressure gauge offset needs regular adjustment. This should be done if the

meter does not indicate zero on all ratios except 100%.

5.2.2 The zero offset on the pressure difference meter can be easily adjusted. Disconnect all

gas inlet and outlet pipes and allow the 821 to stabilize for on hour with the mains supply

switched on. Using a small screwdriver adjust the panel mounted potentiometer

adjacent to the meter to give a central reading of zero.

5.3 Fault Finding

5.3.1 Fuse replacement

If the mains fuse should fail it must be replaced with a fuse of the same rating as listed in

the specification section of the manual. If the fuse fails repeatedly, do not replace it with

a higher rated fuse. There is probably an internal failure that is not apparent. The unit

should be returned to our Service Department.

5.3.2 Gas Pressure Difference Variation

•Check that the input pressures (25 psi (1.7 bar, 170 kPa) SPAN and 35 psi (2.4 bar, 240

kPa) ZERO) are correct and do not vary with demand. If long lengths of pipe have been

used between the gas source and the 821, the pressure should be measured at the 821

ports.

•It may be necessary to regulate the pressure closer to the unit, or to run larger pipes, in

order to reduce the pressure variation.

•The SPAN pressure controls the flow rate. The ZERO pressure must be 5 psi (340

mbar, 34 kPa) greater at all ratios.

•Provided that the pressure difference meter reads zero, the ratio will remain constant for

a wide range of flow rates. However, some gas analysers are sensitive to flow rate

variations and change their full-scale calibration. This is observed as a non-linearity.

The pressure at the SPAN input port must remain constant if the analyser is to yield its

best performance.

•If the pressure indicator moves from zero when you select lower percentages then the

pressure in the zero gas is too low or the tubing is too long producing a drop in pressure.

•If the flow meter registers a falling flow rate when you select higher percentage then the

Span Gas Pressure is too low or the tubing is too long producing a drop in pressure.

5.4 Capillary Set Up Procedure

5.4.1 Requirements:

821S OPERATING MANUAL

Page 13 of 13

S\masters\manuals\821S

Zero grade air

Trace gas of <2000ppm in air

Analyser known to be linear within 0.05%

•Fit capillaries into manifold block.

Do up nut to finger tight and then

one flat. Avoid ingress of

particulate. Note that the 10%

capillary is on the right when facing

the 821S.

•Attach gases and set correct

pressures. Switch on.

•Set 0% on 821S.

•Set reading on analyser to 0%

•Set 100% on 821S.

•Set reading on analyser to 100%.

•Repeat steps 3-6 until steady

readings are obtained.

•Take readings at each point on

821S.

•Calculate percentage obtained from each capillary by subtracting each reading from the

previous reading.

•Arrange the capillaries in ascending order of restriction, i.e. capillary 1 is the lowest flow,

capillary 2 is next lowest etc.

•Fit capillaries in the order 6, 4, 7, 1, 10, 2, 9, 3, 8, 5.

•Repeat steps 2 to 9. The capillaries should now be within ±0.2% of F.S.

%

Set %

Obtained Capillary

Value

Order

100 100 9.8 2

90 90.2 10.1 8

80 80.1 9.7 1

70 70.4 10.0 5

60 60.4 10.4 10

50 50.0 9.9 3

40 40.1 10.0 6

30 30.1 10.2 9

20 19.9 9.9 4

10 10.0 10.0 7

0 0.0

Table of contents