Sigtronics MRIM-2 User manual

INTRODUCTION

Attention Installer: To assure a trouble free installation, please read

these entire instructions through once before beginning.

The Sigtronics Mobile Radio Interface Module is a small unit that allows

emergency personnel to operate the vehicle’s mobile radio using a

headset. When used with a Sigtronics noise attenuating headset (ie.

models SE-8 or SE-48) this unit provides personnel with clear radio

communications in high noise environments. The system allows full

radio monitoring as well as radio transmit capability from the headset

via a Push-To-Talk (PTT) switch.

Applications: The unit is designed for re apparatus, rescue and

ambulance vehicles, marine emergency equipment, airport ground

vehicles, and mobile emergency command centers. Used in applications

where intercom is either not desired or not necessary.

Headphone Output: The Mobile Radio Interface Module is designed

to be used with noise attenuating, full cushion headsets, such as the

Sigtronics SE-8, or SE-48. The Mobile Radio Interface Module incorporates

an automatic headphone limiting circuit to eliminate the possibility of

painful spurious radio or noise spikes from getting to the headset and

to your ears.

Universal Radio Interface is designed to accommodate virtually any type

of communication radio. Adjustments for radio transmit microphone

level are provided to perfectly match the Mobile Radio Interface Module

to your particular radio.

Excellent RF Immunity guarantees clean, clear, radio communications.

Standardized for use with Sigtronics single plug headsets (ie. SE-8,

SE-18, or SE-48).

STANDARD EQUIPMENT INCLUDED

Besides the unit, each Mobile Radio Interface Module comes complete

with the following:

Module Mounting Screws .................................................................. 4

Module Mounting Nuts....................................................................... 4

Headset Jack Box and Cover with Pre-mounted

Headset Jack & Splash Cover............................................................. 1

with Pre-mounted PTT Switch.......................................................... 1

Jack Box Cover Screws ......................................................................... 4

Jack Box Mounting Screws................................................................. 4

Wire Grommet ........................................................................................ 2

Jack Insulator Washer, Flat.................................................................. 1

Jack Insulator Washer, Shoulder....................................................... 1

4 ft Interface Cable................................................................................ 1

4 conductor hook-up wire..........................................................1 Roll

igtronics

®

S

Sigtronics Mobile Radio Interface Module

INSTALLATION AND OPERATING INSTRUCTIONS

Models MRIM-2

Specialists in “SOUND” Management

178 East Arrow Highway, San Dimas, CA 91773 (909) 305-9399

Made in the U.S.A.

MOBILERADIOINTERFACEMODULEINSTALLATION

INSTALLATION OVERVIEW:

Sigtronics has simplied the installation process, to assure perfect

operation. Refer to the Mobile Radio Interface Module Wiring Diagram

see Figure 2 on page 4. If you have any installation questions or problems

that are not addressed in this manual, feel free to call our installation hot

line number located on the last page of this manual.

Installation of the Sigtronics Mobile Radio Interface Module is a four

step process:

I. MODULE CHASSIS INSTALLATION

II. HEADSET JACK AND PTT SWITCH INSTALLATION

III. HEADSET JACK AND PTT SWITCH WIRING

IV. RADIO HOOK UP

I. MODULE CHASSIS INSTALLATION

MODULE PLACEMENT:

The Mobile Radio Interface Module is designed to be remote mounted

behind the dash or panel with four screws mounted through the grommets

on the back of the chassis. Because the Interface Module connects to the

radio, select a mounting location near the emergency radio controls.

Make sure that the transmit mic level adjustment holes on the side of

the Radio Interface Module chassis can be easily accessed for adjustment

with the Module in place. Make sure that neither the Module or cable

interfere with the normal operation of the vehicle.

MOUNTING RADIO INTERFACE MODULE CHASSIS:

1. Remove the four corner panel screws (the smaller ones) from the

top of the Module. Remove the unit from the chassis.

2. Set the Module chassis in the intended mounting place. Using a

small point pen or marker, mark the hole pattern through the four

grommets located on the bottom of the Module chassis.

3. Drill four holes using a 5/32 inch drill (clearance for a 6-32 screw).

4. Secure the Module chassis to the vehicle using the four screws and

locking nuts supplied. Be sure to install the screws with the screw

heads inside the Module chassis. This should assure that these

mounting screws will not touch the Module circuit board when in

place. Do not tighten the nuts and screws so tight as to excessively

crush the grommets.

5. Replace the Module circuit back into the chassis. Make sure that the

transmit mic level adjustments line up with the holes in the Module

chassis. Be sure not to pinch any wires under the panel. Replace the

4 corner panel screws and tighten.

6. Plug the Module unit plug P1 into the mating connector J1 on the

Interface Cable.

II. HEADSET JACK AND PTT SWITCH INSTALLATION

HEADSET JACK PLACEMENT:

It is assumed that it has already been determined in what general area on

the vehicle the headset and PTT switch will be located. To determine the

exact position, it is helpful to have a headset handy to physically gauge

the best place for the jack. There are several things to consider when

selecting a place to mount the headset jack:

1. In general, the headset jack placement and headset cable should

not interfere with the normal operation of vehicle doors or

compartments.

2. The jack position should also take into account how the headset

cord will hang when the headset is in use. The cord should hang

out of the way and should not interfere with vehicle controls.

3. The headset jack should be out of the way so that the headset plug

can’t be hit during use or when entering or exiting the vehicle.

4. For a headset position inside the vehicle, the jack should be placed

towards the middle of the vehicle. It should also be placed up above

and towards the back of the user’s head. This will assure that the

headset cord will not hang between the user and the vehicle door.

Sigtronics provides two ways to mount the headset jack for the Mobile

Radio Interface Module:

1. Mount the jack in the supplied blue jack box. Advantages:

a) Little or no “behind the panel” space required.

b) No vehicle panel thickness limitation.

c) Smaller holes are required to be drilled - a real advantage on

vehicles with thick metal panels.

d) Complete electrical isolation of the jack from the vehicles chassis,

because the jack box is fabricated out of non conductive high

impact plastic.

2. Mount the jack directly on the vehicle with a “through the panel”

mounting scheme. Advantages:

a) Smaller space requirement. (Only slightly larger than the jack

itself).

b) Only one hole to drill (1/2 inch).

c) Most of jack is behind panel and out of the way. Sigtronics

recommends that you use the jack box mounting method, but

either approach can be used.

SPLASH COVER:

If a jack is to be mounted outside the vehicle (ie. on or near a re engines

pump panel), a splash cover should be used to keep excess moisture out

of the jack when it is not in use. Every Mobile Radio Interface Module

comes with one such splash cover already pre-mounted on a jack in a

mounting box. In applications, where the headset is always plugged in,

a splash cover is not required.

JACK BOX MOUNTING:

Place the jack box on the mounting surface and mark and drill the

corresponding mounting holes into the vehicle using a 1/8 inch drill.

Mount the jack box to the vehicle with the provided #10 screws. The

screws require a 5/16 inch hex driver.

For most installations the wiring for the headset jack will come out the

back of the jack box. A hole is already provided in the jack box for this

purpose. Of course, you will also have to drill a similar hole into the vehicle.

Use a 5/16 inch drill for this.

Page 2 SigtronicS MriM-2 www.SigtronicS.coM

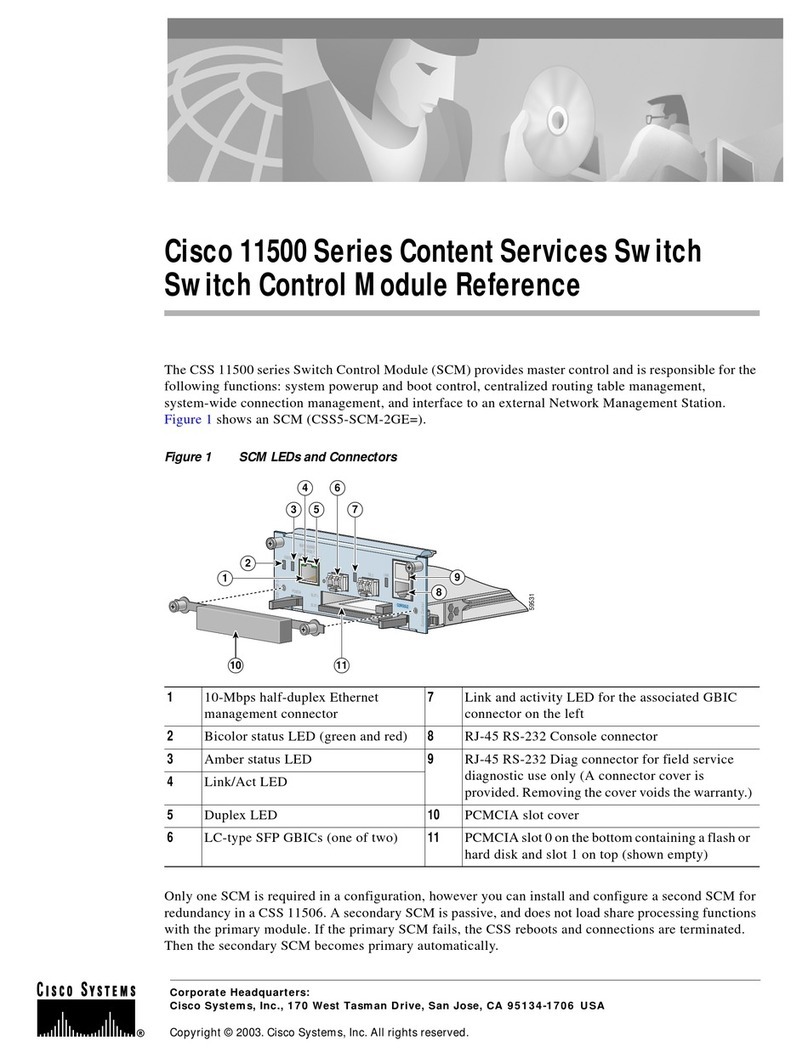

RING

MIC AUDIO

BARREL

COMMON

RETURN

SHOULDER

INSULATING

WASHER

FLAT

INSULATING

WASHER

FLAT

METAL

WASHER

VEHICLE

PANEL

HEADSET JACK

TIP

HEADPHONE

AUDIO

NUT – OR – SPLASH COVER AND NUT

Figure 1

Alternately, the wire can come out of the side of the jack box if desired. You

will have to drill the hole where required. Use a 5/16 inch drill. A rubber

wire grommet is provided for the wire going through the jack box hole.

THROUGH THE PANEL MOUNTING:

For direct mounting of the headset jack on the vehicle panel you will

need to remove the jack and the splash cover from the jack box cover

with a 5/8 inch wrench. For normal jack mounting (with splash cover),

the maximum panel thickness is 0.062 inches or 1/16 of an inch. If you do

not need the splash cover, the maximum panel thickness is 0.10 inches

or a little less than 1/8 of an inch. NOTE: Longer headset jacks that can

accommodate thicker panels are available from your Sigtronics dealer

(order part number 100418 - maximum panel thickness 0.155” with splash

cover and 0.195” without). Mounting on the panel requires that you insert

the jack from the back of the panel. Test jack for clearance and t. Leave

room behind - the jack expands when headset plug is inserted. Make

sure the back of the jack does not interfere with any moving parts of the

vehicle. Drill a 1/2 inch hole in the panel. Install the jack with mounting

washers, splash cover, and nut as in Figure 1 on page 2. Both jack insulating

washers must be used. The jack has to be insulated from mounting spot

to minimize electrical noise getting into the Interface Module system.

No need to tighten the jack now. You may have to remove the jack to

connect the wires.

PTT SWITCH INSTALLATION:

In order to transmit on the radio, you will need a Push-To-Talk (PTT)

switch either on the headset or mounted on the vehicle. If the PTT switch

is already incorporated on the headset as on Sigtronics SE-2P, SE-8P, or

SE-18P headsets, no other PTT is required. If you are using a standard

Sigtronics headset (without a PTT switch on the shell) you will need to

install the included PTT switch on the vehicle to transmit on the radio. If

applicable, use the following to install the PTT switch:

The PTT switch should be placed within easy reach of the user. It is also

helpful if they can be easily seen by the user. As with the headset jack,

you can leave the PTT switch in its mounting box and mount the box

to the vehicle or remove it and install the PTT switch directly on the

vehicle panel. To mount box with switch follow the “Jack Box Mounting”

instructions on this page.

For direct panel mounting of the switch, the maximum panel thickness

is 3/16 of an inch. The PTT switches are mounted through the panel from

the front. In the selected spot, drill a 5/8 inch hole. Mount the switch into

the hole, but only loosely install the provided lock washer and nut from

the back. The PTT switch will likely have to be removed to connect the

wires later. The nut requires a 7/8” wrench.

III. HEADSET JACK AND PTT SWITCH WIRING

The wiring of the headset jack and PTT is straight forward. In general,

three of the 4 foot Interface Cable wires get connected to the Hook-up

Wire (gray) and then the Hook-up wire connects to the jack and the PTT

switch (if applicable). Enough hook-up wire is provided for a typical

vehicle installation. If required, additional hook-up wire can be purchased

through your Sigtronics dealer.

The 4 foot Interface Cable has a 12 pin connector with 11 wires in it.

Before going on, make sure that you have plugged in J1 of the cable

into P1 on the Module.

The headset jack and PTT switch requires just three wires. Refer to the

Mobile Radio Interface Module Wiring Diagram (see Figure 2) for the

exact wiring information.

The connections between the Interface Cable and the hook-up wire should

be soldered and insulated for reliability. Do not use crimp type splices.

They can become intermittent over time. Use a good quality electrical tape,

or better yet, use heat shrink tubing to cover the soldered connections.

The connections to the headset jack and PTT switch will also have to be

soldered. See Figure 1 on page 2 for jack terminal identication. We do

not recommend using screw type terminal strips for headset jack and

PTT connections. There have been several instances where terminal strips

introduced high levels of electrical noise like alternator whine into the

system. It is acceptable however to tie the MRIM-2 red and green power

wires to existing vehicle terminal strips.

The best place to run the wiring between the unit and the jack and PTT

switch is out of sight. It should be run behind vehicle panels and/or up

in the headliner. This will reduce the chance of personnel or equipment

catching on or damaging the wiring. Wire routing should take into account

normal vehicle operations. Wires should not interfere with any of the

vehicle’s controls, compartments, or doors. If the vehicle’s cab tilts up

for engine servicing, run wiring along the existing vehicle wiring bundle.

Make sure that wiring does not interfere or restrict the tilting operation.

Also, make sure that the tilting operation will not cut or sever the wiring.

Make sure that the wiring does not rest on sharp edges. Over time the

vehicle’s vibration may cause a sharp edge to cut into the wire. Use the

provided wire grommets where the four conductor wire goes through

the holes in the jack boxes. Use wire ties or tie wraps to secure and strain

relieve the wire.

At this time do not put the covers on the jack boxes or tighten up the

PTT switch (if applicable). You will need to verify the correct operation

of the system before you close everything up.

POWER CONNECTIONS:

The Mobile Radio Interface Module will run on 11-16 VDC.

CAUTION: This Module is designed for negative ground vehicles only.

It can be used on positive ground vehicles only if a Sigtronics Positive

Ground Adapter is used. Contact your Sigtronics dealer on pricing and

availability.

Make sure that the vehicle power is turned o before connecting the

Mobile Radio Interface Module power wire. The power for the Module

comes in on the red (pin 7) and green (pin 8) wires on the Interface Cable.

Connect the red wire to vehicle power. (Try not to use a power buss that

also runs electrical motors such as fans or light bars with rotating lights.)

Connect the green wire to the vehicle chassis ground.

IV. RADIO HOOK UP

The connection of the Mobile Radio Interface Module to the vehicle’s

radio should be done by someone familiar with the radio such as your

radio installer. Refer to the Mobile Radio Interface Module Wiring Diagram

- Figure 2. Only the radio functions are shown for the radio end of the

Interface Cable. Because the connectors used by radio manufacturers

varies widely, you will have to consult the radio manual or manufacturer

for the connectors and pin assignments used. Sigtronics has extensive

radio interface experience and can assist with any question you might

have concerning this or any other aspect of the Mobile Radio Interface

Module. See our installation hot line number located on the last page

of this manual.

Using the radio manuals and the Mobile Radio Interface Module Wiring

Diagram, identify the correct signal wires or connector pins to attach the

respective Mobile Radio Interface Module wires. For most radios, these

connections are at the back of the radio or radio control head. For some

radios, the only place to connect the MIC HI and LO and PTT HI and LO

wires is to the hand-held microphone connector.* It is best to wire in such

a way that the radio hand microphone can still be used as normal. Make

sure that you do not physically tie the Mobile Radio Interface Module MIC

LO and SPEAKER LO wires to the same pin on the radio, even if they are

tied together inside the radio. As in the headset wiring, the connections

www.SigtronicS.coM SigtronicS MriM-2 Page 3

between the Module and radios should be soldered and insulated for

reliability. Do not use crimp type splices. Use a good quality electrical

tape or heat shrink tubing to cover the soldered connections.

* For the more popular radios of this type Sigtronics manufactures plug

in “Y” adapters to make these connections easy. Contact your Sigtronics

dealer for pricing and availability.

Connect the six wires from the Interface Cable to the appropriate

connections on the vehicle’s radio. Once that is done you will need to set

the Radio Transmit Microphone Level. Radio Transmit Microphone Level

(labeled RADIO TRANSMIT MIC LEVEL) adjustment is provided through

two small holes on the side of the Mobile Radio Interface Module. The

adjustment sets the microphone audio level going to the radio during

transmit. The Transmit Microphone Level adjustment will need to be

initially set to your particular radio. The level once set, should never need

adjustment again unless the type of radio used is changed. The following

simple procedures take you through the adjustment.

RADIO TRANSMIT MICROPHONE LEVEL:

Radio Transmit Microphone Level Adjustment can be made with a small,

at blade screwdriver. Referring to Figure 3, the level adjustment is set

by two controls – a “HI/LO” RANGE switch and a rotary “ADJ” control.

Set the RADIO TRANSMIT MIC LEVEL RANGE switch to the “LO” position

(up). This is the default factory setting. Adjust the “ADJ” control clockwise

to increase the output level to the radio. Counter-clockwise rotation

decreases it. The basic adjustment concept is simple. You will be setting

the level and clarity of outgoing radio transmissions through the Mobile

Radio Interface Module headset, to match or exceed that of transmissions

using the radio’s standard hand microphone. To do this, you will need to

transmit and receive on the vehicle’s radio to a remote station. Arrange

to have someone nearby with a radio compatible to the radio you are

using with the Mobile Radio Interface Module. Then…

1. Turn on vehicle power as well as the radio.

2. Plug a headset into the headset jack. Put on the headsets and position

the boom mic close to the mouth, as is the practice with hand-held

microphones. Voice clarity is best when the mic is about 1/4 inch

away and slightly o center from the lips. Turn the volume control

on the headset, all the way up (clockwise).

3. With the radio’s hand mic, transmit as normal, to the remote

station. Transmit long enough so that the receiving station can

get “calibrated” to your transmission (voice) level.

4. Verify radio reception in the headset. If OK, use the PTT switch

for the headset to transmit to your receiving party. If receiving

station reports weak transmission, use the screwdriver to turn the

RADIO TRANSMIT MIC LEVEL ADJ clockwise a small amount. If they

report garbled, broken, or noisy transmissions, turn the RADIO

TRANSMIT MIC LEVEL ADJ counter-clockwise a small amount. Repeat

as necessary until the receiving party reports that transmissions

through the Mobile Radio Interface Module headset sound as good

or better than when using the radio hand microphone.

5. If the receiving party reports that your transmissions are still weak

with the TRANSMIT MIC LEVEL ADJ at the full clockwise position,

then switch the RADIO TRANSMIT MIC LEVEL RANGE switch to the

“HI” position (down) and repeat steps 3 and 4 above.

Once the level is set, also check radio operation with the vehicle’s engine

running. If radio reception and transmission through the Mobile Radio

Interface Module are ne, this completes the installation. If something

does not work correctly, check the following troubleshooting guide:

Page 4 SigtronicS MriM-2 www.SigtronicS.coM

RADIO TRANSMIT MIC LEVEL

RANGE

LO

HI

ADJ

RADIO TRANSMIT MIC LEVEL

RANGE

LO

HI

ADJ

4 Conductor

Hook-up Wire HEADSET JACK

GREEN TIPGREEN

BLACK BARRELBLACK

RINGREDRED

PTT SWITCH

123

SPEAKER HI (2) VIOLET NOTE 1

(3) VIOLET NOTE 1

(5) WHITE NOTE 2

(11) WHITE / ORANGE

(12) GRAY

(10) BLUE

(6) WHITE NOTE 2

(1) BROWN

(4) BLACK

(8) GREEN

J1

P1

(7) RED

FUSE

(1 AMP)

SPEAKER LO

PTT HI

PTT LO

MIC HI

MIC LO

CHASSIS GROUND

+12

VOLTS DC

Notes:

1. Connect either violet wire to the radio speaker Hi output. Connect the remaining violet wire to speaker Low.

2. Connect either white wire to the radio push-to-talk (PTT) key line input. Connect the remaining white wire to

the PTT key line return (PTT Low)

3. If using a headset with a PTT switch on the shell, omit the PTT switch here and connect the white / orange

wire directly to the ring terminal of the headset jack.

Mobile Radio Interface Module Wiring Diagram

Mobile Radio Interface Module

Figure 2

Radio

Figure 3

MOBILE RADIO INTERFACE MODULE

TROUBLESHOOTING GUIDE

First determine if the trouble occurs with the vehicle engine running.

VEHICLE ENGINE OFF:

1. Can’t hear radio in headset:

a) Make sure the headset is plugged all the way into the jack.

b) Turn up radio volume at the radio as normal.

c) Check the blue and gray wires going to the headset jack.

d) Check violet wire (SPEAKER HI and LO) connections from the Mobile

Radio Interface Module to the radio.

2. Can’t talk to dispatch (transmit) on radio through the headset:

a) Check for power and ground on the Mobile Radio Interface Module’s

red and green wires.

b) Check the connections between Mobile Radio Interface Module

and the radio. Both white wires (PTT HI and LO) and the Brown and

Black wires (MIC HI and LO).

c) Check the gray and white / orange wires going to the PTT / headset

jack.

d) Check the Mobile Radio Interface Module Radio Mic Transmit Level

adjustment.

VEHICLE ENGINE ON:

1. Electricalnoise (alternator whine)in headsets when receiving on radio, or ...

Dispatch reports that they hear electrical noise (alternator whine) when

transmitting from vehicle through the headsets.

a) Check that the barrel of the headset jack is not physically touching

any metal on the vehicle

b) Check that the gray wire is not shorted to the vehicle chassis.

c) Check all six radio Interface wires between the Mobile Radio Interface

Module and the radio - MIC HI, MIC LO, PTT HI, PTT LO, SPEAKER HI,

and LO. Make sure that you have the correct pin numbers for the

radio you are hooking to. Make sure that MIC LO and SPEAKER LO

are not physically tied to the same pin on the radio; even if they are

tied together inside the radio.

d) If the wiring is OK, then noise is coming from radio:

i) Possible bad radio wiring, (Check radio power and ground

connections for loose or corroded connections) or ...

ii) Excessive noise is generated directly by the vehicle’s electrical /

charging system - most commonly known as alternator whine.

This is only present when the vehicle’s engine is running and

recognized by the fact that the pitch or frequency of the whine

changes directly with the change in engine rpm.

The preferred way to solve this type of problem is to have the vehicle’s

electrical / charging system serviced. The most common cause of this

type of noise is bad diodes in the vehicles alternator. Other possible

causes are: Bad vehicle voltage regulator; Bad alternator or battery

cable connections; Missing or bad engine or alternator grounding

straps.

If servicing the vehicle’s charging system is impractical, installing a

good alternator whine power line lter in-line with the radio power

wire(s) will usually accomplish the same thing. All radio power wires will

have to be ltered. Some radios have more than one wire that hooks to

vehicle power. Contact the radio manufacturer for a recommendation

on the best lter for the particular radio. NOTE: This solution should

not be considered a permanent x. Vehicle charging system problems

of this type will eventually cause other equipment failure as well as

shorten the life of the vehicle’s batteries.

2. Dispatch says too much background noise or unclear or weak

transmissions.

a) Check to see if a radio hand mic on the vehicle is also active or “live”

when transmitting through the Mobile Radio Interface Module

headset. Check this while not wearing the headset and by talking

directly into the radio hand mic and pressing the Mobile Radio

Interface Module PTT switch. Do not press the PTT button on the

hand mic itself. If dispatch can hear you loud and clear, then the

background noise pick up is coming from this active hand mic. If

you have this type of hand mic, then it is best to contact the radio

manufacturer for instructions on a possible microphone modication

to x the problem. Alternately, some radio manufacturers can supply

a compatible microphone that does not have this problem.

b) Adjust the Mobile Radio Interface Module Radio Mic Transmit Level. If

the mic level is set too low, you will get reports of weak transmissions.

If the mic level is too high, you will get reports of noisy or garbled

transmissions. See “Radio Mic Transmit Level Adjustment” on page 5.

MOBILE RADIO INTERFACE MODULE SPECIFICATIONS

Input Voltage: 11-16 VDC

Maximum Current: 0.03 Amps

Module Unit Size: 4 x 2.9 x 2 inches

Weight: 7 oz. (not including cable and hardware)

TWO YEAR WARRANTY

Every Sigtronics product has been carefully inspected before shipment. We

guarantee to correct any defect caused by faulty material or workmanship

free of charge to the user who originally purchased the product for a

period of two years from the original purchase date. Our obligation

assumed under this guarantee is limited to the replacing of any part or

parts which prove to our satisfaction, upon examination to have been

defective, and which have not been misused or carelessly handled. The

complete unit must be returned to our factory, transportation charges

prepaid. We reserve the right to decline responsibility where repairs

or replacements have been made or attempted by others. No other

guarantee, written or verbal, on our products is authorized by us.

Repairs required due to abuse, misuse, damage or normal service beyond

the warranty period will be subject to normal service charges.

To expedite factory service work, contact Sigtronics Service Department

and explain the problem. All correspondence relative to service work

should include model and serial number. Frequently problems can be

resolved by phone. The Sigtronics number is located below.

Sigtronics Installation Hot Line Number:

1-800-367-0977 ext. 8

M-F 8:00 am to 4:30 pm Pacic Time

www.SigtronicS.coM SigtronicS MriM-2 Page 5

1-17-2020 mrim_2.pdf

Sigtronics Corporation

178 East Arrow Highway

San Dimas, CA 91773

Phone: (909) 305-9399

E-mail: info@sigtronics.com

Web Site: www.sigtronics.com

igtronics

®

S

Popular Control Unit manuals by other brands

rotork

rotork IQT3 Original instructions

NIPPON VALVE CONTROLS

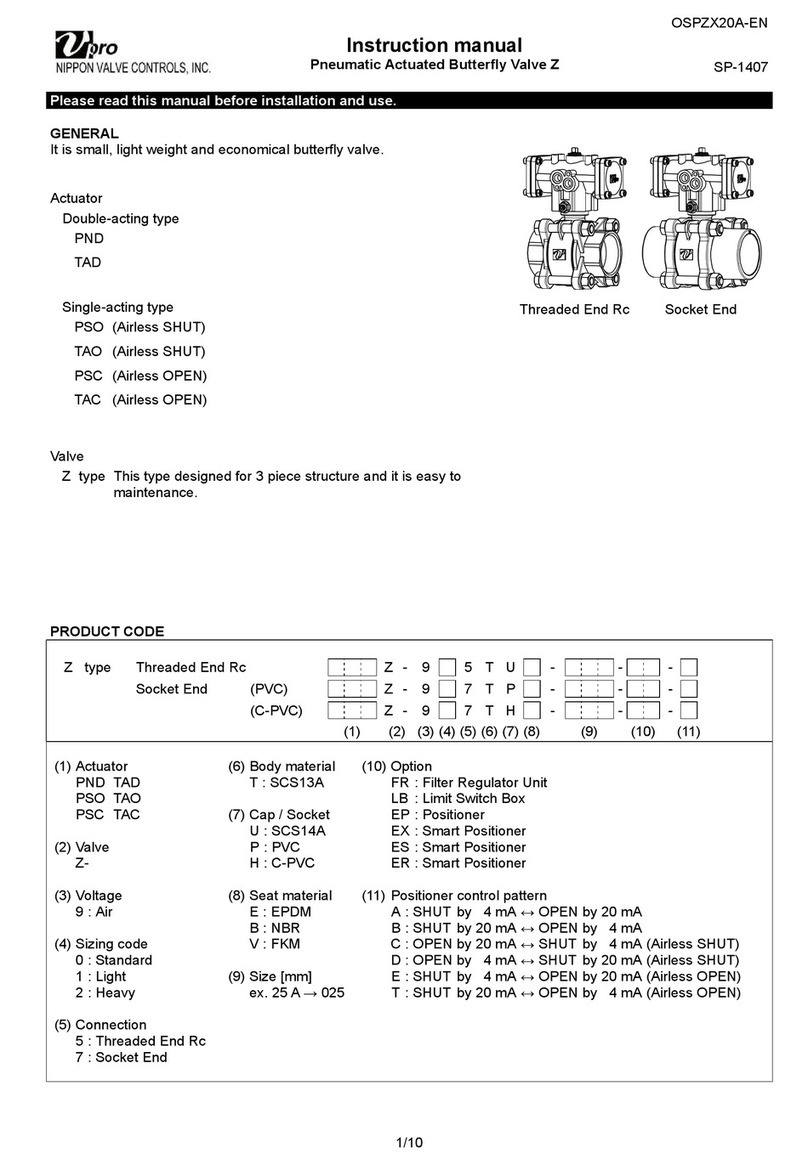

NIPPON VALVE CONTROLS Vpro Z instruction manual

Genebre

Genebre 2528AV Installation, operation and maintenance manual

FUTABA

FUTABA T8FG instruction manual

Emerson

Emerson Fisher POSI-SEAL A31A instruction manual

getAir

getAir LED Installation & user guide

Burkert

Burkert 2101 operating instructions

Trox Technik

Trox Technik EM-TRF Operating and installation instruction manual

Asco

Asco 8210 series Installation & maintenance instructions

Jafar

Jafar 1350 Operation and maintenance manual

Daktronics

Daktronics VX-2428 System manual

ITT

ITT Skotch Trifecta T4405F Installation, operation and maintenance instructions