PRIOR TO USE

Points to check before starting the machine

Note: - Before using this machine a check should be

performed on all of the points listed below. It is important

before use to check the chainsaw is in good working order.

If any defects are detected then the machine should not be

used.

• Check the tension of the chain along the guide bar. A major

cause of problems with chainsaws comes as a direct result of

the tension in the chain. A loose chain will cause excessive

friction, causing wear and damage.

• Make sure the chain is well oiled. Before every use check the

oil level in the chain saw. The saw requires the chain to be well

lubricated in order to pass freely through the guide bar. This unit

requires Chainsaw Oil SAE 30. The oil level should be checked

very regularly to help reduce wear on the saw chain and guide

bar. This chainsaw is self-lubricating.

• Make sure the teeth are sharp.

• Check the power lead is in good condition.

OPERATING INSTRUCTIONS

Fitting The Guide Bar, Chain And Setting The Tension

• Make sure the chainsaw is not plugged in prior to fitting the

guide bar and chain.

NOTE: - Suitable gloves should be worn at all times when

handling the chain.

• Lay the chainsaw on its motor casing; handle side facing down.

Make sure that the chainsaw is in a stable position before going

any further.

• Remove the locking nut and plastic housing covering the drive

sprocket and locating pin.

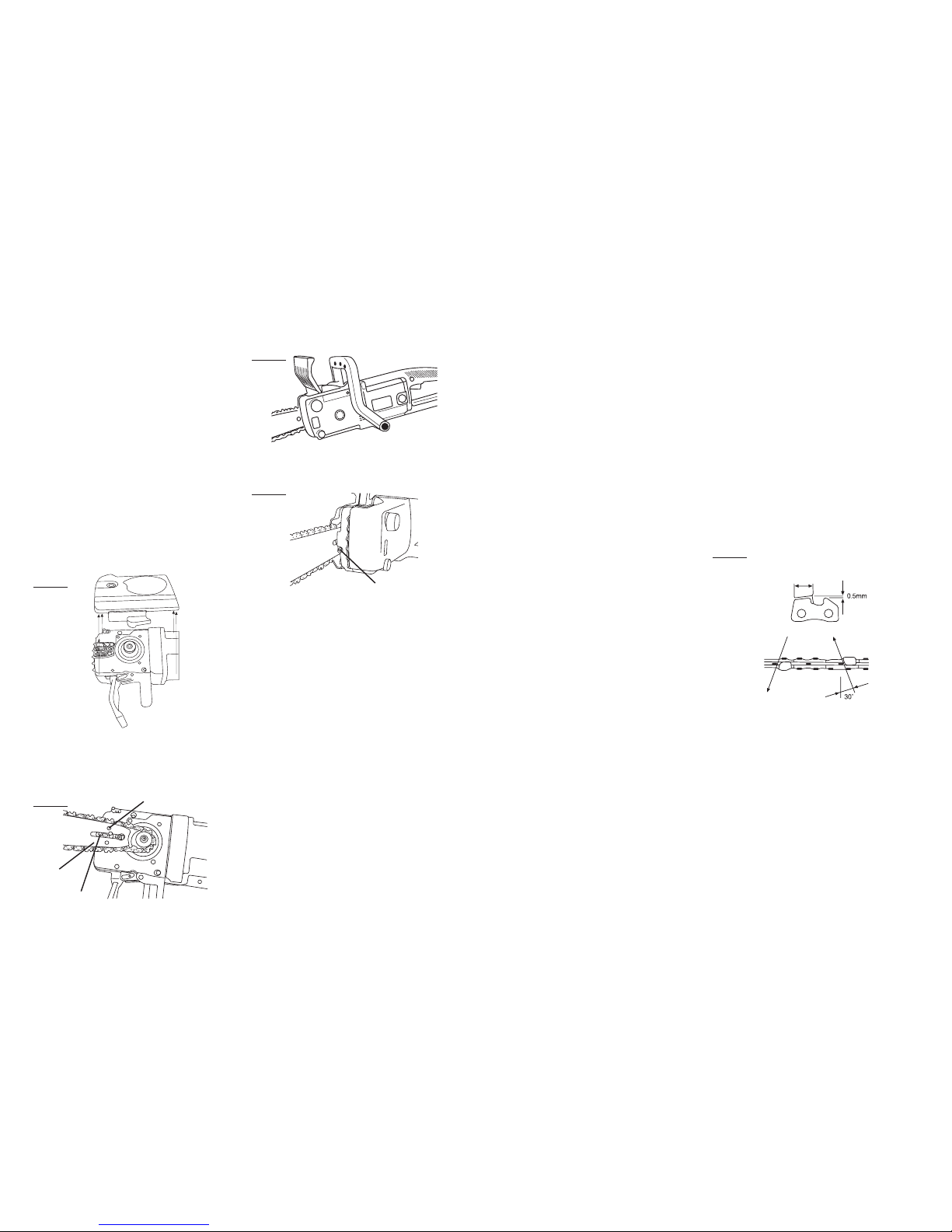

Diagram 1

• Holding the guide bar vertically with the head at the top, insert

the chain onto the guide bar. Make sure that the chain runs

through the groove on the guide bar along both sides.

• Place the guide bar and chain onto the chainsaw body as per

the diagram below. Make sure that the guide bar is properly

positioned over the locating pin and that the tensioning pin is

also in the correct position.

Diagram 2

• With the chain and guide bar now in place run the chain around

the drive sprocket. Make sure that the direction of the blades

matches the direction of rotation of the chainsaw.

• Whilst holding the guide bar in place to stop the chain from

moving replace the plastic housing covering the drive sprocket

and tighten the locking nut. Do not over tighten.

Diagram 3

• Using a Phillips screwdriver adjust the chain tension by

screwing in a clockwise direction. This will pull the chain taught

to the guide bar.

Diagram 4

• The chain has been correctly tensioned when you can rotate the

chain by hand and it is running around the guide bar closely.

Note: - A new chain is liable to be lacking tension at first,

and will require adjusting occasionally for the first few times

in use. Over tensioning the chain will lead to premature wear.

A saw chain, which is too slack, runs the risk of

jumping out of the guide and can cause severe damage to

the machine and possibly the user.

Safe Working Practice

When using this chainsaw it is very important that all points listed

in this section be adhered to at all times. These points are listed

for the users safety and the safety of others in the surrounding

area.

Clothing And Protective Equipment

NOTE: - All of the following must be worn at all times when

using this machine

• Protective jacket conforming to prEN381 – 11 Class 0. To

provide extra protection across the shoulders, arms and front

yoke area.

• Protective trousers conforming to EN381-5 Class 1

• Chainsaw gloves conforming to EN381-7 Class O. These gloves

help prevent slippage and incorporate a special anti cut material

on the back of the hand.

• Hard hat with full face shield and ear defenders.

• Protective chainsaw boots with steel midsole and toecap.

Gaiters to provide extra protection around the shin.

Safety Rules For Making A Cut

• Ensure the protection guard (1) is in the forward position before

starting.

• Use a right hand grip to hold the chainsaw. Right hand on the

trigger and left hand on the front handle.

• Keep the left arm straight at all times for better control of the

machine.

• Hold the chainsaw firmly in both hands keeping the thumb

locked around the front handle.

• Stand to the side of the chainsaw. NEVER STAND BEHIND IT.

• Run the engine at full throttle.

• Use a low kickback saw chain and a reduced kick back

guide bar.

• Keep the chainsaw, chain, guide bar and drive sprocket properly

maintained.

• Always stand with feet well braced and your body balanced.

• Cut only wood with this chainsaw.

• Keep yourself clear of the work. Before making a cut assess the

environment. Calculate how the object being cut will fall.

Determine if the saw may be thrown unexpectedly by the

movement of the cut material.

• Never cut above shoulder level.

• Never make a cut while in a tree, or on a ladder.

• Keep others away from the cutting area. Do not allow others to

hold the wood during cutting.

Checking The Automatic Oil function

Important: the chainsaw will not operate unless the oil tank

is filled

The chain oil flow control (6) adjusts the amount of oil received

by the chain. When the hole in the knob is at the top, it is at

maximum flow and vice versa.

To check that you are getting automatic oil flow, point the tip of

the switched-on chainsaw towards a piece of paper on the floor,

if a patch of oil appears and gets larger the automatic oil flow

is working.

If the automatic oil flow is not working you need to clean the oil

way. Remove the chain bar and clean out the oil way which is the

black hole located above the thread to the left.

Kickback

Kickback is the violent backward and / or upward motion of the

chainsaw guide bar. It occurs when the chain near the tip of the

guide bar contacts on object, such as another log or branch, or

when the wood closes in and pinches the saw chain in the cut.

Kickback can be very dangerous. Be alert at all times, to guard

against a possible kickback reaction. Always be aware of the

position of the tip of the guide bar when making any cuts. The

Oregon®* chain supplied with the chainsaw has been designed

with kickback reducing features. However this does not mean that

kickback will not occur and the user should be aware of possible

kickback at all times.

Cutting In Cold Weather Conditions

Cutting frozen wood will cause rapid wear and breakage around

the rear rivet hole of cutters. Following the steps as outlined

below will help to keep the cold weather wear on the rivets to a

minimum.

• Dilute the saw chain oil 25% with clean kerosene. It is important

that in these conditions the chain is receiving oil from the saw.

• Keep the tension in the chain constant. It should be checked

and adjusted on a regular basis.

• Keep the cutters sharp. The teeth should be touched up every

hour, more often if needed. A dull chain will cause excessive

wear on the guide bar and cause the links to break very quickly.

• Check and adjust the depth gauge on the cutters every time the

saw chain is sharpened.

• Keep the guide bar clean and the oil hole open. The guide bar

is symmetrical and as such should be turned over regularly to

equalise the rail wear.

MAINTENANCE

Running In A New Chain

When this machine is supplied the chain is ready for use.

However it is possible to extend the life of the chain by following

a few simple rules.

• Soak the chain in chainsaw oil SAE 30 overnight. This will allow

the oil to penetrate all the chain components.

• Never run a chain, especially a new one, on a worn drive

sprocket. The drive sprocket system should be replaced once

every 2 chains.

• Once a new chain has been fitted run the saw at half throttle for

a couple of minute without making any cuts. This will allow the

oil to reach all parts of the guide bar and chain. It will also allow

the drive sprocket, guide bar and chain to warm up properly.

• A new chain will lose tension quickly until it is worn in

sufficiently. Keep checking and adjusting the tension for the first

few times the new chain is used.

• Do not ask too much from the new chain. Keep the first several

cuts light. Too much workload on a new chain from the start will

reduce the overall life of the chain.

Sharpening The Chain

In order to extend the saw chains life and the efficiency of the

saw the teeth should be sharpening regularly. Use a round file

with a 4mm diameter to sharpen the teeth. Always sharpen the

teeth in accordance with the original angles.

• When sharpening teeth all blades must be the same length. To

keep all teeth the same shape and size always start with the

most worn blade and file the other blades to match the length.

• Always file the blades on the same side and in the same

direction by pushing from the inside to the outside of the teeth.

In order to avoid cuts when handling the chain always wear

gloves.

• Every 3 times the blades are sharpened check the height of the

depth limiters. The depth limiters spacing is 0.5mm. Adjust the

height of the depth limiters by using a flat file. Make sure when

filing the depth limiters to follow the angle of the front angle in

order to maintain the shape of the blade.

Diagram 5

TROUBLESHOOTING

Poor performance of this chainsaw when making cuts can be as

a direct result of any of the points as listed below.

• Incorrectly sharpened chain angles.

• A dull chain.

• Excessive chain depth-gauge settings.

• Incorrect chain depth settings.

• Loose chain tension.

• Incorrectly installed chain links.

• Loose rivets, or cracks and breaks in any chain link.

• An overly worn drive sprocket.

• A worn guide bar.

• An under lubricated chain, guide bar and drive sprocket.

Tensioning Pin

Guide Bar

Locating Pin

Chain Tensioning Screw

*Oregon® is a registered trademark of Blount International Inc.