silavent Green Line HRX2 Series User manual

LAB939R, Issue 2, July 2014 Page 1

Green Line HRX2

Mechanical Ventilation with Heat Recovery appliance

Installation and Operating Instructions

Models: HRX2-S, HRX2-B, HRX2-FP, HRX2-BFP

These instructions must be given to the householder

DO NOT SWITCH OFF THE UNIT – it is designed to run continuously. If

the unit is switched off, indoor pollutants and moisture levels may

increase which could endanger your health or damage your home.

It is important to follow the advice in this manual and correctly maintain

the system to ensure a healthy indoor environment.

Have you considered an extended warranty package, for extra peace of

mind?

Polypipe offer extended warranty options. Please refer to page 22 for

further information or call 08443 715523.

LAB939R, Issue 2, July 2014 Page 2

Warnings & Safety Information

IMPORTANT!

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE COMMENCING INSTALLATION

1. Do not install this appliance in areas where the following may be present or occur:

•Excessive oil or a grease laden atmosphere

•Corrosive or flammable gases, liquids or vapours

•Be subject to direct water spray

•Ambient temperatures higher than 50ºC and lower than -25ºC

•Possible obstructions that may hinder access or removal of the unit

2. This appliance is not intended for use by young children or infirm persons without adequate supervision.

3. All wiring must be in accordance with prevailing national regulations, for example the current IEE Wiring Regulations

BS7671. The electrical installation should be inspected and tested by a suitably qualified person after completion.

4. The appliance should be provided with a local double pole fused spur fitted with a 3Amp fuse and a minimum contact

separation of at least 3mm.

5. Ensure that the mains supply (Voltage and Frequency) complies with the rating label.

6. This appliance must be earthed.

7. When installing the appliance, care should be taken not to damage any hidden utilities.

8. The installer is responsible for the installation and electrical connection of the HRX2 system on site. It is the responsibility

of the installer to ensure that the equipment is safely and securely installed and left only when electrically and mechanically

safe.

9. All regulations and requirements must be strictly followed to prevent hazards to life and property, both during and after

installation and any subsequent servicing or maintenance.

10. In dwellings where it is intended to install open-flue appliances and extract ventilation, the combustion appliance should

be able to operate safely, whether or not the fans are running. A way of showing compliance with The Building Regulations

in these circumstances would be to follow the installation guidance shown below, and to show by tests that combustion

appliances operate safely, whether or not the fans are running.

A. For gas appliances: where a room contains an open-flue appliance, the extract rate should not exceed

20l/s (72m³/h).

B. For oil appliances: where a room contains an open-flue appliance, the extract rate should be limited to

40l/s (144m³/h) for an appliance with a pressure jet burner and 20l/s (72m³/h) for an appliance with a

vaporising burner.

C. For solid fuel appliances: avoid installing extract ventilation in the same room.

Further reference should be made to Approved Document J of The Building Regulations.

11. A condensate drain should be installed from the appliance to an appropriate drain location. Polypipe recommend

Domus 297 condensate drain kit.

12. The condensate drain and associated pipe work must be cleared of debris prior to commissioning and insulated where it

passes through unheated spaces and voids.

13. This appliance should not be connected to a tumble dryer or cooker hood.

14. The supply air must be drawn from the exterior of the property.

15. The extract air must be expelled to the exterior of the property.

16. It is recommended that the two external terminals or grilles are set at least 2m apart.

17. The supply and exhaust ceiling valves should be positioned at least 300mm from internal walls to allow airflow

measuring equipment to fit correctly over the valves.

18. Ducting should be insulated with Domus Thermal duct insulation where it passes through unheated spaces and voids

(e.g. loft spaces) to reduce the possibility of condensation forming and heat loss.

LAB939R, Issue 2, July 2014 Page 3

Contents

Warnings & Safety Information

1.0 General description Page 4

1.1 Overview Page 4

1.2 Physical specification Page 6

1.3 Optional main features Page 6

1.3.1 Summer bypass Page 6

1.3.2 Frost protection Page 6

2.0 Installation Page 7

2.1 Overview Page 7

2.2 Preparation Page 7

2.3 Installing the frost protection sensor Page 9

2.4 Wall/surface fitting the HRX2 appliance Page 9

2.5 Fitting the bypass valve Page 10

2.6 Fitting the wiring centre Page 11

2.7 Fitting the condensate drain kit Page 12

2.8 Ducting guidelines Page 12

3.0 Electrical Page 14

3.1 Overview Page 14

3.2 Frost protection only, wiring-centre fan connections Page 14

4.0 Commissioning Page 15

4.1 Overview Page 15

4.2 System balancing Page 15

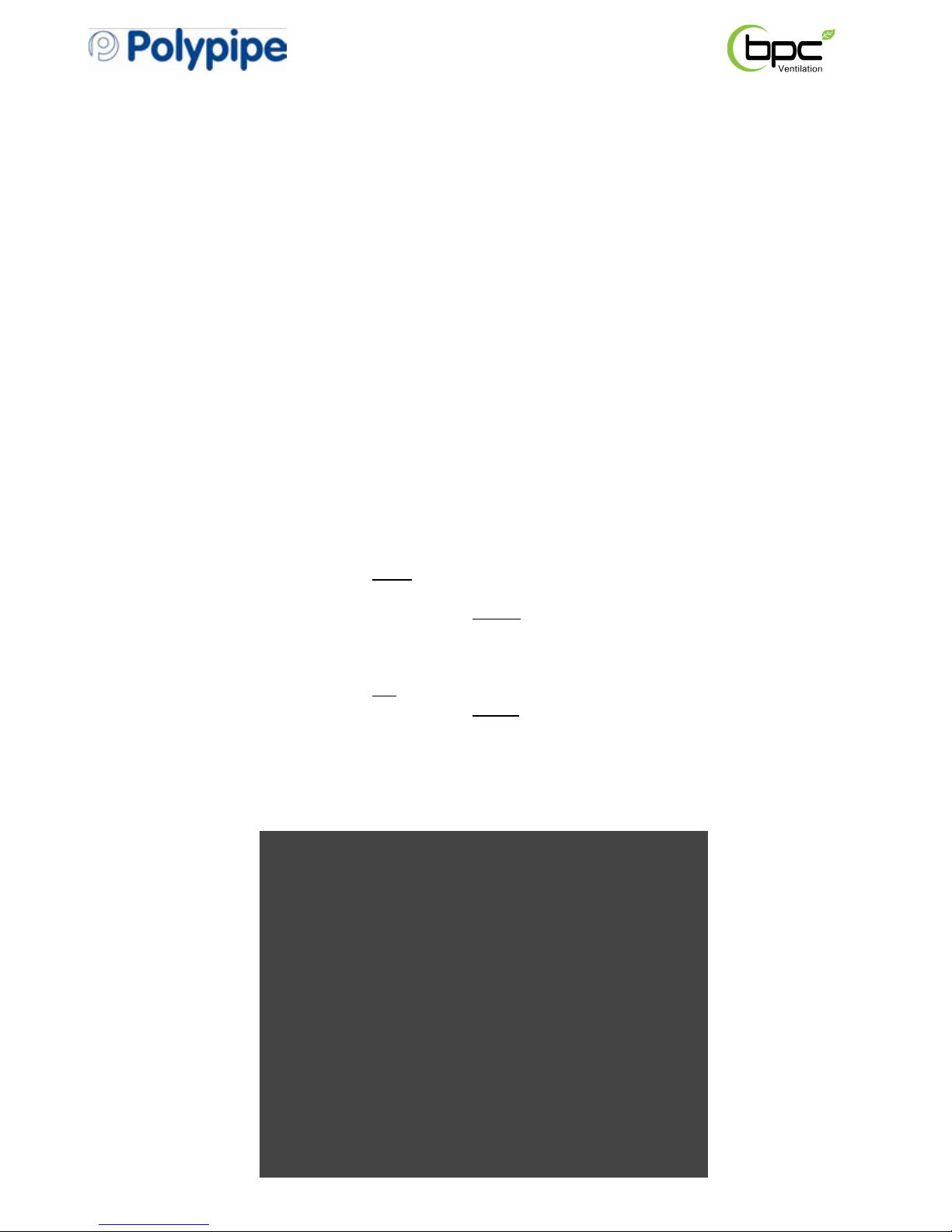

HRX2-S wiring diagram Page 16

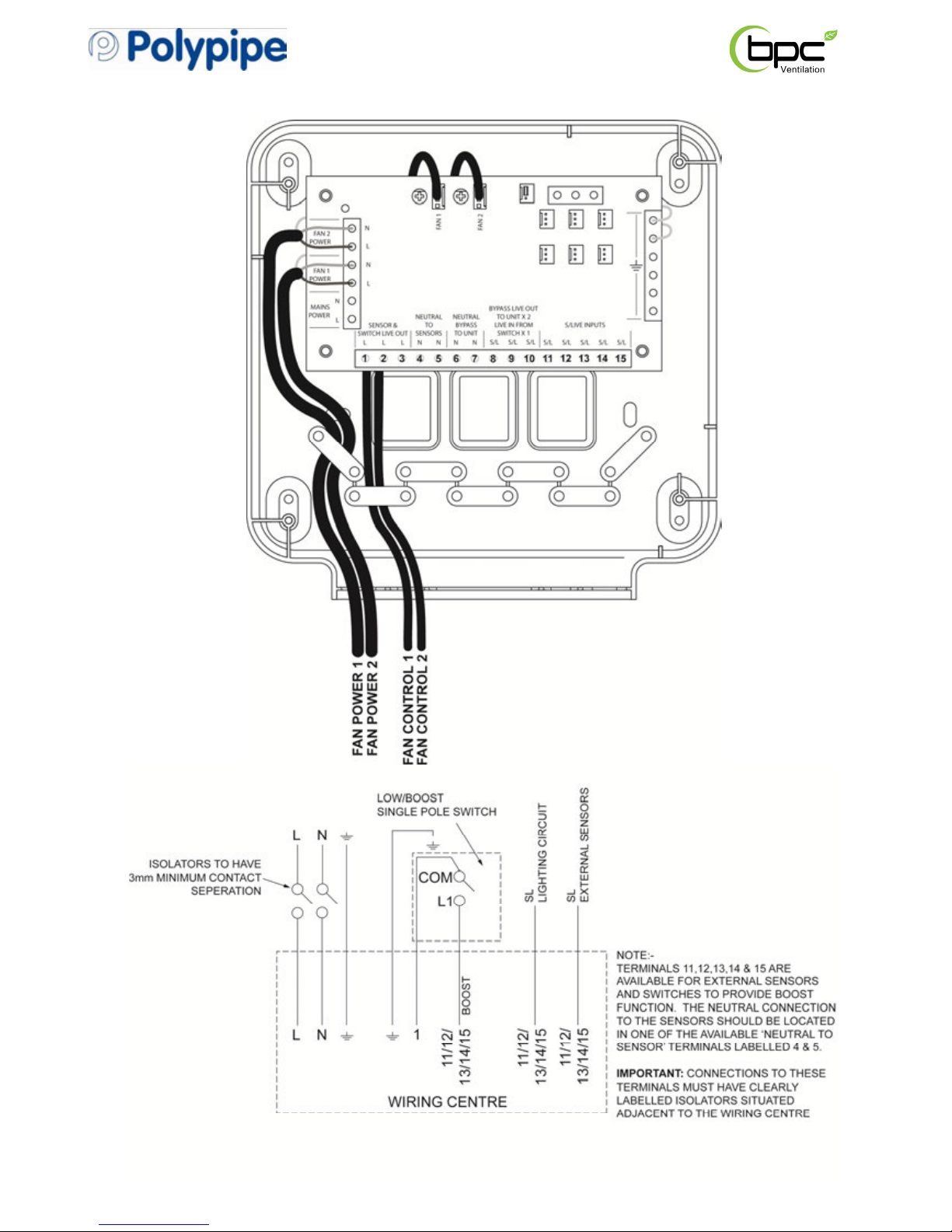

HRX2-B wiring diagram Page 17

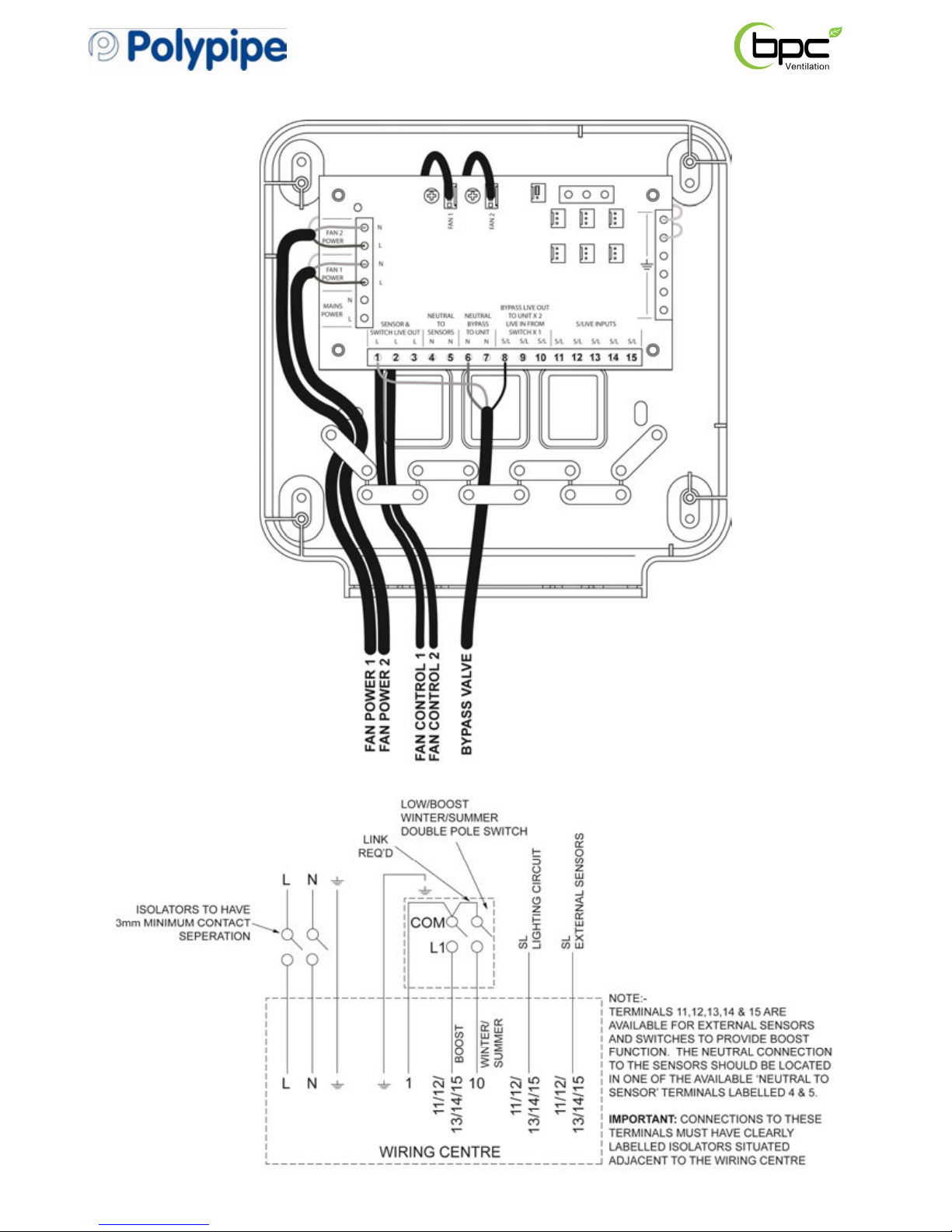

HRX2-FP wiring diagram Page 18

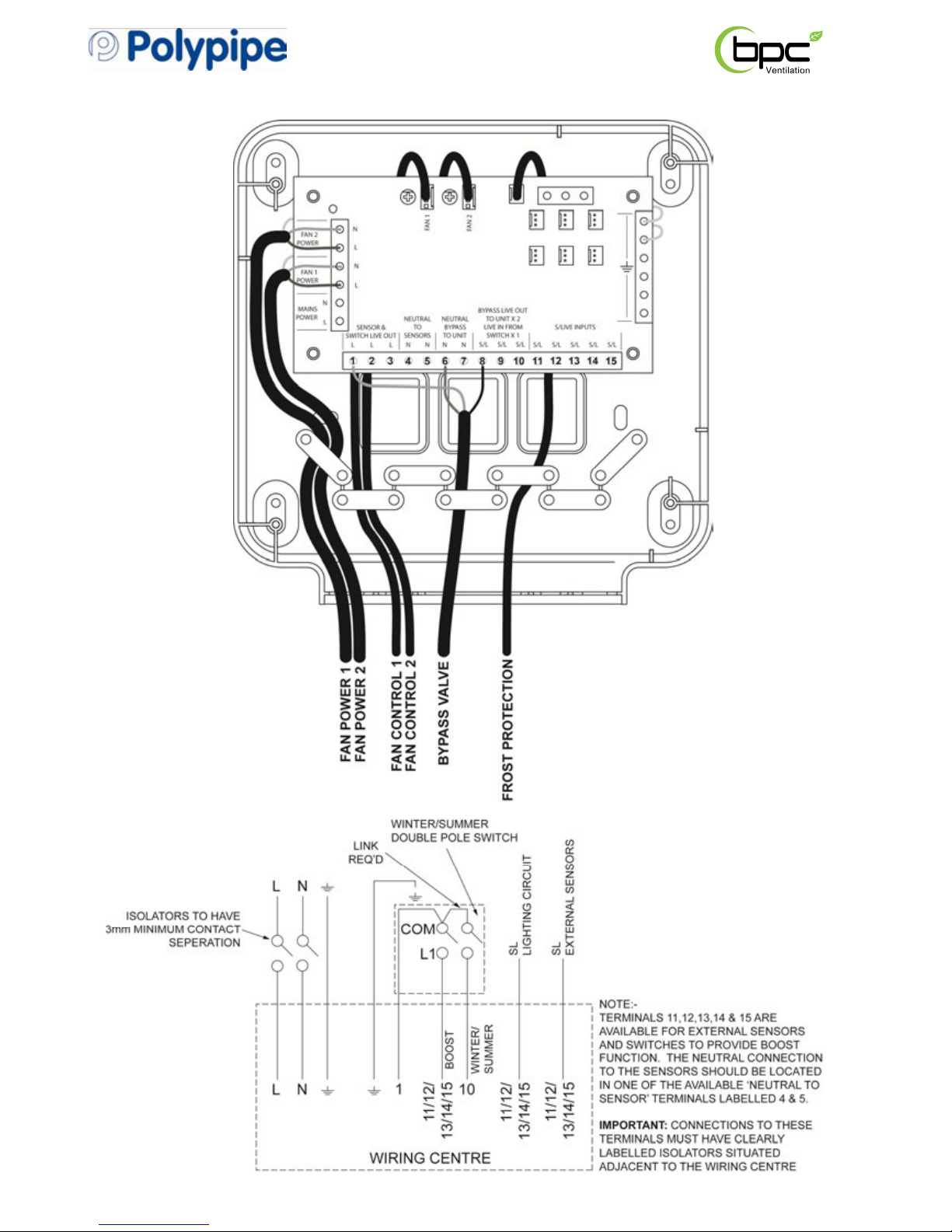

HRX2-BFP wiring diagram Page 19

ANC108A, ANC802A, ANC846A, ANC808A, ANC813A & ELE150R

wiring diagrams Page 20

5.0 Maintenance Page 21

5.1 Routine maintenance Page 21

6.0 Warranty Page 22

LAB939R, Issue 2, July 2014 Page 4

1.0 General description (all models)

1.1 Overview

1.1.1 The Silavent HRX2 appliance is a key part of a whole house ventilation system specifically

designed to improve indoor air quality in dwellings. The system is designed to provide

measured amounts of filtered, fresh air to living areas while constantly removing polluted,

stale air from bathing, cooking and washing areas at the same gentle rate. Any available heat

in the outgoing stale air is recovered by a built-in heat exchanger and used to pre-warm the

fresh supply air.

1.1.2 A manual boost switch is provided to increase the ventilation rate, e.g. when cooking or

showering thereby maintaining a comfortable indoor environment.

1.1.3 The boost facility can also be triggered from a lighting circuit or by a range of sensors,

including humidity control and movement detection (supplied separately – see section 1.1.8)

1.1.4 The G3/EU3 filters in the appliance ensure that the fresh supply air is clean as it enters the

home. Additionally, the stale extract air is filtered to protect the heat exchanger from

unwanted contamination. These filters have to be cleaned regularly, depending on the levels

of pollution. The filters should be replaced when they start to show visible signs of wear.

1.1.5 This product is listed in SAP Appendix Q, therefore, part of the installation process requires

that an installation checklist is completed and submitted to the Building Control Body (BCB).

Blank checklists are available at www.sap-appendixq.org.uk

1.1.6 Pack includes:

•Silavent HRX2 appliance

•Two duct connection plates and a bag of 18 fixing screws.

•Wiring centre

•Ventilation control switch - either one gang boost control (models HRX2-S, HRX2-FP) or two

gang combined boost and summer bypass control (models HRX2-B, HRX2-BFP)

•Installation and operating instructions manual and ‘householder-instruction cover’ with fixings

1.1.7 Ancillary items required:

•Domus Ø150mm rigid duct system (Domus 220mm x 90mm rectangular can be used in

restricted spaces), or Domus radial duct system (see 2.8)

•Optional Domus HRX2-CK1 ‘soft’ duct connection kit (see 2.8.3)

•Domus Thermal duct insulation (see 2.8.4)

•Domus 297 condensate drainage kit (see 2.7)

1.1.8 Ancillary options (see page 20)

•Silavent adjustable overrun timer, code ANC108A

•Silavent humidity control (with adjustable overrun timer), code ANC802A

•Silavent humidity control (with adjustable overrun timer and remote sensor), code ANC846A

•Silavent humidity control (with adjustable overrun timer and manual override with neon

indicator), code ANC808A

•Silavent PIR movement control (with adjustable overrun timer), code ANC813A

•Silavent 6-Switched live backfeed protected junction box, code ELE150R

LAB939R, Issue 2, July 2014 Page 5

LAB939R, Issue 2, July 2014 Page 6

1.2 Physical specification

net weight 20kg

1.3 Optional main features

1.3.1 Summer bypass (HRX2-B, HRX2-BFP models)

The models listed above will be supplied with an additional Winter/Summer switch (see

highlighted option boxes on the appliance cardboard cover). When the switch is set to

summer, the fresh air is no longer pre-warmed by the heat in the outgoing stale air.

Important: when the switch is set to summer, both fans will stop for 45 seconds to allow the

bypass diverter valve to open.

1.3.2 Frost protection (HRX2-FP, HRX2-BFP models)

The models listed above are supplied with an automatic frost protection system. During

periods of very cold weather, the fresh air supply fan will automatically turn off to reduce the

load on your heating system and avoid possible freezing of the heat exchanger. During these

periods, the extract fan will speed up slightly to maintain an even air pressure. See also

section 2.3.

LAB939R, Issue 2, July 2014 Page 7

2.0 Installation

2.1 Overview

2.1.1 The following instructions are intended to help prevent hazards. Installation should only be

carried out by a qualified electrician and competent persons in clean, dry conditions where

dust and humidity are at minimum levels.

Note: we advise installers to fix all mains, switch and sensor wiring (in accordance with the

latest edition of the Wiring Regulations) prior to fixing the HRX2 unit in position. For

convenience, buried cables for the wiring centre should terminate in a 2 gang metal box or

dry-lining box. The wiring centre can be fixed directly onto the box using standard M3.5

screws (not supplied).

2.2 Preparation

2.2.1 When accepting delivery of the appliance, inspect for transit damage. If in doubt, call our

Customer Services team on 08443 715523.

2.2.2 The HRX2 appliance and wiring centre can be fitted directly to a wall or suitable vertical or

horizontal timber support (if loft mounting). Important: if mounting on a horizontal surface,

make sure that adequate space/height has been considered for the condensate drain.

2.2.3 Ensure that the position chosen for the wiring centre is close enough to the HRX2 appliance

so that there is no undue strain applied to the cables between the HRX2 appliance and the

wiring centre. Important: these cables can not be lengthened or shortened.

2.2.4 Appropriate screw fixings to suit the support medium will need to be supplied by the installer.

The support brackets for vertical mounting are pre-drilled to suit 2 x 4mm (No.8) round/pan-

head screws.

2.2.5 Ensure that there is sufficient space for the wiring centre, condensation fittings and ductwork.

2.2.6 Ensure that there is sufficient space at the front of the appliance to access the filters and for

carrying out any future maintenance on the appliance.

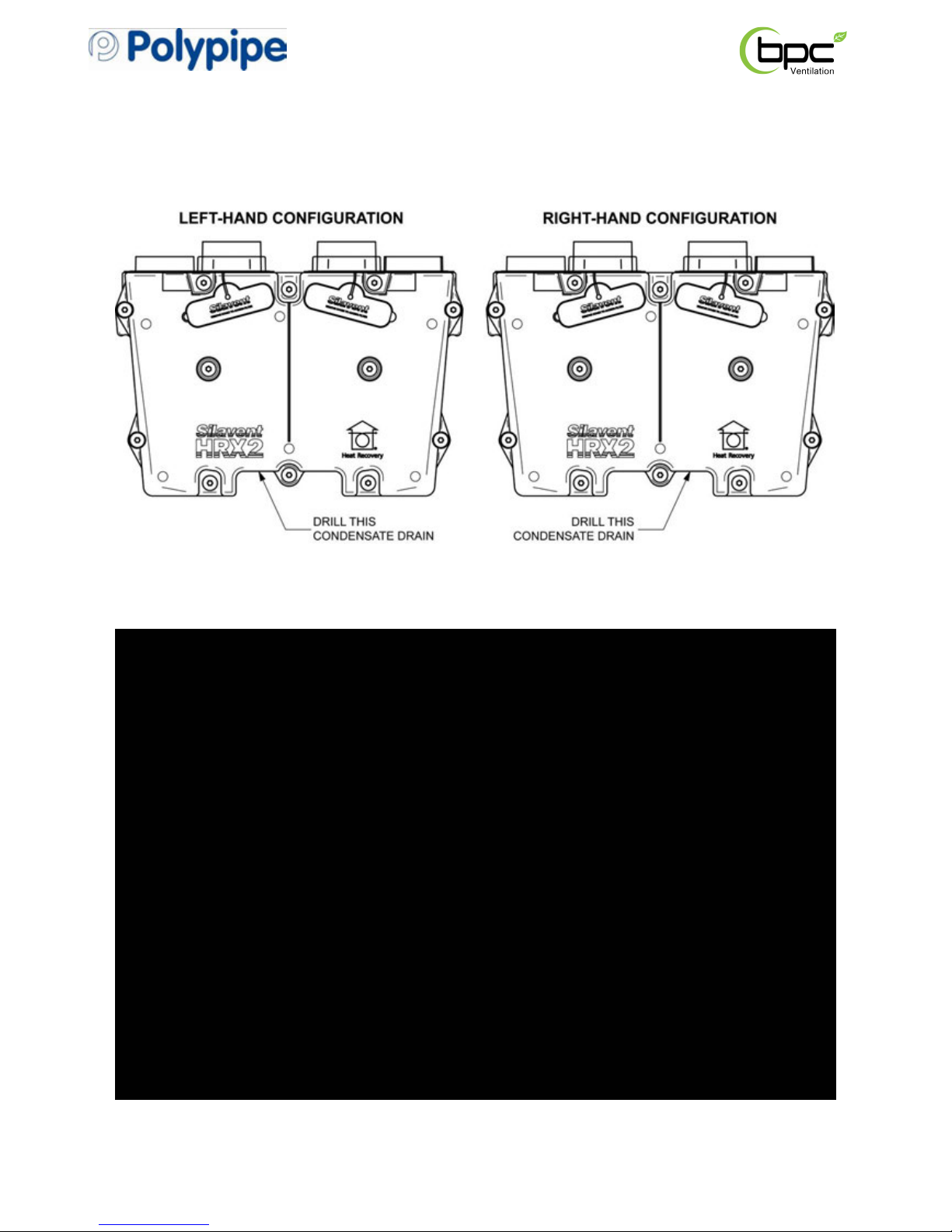

2.2.7 The HRX2 appliance can be mounted as a left-hand or right-hand installation, i.e. for

convenience the two external duct connections can be either on the left or right-hand side.

This feature can be extremely useful in smaller houses or apartments where there is no space

to cross over ducts.

2.2.8 When viewed from above, the two duct configuration options are shown on the diagram

below:

IMPORTANT: The configuration selected will determine the connection point for the

condensate drain – see diagram below.

LAB939R, Issue 2, July 2014 Page 8

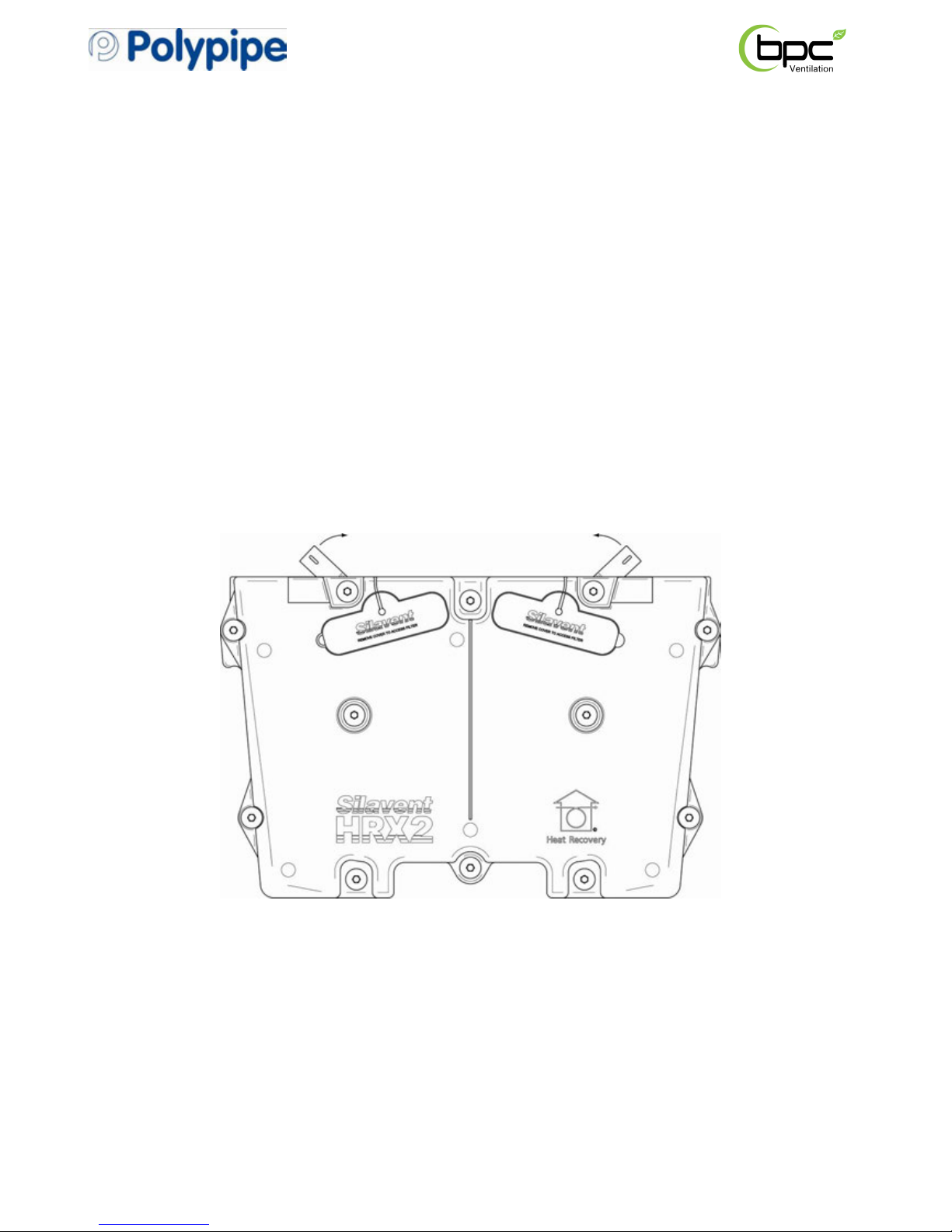

2.2.9 Using a hole-saw of minimum diameter 20mm (3/4”) and maximum diameter 25mm (1”),

remove the closed end of the condensate tray ensuring that any debris is entirely removed.

For convenience a drill centring guide has been moulded into the tray – see diagram below.

LAB939R, Issue 2, July 2014 Page 9

2.3 Installing the frost protection sensor (HRX2-FP, HRX2-BFP)

2.3.1 Important: This operation should only take place after the left or right-handed position of the

appliance has been determined.

2.3.2 Referring to the diagram at 2.2.8;

2.3.3 Directly in line with the ‘INLET FRESH AIR FROM OUTSIDE’ socket and from the ‘back’ or

‘mounting’ side of the appliance, insert the frost sensor filter cover and gently push the cable

into the groove running up the face of the main housing. Ensure that no undue stress is put

on the cable.

2.3.4 See also 3.2 for wiring centre connections.

2.4 Wall/surface fitting the HRX2 appliance

2.4.1 Refer to the diagram on page 6 to determine where the extents of the appliance are in relation

to the support brackets.

2.4.2 Rotate the two support brackets to a vertical position from their horizontal transit position.

2.4.3 Using the support brackets as a template, mark the positions for the two fixings.

2.4.4 Using 2 x 4mm (No.8) round/pan-head screws and appropriate anchors (not supplied), secure

the appliance.

2.4.5 Ensure that no cables are trapped behind the appliance and that the appliance is level front to

back and side to side.

2.4.6 Attach the four black self-adhesive ‘hook’ pads, one onto each corner indentation of the main

body. Attach the four white self-adhesive ‘loop’ pads, one to each corner of the cardboard

‘householder-instruction’ cover. Carefully fit the ‘householder-instruction’ cover by pressing to

engage the ‘hook and loop’ pads.

LAB939R, Issue 2, July 2014 Page 10

2.5 Fitting the bypass valve

2.5.1 Referring to the diagram below; the heat exchanger bypass mechanism is operated in the

same way as a motorised 3-port valve, diverting the warm, stale exhaust air around the heat

exchanger when ‘SUMMER’ operation is selected.

2.5.2 Select the appropriate air path and fit the two duct connection plates to suit using the screws

provided.

LAB939R, Issue 2, July 2014 Page 11

2.5.3 The bypass valve can be fitted directly onto the appliance using the flexible hose and hose

clamps provided or mounted remotely using extra duct. Ensure that the bypass valve cable

will reach the wiring centre.

2.6 Fitting the wiring centre

2.6.1 Remove the cover of the wiring centre by removing the four retaining screws while taking care

not to dislodge any of the cables.

2.6.2 Carefully remove sufficient knock-out panels in the mounting plate to provide access for the

mains supply, switch and external sensor cables.

Either;

2.6.3 Pass the cables through the knock-outs and push the mounting plate firmly against the

mounting surface. Using 2 x M3.5 electrical screws (not supplied) through the upper fixing

holes, attach the mounting plate to the 2 gang metal box or dry-ling box already installed (not

supplied).

Or;

2.6.4 Pass the cables through the knock-outs and push the mounting plate firmly against the

mounting surface. Using the mounting plate as a template, mark the positions for the two

lower fixing holes. Using 2 x 3mm (No.6) round or pan head screws and appropriate anchors

(not supplied), secure the mounting plate.

2.6.5 Make the wiring connections – see section 3.0

2.6.6 Refit the cover.

LAB939R, Issue 2, July 2014 Page 12

2.7 Fitting the Domus 297 condensate drain kit

2.7.1 Using a small amount of solvent weld suitable for ABS pipe fittings (not supplied), attach the

threaded socket to the selected condensate outlet spigot (see no 2.1.9). Important: follow the

health and safety and user instructions supplied with the solvent weld. This is particularly

important when working in confined spaces.

2.7.2 When the threaded socket is secure, fit and hand-tighten the threaded elbow, making sure

that the rubber seal washer is seated correctly. Gently push the waterless trap onto the elbow

stem. Important: check that the arrows printed on the trap point away from the HRX2

appliance (in the direction of flow) and prior to fitting, ensure that the waterless trap operates

correctly by running a trickle of water from a tap through the trap in the direction of the arrows.

2.7.3 Using the remainder of the kit items complete the condensate drain-system to suit the

dwelling layout. Important: the drain must incorporate a continuous fall of approximately 0.5º

(9mm in every 1000mm) to the nearest waste water network.

2.7.4 The condensate drain system should be adequately supported and suitably insulated if it

passes through unheated spaces and voids (e.g. loft spaces) to prevent freezing.

2.8 Ducting guidelines

2.8.1 Please refer to the design drawings for the proposed ducting layout.

2.8.2 Four Ø150mm diameter sockets are provided for connecting the ducting. Rigid ductwork

should be securely connected to the sockets using Domus DDSEAL acrylic sealant; failure to

do this will cause unnecessary air leakage and impair performance. Ducting must be

connected to all four sockets according to left or right-hand configuration (see 2.2.7).

2.8.3 Alternatively, heavy duty flexible hose connection kit, HRX2-CK1, is available to make

soft/offset connections between the HRX2 and the rigid duct system.

2.8.4 Where ducting passes through unheated areas and voids (e.g. loft spaces) it must be

insulated using Domus Thermal duct insulation in order to comply with The Building

Regulations. Additionally, both ducts connecting the HRX2 to outside must be insulated when

passing through heated areas to avoid condensation forming on the outside of the ducts.

LAB939R, Issue 2, July 2014 Page 13

2.8.5 Alternative proprietary duct insulation may be used provided it complies with the 2010

Domestic Ventilation Compliance Guide.

2.8.6 When passing through a fire-stopping wall or fire-compartment wall, Domus FireBrake

intumescent duct connectors should be used in order to comply with The Building

Regulations.

2.8.7 Alternative proprietary fire-stopping methods may be employed provided they comply with

Approved Document B of The Building Regulations.

2.8.8 Rigid ducting – install using the least number of fittings to minimise resistance to airflow.

Important: Reducing the duct size below Ø150mm diameter or 220mm x 90mm rectangular

may have an adverse effect on airflow performance. All duct runs should be as short and as

straight as possible for maximum performance.

2.8.9 Flexible ducting – ensure flexible ducting lengths are kept to a minimum and ducting is pulled

taut so that it is smooth and straight. Where bends are necessary and where ducting runs in

restricted areas, ensure that the ducting is not crushed. Mechanically fix flexible ducts using

Domus 125-6 hose clips and tape seal using Domus 50TP45 duct tape or any good quality

proprietary duct tape for added air-tightness.

2.8.10 The fresh supply air must be drawn in from the exterior of the property. If drawn through a

wall, a Domus 905 airbrick or Domus 6904 fixed louvred grille should be fitted. If drawn in

through the roof a Domus 4411 universal roof terminal should be fitted or a proprietary roof

terminal designed for mechanical ventilation with a free area of at least 15175mm².

2.8.11 The stale extract air must be expelled to the exterior of the property. If expelled through a

wall, a Domus 905 airbrick or Domus 6904 fixed louvred grille should be fitted. If expelled

through the roof a Domus 4411 universal roof terminal should be fitted or a proprietary roof

terminal designed for mechanical ventilation with a free area of at least 15175mm².

2.8.12 It is recommended that the fresh supply and stale exhaust external inlets and outlets should

be fitted at least 2m apart to avoid recirculation of stale exhaust air.

2.8.13 Further details regarding installation can be found in the 2010 Domestic Ventilation

Compliance Guide.

LAB939R, Issue 2, July 2014 Page 14

3.0 Electrical

3.1 Overview

3.1.1 WARNING: This appliance must be earthed.

3.1.2 Important: All wiring must conform to the prevailing national regulations, for example

the latest edition of BS7671: IEE Wiring Regulations.

3.1.3 Important: The electrical installation must be carried out by a qualified electrician.

3.1.4 This appliance is suitable for 230V 50Hz single phase supply only, fused at 3 Amps.

3.1.5 A double-pole switch having a minimum contact separation of 3mm must be used to provide

isolation for the appliance.

3.1.6 Refer to page 14 for HRX2-S, wiring diagram, page 15 for HRX2-B, wiring diagram, page 16

for HRX2-FP wiring diagram and page 17 for HRX2-BFP wiring diagram.

3.1.7 Supplementary sensor diagrams are shown on page 18.

3.1.8 External wiring (1.5mm² max.) and isolators to be supplied by others.

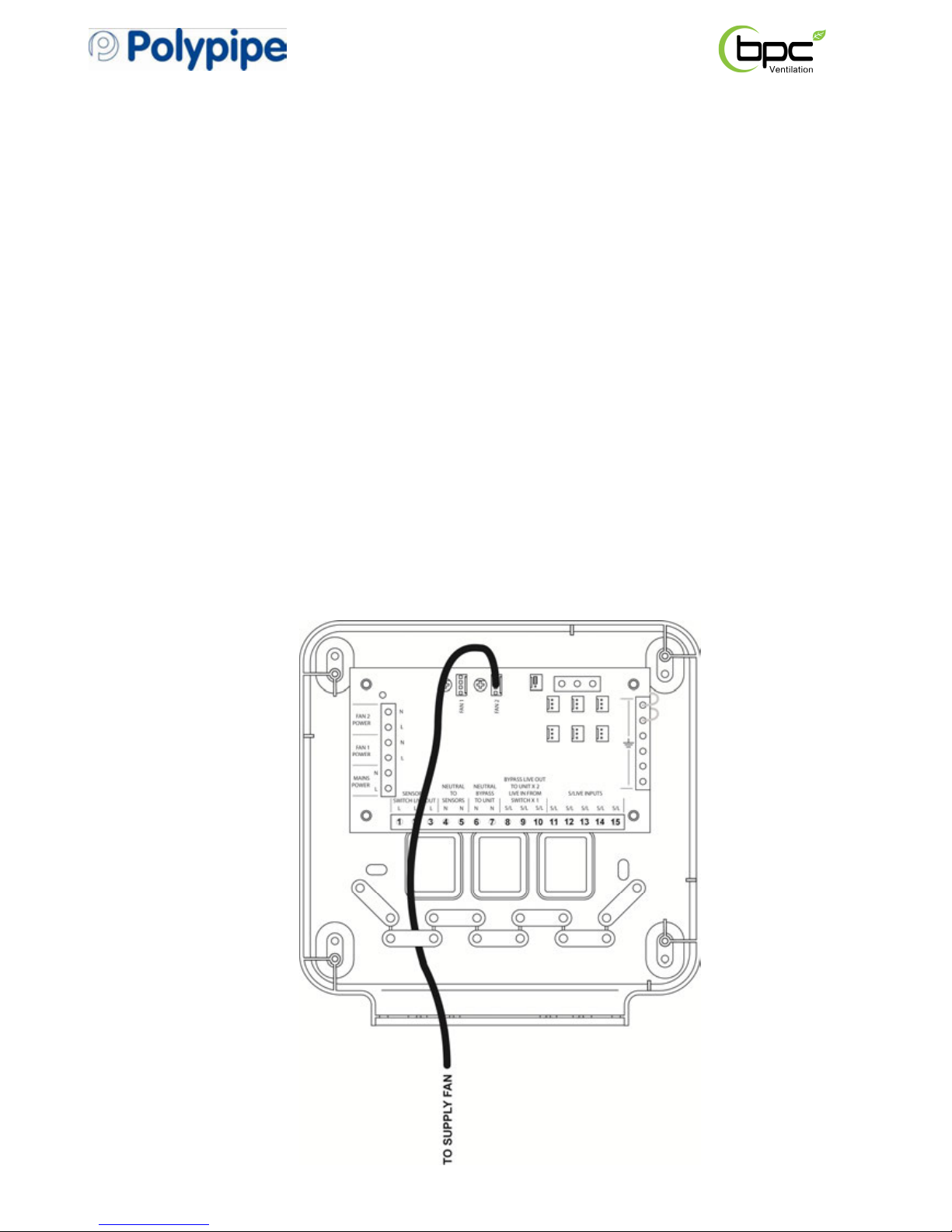

3.2 Frost protection only, wiring-centre fan connections (HRX2-FP, HRX2-BFP)

3.2.1 Important: the fan selected as SUPPLY FRESH AIR TO ROOMS must be connected as

shown in the diagram below.

LAB939R, Issue 2, July 2014 Page 15

4.0 Commissioning

4.1.1 Overview

4.1.2 When the wiring connections have been checked, and it is safe to do so, switch on the mains

supply and check that the system is operating correctly. The appliance should switch between

low and boost speeds using the manual boost switch (see 1.1.2).

4.1.3 Airflow rates will need to be set at each room’s air valve in accordance with the 2010

Domestic Ventilation Compliance Guide to balance the system. Airflow measurements should

be performed using a calibrated airflow measuring device and the results recorded in litres

per second (l/s) onto the Inspection Checklist and Airflow Measurement Test Sheet contained

within the 2010 Domestic Ventilation Compliance Guide. The most common method uses a

vane anemometer, or similar, placed in a hood which completely covers the air valve to

measure the extract or supply airflow rate. The instrument should be calibrated annually by

returning the instrument to a UKAS accredited calibration centre and be capable of achieving

an accuracy of ±5%.

4.1.4 Each room airflow rate will need to be recorded on the Inspection Checklist and Airflow

Measurement Test Sheet. A completed copy must accompany these instructions and be

handed over to the dwelling owner upon completion of the installation.

4.2 System balancing

•Fully open all of the air valves

•Switch the system to boost

•Close all internal and external doors and windows

•Measure the total air volume of the extract valves (wet rooms)

•Remove the rubber tamper-deterrent cap and using a small screwdriver, adjust the

‘boost’ control on the wiring centre to achieve the total design extract rate

•Adjust individual room air valves to achieve the individual room design extract rates

•Switch the system to low

•Measure the total air volume of the supply valves (habitable rooms)

•Remove the rubber tamper-deterrent cap and using a small screwdriver, adjust the

‘low’ control on the wiring centre to achieve the total design supply rate

•Adjust individual room air valves to achieve the individual room design supply rates

•Using the lock nuts fitted to the air valves, lock in position

•Refit the rubber tamper-deterrent caps to the lid of the wiring centre

LAB939R, Issue 2, July 2014 Page 16

HRX2-S wiring diagram

LAB939R, Issue 2, July 2014 Page 17

HRX2-B wiring diagram

LAB939R, Issue 2, July 2014 Page 18

HRX2-FP wiring diagram

LAB939R, Issue 2, July 2014 Page 19

HRX2-BFP wiring diagram

LAB939R, Issue 2, July 2014 Page 20

ANC108A, ANC802A, ANC846A, ANC808A, ANC813A and ELE150R wiring diagrams

NOTE:-

TERMINALS 11,12,13,14 & 15 IN THE WIRING CENTRE ARE AVAILABLE FOR EXTERNAL SENSORS AND SWITCHES

TO PROVIDE BOOST FUNCTION

IMPORTANT: CONNECTIONS TO THESE TERMINALS MUST HAVE CLEARLY LABELLED ISOLATORS SITUATED

ADJACENT TO THE WIRING CENTRE

ANC108A

–

OVERRUN TIMER

ELE150R

–

SWITCHED LIVE EXTENSION

BOARD

ANC802

–

HUMIDISTAT WITH TIMER,

ANC846A

–

HUMIDISTAT WITH TIMER AND REMOTE SENSOR

ANC808A – HUMIDISTAT WITH PULLCORD

ANC813A

–

PIR WITH OVERRUN TIMER

This manual suits for next models

4

Table of contents

Other silavent Fan manuals

Popular Fan manuals by other brands

Somogyi Elektronic

Somogyi Elektronic Home TF 31 instruction manual

Craftmade

Craftmade Rush RSH65 installation guide

Multifan

Multifan PV600 Assembly manual

WINGBO

WINGBO WBCF-BS88 Series installation instructions

Sonnenkonig

Sonnenkonig LIVORNO user manual

aireRyder

aireRyder FN75539 Instruction for use & installation instructions