NIPPON VALVE CONTROLS Vpro Z User manual

OSPZX20A-EN

1/10

Instruction manual

Pneumatic Actuated Butterfly Valve Z

SP-1407

Please read this manual before installation and use.

GENERAL

It is small, light weight and economical butterfly valve.

Actuator

Double-acting type

PND

TAD

Single-acting type

PSO (Airless SHUT)

TAO (Airless SHUT)

PSC (Airless OPEN)

TAC (Airless OPEN)

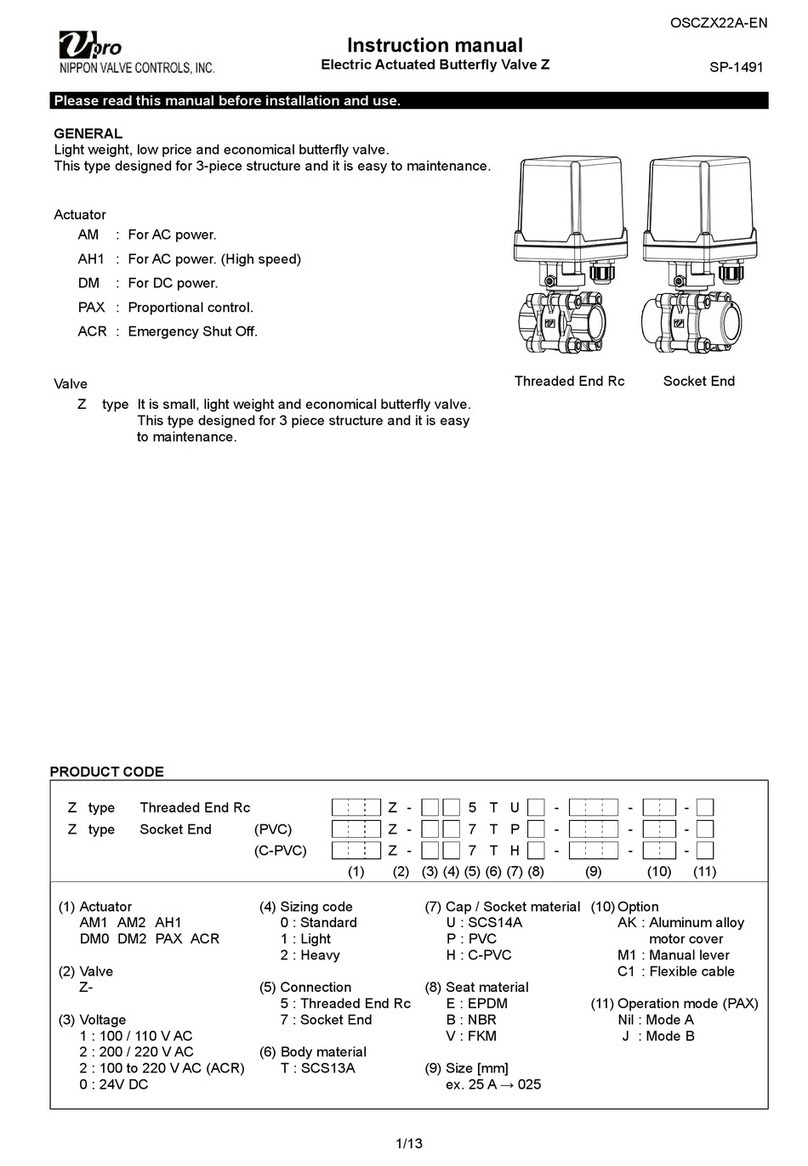

Valve

Z type This type designed for 3 piece structure and it is easy to

maintenance.

Threaded End Rc Socket End

PRODUCT CODE

Z type Threaded End Rc Z - 9 5 T U - - -

Socket End (PVC) Z - 9 7 T P - - -

(C-PVC) Z - 9 7 T H - - -

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

(1) Actuator

PND TAD

PSO TAO

PSC TAC

(2)

Valve

Z-

(3)

Voltage

9 : Air

(4) Sizing code

0 : Standard

1 : Light

2 : Heavy

(5) Connection

5 : Threaded End Rc

7 : Socket End

(6) Body material

T : SCS13A

(7) Cap / Socket

U : SCS14A

P : PVC

H : C-PVC

(8) Seat material

E : EPDM

B : NBR

V

: FKM

(9) Size [mm]

ex. 25 A 025

(10) Option

FR : Filter Regulator Unit

LB : Limit Switch Box

EP : Positioner

EX : Smart Positioner

ES : Smart Positioner

ER : Smart Positioner

(11) Positioner control pattern

A : SHUT by 4 mA OPEN by 20 mA

B : SHUT by 20 mA OPEN by 4 mA

C : OPEN by 20 mA SHUT by 4 mA (Airless SHUT)

D : OPEN by 4 mA SHUT by 20 mA (Airless SHUT)

E : SHUT by 4 mA OPEN by 20 mA (Airless OPEN)

T : SHUT by 20 mA OPEN by 4 mA (Airless OPEN)

OSPZX20A-EN

2/10

VALVES SPECIFICATIONS

Water Oil Air, Gas Steam Chemicals Sea water Slurry Negative pressure

Valve type Z

Design 3 piece structure

Connection Threaded End Rc Socket End

Fluid

Max pressure 1 MPa

Size [mm] 015 to 050

Material Body SCS13A

Disk PPS

Cap SCS14A -

Socket - PVC C-PVC

Seat EPDM NBR FKM

Stem seal O-ring Depend on seat material

SEAT MATERIAL GUIDE

Seat material Fluid temp. Use

EPDM -20 to +80 °C

NBR -10 to +60 °C

FKM -0 to +90 °C

Note) • EPDM seat cannot be used for oil.

• Unsuitable for steam or hot water over 80 °C.

• Can flow the seawater with PVC socket and

EPDM sheet.

PRESSURE & TEMPERATURE RATING

Valve seat material Cap / Socket

INHERENT FLOW CHARACTERISTIC

Cv

value

(%)

Valve opening

(%)

Range ability 30:1

OSPZX20A-EN

3/10

PNEUMATIC ACTUATOR SPECIFICATIONS

PND type

Classification Double-acting type

Actuator type PND-03S PND-03D PND-04D PND-05D

Weight [kg] 0.2 0.3 0.5 0.8

Air consumption [ ]

(round-trip) 0.05 0.08 0.19 0.35

Operation time [s] Less than 1.

Operation SHUT by air to port A. OPEN by air to port B.

Air pressure 0.4 to 0.7 MPa

Piping connection Rc 1/8

Method of operation Scotch yoke

Housing material PPS resin

Ambient temperature -10 to 50 °C (Please be careful when you use in 5 °C or less, so that there no freeze.)

Manual operation Operates the upper shaft of the actuator directly.

PSO PSC type

Classification Single-acting type (Spring-return)

Actuator type PSO - 03S

PSC - 03S

PSO - 03D

PSC - 03D

PSO - 04D

PSC - 04D

PSO - 05D

PSC - 05D

PSO - 05W

PSC - 05W

Weight [kg] 0.2 0.4 0.6 1.2 1.8

Air consumption [ ]

(round-trip) 0.03 0.04 0.1 0.2 0.53

Air exit One side Both sides

Operation time [s] Less than 1.

Operation PSO : OPEN by air to intake port. SHUT by spring-return. (Airless SHUT)

PSC : SHUT by air to intake port. OPEN by spring-return. (Airless OPEN)

Air pressure 0.4 to 0.7 MPa

Piping connection Rc 1/8

Method of operation Scotch yoke

Housing material PPS resin

Ambient temperature -10 to 50 °C (Please be careful when you use in 5 °C or less, so that there no freeze.)

Manual operation No manual operation.

OSPZX20A-EN

4/10

PNEUMATIC ACTUATOR SPECIFICATIONS

TAD type

Classification Double-acting type

Actuator type TAD-040 TAD-050 TAD-063 TAD-080 TAD-100 TAD-125 TAD-160

Weight [kg] 0.9 1.3 2.1 3.4 6.1 9.8 18.2

Air consumption [ ]

(round-trip) 0.11 0.18 0.34 0.66 1.36 2.72 5.56

Operation SHUT by air to port A. OPEN by air to port B.

Air pressure 0.4 to 0.7 MPa

Piping connection Rc 1/8 Rc 1/4

Method of operation Rack-and-pinion Scotch yoke

Housing material Aluminum alloy

Ambient temperature -10 to 50 °C (Please be careful when you use in 5 °C or less, so that there no freeze.)

Manual operation Operates the upper shaft of the actuator directly.

TAO TAC type

Classification Single-acting type (Spring-return)

Actuator type TAO-040

TAC-040

TAO-050

TAC-050

TAO

-

063

TAC

-

063

TAO-080

TAC-080

TAO-100

TAC-100

TAO-125

TAC-125

TAO

-

160

TAC

-

160

Weight [kg] 2.3 3 4.9 8.5 16.4 27.6 51.2

Air consumption [ ]

(round-trip) 0.23 0.34 0.67 1.26 2.62 4.44 8.77

Operation TAO : OPEN by air to intake port. SHUT by spring-return. (Airless SHUT)

TAC : SHUT by air to intake port. OPEN by spring-return. (Airless OPEN)

Air pressure 0.4 to 0.7 MPa

Piping connection Rc 1/4

Method of operation Rack-and-pinion Scotch yoke

Housing material Aluminum alloy

Ambient temperature -10 to 50 °C (Please be careful when you use in 5 °C or less, so that there no freeze.)

Manual operation No manual operation. Option: MT (Manual handle unit)

OSPZX20A-EN

5/10

PNEUMATIC ACTUATOR SPECIFICATIONS

OPTIONAL PARTS

Classification Code PND PSO PSC TAD TAO TAC

Speed Controller with bypass valve (Housing material: PPS) BS

FR Unit (Regulator with Filter) TA2-FR (KONAN) FR

Limit Switch Box (Standard load signal) LB

Explosion Proof Limit Switch / VCX7001 (azbil) Ex d e II C T6 LR

Speed Controller (with One-touch Fitting) One set SE

Speed Controller (with One-touch Fitting) Two sets SS

Speed Controller (with One-touch Fitting) Dual Speed Controller SF

Manual handle unit (for TAO-050 to 160 / TAC-050 to 160) MT

Sealing the spring unit. (Oil-free) 92

Smart positioner for PSO / PSC (Except 03S) EX

Explosion Proof Electro-Pneumatic Positioner Ex dmb II B T5 (TIIS) EP

Smart positioner ES

ER

Smart positioner (with 4 to 20mA output) ET

EU

SHUTby 4 mA. OPEN by 20 mA. A

SHUTby 20 mA. OPENby 4 mA. B

OPENby 20 mA. SHUT by 4 mA. (Airless SHUT) C

OPENby 4 mA. SHUT by 20 mA. (Airless SHUT) D

SHUTby 4 mA. OPEN by 20 mA. (Airless OPEN) E

SHUTby 20 mA. OPENby 4 mA. (Airless OPEN) T

SHUT by 4 mA. OPEN by 20 mA. A

SHUTby 20 mA. OPENby 4 mA. B

OPENby 20 mA. SHUT by 4 mA. (Airless SHUT) C

OPENby 4 mA. SHUT by 20 mA. (Airless SHUT) D

SHUTby 4 mA. OPEN by 20 mA. (Airless OPEN) Y

SHUTby 20 mA. OPENby 4 mA. W

OPENby 4 mA. SHUT by 20 mA. (Airless SHUT) X

SHUTby 4 mA. OPEN by 20 mA. (Airless OPEN) E

SHUTby 20 mA. OPENby 4 mA. (Airless OPEN) T

5-Port Solenoid Valve Voltage: 100 V AC 1S

(with speed controller, silencer, DIN connector) Voltage: 200 V AC 2S

Voltage: 110 V AC 3S

Voltage: 220 V AC 4S

VZ3190- D-X213 Voltage: 24 V DC 5S

Positioner operationSmart positioner

OPEN by

l

o

s

s

o

f

s

i

g

n

a

l

Smart positioner

SHUT by

loss of signal

OSPZX20A-EN

6/10

PNEUMATIC ACTUATOR SPECIFICATIONS

SOLENOID VALVE (Applicable Pneumatic Actuators: PND-05D / TAD / TAO / TAC)

Classification ( : Voltage code) Code

5-port Solenoid Valve

Return

(with bypass valve)

Lead wire 4N3S102K-L N43SL : Voltage

1 : 100V AC

3 : 200V AC

5 : 24V DC

DIN Connector 4N3S102K-D N43SD

DIN Connector (with lamp) 4N3S102K-N N43SN

Watertight cover 4N3S102K-W N43SW

5-port Explosion proof

solenoid valve Return

(with bypass valve)

Conduit 4N4S102K-E01-H B0-R 4N4S01- B0, NO

Flame proof packing

(Cable size 9.5 to 10.4 mm)

4N4S102K-E10-H B0-R 4N4S10- B0, NO

Operate by solenoid valve (Normally Open)

PND / TAD SHUT by solenoid off. OPEN by power to solenoid.

PSO / TAO (Airless SHUT) OPEN by power to solenoid. SHUT by solenoid off. (Spring-return)

PSC / TAC (Airless OPEN) SHUT by power to solenoid. OPEN by solenoid off. (Spring-return)

OSPZX20A-EN

7/10

PNEUMATIC ACTUATOR SPECIFICATIONS

DIMENSIONS

PND

Actuator H W N N1

PND-03S 65 83 54 30

PND-03D 73 113 54 30

PND-04D 90 132 67 36

PND-05D 98 157 82 44

PSO PSC

Actuator H W N N1

PSO-03S PSC-03S 65 109 54 30

PSO-03D PSC-03D 73 165 54 30

PSO-04D PSC-04D 90 190 67 36

PSO-05D PSC-05D 98 247 82 44

PSO-05W PSC-05W 98 288 95 48

TAD

Actuator H W N N1

TAD-040 89.5 110 57 32

TAD-050 123 170 82 36

TAD-063 138 204 95 38

TAD-080 171 240 116 45

TAD-100 202 294 143 57

TAD-125 227 366 150 60

TAD-160 273 446 181 68

TAO TAC

Note) Cylinder direction of TAC-040 is the same as TAO.

Actuator W W1 N N1

TAO-040 TAC-040 249 55 92 46

TAO-050 TAC-050 305 85 103 50

TAO-063 TAC-063 367 102 119 52

TAO-080 TAC-080 435 120 142 59

TAO-100 TAC-100 530 147 174 71

TAO-125 TAC-125 688 183 193 74

TAO-160 TAC-160 838 223 231 82

03S 03D ~ 05D

H

N

N1

W

26

W

03S 03D ~ 05W

H

N

N1

W

26

W

N1

N

H

W

W1

W

N1

N

H

TAO TAC

OSPZX20A-EN

8/10

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

HANDLING & STORAGE

HANDLING

Proper care in handling the valve should be taken to

prevent damage. Do not drop or throw it.

STORAGE

• Store the valve in the protected area from dust,

moisture, and direct sunlight.

If possible, should be kept in the original packaging.

• Do not remove a dust proof cap until the piping.

CHECKING

• Check the product code before installation.

• Confirm that there is no screw loose or part

deformation.

INSTALLATION

PRECAUTIONS

• Flush the pipeline carefully before installing the valve.

Foreign particles, such as sand or pieces of welding

electrode, will damage the ball and seats.

• Avoid oil or grease when using EPDM seat.

• The butterfly valve should be piped upstream of the

elbow. When piping downstream from the elbow,

considered a straight line that is at least five times the

length of the pipe.

• The valve stem should be mounted perpendicular to

the flow for biased fluid.

Threaded End Rc

If seal tape or sealant protrudes into the valve,

malfunction may result.

Pay attention to tape treatment and coating amount.

Socket End

Should use adhesive suitable for valve materials.

ENVIRONMENT

• Do not install in place where corrosive gas is present

or where vibration is heavy (0.5 G or more).

• When radiant heat causes the surface temperature of

the control unit to exceed 50 °C, provide an

appropriate shielding plate.

• If there is a possibility that the fluid and drive part

freeze, please take measures to prevent freezing.

• For single-acting type, prevent water and dust from

coming into air exit.

POSITIONING

Should be positioned through 90° upward from

horizontal. Provide space around the product to allow

manual operation, inspection and replacement work.

AIR PIPING

• Pneumatic actuator has an air supply ports to operate

piston.

Double-acting type

PND : Rc 1/8

Coupling OD

less than 14.5

TAD-040 : Rc 1/8

TAD-050 to 160 : Rc 1/4

Single-acting type

PSO / PSC : Rc 1/8

TAO / TAC : Rc 1/4

• Piping of double-acting type is connected by seal tape

on PORT A / B. Piping of single-acting type is put seal

tape only on the air intake port.

• PND / PSO / PSC: PPS resin air supply port may be

damaged if over tighten, please lightly tighten by

hand.

• Never put anything on the actuator or make it into a

foothold.

Fast

Slow Fast

Slow

PORT A PORT B

Air intakePlug

OSPZX20A-EN

9/10

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

OPERATION

AIR SOURCE

• Use the filtered dry air (less than 40 ).

• Extra attention is needed where it's cold climate

(below 5 °C).

• When air pressure is high, reduce it to standard

pressure (0.4 to 0.7 MPa). Air pressure should not

exceed 0.7 MPa during operation test.

• Capacity of compressor and air tank are to be

c

alculated by capacity of piping and air consumption.

A margin of 30% is required.

TEST OPERATION

Check the operation of pneumatic actuator before

fluid enters the piping.

Double-acting

type

Stop the air from the air source.

Release the residual pressure in the

air cylinder. Open the air equalizer.

Move the manual shaft of actuator

with a wrench.

Single-acting

type

Send the standard pressure air.

Confirm the opening / closing

operation by slowly moving the

actuator.

TESTING

After piping, check following points.

• Piping is correct.

• Air or fluid leakage from connection. Flow direction

of air is correct.

• Air pressure is in the range.

• Nothing interferes with operation when limit switch

or solenoid valve is attached.

ATTENTION

The opening and closing operation of the pneumatic

actuator is fast, which may affect the product life.

Please adjust the operation time of pneumatic

actuator using a speed controller.

Valve size Adjustment of operation time.

015 to 040 mm More than 1 second.

050 to 150 mm More than 2 seconds.

MANUAL OPERATION

• Double-acting; stop the air supply and do not leave

the air inside of cylinder.

• Single-acting; cannot be operated manually.

Optional code with the handle: TAO-MT / TAC-MT.

• Before automatic operation, be sure to remove

wrench.

OPERATION (PND / TAD)

After turning air pressure to 0, turn manual shaft

slowly with a smooth-jawed wrench to check the

direction of OPEN/SHUT position.

PND TAD

MAINTENANCE

• Do the routine maintenance at least once in half a

year.

• Do not set or take spring unit parts apart after

installing the pneumatic single-acting actuator.

Can be used with no oil supply.

• Confirm the air leakage.

• Confirm the air supply pressure.

• Confirm the dirt or grit inside of cylinder.

Lubrication Procedure (TAD / TAO / TAC)

In case of lubricating, use turbine oil or the

equivalent through a lubricator. (ISO VG 32.46).

Once lubricate, do the regularly.

Inspection items

• Confirm operation of opening and closing.

• Confirm whether screws are loose or not.

• Confirm the fluid temperature or pressure.

• Confirm the leak from valve stem.

• Confirm the bolt tightening torque.

Manual shaft

OSPZX20A-EN

Document is subject to change without notice.

NIPPON VALVE CONTROLS, INC.

1-21-19 Meieki minami, Nakamura-ku, Nagoya 450-0003 JAPAN

TEL: 81-52-582-6435 FAX: 81-52-582-6439

10/10

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

TROUBLESHOOTING

Problem Cause Solution

Fail to

operate.

Air doesn't

come out.

Supply air.

Air pressure is

too low.

Adjust to standard

pressure level.

Stop in the

mid position.

Biting of valve

seat.

Remove a foreign

object.

Leakage

from

valve seat

Seat is worn or

damaged.

Replace the valve.

Leakage

from

valve stem

Packing is

worn or

distorted.

For more information contact

NIPPON VALVE CONTROLS, INC. for consultation.

This manual suits for next models

1

Table of contents

Other NIPPON VALVE CONTROLS Control Unit manuals