SigTEL Compact ECU-4 Instruction Manual

THIS GUIDE IS ONLY FOR SUITABLY SKILLED AND EXPERIENCED INSTALLERS OF EMERGENCY VOICE COMMUNICATION SYSTEMS (EVCS) and summarises key information provided in the

full manual (Document No. DAU0000091). Section numbers, e.g. , reference sections in the full manual with additional information.

SigTEL (1 to 16 Lines) Standalone EVCS - Quick Start Installation Guide

FUSE

16 x

extensions

EVC302F EVC301RPOEVC302GS

3A fusedspur

Outstation lines: 2-core

enhanced

fire ratedcable (1.0 to 1.5 mm

2

)

, up

to 1 km in length.

Power supply: Fixedwiring,

2-core enhancedfire rated

cable (0.75 mm

2

to 2.5 mm

2

).

NC951

NC951 lines: 2-core cable.

ECU-16 Wall

Controller

1

2

4

3

ECU-224Desk Controller

ECU-224DeskController

ECU-224DeskController

power

power

power

sync

sync

sync

f

ault

f

ault

f

ault

ECU-224 Desk

Control Unit

(Optional)

Cat 5 socket

andback box

ECU-16 (shown left) has

16 available extensions.

ECU-8 has eight and

ECU-4 has four.

1 of 2

Approved Document No. DAU0000093 Rev 4

SigTEL

Emergency Voice

Communication System

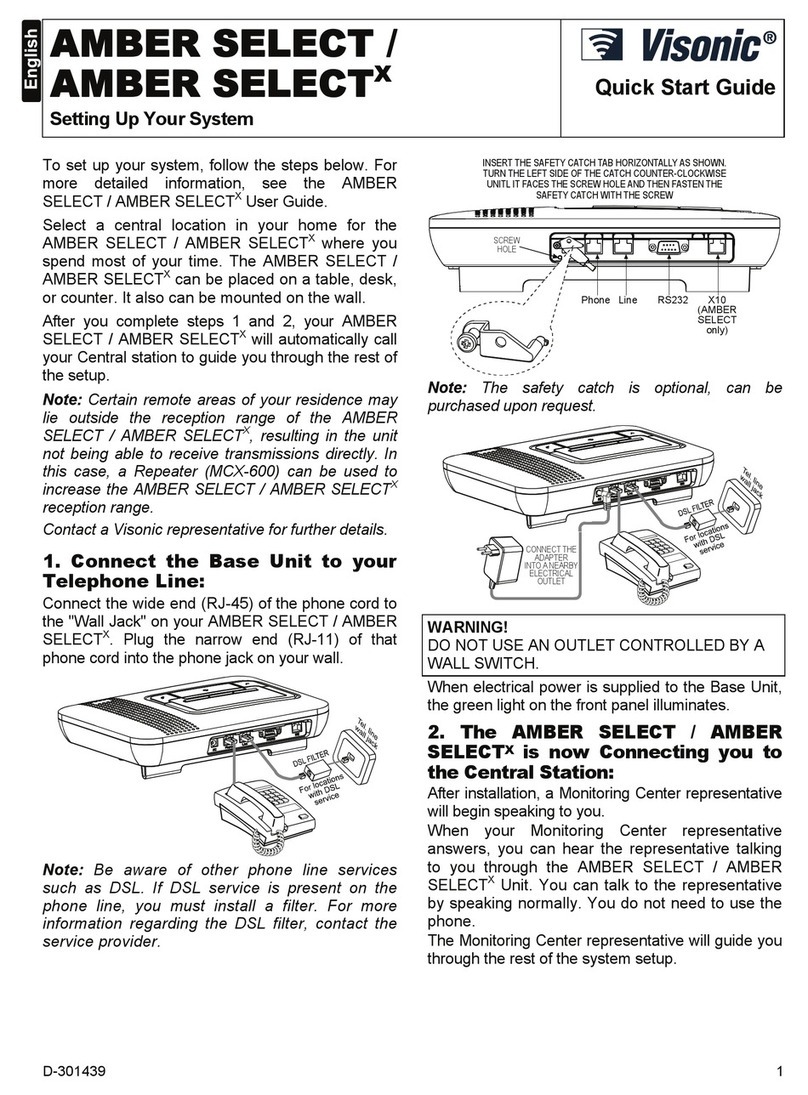

SigTEL EVCS Typical Wiring Overview

Install the EVCS

Location

Site all equipment indoors in well-lit areas, free from obstruction. Site wall controllers in the control room or lobby, 1.4

metres above final floor level (FFL). Fit Type A (fire telephone) outstations in fire fighting lobbies and fire access points,

1.3 to 1.4 metres above FFL. Fit Type B (disabled refuge) outstations in disabled refuges, 0.9 to 1.0 metre above FFL.

Mounting

Remove base PCBsbefore first fix installation to protect them and expose the base mounting holes. Wall mount the

controllers, either surface or semi-flush. Fix the base securely onto a wall using No.8 round-head, or countersunk screws.

After mounting, remove any dust/swarf and re-install base PCBs. Ensure all connecting looms are refitted.

6.1

6.1

Wiring

See Fig 1above for cable types. Install wiring in accordance with the relevant national, regional or local regulations (in the UK this is the IEE

Wiring Regs BS 7671 and BS 5839 Part 1). Use enhanced fire-rated cables from the controller to the Type A & B outstations and the power supply.

Test Extensions

Test all extensions for faults before terminating to the controller using a FITT EVCline tester.

CAUTION: DO NOT use an Insulation Resistance Tester with any devicesconnected asthey will be destroyed and the warranty will be void.

Fit Outstations& NC951Interface

Maximum recommended cable distance to the outstations is 1 km, beyond which audio quality may degrade. For wiring and connection

details refer to Type A outstation instructions (Doc. No. DCM0003819) and Type B outstation instructions (Doc. No. DAU0302000).

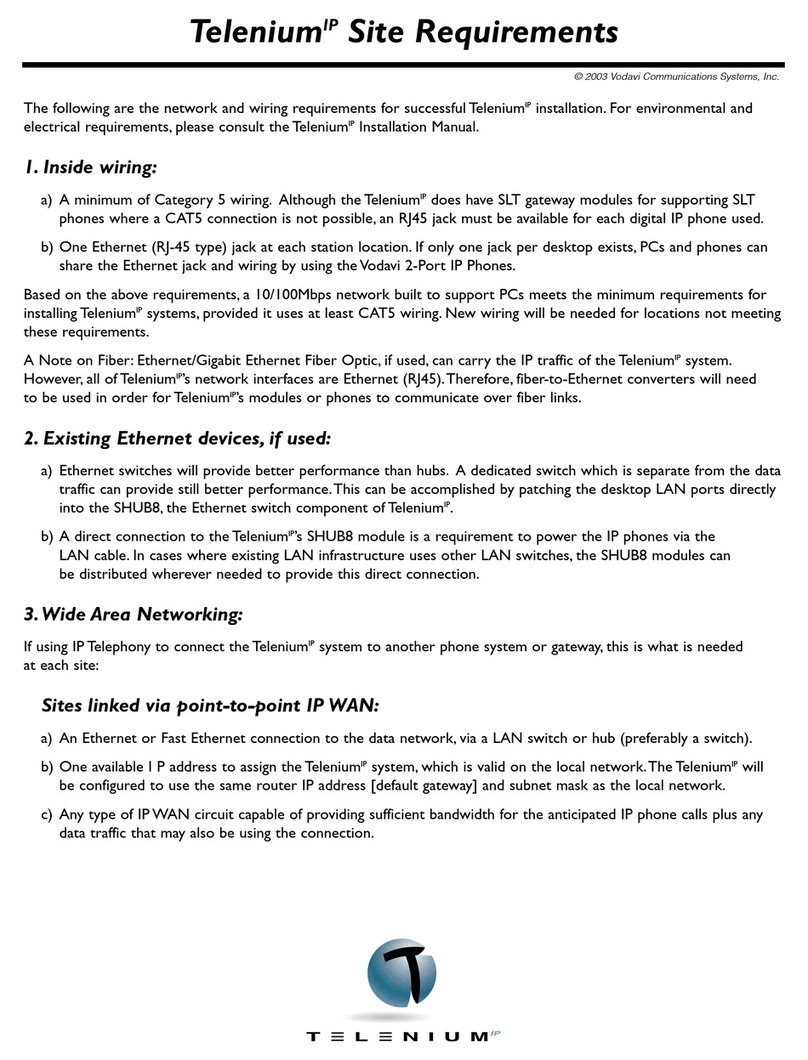

Connect Extensionsand Optional Desk Control Unit to the Wall Controller

Do not connect extensions to the controller until they have been tested, fault-free and suitable cable glands fitted. Connect extensions

directly to the Master Exchange PCB inside the controller (see Fig 2 left). Connect screens to the earth terminal in the back of the enclosure.

For an optional Desk Control Unit (ECU-224), mount a CAT5 wall socket near to the controller’s location and connect from the wall socket to

the ECU-224 using a CAT5 lead (supplied). Connect two 4-core fire-rated cables (not supplied) from the controller to the wall socket.

8 x Extensions from Outstations &NC951

16 x Extensions from Outstations &NC951

L1 L2

+ - + -

L3 L4

+ - + -

L5 L6

+ - + -

L7 L8

+ - + -

N/O C N/C 0V +24 OP3 OP2 OP1

I/P A I/P B I/P C

+ - + - + -

All screens connect

to Earth terminal

ECU-16

Master Exchange PCB

CD

B

L9 L10

+ - + -

L11 L12

+ - + -

L13 L14

+ - + -

L15 L16

+ - + -

C

L1 L2

+ - + -

L3 L4

+ - + -

L5 L6

+ - + -

L7 L8

+ - + -

N/O C N/C 0V +24 OP3 OP2 OP1

I/P A I/P B I/P C

+ - + - + -

All screens connect

to Earth terminal

ECU-8 or ECU-8NT

Master Exchange PCB

B

C

Fig 2

7

4

11

13.1

SigTEL EVCS Components

12

Fig 1

Part No. Description

ECU-4 4 Line Master EVCWall Controller c/w handset & display, requires two 12V 7 Ah batteries

ECU-8 8 Line Master EVCWall Controller c/w handset & display, requires two 12V 7 Ah batteries

ECU-1616Line Master EVCWall Controller c/w handset & display, requires two 12V 7 Ah batteries

ECU-8NT 8 Line Master EVCWall Controller (no handset) c/w display, requires two 12V 7 Ah batteries

ECU-224 1-224 Line Desk Control Unit c/w handset and display

EVC302F/GF Disabled Refuge (Type B) Outstation, flush mounting, stainless steel (‘G’ - Green fascia)

EVC302S/GS Disabled Refuge (Type B) Outstation, surface mounting, stainless steel (‘G’ - Green fascia)

EVC301RPO Red Fire Telephone (Type A) Outstation c/w handset (push to open)

EVC301RLK Red Fire Telephone (Type A) Outstation c/w handset (lift lock)

BF359/1 Weatherproof enclosure for EVC302F/GF

BF359/3M Stainless steel enclosure for controller (ECU-4 / ECU-8 / ECU-16)

BF359/3S Stainless steel enclosure for controller (ECU-8NT)

NC951 Disabled Persons Toilet Alarm (DPTA)

FITT EVCLine Tester

BC286/2 24 V 7 Ah battery (2 x 12 V) used with controller (ECU-4 / ECU-8 / ECU-16/ ECU-8NT)

EVC385 Grey flush bezel for controller (ECU-4 / ECU-8 / ECU-16/ ECU-8NT)

T-BEZ301 Red flush bezel for EVC301RPO and EVC301RLK

EVC423 PCprogramming software

3

13.5

Commission the EVCS

Eng. Opts

System Healthy

Name List

>

Config

LCD Contrast

About...

Edit Phonebook

> Extension 1

Extension 2

Extension 3

Extension 4

Press Engineer Mode button

(located back of wall controller’s lid)

EVCS

WC

Before commissioning the system ensure that all equipment is fully installed, connected and wiring tested. Check all

handsets are on-hook, no calls or faults are present on the system and the controller shows ‘System Healthy’ status at

Naming Extensions

Select ‘Edit Phonebook’ option.

and - highlights extension

CALL/ACCEPT - selects 1st character

and - changes character

CALL/ACCEPT - moves to next character

END - moves to previous character & exits

DIRECTORY - saves changes

At the wall controller, with the handset on-hook, select the ‘Edit Phonebook’ option by following the flow chart below. With an

operator at the controller, go to each outstation in turn and make a call to the controller lift. The outstation’s channel is opened for

speech and automatically selected for editing. Check audio quality of the line and inform the operator at the controller your position.

They can edit the outstation name directly (see Naming Extensions below). Repeat this process for all remaining outstations.

Press Engineer Mode button

(located back of wall controller’s lid)

>

Phone Opts

System Opts

System Admin

Factory Dfts

Config

: 1

: 0 : 3

: 5

Auto Learn

System Healthy

Edit Phonebook

>

LCD Contrast

About...

Eng. Opts

Config

System Cfg

Sys Cfg

System Healthy

>Wall Units 1

EVCS

WC

EVCS

: 1

: 5

System Updated

Configure the system

FUNCTION (1)

= USER OPTS MENU & PIN CODE ENTRY

DIRECTORY (2)

= DIRECTORY & PIN CODE ENTRY

SILENCE (3)

BUZZER

= SILENCE BUZZER & PIN CODE ENTRY

(4)

= PIN CODE ENTRY

= SCROLL UP

= SCROLL DOWN

CALL/ACCEPT

= MAKE/ACCEPT CALLS & SELECT MENUS

END

= END CALL, ESC TO PREVIOUS DISPLAY

& LAMP TEST

Using the Wall Controller’sKeypad

2 of 2

Approved Document No. DAU0000093 Rev 4

SigTEL

Emergency Voice

Communication System

Change PIN Code

Connecting Mainsand Batteries

See Fig 1overleaf for mains cable type. Connect a 230 Vac supply to the

controller via top right knockouts (or, where convenient). Terminate the

mains cable at the Power Supply PCB (plug P2) and NOT to main earth chassis

(see Fig 3 right).

For the emergency standby power supply, only use good quality, sealed VRLA

batteries. Position and connect two 12 V, 7 Ah batteries (BC286/2) inside the

controller using the supplied battery connection leads (see Fig 4 far right).

10

18.1

Set Up Latch Faults 18.3

Clear Recent Calls 18.4

Set up Auto-Answer 18.5

Add/Remove Controllers, Outstations & DPTA

17.3

Check audio quality and interactively name extensions17.5

17.1

24 V

battery connection leads

(supplied)

+

–

+

–

GND

B

+

–

+

–

Controller

Battery Connector

Master Exchange PCB Power Supply

PCB

12V, 7Ah 12V, 7Ah

12V, 7Ah 12V, 7Ah

C

A

B

C

D

Mains Fuse

1 A HRC

L E N

Batt fuse

1 A (F)

Power Supply

PCB

To 3 A fusedspur

Cable gland

Power Supply leadBattery

Connector

P2

Power Supply

PCB

MCU

Master Exchange PCB

WARNING: If re-connectingthe

Power Supply leadcheck that

the pins are not mis-aligned!

230 VAC

230 Vac

Fig 3 Fig 4

What the symbolsmean

Additional Engineer Functions

Check the wall unit

count is set to 1

16

Check the number of

controllers and

outstations displayed

are correct

Observe correct polarity!

Press END button to

return to ‘System

Healthy’ display

HINT!

PCTools (EVC423) are available that allow quick and easy editing of

extension names and also provide limited engineering functions.

Contact your supplier for details.

its LCD display. Configure the system by following the flow chart below.

14.3

- No. of type A (fire telephone) outstations

- No. of type B (disabled refuge) outstations

WC- No. of disabled persons toilet alarms (DPTA)

- No. of wall units c/w phone ECU-4 /-8 /-16

- No. of desk control units ECU-224

- No. of wall units ECU-8NT

First Come, First Served 18.6

Manufacturer: SigNET ACLtd, 6Tower Road, Washington, Tyne & Wear NE37 2SH. www.signet-ac.co.uk. E&OE. No responsibility can be accepted by the manufacturer or distributors of these power supplies for any misinterpretation of this instruction, or for the compliance of

the system as a whole. The manufacturers policy is one of continuous improvement and we reserve the right to make changes to product specifications at our discretion and without prior notice.

Other manuals for Compact ECU-4

1

This manual suits for next models

4

Popular Telephone System manuals by other brands

Vodavi

Vodavi Telenium IP installation manual

Panasonic

Panasonic KX-T336 System reference manual

Interalia

Interalia DMU operating manual

TransTel Communications

TransTel Communications SuperKey SK-824 Features and services description

Lucent Technologies

Lucent Technologies MERLIN LEGEND Release 3.1 MLX Queued Call... Operator's guide

AT&T

AT&T Merlin II R3 System administration Quick reference guide