Silvey RAZUR SHARP II User manual

RAZUR SHARP II

THE ‘R2’ SQUARE CHISEL

CHAIN GRINDER

OWNERS MANUAL

MANUFACTURED BY:

4007 CRATER LAKE HIGHWAY

MEDFORD, OR 97504

Phone: 541-734-4118

Fax: 541-734-2324

E-mail: info@silveychaingrinder.com

www.silveychaingrinder.com

~ 2 ~

RAZUR SHARP II® -Table of Contents

Before You Begin................................................................. Page 3

Why to save R2 box, how to assemble the stand.

Basic Instructions............................................................... Page 4

Step by step, guide for sharpening your square chisel saw chain

with the Razur Sharp II®for the first time.

Read completely before using this grinder.

Sharpening For the First Time.............................................. Page 6

Maintenance and Tips..........................................................Page 7

This section covers replacing diamond dressers, maintenance, changing

and care of your grinding wheel.

Compensating for Wheel Wear…..........................................Page 8

This section covers fine-tuning and reshaping the grinding wheel

Reshaping the wheel...........................................................Page 9

Changing angles of the top plate.

Tips on grinding..................................................................Page 10

"Secrets" of master chisel chain grinding.

Other Tips on grinding........................................................Page 11

Razur Sharp II® - Exploded View..........................................Page 12

Razur Sharp II®- Parts List..................................................Page 13

Razur Sharp II®- Stand....................................................... Page 14

~ 3 ~

RAZUR SHARP II ® -

Before you Begin

The following instructions are condensed because you

probably already know how to sharpen square chisel bit saw

chain.

Your Razur Sharp II has been set,

tested, and adjusted before it left Silvey.

The R2 is also shipped with a

Silvey®SNO21-H wheel that has been dressed.

Inspect the grinder for damage before you use it.

Rough handling by shippers can result in bent or

broken parts.

Also, check the grinding wheel for cracks and chips. If the wheel is cracked, chipped or out of

balance, it may break apart when you turn the grinder on and could cause injury to you or the

grinder.

Please: Read all of the operating instructions thoroughly before you start to use your grinder.

You may contact us directly for additional help.

If you purchased and picked up your Razur Sharp II®grinder from a shop, your grinder is

probably assembled and mounted on the stand. If you ordered your Razur Sharp II®and had

it sent to you, this section will be helpful.

RAZUR SHARP II®-

Unpacking & Assembling the Grinder

Open the top of the box - DO NOT destroy it. You may need to use the

box and packing materials in the future. For example, if you need to

send it in for repairs or to be rebuilt.

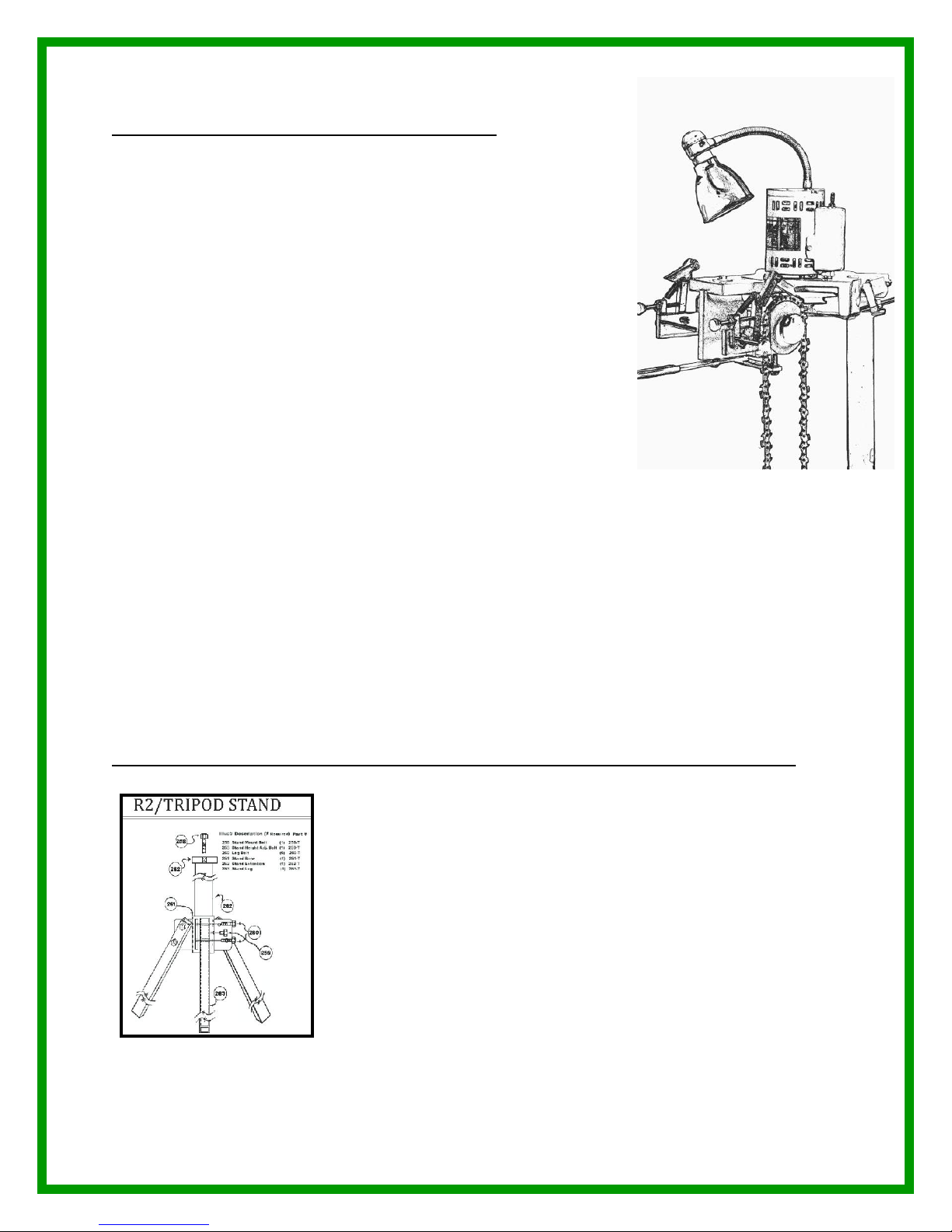

In the shipping box there was:

Razur Sharp II grinder

Instructions

1) Stand Base #261-T

3) Stand Legs #263-T

Bolt Bag: 1) Stand Mount Bolt # 258-T

1) Stand Height Adjustment Bolt # 259-T

6) Leg Bolts # 260-T

Larger view of stand on page 14.

The Stand Extension Pole was shipped in a separate box.

~ 4 ~

RAZUR SHARP II®

- Basic Operating Instructions

1) Check to be sure that nothing is touching the grinding wheel.

Retract the wheel dressers and move anything else that may come in

contact with the wheel. Locate the large handle lever on the bottom

front of the grinder. Move this handle until the chain bar assembly is

away from wheel.

2) Find the toggle switch on top of the motor. The motor is reversible and the switch has three

positions: back, middle and forward. One position makes the grinding wheel rotate clockwise,

the middle positition is off and the other positition makes the grinding wheel rotate counter -

clockwise.

Turn the grinder to one of the ON positions. Check the rotation of the wheel.

You want the grinding stone to be rotating counter-clockwise before you dress the wheel.

If you grind with wheel rotating clockwise the momentum of the wheel tends to pull the

dresser pivot into the motor mount.

If the wheel is going in the wrong direction turn the motor off . Allow the wheel to stop turning

before you turn it back on in the opposite direction. Do not try to change rotation while the

wheel is rotating even if the motor is turned off. Do not put any thing in contact with the wheel

to slow it down –Allow it to stop on it's own.

3) Find the switch on the lamp and turn it on. The lamp is

mounted on a flexible arm. Move the lamp to a position

where you can easily see the corner of the stone. This is

done by shinning the light on the top side of the stone so the

leading edge is slightly shadowed. The light bulb you use

is no more than 50 Watts MAX!

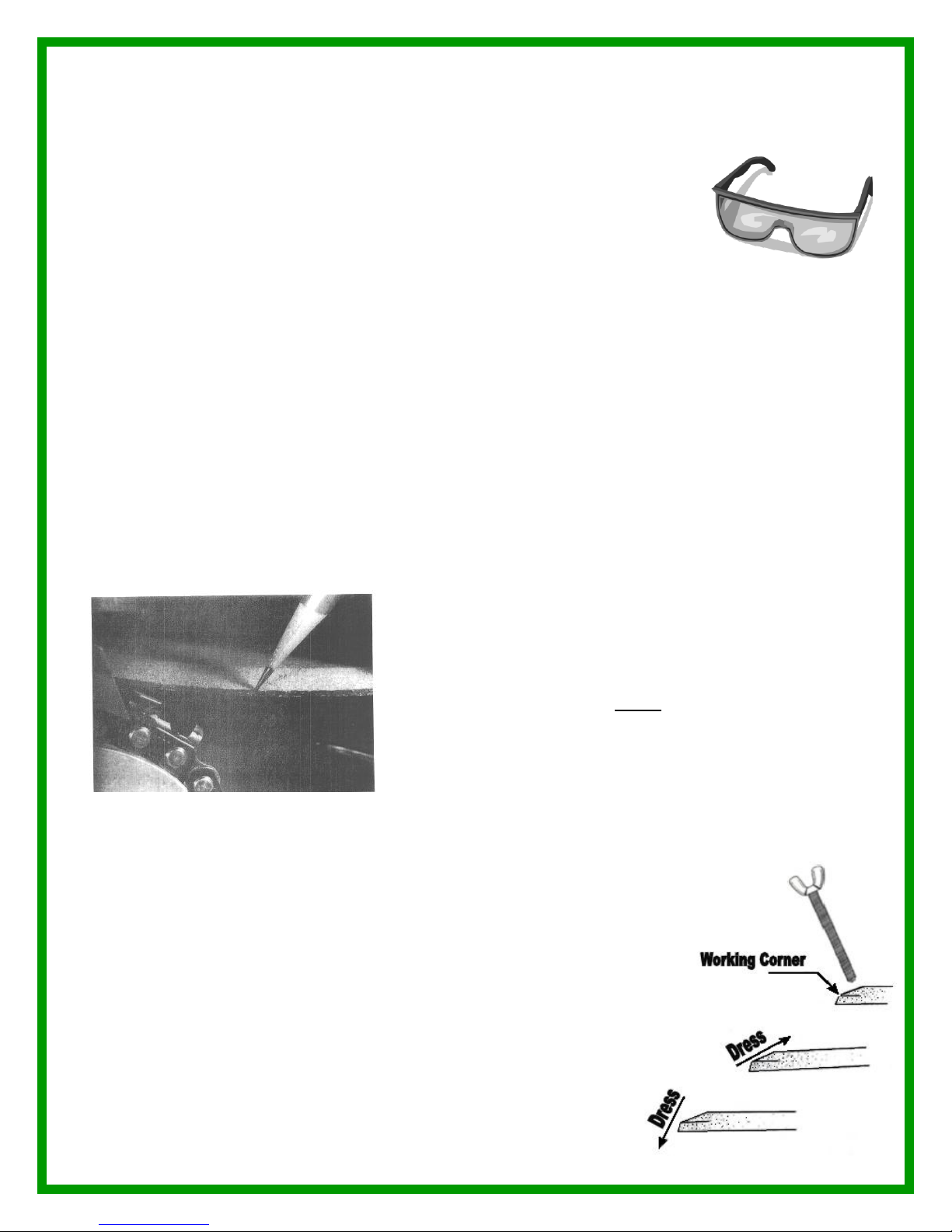

4) Find the diamond tipped wheel dressers.

They are located on the motor mount that covers the

grinding wheel.

These dressers pivot on their mounts and are used for shaping the grinding wheel;

adjust the diamond dressers so the dresser tips barely touch the grinding wheel when

pivoted in their mounts.

5) Turn the grinder ON so that the motor runs counter - clockwise.

Pivot the diamond dressers on their mounts and remove a small

amount of material, making easy and complete passes.

Tighten the diamond dressers in small increments to increase their depth.

Slowly shape the wheel like the drawings. Do not overload the diamond

dressers, forcing them to make hard cuts will shorten their life.

Dressing the stone restores the working corner. It also cuts away dull

abrasive material and exposes a fresh surface for grinding.

~ 5 ~

RAZUR SHARP II®

- Basic Operating Instructions

WARNING: Dressing out large amounts of wheel material in one pass

may cause the wheel to chip or break while it is spinning.

This could injure you and damage your grinder.

Always dress away from the working corner of the wheel.

This keeps the corner from crumbling. Once the wheel is shaped, it will require light dressings

between chain sharpening. If a chain is very dull, the stone may need to be dressed more

often.

6) With the motor off and the stone stops turning. Place the chain in the holder with the teeth

facing INTO the leading edge of the stone.

7) Advance the chain on the holder and place a cutter tooth in front of the chain stop. The

cutter should be facing the stone with its open side in. Locate the feed arm and slide the

appropriate cutter tooth close to the grinding wheel. Do not hit or force the chain into the

wheel as the grinding wheels are very brittle. A crack or chip may cause it to blow apart when

the grinder is turned ON again which can cause injury.

8) Find the two black thumbscrews. Use the thumbscrew that adjusts the stop on the cutter's

heel and the thumbscrew that stops the slide depth to align the corner in the grinding wheel

with the corner of the chisel cutter.

9) At the tip of the pencil shown below, the edge of the

stone aligns perfectly with the corner of the chisel cutter.

Proper positioning should look like this.

10) Move the feed arm so the cutter slides away from the

grinding wheel. Double check and make sure nothing is touching the wheel. Turn the motor

ON and watch the rotation of the grinding wheel, it should rotate so the wheel is turning into

the cutter tooth. If it is not turning into the tooth, turn the motor off letting the wheel stop

turning on it's own and turn the motor back on so the wheel is turning into the tooth. Not only

does grinding INTO the tooth keep the bur on the inside of the tooth, it directs the sparks into

the shroud area of the grinder.

~ 6 ~

RAZUR SHARP II®

- Sharpening for the First time

11) Grinding INTO the tooth will NOT splinter the chrome allowing the tooth to stay sharper

longer. The chrome is the hardest part of the tooth, if it is

splintered, it will not hold an edge very long. Which is the

reason why Silvey®chisel & round grinders have two (2)

direction motors.

12) Begin sharpening the first tooth, ALWAYS grinding into

the tooth. Grind a little at a time, to be sure you don't burn the

tooth.

Remember

Brown discoloration = Tooth too hot

Blue discoloration = Tooth way too HOT!

If the chain is really "Rocked", do not try to take it all off at one time. Go around the chain as

many times as needed to take off the discoloration, taking a little of each time. If the working

edge of the stone is dark and the teeth are heating up, the stone may need to be dressed to

expose sharper abrasive material.

13) Make final adjustments using the cutter stop and depth screw. Slide the chain away from

the stone and check to be sure the corners line up and all of the dull material is removed. All

of the material must be removed for the chain to be properly sharpened.

14) Once the first tooth is sharpened to your satisfaction, proceed to the next cutter tooth

that is on the same side of the chain. Continue to sharpen every other tooth in sequence until

all the cutting teeth on that side are sharpened.

15)Remove the chain from the chain holder and put it in the holder on the other side.

Start the steps over starting with Step 6. When one tooth is ground on that side has been

ground check to be sure that the sharpened cutter on this side is equal in length with the

sharpened cutters on the other side.

16) Although both teeth are sharp, if both teeth are NOT of equal length,

the chain will not cut straight. To perform at its best a chain needs to have

all of its teeth the same length. When you are satisfied with this tooth,

proceed to the next cutter on the same side. Continue until all teeth on that

side are sharpened.

17) All of the cutter teeth should be sharp now.

You may want to remove the gullet material and check

the rider depth gauges before installing this chain back

onto your saw. This is also a good time to look the

chain over for any cracks, breaks, bends or unusual

wear. The cutter pictured needs to have its gullet removed and it's riders checked.

~ 7 ~

RAZUR SHARP II®

- Maintenance & Tips

Your grinder should be stored inside out of the weather. Although it doesn't appear to be,

your grinder is a delicate tool and should be treated with care.

The grinder dust that is made when sharpening chain is composed of small particles of metal

and wheel abrasive. The grinder should be kept clean at all times and the motor and switch

should be kept free from this conductive dust.

Lubrication of moving parts should be done with graphite or another dry lubricant. Oil or wet

lubricants DO NOT work because they attract grinder grit (dust).

Diamond Dressers

Diamond dresser tips will wear and the diamonds will wear out.

The multi-point dressers will slough off diamonds as they get dull

about ¼" down. The single point dressers only have one diamond

and will need to be replaced when it gets dull.

When you see 'sparks' while dressing your wheel, the diamonds are

probably gone and the dresser needs to be replaced. Just unscrew

the old diamond dresser and thread in a new one.

Multi-point stone dressers allow the operator to make a smooth

stone surface and crisp working corner. Since the grinding wheelsurface determinesthe ultimate

shape and finish on the cutter tooth, it is extremely important that the wheel be smooth and well

shaped.

Replacing the Grinding Wheel

The Silvey®SNO21-H wheel has been specifically

formulated to the optimum specifications of grit, bond

and motor RPM for Silvey®grinders.

The grinding wheel can be reached by

removing the wheel cover which is held in place by

two screws. Be sure to replace the arbor nut, flange

washer and wheel cover before operating the

grinder again.

~ 8 ~

RAZUR SHARP II®

- Maintenance& Tips

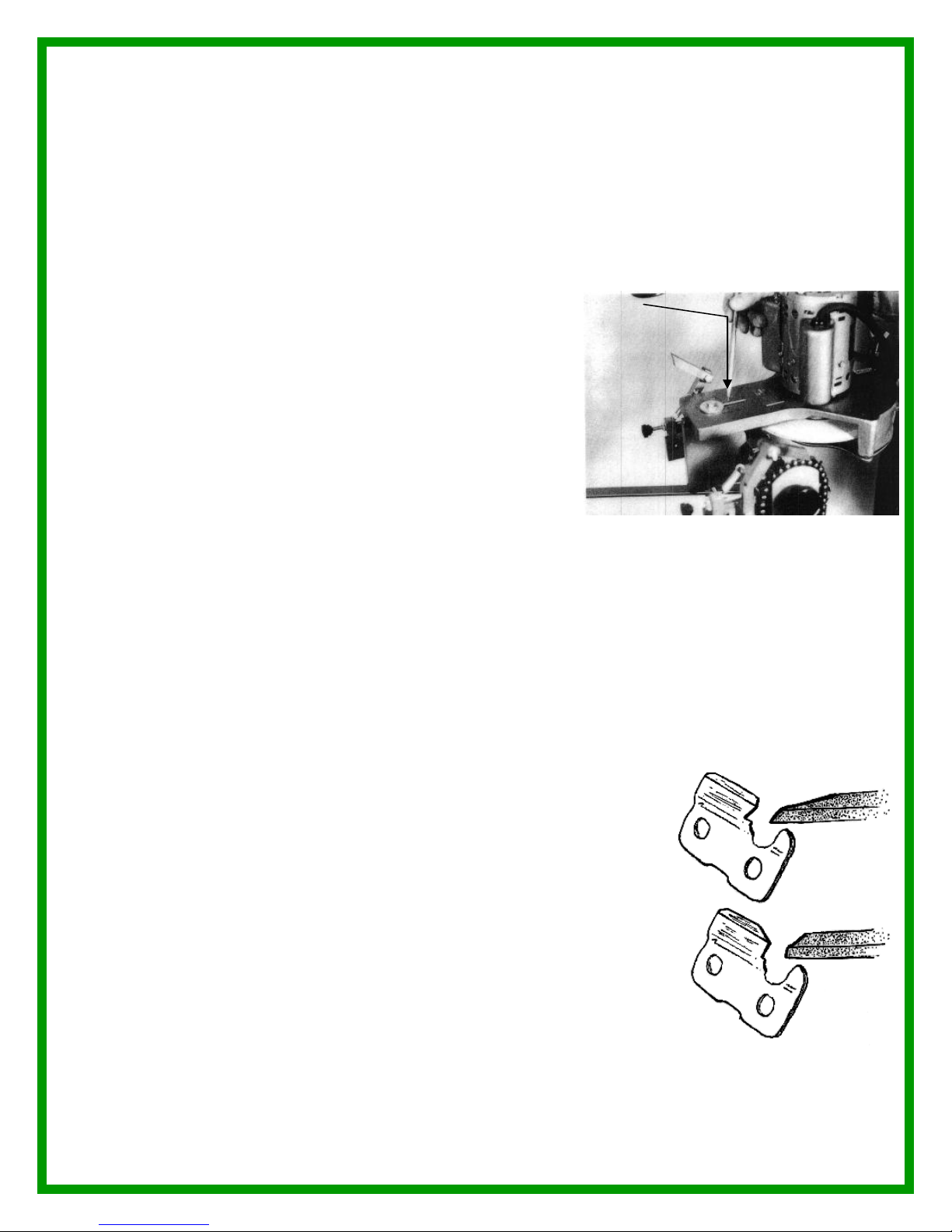

Compensating for Wheel Wear

Your grinding wheel will gradually become smaller in diameter as you dress the stone with

the diamond dresser and sharpen chain. This can be compensated for by sliding the chain

carriage assembly closer to the grinding wheel.

This adjustment slot is located on the grinder housing pictured.

Use the diameter scale on the topof the grinder to determine

the size of the stone. Use the scale and pointer under the

grinder to match chain holder mechanism with the wheel

diameter.

This adjustment allows the operator to keep the location

where the cutter tooth comes in contact with the arch of

the grinding wheel the same, even though the wheel

diameter wears smaller.

If you like your top angle blunt, lag behind the scale when compensating for wear.

If you like your top angle greater, lead the scale a little.

Fine Tuning

There is not one formula for sharpening chisel chain on which all Professional filers

would agree is best. Everyone who runs and grinds chisel chain has their own grinding style.

Some of the factors that determine the type of grind that will work for you are size and type of

wood being cut, the kind and size of saw that is being run and so on.

Outlined in the next section are some guidelines that will hopefully give you a place to start in

developing your own grinding style.

Reshaping the grinding wheel

1)The mounting blocks for the diamond dressers for the wheel may

be pivoted. This will change the grinding wheel shape by changing the

path of the diamond dressers.

2) The shape of the chain's cutter face is greatly affected by the

shape of the grinding wheel. The angle of the outer edge of the

wheel is a determining factor in the angle ground into the cutter's side

plate.

The angle of upper dressed surface of the wheel is a determining factor of the inner angle

ground into the cutter's top plate and also determines the outer top plate angle.

~ 9 ~

RAZUR SHARP II®

- Reshaping the grinding wheel

The diameter of the grinding wheel and the location on the arch of the wheel where the cutter

tooth comes in contact with the grinding surface are also determining factors on the angles

ground into the cutter tooth.

(See: Compensating for Wheel Wear. In the Maintanence section)

When changing the angles of the mounting blocks, move them only a small amount, redress

the grinding wheel and then test grind.

A little change has a big effect on the grind in the cutter tooth.

3) Make sure that the leading edge of the stone is thick enough to remove some of the gullet

area but don't make it so thick that it cuts deeply into the tie strap under the cutter, this

weakens the tie straps. Surface strength is important to the cutter chassis.

Chain breakage, that would otherwise not develop, often occurs on tie straps that have been

ground into.

Changing the Inner Angle of the Top Plate

1) The inner angle of the top plate is changed by lowering or raising the grinding stone

holder. To raise or lower the grinding stone you must first remove the lower shroud guard

and the nut and support washer that hold the stone onto the holder.

There is an allen head set screw located in the thread area of this holder.

You probably noticed it when you changed

grinding wheels.

This set screw can be loosened and the holder

will slide on the motor shaft.

Adjustments to the stone should be made a little

at a time, as small changes make big differences

in the grind on the cutter tooth. Be sure to tighten

all screw and replace the guard before operating

the grinder again.

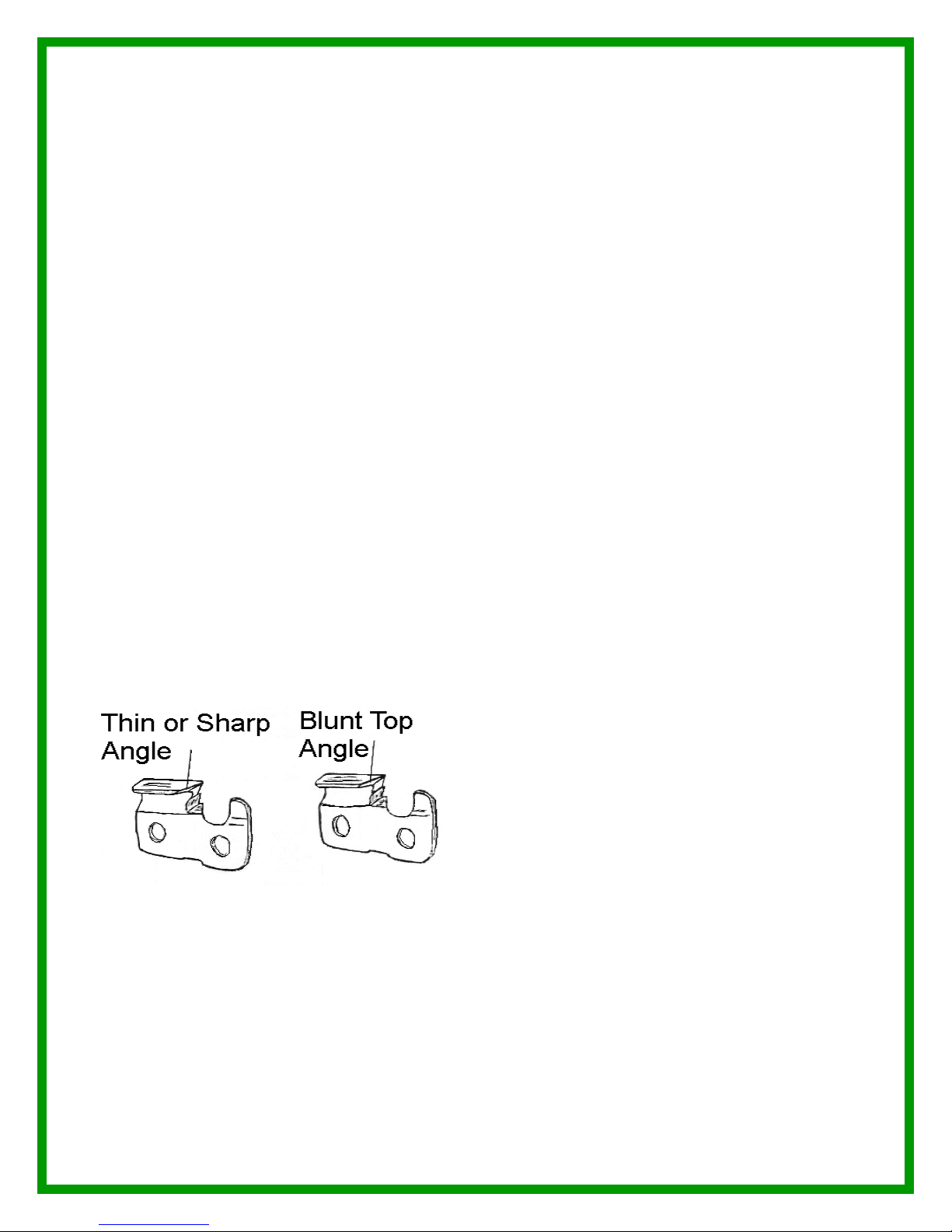

2) Generally, a thicker inner top plate angle will keep its edge a little longer. A thinner angle

will cut better but will get dull faster.

This grinder will grind thicker top plate as the cutter plate tooth becomes shorter. You may

want to adjust for this if you have a series of chains with short cutters to grind.

If you prefer thicker inner angles on new chains, lowering the grinding wheel will cause the

grinder to cut thicker top plates.

~ 10 ~

RAZUR SHARP II®-

Tips on Grinding

TIP: Do not overheat the tooth when grinding.

You do not need a thermometer tomonitor heat, simplywatch the surface of the cutter tooth. If the

tooth starts to discolor, you are getting it too hot. If you heat a toothto the point that it turns blue,

you have ruined it. The blue color indicates the temper of the steel in the cutter tooth has

changed.

Blue teeth occurwhen you aretrying to grind too fast orwhen you are sharpening a "rocked"

or extremely dull chain.When you grind out extensive tooth damage, you will be inclined to

remove it faster than you should.

Trysetting the grinder to remove onlyhalf of the damage oneach tooth.When you have

ground all the cuttersand are back to where you started, reset the feed stop and grind out the

rest of the damage on a second pass. By limiting the amount of material, you remove each

pass you may reduce heating potential. Anotheradvantageof "double"grindingisthatthe teeth

getachancetocool between the first and second grind.

Another cause of overheating is a dull grinding wheel.When the working comer of the stone

and the areaaround itbegins to darken, it is getting dull. A dull stone does not grind welland

an inexperienced operatormaybe inclined to increase grinding pressure. To sharpen the

wheel, run the dressers over it until the dark spots are gone. This will clean the wheel and

expose fresh abrasive material.

TIP: Align the corner of the tooth with the working corner of

the stone.

The key to successful chisel chain grinding can be summed up with

this tip.

To obtain maximum "stay sharp" ability and cutting speed, these

two corners should be aligned perfectly. If you grind "high" or above

the corner, the chain will perform badly. It may look sharp to you but

it will act as if it is dull. If you grind too "low" below the corner, the

chain will cut but won't stay sharp very long.

If you look at a low chain closely, it will have a "bird's beak" edge on

the corner of the tooth. This edge has little support and will become

dull easily. In fact, even hitting a knot will dull a "low" ground chain.

The best rule to remember is:

Align the corners perfectly but if you need to allow for a little error:

Be a little low.

~ 11 ~

OTHER GRINDING TIPS - Dos & Don'ts

Do not grind with the corner or the stone high into the tooth; this makes a chain perform very

poorly.

Do not leave a long and/or tall gullet.

•Do not grind into the side straps.

•Do not try to adjust your grinder to corner both on the top side of the cutter and

on the inside or the tooth.

This ‘corner to corner" grind is almost impossible to get with an assembled chain.

Most of the time you want a thinner top plate than a “corner to corner” grind would

get you anyway.

•Do not make big adjustments to the stone dressing blocks or the stone holder at one

time.

•Do not change more than one thing at a time when you are trying to change how your

grinder is set up; these are sensitive adjustments.

•Do always wear eye protection.

•Do grind a little at a time: even if it means going around the chain twice or more.

•Do check your chains for damage or breaks when you have them off for sharpening.

•Do make the cutter teeth equal in length on both sides.

•Do grind away all of the dull cutter tooth so the corner chrome has a clean sharp edge.

•Do keep your grinder clean and well maintained.

•Do mark where your dressing blocks are before you move them so you can “find your

way back” if the changes you made were wrong.

•Do always try to make a better chain: There is not one best way or formula for grinding

chisel chain.

•Do call, write, email or stop in if you have a question or problem with your grinder.

~ 12 ~

~ 13 ~

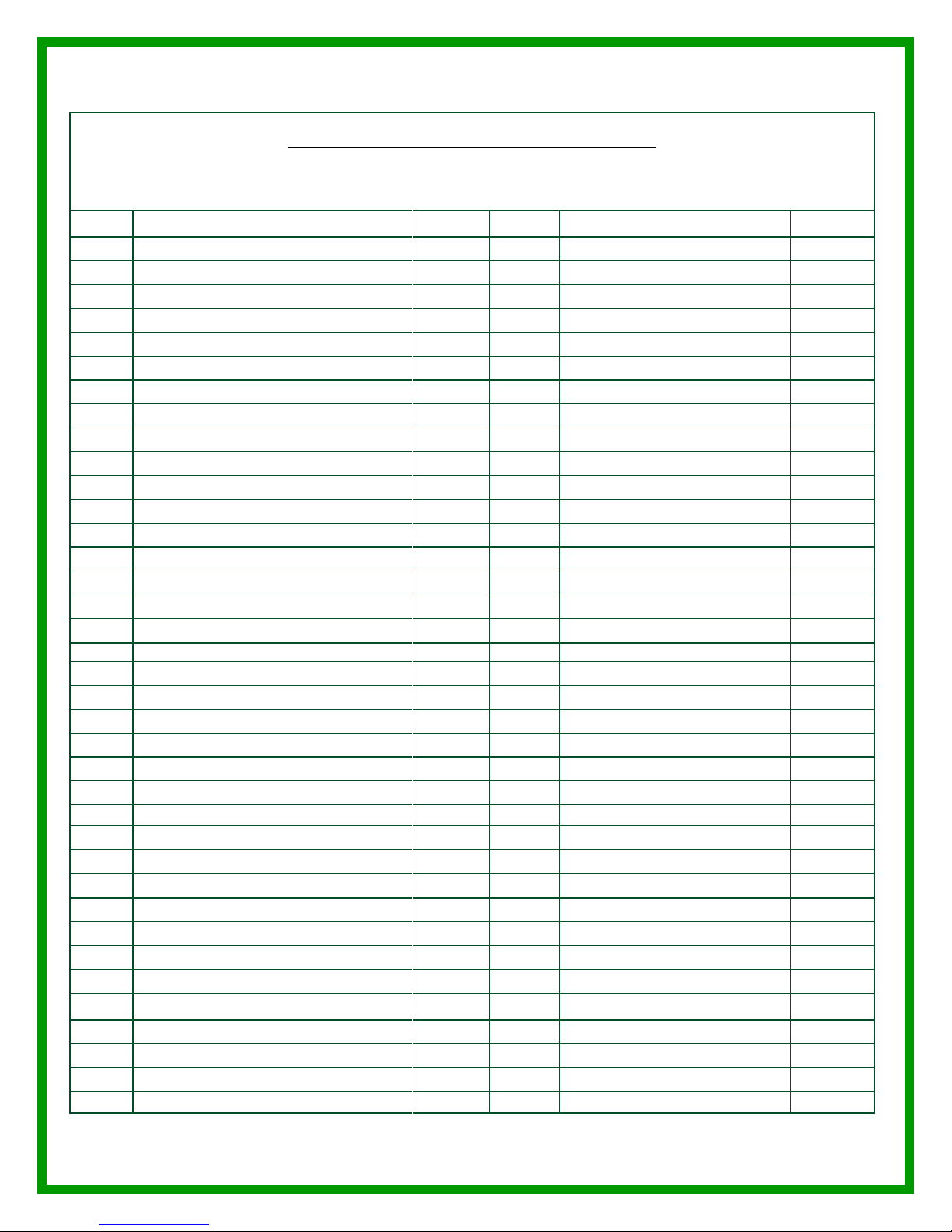

Razur Sharp II Parts List

ILLUS# DESCRIPTION PART# ILLUS# DESCRIPTION PART #

SN

Serial Number Location

11

152

Cross Slide Mount

152-R

1

Motor

1-R

153

Cross Slide Extrusion

153-R

3

Motor Cord

3-R

154

Cross Slide Bar

154-R

4

Arbor

4-R

155

Chain Bar Mount

155-R

5

Arbor Flange

5-R

156

Chain Bar Mount Screw

156-R

6

Motor Mount Screw

6-R

157

Stop Mount Bracket

157-R

6B

Motor Lock Washers

6B-R

158

Handle

158-R

7

Switch

7-R

159

Handle Link

159-R

8

Arbor Nut

8-R

160

Handle Mount Spacer - Lg.

160-R

9C

Gib (Side)

9C-R

161

Handle Bushing.

161-R

9D

Gib (Small)

9D-R

R - 2 Handle Assembly

181-R

15

Lamp Assembly

15-R

Oil Plug

182-R

16

Boot

16-R

162

Dresser Block

162-R

17

Spring (Small)

17-R

163

Dresser Arm

163-R

18C

Wheel Cover

18C-R

164

Dresser Arm Bolt

164-R

19C

Motor Mount & Wheel Guard

19C-R

165

Lock Nut

165-R

24B

Stop Pawl

24B-R

166

Dresser Block Bolt.

166-R

27

Chain Bar Screw

27-R

167

Fiber Washer

167-R

39

Chain Bar Stop Screw & Knob

39-R

168

Plastic Lock Washer

168-R

39B

Tooth Length Adj. Screw & Knob

39B-R

169

Cross Slide Mounting Bolt

169-R

Cord Lock

46B

170

Washer

170-R

53C

Tooth Length Adj. Screw Mount

53C-R

171

Fender Washer

171-R

57

Handle Mount Bushing

57-R

172

Cross Slide Assy Mount Bolt

172-R

63

Diamond Dresser

63-R

173

Handle Bolt

173-R

89

Handle Connector Bolt

89-R

174

Stop Mount Bracket Bolt

174-R

91

Tie Down

91-R

175

Handle Mount Bolt

175-R

92

Foam Tape

92-R

176

Aluminum Spacer

176-R

101

Nut

101-R

258

Stand Mount Bolt

258-RT

103A

Gib Adjustment Screw & Nut (Front)

103A-R

259

Stand Height Adj. Bolt

259-RT

103B

Gib Adj ustment Screw & Nut (Bottom)

103B-R

260

Leg Bolt

260-RT

108

Nut

108-R

261

Stand Base

261-RT

111

Arbor Set Screw

111-R

262

Stand Extension

262-RT

112

Wheel Cover Screw

112-R

263

Stand Leg (Price Each Leg)

263-RT

114

Grinding Wheel **( SNO21-H )

114C-R

Tripod Stand Complete

300-RT

Motor Bearings (Front End - Shaft)

146-A

Cross Slide Assembly

177-R

Motor Bearings (Back End)

146-B

R - 2 Handle Assembly

181-R

151A

Chain Bar

151A-R

Oil Plug

182-R

151B

Chain Bar 50 / 63

151B-R

~14~

Table of contents

Other Silvey Grinder manuals