Introduction

This manual is an integral part of the chainsaw and should be kept

with it at all times. If the chainsaw is re-sold this manual should be

included in the sale.

Safety Messages

A safety message is to alert you to potential dangers that could hurt

you or others. Each safety message is preceded by one of three

words DANGER, WARNING or CAUTION.

These words mean

DANGER: YOU WILL BE KILLED OR SERIOUSLY INJURED IF

YOU FAIL TO FOLLOW THE INSTRUCTIONS.

WARNING: YOU CAN BE KILLED OR SERIOUSLY INJURED IF

YOU FAIL TO FOLLOW THE INSTRUCTIONS.

CAUTION: YOU CAN BE SERIOUSLY INJURED IF YOU FAIL TO

FOLLOW INSTRUCTIONS.

Each safety message tells you what the hazard is, what can

happen and what you can do to avoid and reduce injury.

There are other important messages preceded with the word

NOTICE.

NOTICE: MEANS YOUR CHAINSAW OR OTHER PROPERTY

COULD BE DAMAGED IF YOU FAIL TO FOLLOW

INSTRUCTIONS.

The purpose of these messages is to help prevent damage to you,

your chainsaw, other property and the environment.

General Safety Instructions

Even when used as prescribed it is not possible to eliminate all

residual risk factors. Use with caution.

Keep guards in position

• Always keep guards in position, in good working order, correctly

adjusted and aligned. Never attempt to use a tool without any guard

supplied with it.

Remove adjusting keys

• Always check to see that keys and adjusting wrenches are removed

from tool before turning on.

Clean work area

• Accidents occur where benches and work areas are cluttered or

dirty, oors must be kept clear, avoid working where the oor

is slippery.

Dangerous environment

• Provide adequate surrounding work space and keep area well lit.

Do not use tools where there is a risk of explosion or re from

combustible material, ammable liquids, ammable gases

or dust of an explosive nature.

Children & Pets

• Children and pets should always be kept at a safe distance

from your work. Make your workshop child-proof. Lock tools

away where children can’t get access to them.

Use the correct tool

• Don’t force, or attempt to use a tool for a purpose it was not

designed for. Do not use a small tool to do the job of a heavy duty

tool.

Wear correct clothing and footwear

• Don’t wear loose clothing, neckties or jewellery or other items which

may get caught in moving parts. Wear non-slip footwear, cover or

tie back long hair. Use safety footwear if necessary.

Protect your head

• Wear safety goggles at all times, every day glasses are not

sufcient for eye protection, as lenses are not impact resistant and

could shatter. Use an approved face or dust mask when operation

creates dust. Ensure dust extraction equipment is functioning

and correctly used. Hearing protection should be used if the sound

intensity level for the operator could exceed 80dB(A). Use a hard

hat where there is a risk of falling objects or striking your head on

low level obstructions.

Protect yourself from vibration.

• Hand held tools may produce vibration. Vibration can cause

disease. Gloves to keep the operator warm and dry and therefore

maintain good blood circulation in the ngers may help. This tool

has not been designed for extended or industrial operation.

Secure work

• Always secure work. Where practical use a clamp or vice, it will

allow you to use both hands to operate your tool.

Keep your balance

• Don’t over reach, keep proper footing at all times to ensure

correct balance.

Maintain your tool

• Keep your tool in good working order, keep tools sharp and clean

for best and safest performance. Ensure ventilation holes are kept

clean and unrestricted at all times.

Accessories

• The use of any attachment or accessory other than those

mentioned in this manual could result in damage or injury. The use

of improper accessories could be dangerous.

Never stand on your power tool

• Standing on your tool could cause serious injury if the tool is tipped

or if the cutting tool is accidentally contacted. Do not store materials

above or near the tool so that it is necessary to stand on the tool or

its stand to reach them.

Check for damaged or missing parts.

• Before each use check if any part of the power tool is damaged or

missing, check carefully that it will operate properly and perform its

intended function. Check alignment of moving parts for binding. Any

guard or other part that is damaged should be correctly repaired or

replaced. Do not use if the power switch does not turn the power on

and off. Check any other condition that may affect the safety of the

power tool. DO NOT USE IF DEFECTIVE.

Direction of feed

• Feed work into a blade or cutter against the direction of rotation of

the blade or cutter only.

Don’t leave the tool running unattended

• Always wait until your power tool has come to a complete stop

before leaving it.

GENERAL WARNINGS

Wear close tting, durable work clothing that will provide

adequate protection. Long trousers, jacket, safety work shoes,

heavy duty work gloves, hard hat, safety face shield or safety glasses

for eye protection and a good grade of ear protection.

Turn unit off before, setting down, or checking ttings.

Hold unit rmly, hold with both hands, the thumb and ngers

encircling both handles.

Keep all screws and fastener tightened, never operate machinery

improperly adjusted or unsecurely assembled.

Keep handles dry, keep clean and free of fuel mixture.

Do not use any other fuel, always use recommended fuel.

Follow instructions in the fuel and lubrication section of the user

guide. Failure to do this will result in permanent engine damage

voiding manufacturer’s warranty.

Do not smoke while refuelling or operating unit.

Do not touch or let hands or body come into contact with the units

mufer. Hold unit with both hands, thumb and ngers encircling both

the handles.

NEVER allow children to operate unit.

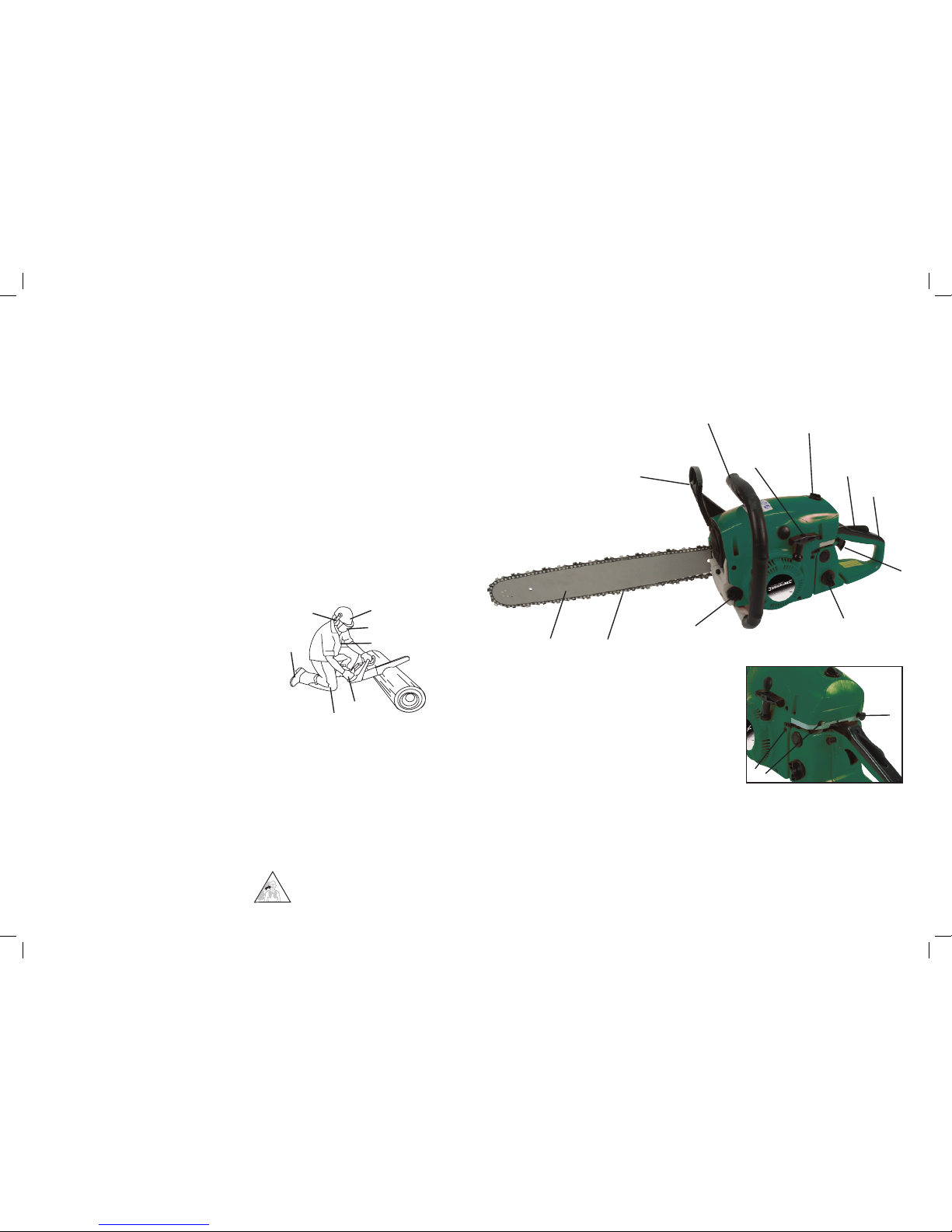

Product Familiarisation

52cc Petrol Chainsaw

508mm Bar

Hard hat

Face shield

Jacket

Leather gloves

Leg protection

Safety boots

Ear protectors

1. Front guard

2. Starter knob

3. Air cleaner cover

4. Choke knob

5. Throttle interlock

6. Rear handle

7. Throttle trigger

8. Carburetor adjustment screws

9. Ignition switch

10. Fuel tank ller

11. Oil tank ller

12. Front handle

13. Saw chain

14. Guide bar

This product produces poisonous exhaust fumes

as soon as the engine is running. These gases

may be colourless and odourless. To reduce the

risk of serious or fatal injury, never run the machine

indoors, or in poorly ventalilated areas. Ensure

proper ventilation when working in trenches or other

conned spaces.

SPECIFICATION

Fuel: Unleaded petrol / 2 stroke mix (25:1)

Fuel tank capacity: 520ml

Oil tank capacity: 260ml

Engine displacement: 51.2cc

Maximum engine power: 2.6kW

Maximum engine speed with

cutting attachment: 10000RPM

Maximum engine speed at idling: 3000RPM

Sprocket: 7 Tooth

Saw chain type: USA Semi-chisel

Saw chain pitch: 3/8"

Saw chain gauge: 1.27mm(0.058")

Guide bar type: Sprocket nose

Guide bar size: 508mm (20")

Max cutting length: 480mm

Oil feeding system: Automatic

Sound pressure: 104dB(A)

Sound power: 116dB(A)

Weighted vibration: Front: 7.07m/s2

Rear: 7.62m/s2

4

9

8

13

1

11

2

3

5

6

7

10

14

12

634009_Instructions.indd 2 16/11/2010 12:32