Siko AG03/1 User manual

025/21

AG03/1

Actuator with Interface

User Manual

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 2 of 63

Table of Contents

1General Information .................................................................................................. 6

1.1 Documentation.........................................................................................................6

1.1.1 History ................................................................................................................6

1.2 Definitions ..............................................................................................................6

1.3 Intended Use...........................................................................................................7

1.4 Switching on the operating voltage.............................................................................7

2Display and control keys ............................................................................................ 7

2.1 General information..................................................................................................7

2.2 LED displays.............................................................................................................7

2.2.1 Status LED ...........................................................................................................8

2.2.2 COM LED ..............................................................................................................8

2.3 Operating keys .........................................................................................................8

2.3.1 Setup Operation....................................................................................................8

2.3.2 Ex-works setting ...................................................................................................9

3Operation description ................................................................................................ 9

3.1 Operating modes ......................................................................................................9

3.1.1 Positioning Mode..................................................................................................9

3.1.1.1 Target Window Positioning Mode .......................................................................10

3.1.1.2 Travel range....................................................................................................10

3.1.1.3 Software Limits ...............................................................................................11

3.1.1.4 Loop positioning .............................................................................................11

3.1.1.5 Inching mode .................................................................................................12

3.1.1.5.1 Inching mode 1 ...........................................................................................12

3.1.1.5.2 Inching mode 2 ...........................................................................................13

3.1.1.6 ControlWord in positioning mode.......................................................................14

3.1.1.7 StatusWord in positioning mode ........................................................................15

3.1.1.8 Sequence schedule in positioning mode..............................................................17

3.1.2 Speed Mode........................................................................................................17

3.1.2.1 Target window speed mode ...............................................................................18

3.1.2.2 ControlWord in speed mode...............................................................................19

3.1.2.3 StatusWord in speed mode ................................................................................20

3.1.2.4 Sequence schedule in speed mode......................................................................22

3.2 Battery buffering....................................................................................................22

3.2.1 Emergency operation...........................................................................................23

3.3 Parameterization ....................................................................................................23

3.4 Calibration.............................................................................................................23

3.5 Additional functions ...............................................................................................24

3.5.1 Scaling..............................................................................................................24

3.5.1.1 Example of spindle drive...................................................................................24

3.5.1.2 Example rack/pinion straight toothed, metric pitch ..............................................25

3.5.1.3 Example of external gear ..................................................................................25

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 3 of 63

3.5.2 Protection functions............................................................................................26

3.5.2.1 Limiting of current ..........................................................................................26

3.5.2.2 I²t monitoring.................................................................................................26

3.5.2.3 Torque deactivation .........................................................................................27

3.5.2.4 Temperature monitoring ...................................................................................28

3.5.2.5 Overvoltage protection in case of feedback .........................................................28

3.5.2.6 Position lag monitoring....................................................................................28

3.5.2.7 Oscillation detection........................................................................................29

3.5.3 Restore factory setting ........................................................................................29

3.6 Warnings/errors......................................................................................................29

3.6.1 Warnings ...........................................................................................................29

3.6.2 Errors ................................................................................................................29

3.6.2.1 Error Codes .....................................................................................................30

4Parameter ............................................................................................................... 31

4.1 Process data ..........................................................................................................31

4.1.1 ControlWord .......................................................................................................31

4.1.2 StatusWord ........................................................................................................32

4.1.3 TargetValue........................................................................................................32

4.1.4 ActualValue........................................................................................................32

4.1.5 GenericMappingParameter1...................................................................................33

4.1.6 UnsignedInteger8 ...............................................................................................33

4.1.7 GenericMappingChannel1 .....................................................................................33

4.1.8 GenericMappingChannel2 .....................................................................................34

4.2 Positioning............................................................................................................34

4.2.1 OffsetApplication ................................................................................................34

4.2.2 SpindlePitch.......................................................................................................35

4.2.3 CountingDirection...............................................................................................35

4.2.4 CalibrationValue..................................................................................................35

4.2.5 TargetWindow.....................................................................................................36

4.2.6 LoopType...........................................................................................................36

4.2.7 LoopLength........................................................................................................37

4.2.8 GearRatioNumerator ............................................................................................37

4.2.9 GearRatioDenominator .........................................................................................37

4.2.10 DeltaInch...........................................................................................................38

4.2.11 TargetWindowReachedMode..................................................................................38

4.3 Actuator................................................................................................................38

4.3.1 OperatingMode ...................................................................................................38

4.3.2 AccelerationPositionMode ....................................................................................39

4.3.3 VelocityPositionMode ..........................................................................................39

4.3.4 DecelerationPositionMode ....................................................................................40

4.3.5 AccelerationVelocityMode.....................................................................................40

4.3.6 AccelerationInchingMode.....................................................................................40

4.3.7 VelocityInchingMode ...........................................................................................41

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 4 of 63

4.3.8 Inching2Offset ...................................................................................................41

4.4 Limit values...........................................................................................................41

4.4.1 SoftwareLimit1 ...................................................................................................41

4.4.2 SoftwareLimit2 ...................................................................................................42

4.4.3 ContouringErrorLimit ...........................................................................................42

4.4.4 TorqueDeactivation .............................................................................................42

4.4.5 PeakCurrentLimit.................................................................................................43

4.4.6 PeakCurrentTime .................................................................................................43

4.4.7 ContinuousCurrent...............................................................................................44

4.5 Options.................................................................................................................44

4.5.1 Inching2StopMode ..............................................................................................44

4.5.2 Inching2AccelerationMode ...................................................................................44

4.6Controller parameter ...............................................................................................45

4.6.1 ControllerParameterP ...........................................................................................45

4.6.2 ControllerParameterI ...........................................................................................45

4.6.3 ControllerParameterD...........................................................................................46

4.7 Device information .................................................................................................46

4.7.1 OutputStageTemperature......................................................................................46

4.7.2 ControlVoltage....................................................................................................46

4.7.3 OutputStageVoltage.............................................................................................47

4.7.4 BatteryVoltage....................................................................................................47

4.7.5 MotorCurrent......................................................................................................47

4.7.6 ActualPosition....................................................................................................48

4.7.7 ActualVelocity ....................................................................................................48

4.7.8 MotorThermalLoad...............................................................................................48

4.7.9 DiagnosticParameter............................................................................................49

4.7.10 Production Date..................................................................................................49

4.7.11 I2tOverload........................................................................................................50

4.7.12 ActualContouringError..........................................................................................50

4.8 Error memory .........................................................................................................50

4.8.1 ErrorCount .........................................................................................................50

4.8.2 ErrorBuffer.........................................................................................................51

4.8.3 ErrorCounters......................................................................................................51

5IO-Link................................................................................................................... 52

5.1 Description............................................................................................................52

5.2 Process data input / output .....................................................................................53

5.2.1 Process data in Position Mode operating mode........................................................53

5.2.1.1 Process data output (Master Device) ..............................................................54

5.2.1.2 Process data input (Device Master) ................................................................54

5.2.2 Process data in Velocity Mode...............................................................................55

5.2.2.1 Process data output (Master Device) ..............................................................56

5.2.2.2 Process data input (Device Master) ................................................................56

5.3 Generic Mapping Channels .......................................................................................57

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 5 of 63

5.4 Object Directory .....................................................................................................58

5.4.1 IO-Link specific objects........................................................................................58

5.5 IO-Link System Commands .......................................................................................59

5.6 IO-Link DeviceAccessLocks.......................................................................................59

5.7 IO-Link Event Codes................................................................................................60

5.8 IO-Link Event Codes................................................................................................60

6Block wiring diagram ............................................................................................... 62

General Information

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 6 of 63

1General Information

1.1 Documentation

The following documents are available for this product:

Data sheet: describes the technical data, the dimensions, the pin assignments, the

accessories and the order code.

Assembly instructions: these describe the mechanical and electrical assembly with all

safety-relevant conditions and the associated technical specifications.

User manual for connecting the actuator to an IO-Link master and for commissioning.

IODD file (IO-Link Device Description): connection and configuration with an IO-Link

master is possible with the help of this file using commercially available IO-Link masters

and their configurators.

These documents are also available at http://www.siko-global.com/p/ag03-1.

1.1.1 History

Change

Date

Description

189/20

September

17, 2020

Document prepared

025/21

February

08, 2021

From FW-V1.02

Section 1.1.1 History new

Section 2.3.2 Ex-works setting new

Section 3.2.1 Emergency operation revised

Section 3.6.2.1 Error Codes Code 53 new/13 removed

Section Fehler! Verweisquelle konnte nicht gefunden werden.

Fehler! Verweisquelle konnte nicht gefunden werden. new

Section 5.7 IO-Link Event Codes: Code 6163 new/6153 removed

Status word bit bs13_CalibrationRequest new

Supplements and corrections

From FW-V2.00

Section 3.6.2.1 Error Codes Code 52 new

Section 5.7 IO-Link Event Codes Code 6162 new

1.2 Definitions

If not explicitly stated, decimal values are given as digits without addition (e.g., 1234),

binary values are marked with b (e.g.; 1011b), hexadecimal values with h (e.g.; 280h) after

the digits.

Individual bits of the ControlWord or StatusWord are abbreviated as follows:

ControlWord Bit 7: CW.7

StatusWord Bit 10: SW.10

Display and control keys

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 7 of 63

1.3 Intended Use

Unless otherwise described, normal operation of the system with unchanged factory settings

is assumed for the further functional description.

The AG03/1 actuator is used for adjustment and positioning tasks on systems and machines.

The actuator is only intended for use in industrial applications that are not subject to any

particular electrical or mechanical safety requirements.

1.4 Switching on the operating voltage

After the operating voltage control is switched on, the device initializes itself. The device

parameters are loaded from the nonvolatile memory into the main memory of the controller

during initialization. At first use, the default values are used during initialization. After the

external power supply is supplied again or a software reset (warm start), the actuator works

with the last saved parameters. If no error has been detected, the actuator starts normal

operation and can communicate with an IO-Link master. To be able to start a travel job, the

operating voltage output stage must be switched on.

2Display and control keys

2.1 General information

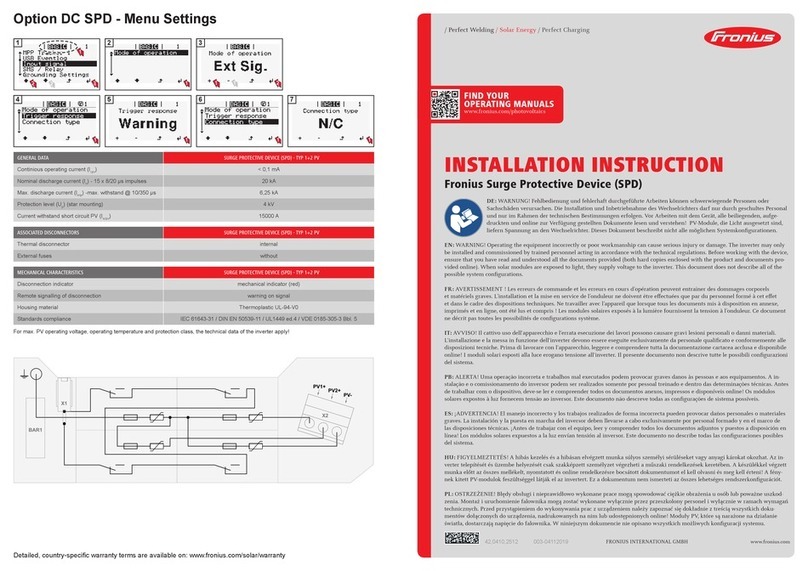

Fig. 1: Control elements

2.2 LED displays

Two LEDs inform about the operating state of the actuator.

Status LED

COM LED

Display and control keys

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 8 of 63

2.2.1 Status LED

The state of the operating voltage output stage is only signaled when the

operating voltage control is switched on.

LED status

Description

Green

All operating voltages OK

Green,

flashes 50:50

Operating voltage control OK

Operating voltage output stage is missing or outside the permissible range

Red

Error

Red,

flashes 50:50

Switch-on lock active

Red,

Flashes 2x

Battery emergency operation active

orange,

flashes

Delay time for setting the factory setting via operating keys expires

Off

Operating voltage control is missing or outside the permissible range

Table 1: Status LED

2.2.2 COM LED

LED status

Description

Green

Operating voltage control OK

Green,

flashes 90:10

Operating voltage control OK

IO-Link SDCI communication active

Off

Operating voltage control is missing or outside the permissible range

Table 2: COM LED

2.3 Operating keys

2.3.1 Setup Operation

Manual setup mode is only available if IO-Link SDCI communication is not

active.

The operating keys can be used to start manual setup mode (corresponds to inching mode 2).

This makes it possible to move the actuator without a higher-level control.

Clockwise button

Counterclockwise button

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 9 of 63

2.3.2 Ex-works setting

The ex-works setting can only be established using the operating keys if IO-

Link SDCI communication is not active and the operating voltage output

stage is switched off.

Pressing the clockwise and counterclockwise buttons simultaneously for at least 5 seconds

resets all parameters to the ex-works setting. The elapse of the delay time is signaled by

orange flashing of the status LED. A warm restart is then initiated, and the status LED

switches off briefly.

3Operation description

3.1 Operating modes

A distinction is made between the operating modes of positioning mode and speed mode. In

the positioning mode, it is also possible to move in inching mode.

3.1.1 Positioning Mode

In the positioning mode, positioning to the specified target value is performed using a ramp

function (cf. Fig. 3: Ramp travel positioning mode direct), which is calculated based on the

instantaneous actual position as well as the programmed controller parameters acceleration

and speed.

After activation of the travel job, the actuator accelerates with the programmed acceleration

AccelerationPositionMode to the predetermined speedVelocityPositionMode. The amount of

delay to the target value is also determined by the parameter AccelerationPositionMode.

Alternatively, the DecelerationPositionMode parameter can be used to select a value that

differs from the acceleration.

The actuator is tracked by means of a PID positioning controller of the calculated path. If you

change the coefficients ControllerParameterP, ControllerParameterI and ControllerParameterD,

adjustments can be made to the controlled system.

Changing the controller parameters during a positioning operation has no effect on the

current positioning mode.

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 10 of 63

Fig. 2: Ramp travel positioning mode direct

3.1.1.1 Target Window Positioning Mode

If the actual position is within the window defined by the TargetWindow parameter, this is

signaled in the StatusWord with SW. 5 = 1. The behavior of the drive after reaching the

programmed window can be defined by the TargetWindowReachedMode parameter.

Example:

TargetWindow = 5

TargetPosition = 100

Fig. 3: Target Window Positioning Mode

3.1.1.2 Travel range

The travel range depends on the encoder and the scaling (cf. Section 3.5.1). The number of

revolutions according to the product data sheet cannot be exceeded!

Start position

Target

position

Time

Speed

VelocityPositionMode

AccelerationPositionMode

DecelerationPositionMode

AccelerationPositionMode

+

-

100

TargetWindow

TargetWindowReachedMode

95

105

SW.5

0

1

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 11 of 63

Fig. 4: Travel range

3.1.1.3 Software Limits

If the actual position is outside the range defined by the SoftwareLimit1

and SoftwareLimit2 parameters, you must move from this position in the

direction of the permitted range using inching mode 1 or 2!

If SoftwareLimit1 is equal to SoftwareLimit2, limit value monitoring is

deactivated. When the encoder resolution is exceeded, the actual position

changes suddenly.

The target position is checked for validity based on the two parameters SoftwareLimit1 and

SoftwareLimit2 . If the target position is outside the defined range or equal to the limits, the

travel job is not executed. There is no acknowledgment via SW.10. If the permissible range is

left, e.g., in inching mode, the actuator is activated and coasts to a stop. This must be

considered in parameterizing the software limits.

Fig. 5: Software Limits

3.1.1.4 Loop positioning

A travel job is not executed if a loop positioning would exceed the limits

set by the SoftwareLimit1 and SoftwareLimit2 parameters even though the

target value is within the limits.

When operating the drive, it is possible to compensate for a mechanical clearance by means of

the loop positioning. In this case, the target value is always taken from the same direction.

Upper limit

Lower limit

+

-

0

Travel range

SoftwareLimit1

SoftwareLimit2

+

-

0

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 12 of 63

This approach direction can be determined with the LoopType parameter. The loop length is

set via the LoopLength parameter.

Example:

The direction in which each target position is to be moved is positive.

The target position is approached directly.

Case 2

The actuator extends the loop length beyond the target position, and then the target value is

approached in the positive direction.

Fig. 6: Loop POS positioning

3.1.1.5 Inching mode

The spindle play (loop positioning) is not compensated in this operating

mode

Inching mode is only possible in positioning mode. Acceleration as well as speed in inching

mode can be programmed via parameters.

3.1.1.5.1 Inching mode 1

If the value of the SpindlePitch parameter is zero, the travel path is

specified in increments. If the SpindlePitch parameter is not equal to zero,

the specification of the DeltaInch parameter refers to the travel path in user

units.

If the actual position is outside the programmed limit values, inching mode

1 or 2 must be used to move from this position in the corresponding

direction!

The actuator travels from the current actual position once by the value DeltaInch, depending

on the sign of the entered value.

TargetPosition

+

-

Positioning in the positive direction

Positioning in the negative

direction

Positioning: Loop POS

LoopLength

TargetWindow

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 13 of 63

Delta Inch < 0: Travel direction negative

Delta Inch > 0: Travel direction positive

When the target position is reached, this is signaled accordingly.

The following conditions must be met for inching mode 1 and 2 to be started:

Output stage operating voltage is present

Operation enabled

Drive stationary

3.1.1.5.2 Inching mode 2

The actuator travels from the current actual position as long as the command for this is

present. The inching speed can be influenced by two parameters and is calculated in the

actuator as shown in the following example:

VelocityInchingMode = 10 rpm (can only be changed at standstill)

Inching2Offset = 85% (can be changed during inching mode)

The resulting inching speed in this example is:

Inching speed = VelocityInchingMode * Inching2Offset = 10 rpm * 85% = 9 rpm

Results are always rounded to whole numbers.

The minimum speed is 1 rpm.

The Inching2AccelerationMode parameter can be used to set a step-by-step acceleration to

the end value VelocityInchingMode. The velocity profile then corresponds to the following

process:

Fig. 7: Inching mode 2 –Inching2AccelerationMode

20%

50%

4 s

2 s

1 s

100%

Speed

Time

VelocityInchingMode

AccelerationInchingMode

10%

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 14 of 63

3.1.1.6 ControlWord in positioning mode

The ControlWord differs in function depending on the operating mode (cf. OperatingMode

parameter).

The designation of the individual bits of the ControlWord as well as their significance:

Bit

Designation

Value = 0

Value = 1

0

bc00_CoastStop

Coast Stop active

Cancellation of travel job.

The motor is de-energized

and coasts to a standstill

without any control.

Coast Stop not active

(Operating condition)

1

bc01_QuickStop

Quick Stop active

Cancellation of travel order.

The motor is braked to a

standstill with maximum

deceleration and remains in

control.

Quick Stop not active

(Operating condition)

2

bc02_NormalStop

Normal Stop active

Cancellation of travel job.

The motor is braked to a

standstill with maximum

deceleration and remains in

control.

Normal Stop not active

(Operating condition)

3

bc03_IntermediateStop

No intermediate stop

Intermediate stop active

4

bc04_StartTravelJob

-

Start travel job (edge-

controlled, positive)

5

bc05_ErrorAck

-

Acknowledge error

(Edge-controlled, positive)

The actuator then changes

to the switch-on lock state.

6

bc06_InchingMode1

No inching mode 1

If the travel job has not yet

ended, it is aborted.

Inching mode 1

As long as this bit is set,

the actuator travels once

around the distance defined

in the DeltaInch parameter.

7

bc07_InchingMode2Pos

No inching mode 2 positive

Inching mode 2 positive

The actuator travels in the

positive direction.

8

bc08_InchingMode2Neg

No inching mode 2 negative

Inching mode 2 negative

The actuator travels in the

negative direction.

9

bc09_Reserved

Always 0

-

10

bc10_MoveRelative

Absolute positioning

Relative positioning

11

bc11_Reserved

Always 0

-

12

bc12_Reserved

Always 0

-

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 15 of 63

Bit

Designation

Value = 0

Value = 1

13

bc13_Reserved

Always 0

-

14

bc14_GuardingBit

Is mirrored in StatusWord

Is mirrored in StatusWord

15

bc15_CalibrationExecute

-

Trigger calibration (edge-

controlled, positive)

Table 3: ControlWord in positioning mode

3.1.1.7 StatusWord in positioning mode

The StatusWord shows the current status of the actuator.

The designation of the individual bits of the ControlWord as well as their significance:

Bit

Designation

Value = 0

Value = 1

0

bs00_Supply

Operating voltage output

stage is missing or outside

the permissible range

Operating voltage output

stage OK

1

bs01_ReadyToTravel

No travel readiness

Travel readiness available

2

bs02_UpperLimit

No limit value violation

Upper limit value exceeded

3

bs03_LowerLimit

No limit value violation

Lower limit value

undershot

4

bs04_ActuatorTravels

Actuator stationary (speed

< 2 rpm)

Actuator travels

5

bs05_TarWinReached

Actuator is outside the

target window

Position value is within the

target window

6

bs06_ActiveTravelJob

No travel job active

Travel job active

7

bs07_GeneralError

No error

Error acknowledgment with

positive edge at CW.5

8

bs08_OperationEnabled

Operation not enabled

Operation enabled

The state of the drive is

defined by the

TargetWindowReachedMode

parameter.

9

bs09_SwitchLock

No switch-on lock

Switch-on lock (cf. Section

3.1.1.8)

10

bs10_TravelJobAck

No acknowledgment

Acknowledgment

The bit is set when the

travel job has been

accepted. If bit CW.4 is

reset, this bit is also reset.

11

bs11_BatteryState

Charging state OK

Charging state critical

12

bs12_TorqueDeactState

Torque deactivation not

active

Torque deactivation active

The motor current was

greater than set under

TorqueDeactivation

parameter.

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 16 of 63

Bit

Designation

Value = 0

Value = 1

13

bs13_CalibrationRequest

No calibration request

Calibration Request

The drive can only be

moved in jog mode 2. The

software limits are ignored.

14

bs14_GuardingBit

Mirrored from ControlWord

Mirrored from ControlWord

15

bs15_CalibrationExecuted

No acknowledgment

Acknowledgment

The bit is set when the

calibration has been

performed successfully. If

bit CW.15 is reset, this bit

is also reset.

Table 4: StatusWord in positioning mode

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 17 of 63

3.1.1.8 Sequence schedule in positioning mode

Operation enabled

SW = 0x00 x001 00x0 xxx1

Travel ready

SW = 0x00 x001 00x0 0011

Operating voltage ON

CW = 0x00 0000 0000 0000

Enable operation

CW = 0x00 0000 0000 0111

Activate travel job

CW = 0x00 0000 0001 0111

Travel job active

SW = 0x0x x101 01x1 0001

Intermediate stop active

SW = 0x00 x101 01x0 0011

Intermediate stop

CW.3 = 1 Continue positioning

CW.3 = 0

Inching 1 or 2 ON

CW = 0x00 0000 0100 0111

or

CW = 0x00 0000 1000 0111

or

CW = 0x00 0001 0000 0111

Inching 1 or 2 active

SW = 0x0x x001 00x1 0001

Inching OFF

CW = 0x00 0000 0000 0111

Start

Release switch lock

CoastStop CW.0 = 1/0 or

QuickStop CW.1 = 1/0 or

NormalStop CW.2 = 1/0

Switch lock

SW.9 = 1

Acknowledge error

CW.5 = 1

Error

SW.7 = 1

CW = ControlWord

SW = StatusWord

x = Bit can be 0 or 1

Cancel travel job

CoastStop CW.0 = 1/0 or

QuickStop CW.1 = 1/0 or

NormalStop CW.2 = 1/0

Travel job ended

SW = 0x00 x001 0010 0011

Specify target position

Target window reached

SW = 0x00 x101 011x 0001

Fig. 8: Sequence schedule in positioning mode

3.1.2 Speed Mode

SoftwareLimit1 + 2 are disabled in this operating mode.

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 18 of 63

When the absolute value encoder resolution is exceeded, there is a jump to

the actual position.

The speed mode is set with the OperatingMode parameter. In speed mode, the actuator

accelerates to the target speed after the target value is released and maintains this speed

until the target value is blocked or a new target speed is specified. When the set speed is

changed, the speed is immediately adjusted to the new value.

The travel direction in speed mode is determined by the sign of the target value.

Fig. 9: Ramp Speed Mode

The following conditions must be met for speed mode to be started:

Output stage operating voltage is present

Operation enabled

Drive stationary

3.1.2.1 Target window speed mode

If the actual speed is within the window defined by the TargetWindow parameter, this is

signaled in the StatusWord.

Example:

TargetVelocity = 80

TargetWindow = 5

Speed

Tim

e

Target value speed

(target value)

AccelerationVelocityMode

‘Stop’

Target value

enabled

Block target

value

or target value = 0

Block operation

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 19 of 63

Fig. 10: Target window speed mode

3.1.2.2 ControlWord in speed mode

The ControlWord differs in function depending on the operating mode (cf. OperatingMode

parameter).

The designation of the individual bits of the ControlWord as well as their significance:

Bit

Designation

Value = 0

Value = 1

0

bc00_CoastStop

Coast Stop active

Cancellation of travel job.

The motor is de-energized

and coasts to a standstill

without any control.

Coast Stop not active

(Operating condition)

1

bc01_QuickStop

Quick Stop active

Cancellation of travel

order. The motor is braked

to a standstill with

maximum deceleration and

remains in control.

Quick Stop not active

(Operating condition)

2

bc02_NormalStop

Normal Stop active

Cancellation of travel job.

The motor is braked to a

standstill with maximum

deceleration and remains

in control.

Normal Stop not active

(Operating condition)

3

bc03_Reserved

Always 0

4

bc04_StartTravelJob

-

Start travel job (edge-

controlled, positive)

5

bc05_ErrorAck

-

Acknowledge error

Speed

Time

Time

SW.5

0

1

80

75

85

Operation description

AG03/1 Date: 2/08/2021 Art. No. 90425 Change Status 025/21 Page 20 of 63

Bit

Designation

Value = 0

Value = 1

(Edge-controlled, positive)

The actuator then changes

to the switch-on lock

state.

6

bc06_Reserved

Always 0

-

7

bc07_Reserved

Always 0

-

8

bc08_Reserved

Always 0

-

9

bc09_Reserved

Always 0

-

10

bc10_Reserved

Always 0

-

11

bc11_Reserved

Always 0

-

12

bc12_Reserved

Always 0

-

13

bc13_Reserved

Always 0

-

14

bc14_GuardingBit

Is mirrored in StatusWord

Is mirrored in StatusWord

15

bc15_CalibrationExecute

-

Trigger calibration (edge-

controlled, positive)

Table 5: ControlWord in speed mode

3.1.2.3 StatusWord in speed mode

The StatusWord shows the current status of the actuator.

The designation of the individual bits of the ControlWord as well as their significance:

Bit

Designation

Value = 0

Value = 1

0

bs00_Supply

Operating voltage output

stage is missing or outside

the permissible range

Operating voltage output

stage OK

1

bs01_ReadyToTravel

No travel readiness

Travel readiness available

2

bs02_Reserved

Always 0

-

3

bs03_Reserved

Always 0

-

4

bs04_ActuatorTravels

Actuator stationary (speed

< 2 rpm)

Actuator travels

5

bs05_TarWinReached

Actual speed is outside the

target window

Actual speed is within the

target window

6

bs06_ActiveTravelJob

No travel job active

Travel job active

7

bs07_GeneralError

No error

Error

Error acknowledgment with

positive edge at CW.5

8

bs08_OperationEnabled

Operation not enabled

Operation enabled

The position control of the

actuator is activated

9

bs09_SwitchLock

No switch-on lock

Switch-on lock (cf. Section

3.1.2.4)

10

bs10_TravelJobAck

No acknowledgment

Acknowledgment

Other manuals for AG03/1

2

Table of contents

Popular Surge Protector manuals by other brands

LPS

LPS PP-2/110 Series installation instructions

Campbell

Campbell svp48 instruction manual

Patton electronics

Patton electronics 503S user manual

Superior Electric

Superior Electric STABILINE PT2 Series Installation, operation and maintenance manual

Emos

Emos P54222 manual

Acoustic Research

Acoustic Research PW1000 quick start guide