Signtex Lighting RPROAC Series Manual

Before connecting to power supply, TURN OFF ELECTRICAL

POWER AT CIRCUIT BREAKER OR FUSE

Disconnect AC power before servicing.

Refer to wiring diagram for proper connections.

All servicing should be performed by qualified personnel.

Consult your local building code for approved wiring and installation.

Do not use outdoors.

Suitable for indoor damp locations (when specified).

Do not let power cords touch hot surfaces.

Do not mount near gas or electric heaters.

Mount and secure exit sign at a location and height to avoid

ready access and tampering by unauthorized persons.

(Exception: Floor proximity installations)

The use of accessory equipment is not recommended by

the manufacturer and may cause an unsafe condition.

Do not use this equipment for other than intended use.

IMPORTANT SAFEGUARDS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

S P E C I F I E D E M E R G E N C Y L I G H T I N G

Signtex Inc

LIGHTING

Series RPROBB & RPROAC

Installation Instructions & Users Manual

Rapier Open Face Die Cast LED System

Battery Backup & AC Models 03.15.03

-2-

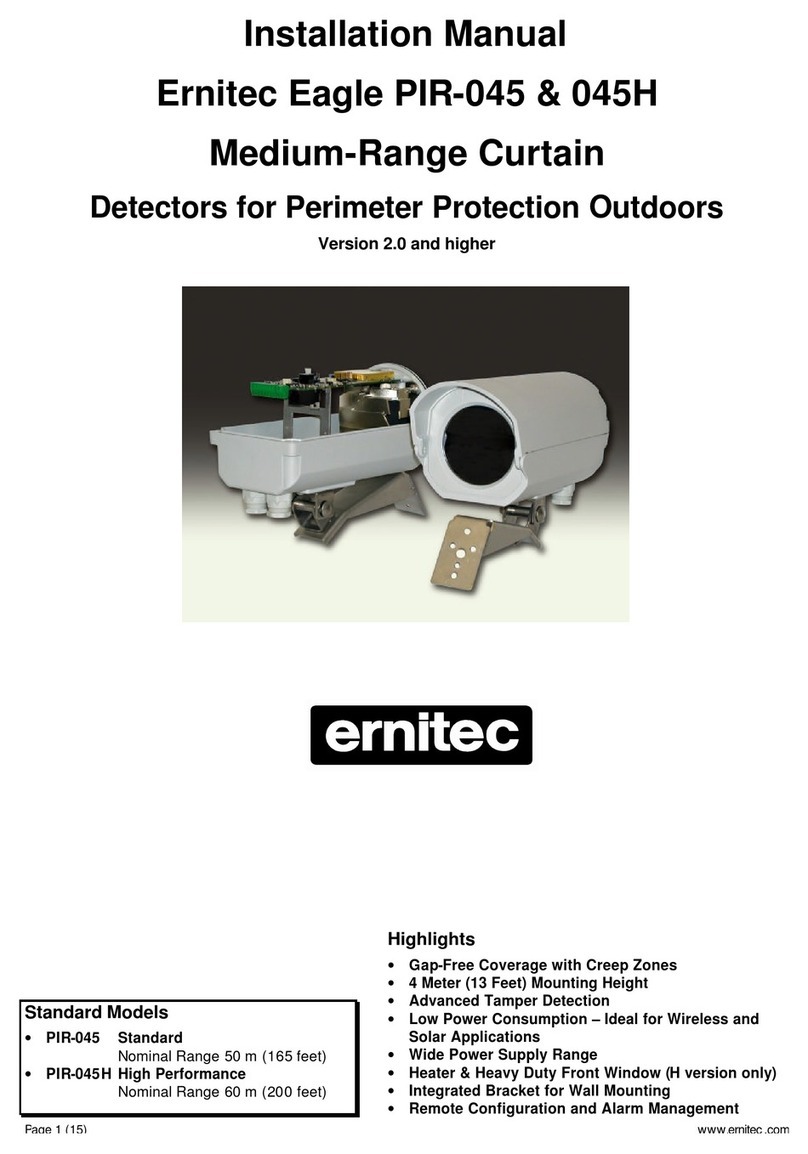

BACKPLATE

BACKPLATE

SIGN

HOUSING

ALL INSTALLATIONS REQUIRE STANDARD TYPE 4" x 4" SQ x 2 1/8" DEEP J- BOX.

SET ADAPTOR PLATE ¼"- 3/8" BELOW FINISHED PANEL SURFACE

Before installing or connecting any primary power wiring,

DISCONNECT MAIN POWER SUPPLY AT THE CIRCUIT BREAKER OR FUSE.

WALL MOUNT

WALL MOUNT

1. Install J-Box 1/8"-1/4" below finished panel surface. Connect Power Module AC wiring to

building supply in J-Box, using wire nuts or connectors supplied.

BATTERY MODELS: BLACK: 120 277 VAC WHITE: Common

AC MODELS: Non- Polarized Line in.

2. Route wire nuts to side of J-box, insert Power Module into box and secure with 2 #8-32 box

screws.

NOTE: Power module orientation is universal, position as required to clear connectors

and wire nuts in J-box.

3. Remove back plate from sign assembly by inserting pin (small screwdriver or allen key)

into 2 release holes in top edge, press down to release clips and hinge cover away from

housing.

4. Support backplate on raised flat surface and knock out oval opening

in center.

NOTE: Remove any sharp edges around opening by file or sharp metal blade. Drill 3/16"

diameter holes at locations noted above. For additional support drill out 2 additional 3/16"

dia holes at left and right sides on center. Locate back plate in position on wall and mark

support holes; install wall anchors for support screws.

5. For battery backup models, connect 2-pin polarized battery plug.

6. Run LED lamp plug through backplate. Attach back cover to j-box with 2 #8-32 screws

supplied. Install and tighten 2 support screws. DO NOT OVERTIGHTEN.

7. Insert 2 tabs on base of sign assembly into slots in base of back cover. Connect LED lamp

plug.

8. Hinge sign assembly into position and snap closed.

To remove signs, repeat step 3.

WALL

POWER

MODULE

ADAPTOR

PLATE

BACKPLATE MT. SCREWS

#8-32 SELECT LENGTH

1/2" - 3/4"

REMOVE

K.O. FOR WIRING

DRILL OUT 3/16" DIA

IN TWO PLACES TO

MATCH

J-BOX LOCATION

DRILL 3/16" IN TWO PLACES

FOR ADDITIONAL WALL MT.

SUPPORTS

USING SCREW ANCHORS

1 1/2" SQ.

EXTENSION

AC POWER

INPUT

120/277 VAC

POWER MODULE

MOUNT SCREWS

#8-32 (2 REQD)

POLARIZED

LED LAMP

PLUG

GRD

J- BOX

4" x 4"

x 2 1/8"

LOWER

BRACKET

SPACER

TEST

PANEL

DIFFUSER

LENS

TEST SWITCH

AND LED INSULATOR

PLUG

CONNECTOR

WIRING TO

POWER

SUPPLY

TEST PANEL ASSEMBLY

Series RPROBB & RPROAC

Rapier Open Face Die Cast LED System

Battery Backup & AC Models 03.15.03

CANOPY

MOUNT SCREWS

(2 REQD)

CANOPY PLATE

(SEE FIG 1 FOR MOUNT)

POWER MODULE

MOUNT SCREWS

#8-32 (2 REQD)

POWER MODULE

MOUNT SCREWS

#8-32 (2 REQD)

-3-

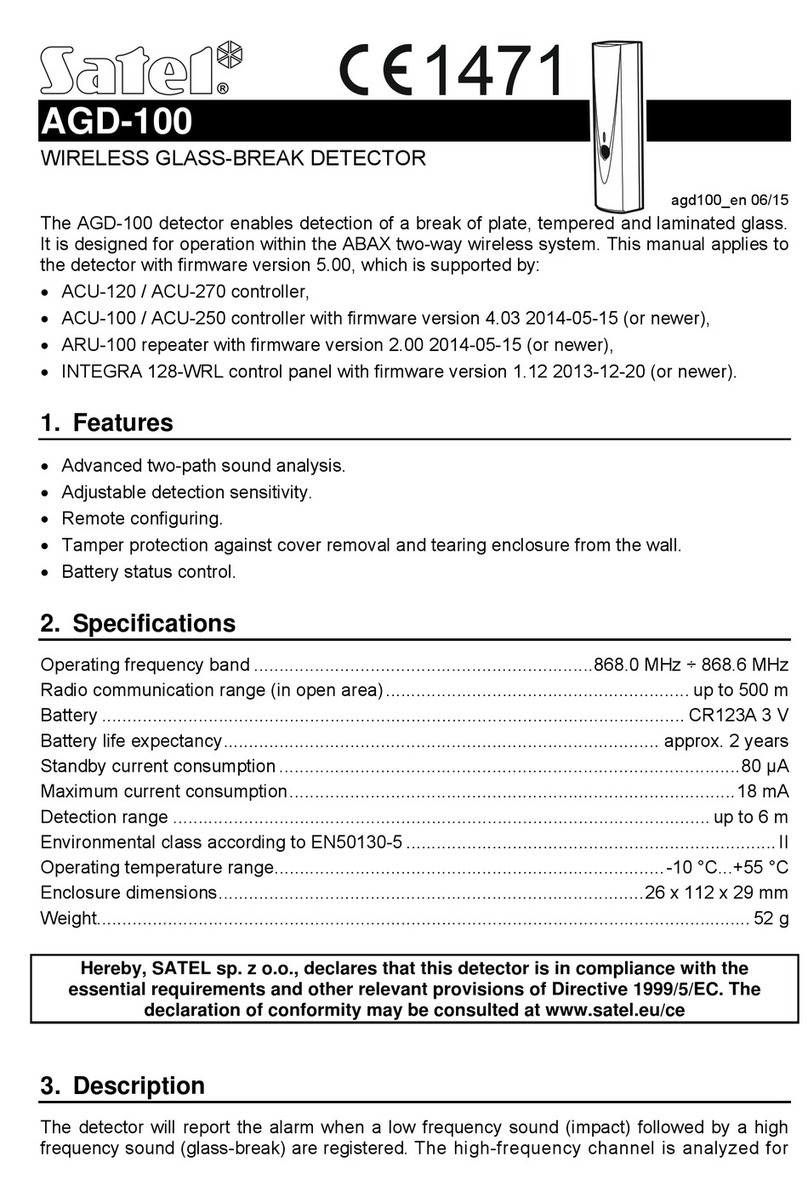

CANOPY MOUNT

SCREWS

(2 REQD)

TOP OR END MOUNT

1. Follow WALL MOUNT steps 1-3.

2. For battery backup models, connect 2-pin polarized battery plug.

3. See Fig.1 and 2 below. Route LED connector through slot in top of housing and through canopy.

Insert 6-32 X 3/4" flat head screws into housing and lock down two nuts firmly.

Run flat washers on screws, position canopy, and firmly tighten two lock nuts as shown.

4. Raise sign to J-box, insert excess wiring and plug into center cavity and secure sign assembly with

2 #8-32 color- matched screws supplied.

CHEVRON ARROW SELECTION

1. With backplate removed, place sign face on scratch- free surface.

2.Remove four #8-32 screws and detach two corner brackets and one lower bracket. Retain all

screws.

3. Remove lens diffuser and place on scratch- free surface. LED panel and test panel assembly

(in battery backup models only) can be left in place.

4. Place sign face down on raised wooden blocks (or other scratch- free surface), and carefully knock out

selected chevron with hammer and small punch.

5. Place upper edge of lens diffuser against flexible spacers, compress spacers slightly and lower bottom

edge of diffuser into place next to LEDs. Replace three brackets and continue with installation

J- BOX

CANOPY PLATE

POWER MODULE

#6-32 LOCKNUT (2 REQD.)

#6 FLAT WASHER (2 REQD.)

#6-32 SMALL PATTERN

NUT ( 2 REQD)

#6-32 X 3/4" SCREW,

FLAT HD (2 REQD.)

SIGN HOUSING

CANOPY

TOP MOUNT

END MOUNT

AC POWER INPUT

120/277 VAC

CEILING

FIG 1 FIG 2

POWER

MODULE

ADAPTOR PLATE

1 1/2" SQ. EXTENSION

AC POWER

INPUT

120/277 VAC

GRD

J- BOX

WALL

Series RPROBB & RPROAC

Rapier Open Face Die Cast LED System

Battery Backup & AC Models 03.15.03

-4-

Wiring

1. This equipment to be connected to an un- switched

circuit only.

2. For exits with Master- Remote or Self-Diagnostics,

refer to supplementary data sheet for wiring diagrams

and additional instructions.

3. CAUTION: Damage to battery will occur if battery

connector is connected to charger board for

prolonged period of time without continuous AC

power provided.

Inspection and Maintenance

Important Note: Emergency lighting systems

should be tested as often as local codes require,

or at least monthly, to a certain that all

components are operational. Allow battery to

charge 8 hours before initial testing, and 24 hours

to fully charge battery.

1. Normal Operation: When unit is functioning

properly, with AC power supplied, the Status light and

exit lamp will be on.

2. To Test: Press manual test switch. Status light will

turn off and exit lamp will remain on in DC mode.

Note: Turn off AC power and disconnect battery before

servicing unit.

Battery Replacement

Remove fixture from J-Box. Locate battery wiring and

disconnect 2- pin polarized battery plug. Pry battery

out of cavity to release hook and loop fastener. Replace

battery, reconnect battery plug and replace fixture.

Power Module Replacement

Remove fixture from J-Box. Remove two #8-32 screws

to J-Box and remove Power Module Assembly from J-

Box.Disconnect wire nuts or push nut connectors to AC line

inputs. To replace with new Power Module, reverse this

sequence.

220 VFW Avenue, Grasonville, MD 21638

TEL: (410) 827-8300 Fax:(410)827- 8866

sales@signtexinc.com www.signtexinc.com

Signtex Inc

LIGHTING

BATTERY DIAGNOSTIC FUNCTIONS:

Microprocessor programmed to perform tests as follows:

Continuous

Monitoring w/ 1

Second Sampling

Lamp

Connections

Transfer switch

function

Test switch

indicator

function

Full 90 minute

emergency

operation test

with test/ fail

and manual

report signal

Battery discharge

rate under

full load

Battery

Connections

Every

28 Days

Every

12 Months

SELF- TEST DIAGNOSTIC FUNCTIONS

STATUS

NORMAL FULL CHARGE

NORMAL FAST CHARGE

FAILED BATTERY

FAILED LAMP

FAILED TRANSFER

FAILED CHARGER

GREEN ON

ORANGE ON

RED FLASH FAST

GREEN FLASH

ORANGE FLASH

RED FLASH SLOW

LED DISPLAY

Series RPROBB & RPROAC

Rapier Open Face Die Cast LED System

Battery Backup & AC Models 03.15.03

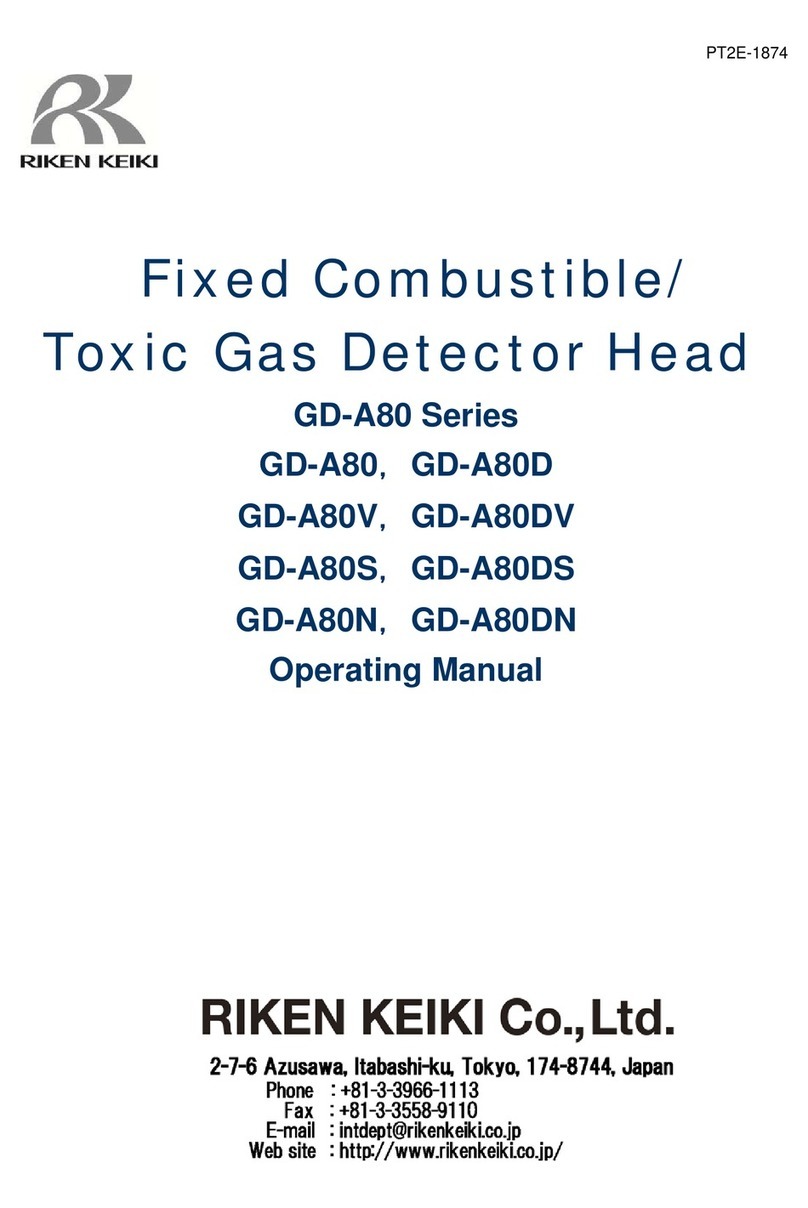

Wiring Diagrams & Instructions

POWER

MODULE

R E D

B R O W N

OUTPUT 2.4-5 VDC

E ME R G E N C Y S I G N S A C F I X T U R E S

FIXTURE HOUSING

BLK

R E D

R E D

V I O L E T

V I O L E T

B R O W N

B R O W N

Y E L L O W

G R E E N

P I N K

O R A N G E

B L A C K

OUTPUT 2.4-5 VDC

RED

LAMP CIRCUIT BOARD

LAMP CIRCUIT BOARD

FIXTURE

GROUND

NEUTRAL

120-277 VAC

B L A C K

W H I T E

G R E E N GROUND

NEUTRAL

LINE

LINE

120-277 VAC

B L U E

B R O W N

G R E E N

POLARIZED

CONNECTOR

TEST PANEL

DIAGNOSTICS INDICATOR

CHARGE LIGHT

TEST SWITCH

8-PIN POLARIZED

2-PIN POLARIZED

CONNECTOR

CONNECTOR HOUSING

BATTERY

This manual suits for next models

1

Popular Security Sensor manuals by other brands

ANALOX

ANALOX A50 quick start guide

ESYLUX

ESYLUX PD-C360i/8 mini KNX operating instructions

Ksenia

Ksenia velum DT AM installation guide

AMP Lighting

AMP Lighting VAC-MOTION1-4-BBZ Installation & maintenance guide

Agilent Technologies

Agilent Technologies VS Series Field installation instructions

Alula

Alula RE209 quick start guide