Simarghu SIMFIRE ARB-1 User manual

www.simarghu.com

Arborist Harness

Baumzüchter-Klettergurt

Harnais d’arboriste

Arnés del arborista

Imbracatura per arborista

Arborist uitrusting

UK

DE

FR

ES

IT

NL

MADE IN THE UK

2

CONTENTS 1. GENERAL INFORMATION

DESCRIPTION

This harness has been designed and manufactured specially for

arborists. It MUST NOT be used under any circumstances to

arrest a fall.

This product is manufactured and tested to conform with:

EN 813:1997 EN 358:2000

SIMARGHU®

PO BOX 412

Carlisle

CA1 9GR

T: +44 (0)1228 371 583

www.simarghu.com

PATENT PENDING

1General Information 2-3

2Use 4

2.1 Sizes 4

2.2 Part Identication – Male (FIRE) & Female (GEMINI) 4-6

2.3 How to put on Harness 7

2.4.1 Adjustment - Waste Belt 8

2.4.2 Adjustment - Leg Strap 8

2.4.3 Adjustment - Rear Straps 8

2.4.4 Adjustment - Sub Harness (Gemini Only) 9

3Floating Rope Bridge 9

3.1 Leg Riser Adjustment 9

4Lower Multi Rings 10

5Attachment Points – Male (FIRE) & Female (GEMINI) 11

5.1 Rope Bridge Set Up 12

6Suspension Trauma 12

7Harness Labelling 13

8Harness Inspection 13

9Maintenance & Storage 14

10 Service Life 14

11 Examination Form 15

12 Certicate of Conformity 16

3

UK

WARNING

Incorrect use of this harness could be fatal, so prior to

use YOU MUST:

• Read and thoroughly understand this operating manual before

using this harness.

• Be a person in t medical condition that can work at height and

do so in both normal and emergency situations. If there are any

points in this operating manual that you are unsure of, seek

advice from a trained individual.

• Be fully trained and competent in the use of the harness and

familiar with the correct actions in case of an emergency prior

to working at height.

• Carry out appropriate visual and functionality checks before

wearing this harness.

• Assess the work area to ensure adequate supporting structural

attachments are to be used.

• Understand and accept the risk involved in use of this product.

WARNING

If you are in any doubt about the condition or function

of this harness you must remove it from service

immediately and contact the seller or manufacturer.

A rescue plan should always be put in place ahead of working at

height to ensure procedures can be put into action in the event of

an accident or problem.

This product must only be serviced by a trained and competent

individual. Under no circumstances should the integrity of this

harness be undermined by making modications, repairs or

alterations.

FAILURE TO COMPLY WITH ANY OF THESE

FACTORS MAY RESULT IN SERIOUS INJURY

OR DEATH.

4

UK

WARNING

Although each harness is similar, there are important

dierences.Please ensure that you select the correct size and

fit for your build.

2. USE

2.1 SIZES 2.2 PART IDENTIFICATION

MODEL SIZE

GUIDE WAIST THIGH

SIMFIRE ARB-1 Small/

Medium

Min 27” (68cm)

/ Max 34” (86cm)

Min 17” (43cm)

/ Max 27” (68cm)

SIMFIRE ARB-2 Medium/

Large

Min 34” (86cm)

/ Max 42” (106cm)

Min 17” (43cm)

/ Max 27” (68cm)

SIMGEM ARB-3 Small/

Medium

Min 26” (66cm)

/ Max 34” (86cm)

Min 17” (43cm)

/ Max 27” (68cm)

FEATURES

1Back Pad

2Leg Loops

3Leg Strap Adjustment Buckles

4Leg Pads

5Waist Belt Adjustment Buckle

6Rope Bridge

7Rings - Side ‘D’ Rings, 7a Front ‘D’ Rings, 7b Bridge Ring

8Lower Multi Rings

9Rear Straps Adjustments Buckles

10 Shoulder Strap Attachment

11 Accessory Loops

12 Accessory Rings

13 Chainsaw Attachment Points

14 Floating Bridge Adjustment Buckles

15 Floating Bridge Strap

16 Leg Riser Adjustment Buckles

17 Label (below stretch panel)

18 Sub Harness (female GEMINI only)

19 Tool Hooks Points

5

UK

1

4

2

3

7b

16

15

8

6

7

11

7a

5 101719 19

13

15

7

9

11

14

7

12

MALE (FIRE) HARNESS - FRONT VIEW MALE (FIRE) HARNESS - BACK VIEW

6

UK

1

4

2

3

18

16

7b

15

8

6

7a

5 10

15

9

11

14

12

13

FEMALE (GEMINI) HARNESS - FRONT VIEW FEMALE (GEMINI) HARNESS - BACK VIEW

171919 19 19

7

UK

2.3 HOW TO PUT ON THE HARNESS

1. Open waist belt buckle.

2. Open leg strap buckles.

3. Hold the harness using the back

pad on each side and step in.

4. Ensure it is in the correct position,

just above the hip bones.

5. Close the waist belt buckle and

adjust to a comfortable t.

6. Close leg strap buckle and adjust.

Ensure that they are not twisted,

and the leg pads are at the back of

the thighs.

8

UK

2.4.1 ADJUSTMENT - WAIST BELT 2.4.2 ADJUSTMENT - LEG STRAP

Adjust leg strap pads by simply moving the webbing

through leg adjustment buckle, if any further

adjustments are needed release webbing from the

keeper and slide through to your required length. Any

excess webbing needs to be tucked neatly back into

the keeper.

PLEASE NOTE: The leg straps are intended to be a

relaxed fit at the thigh, as shown, however if preferred a

tighter fit can be used.

2.4.3 ADJUSTMENT - REAR STRAPS

The rear straps set the position

between the leg loop and the waist

belt. This ensures that the harness

is not slack and supports the thighs

without causing discomfort.

Adjust these straps by feeding the

webbing through the buckle to a

position which provides the best

balanced and comfort.

The waist belt should be adjusted

so that your body feels supported

and comfortable.

This adjustment is only required

once.

PLEASE NOTE: Any excess

webbing needs to be tucked neatly

back into the keeper.

9

UK

2.4.4 FEMALE (GEMINI) HARNESS ONLY

3. FLOATING BRIDGE

3.1 LEG RISER ADJUSTMENT

With a combination of adjustments

to the leg riser (16) and the oating

bridge strap (15) an optimum

position for the lower multi rings

(8), can be customised for each

user. This unique customisation

can be further enhanced by

selecting a suitable corresponding

position for the bridge rope.

The lower multi rings can be tted

with more than one rope bridge,

part number SBR125.

The female harness (GEMINI) comes with the

same benets and features but with the addition

of a sub harness.

The sub harness has been specially

designed for female anatomical support to

reduce potential injury in the event of a fall.

These straps should be pulled down and

adjusted to a ‘snug t’.

WARNING

The female harness (GEMINI) should

NOT be used by a male.The harness

has been designed to fit the female

form only.

WARNING

No more than three rope

bridges should be used

at any one time.

10

UK

4. LOWER MULTI RINGS

The two unique lower multi rings

give the exibility of three alternative

placement points allowing for a

maximum of three separate bridges.

The wearer can set the most suitable

angle by choosing either one of the

placement points. This exibility

ensures optimum balance and superior

comfort.

11

UK

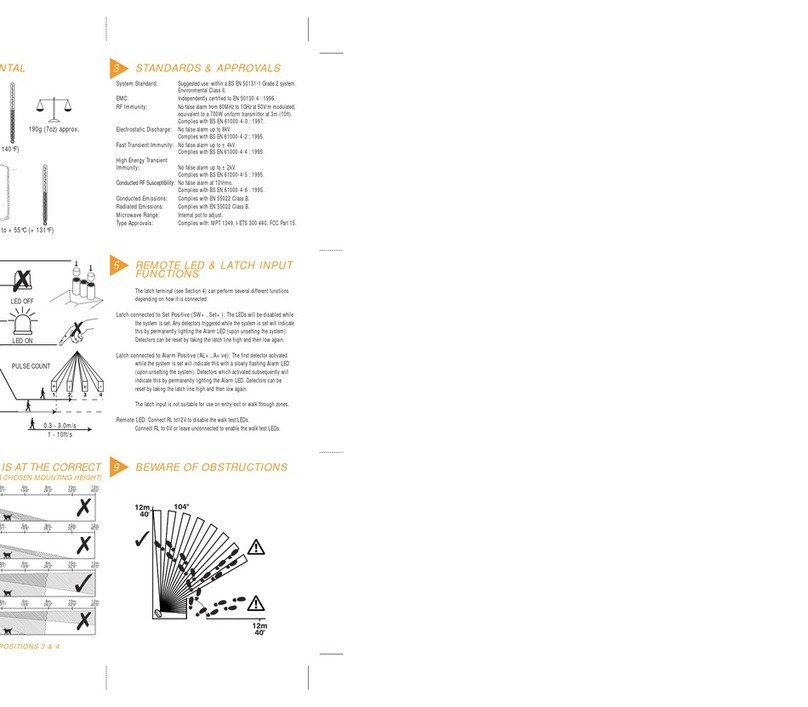

5. ATTACHMENT POINTS

DESCRIPTION

1Side ‘D’ Rings

2Front ‘D’ Rings

3Rope Bridge Hole

4Lower Multi Rings

5Accessory Loops

6Accessory Rings

7Tool Hooks

8Chainsaw Attachment Points

9Main Attachment Point

9

1

2 2

5

3 3

4 4

PLEASE NOTE: The medium/large harness

(male SIMFIRE ARB-2) comes with 2 side and

2 front ‘D’ rings along with 4 accessory loops.

Both the smaller FIRE harness (male SIMFIRE

ARB-1) and the GEMINI Harness (female

SIMGEM ARB-3) come with 2 front ‘D’ rings

and 2 accessory loops.

MALE (FIRE) HARNESS FEMALE (GEMINI) HARNESS

FRONT

BACK

6

5

8

7 7 77 77

5

6

8

5

12

UK

5.1 ROPE BRIDGE SET UP

To secure the rope bridge a stopper knot is required. This ensures

that the rope does not pass through the connecting lower multi

ring. For extra security ensure that there is at least a 75mm (3”) tail

when tying o the knot.

a. Pass the rope through the main

centre hole (main connection point)

from outside to inside, and tie o.

c. Pass the other end of the rope through

the centre hole of the second multi ring

from inside to outside and tie o.

b. Feed ring through rope.

Lower multi ring holes (2) can only be used for bridge rope

attachment and must not be used as an attachment point for

anything else. Large hole (3) can be used as an attachment point.

PLEASE NOTE: In some situations you may

need to shorten the rope bridge.To do this tie

a secondary stopper knot.

Hanging in the harness for long periods of time without movement

will cause the ow of blood to be restricted. This will eventually

lead to orthostatic intolerance or HSS (Harness Hang Syndrome).

In such an event the FOLLOW YOUR RESCUE PLAN AND

CALL THE EMERGENCY SERVICES.

6. SUSPENSION TRAUMA

2

3

2 2

WARNING

Typical symptoms of HSS include sweating, shortness of

breath, blurred vision, dizziness, nausea, hypertension and

numbness of the legs etc. These symptoms will vary from

person to person.

13

UK

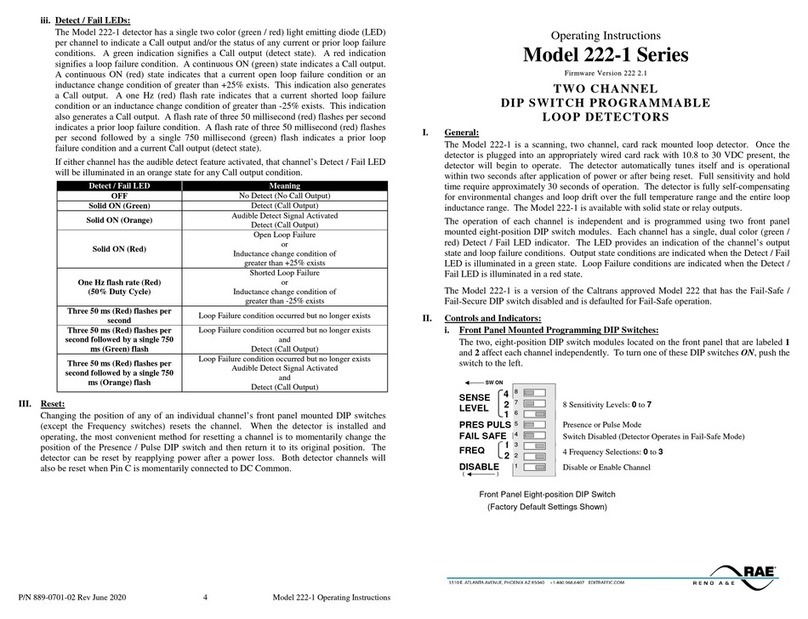

WEBBING Examine for cuts, cracks, tears, abrasions* and scorch

marks, burns or chemical attack.

STITCHING Look for broken stitches, lose or worn threads.

METALWARE Inspect for any signs of damage, distortion, or corrosion

as well as ensuring correct operation.

LABELLING Ensure all label information is still legible.

7. HARNESS LABELLING 8. HARNESS INSPECTION

REGULAR CHECKING AND RECORD KEEPING

This harness and all other equipment must be visually inspected

by a competent individual when delivered to site, and thoroughly

inspected before and after every use. If you are unsure or have

any doubt about the condition of the harness you MUST

remove it from service.

A record card is included with this manual and should be lled

in after each routine inspection. Registration and record keeping

can also be completed online by visiting www.simarghu.com/

register and entering the product’s unique serial number.

*Common abrasion wear within webbing may be caused by passage over

sharp edges when under tension which may result in serious weakening. Slight

damage to the outer bres and threads could be considered harmless; however

serious damage such as reduction of the thickness or width of webbing should

lead to rejection and immediately removed from service.

1CE Mark

2EN Standards

3Manufacture

4Max Load

5Product Reference

6Serial Number

7Date of Manufacture

8Read Manual

9QR Code

10 Size Guide THOROUGH INSPECTION IS TO BE GIVEN TO EACH OF

THE FOLLOWING KEY AREAS:

POSITIONING ONLY! - NOT FOR FALL ARREST

EN358: 2000

EN813: 1997

MAX LOAD: 120KG

MODEL: SIMFIRE ARB-1

SN: ARB1-000000

DOM: 0317

2

8

9

1

4

5

6

7

10

S/M

3

14

UK

9. MAINTENANCE & STORAGE

All maintenance work MUST be carried out by a competent fully

trained person. However users should clean the harness when

required.

CLEANING SHOULD BE DONE WHEN:

• The harness has been used in salty environment.

• If the harness has a coating of oil, soil, mud or any contaminant.

WHEN CLEANING:

Place the harness on a at surface. Using a damp sponge wipe

down harness to remove excess dirt, dust or sand. DO NOT

use cleaners that contain chlorine, bleach or abrasives. DO NOT

immerse the harness in water.

If the harness is defective in any way please complete the

Examination Form stating all defects and remove from service

immediately, and contact:

SIMARGHU®

PO BOX 412

Carlisle

CA1 9GR

T: +44 (0)1228 371 583

E: info@simarghu.com

www.simarghu.com

10. SERVICE LIFE

This product has a life of 10 years from date of manufacture and 5

years from date of rst use.

Extreme factors may considerably reduce the serviceable life of

a harness. For example, if the harness has been damaged due

to mechanical wear, harsh treatment, prolonged exposure to UV

Rays or other environmental factors such as contact with salt or

sand, exposure to high heat or cold and icy conditions.

If the harness is bleached of colour, abraded, worn or cracked

bres then it MUST be removed from service.

WARNING

If the user is in any doubt about the condition of the product

however insignificant, they must either render it unusable

and remove from service immediately or place in quarantine

so that it may not be used by mistake. The harness can

only be returned to service by written authorisation by

manufacturer or a trained individual.

15

UK

11. EXAMINATION FORM Harness Serial Number :

DESCRIPTION

STRAPS - Check ALL webbing for any damage. This may include cuts, burns, cracks and tears

due to heat or chemical contact. Examine waist belt strap, leg loop/straps and shoulder straps if

present. NOTE: remember to check webbing hidden by buckles.

ADJUSTMENT BUCKLES - Examine the condition of the buckles for any marks, cracks, ware and

tear, deformation or corrosion. Check that the buckles are fully functional and are threaded

correctly with no twists.

ATTACHMENT POINTS - Examine the condition of the metal attachments for any marks, cracks,

wear and tear, deformation or corrosion. Check the textile attachments for any cuts, abrasions or

tears. NOTE: Ensure that ALL attachments are present.

SEWING - Check ENTIRE HARNESS for any broken, cut loose or worn thread on structural

bartacks.

LABELLING - Check that label is present and legible. Check date to ensure product is within its life

span.

COMFORT PARTS - Examine backpad, leg pads, keepers, accessory loops for any cuts, burns,

wear and tear, cracks.

CONDITION

PASS FAIL List all salient points about each

part stating all issues present

DEFECTS

Tested by :

UNFIT FOR USEFIT FOR USEVERDICT

Signature : Date of Examination : Next Examination Due :

Date of Manufacture : Date Issued :

Registration and Record Keeping can also be completed online by visiting www.simarghu.com/register and entering the product’s

unique serial number. Registering in this way will ensure that the harness is kept in optimum condition throughout its working life.

16

UK

VISUAL INSPECTION –– 100% Each and every

product covered by this certicate has been visually

inspected during manufacture and on packing. The

following points were addressed and checked against

the approved build standard:

Correct webbing used (Black/Red – Female

and Black/Grey – Male)

All webbing checked for damage/wear or

cuts

All structural stitching checked

completeness loose threads

Adjustment buckles function correctly and

checked for any damage

All attachment points present and

examined for damage

All engraving examined on hardware

ensuring quality and correctness

Labelling inspected for both clarity,

correctness and position

Goods inspected to both working sample

and approved specication

All comfort parts examined (back pad, leg

pads) keepers and accessory loops

Stowage bag checked

12. CERTIFICATE OF CONFORMITY

ARBORIST HARNESS HARDWARE STATIC TESTING –– 1 o part per

batch was tested to ensure the product functioned as

per specication. The part was attached to a test rig,

and then load was applied and recorded by a digital

load cell:

Multi ring held for 3 min with a load of 15kN

34mm/40mm ring held for 3 min with a load

of 30kN

Parts were checked for damage, all observations and

results were recorded.

DECLARATION –– All test equipment is maintained

in a calibrated condition and inspected periodically

to assure conformance with national standards. All

inspection and test was performed by trained and

competent personnel and the product was found to

conform to European Standard BS EN 358: 2002 and

EN 813:1997.

SIMARGHU®, PO BOX 412, Carlisle, CA1 9GR

www.simarghu.com

MANUFACTURE –– This product has been

manufactured to the regimented and documented

procedures within a quality environment that ensures

that all material is traceable back to specication and

source. Specication and inspection is documented

under...

MODEL NO.:

DESCRIPTION:

DATE OF MANUFACTURE:

SERIAL NO.:

QUANTITY:

SIGNED:

INSPECTOR:

DATE:

REF:

BATCH NUMBER(S):

PATENT PENDING

Baumzüchter-Klettergurt

DE

18

DE

INHALTSVERZEICHNIS 1. ALLGEMEINE INFORMATIONEN

BESCHREIBUNG

Dieser Klettergurt wurde speziell für Baumpeger entworfen und

hergestellt. Er sollte AUF KEINEN FALL verwendet werden, um

einen Sturz aufzuhalten.

Dieses Produkt ist hergestellt und getestet nach den Normen:

EN 813:1997 EN 358:2000

SIMARGHU®

PO BOX 412

Carlisle

CA1 9GR

T: +44 (0)1228 371 583

www.simarghu.com

PATENT ANGEMELDET

1Allgemeine Informationen 18-19

2Verwendung 20

2.1 Grössen 20

2.2 Zuordnung der Einzelteile – Männlich (FIRE) & Weiblich (GEMINI) 20-22

2.3 Anziehen des Klettergurt 23

2.4.1 Anpassung - Rüchenpolster 24

2.4.2 Anpassung - Beingurt 24

2.4.3 Anpassung - Hinterriemen 24

2.4.4 Anpassung - Untergurt (Nur Gemini) 25

3Schwimmende Seilbrücke 25

3.1 Anpassung des Beinaufstellers 25

4Untere Multiringe 26

5Befestigungspunkte – für Männer (FIRE) & für Frauen (GEMINI) 27

5.1 Einrichtung der Seilbrücke 28

6Durch Hängetrauma 28

7Kennzeichnung des Klettergurt 29

8Überprüfung des Klettergurt 29

9Pege & Lagerung 30

10 Lebensdauer 30

11 Prüfungsformular 31

12 Konformitätszertikat 32

19

DE

ACHTUNG

Falsche Verwendung des Klettergurt kann fatale Folgen

haben, deshalb MÜSSEN Sie im Vorfeld der Nutzung:

• Diese Bedienungsanleitung vor der Verwendung des

Klettergurts lesen und komplett verstehen.

• Eine im medizinischen Sinne tte Person sein, die in der

Höhe arbeiten kann und das sowohl in normalen wie in

Notfallsituationen. Wenn es irgendwelche Punkte in der

Bedienungsanleitung gibt, derer Sie sich nicht ganz sicher sind,

suchen Sie bitte den Rat einer qualizierten Person.

• Seien Sie voll ausgebildet und kompetent bei der Verwendung

des Klettergurt und machen Sie sich vertraut mit den richtigen

Handlungsweisen im Fall eines Notfalls bevor Sie in der Höhe

arbeiten.

• Führen Sie sorgfältige visuelle und Funktionalitätschecks vor

dem Tragen des Klettergurt.

• Schätzen Sie den Arbeitsbereich ein, um sich zu vergewissern,

dass es adäquate unterstützende Anschlagpunkte gibt, die

benutzt werden können.

• Verstehen und akzeptieren Sie das Risiko, das mit der

Benutzung dieses Produkts verbunden ist.

ACHTUNG

Wenn Sie nur den geringsten Zweifel in Bezug auf den

Zustand oder die Funktionsfähigkeit des Klettergurts

haben, müssen sie ihn sofort aus der Verwendung

entnehmen und den Verkäufer oder Hersteller

kontaktieren.

Ein Fluchtplan sollte immer dort angebracht sein, wo in der Höhe

gearbeitet wird, um sicherzustellen, dass Prozesse im Fall eines

Unfalls oder eines Problems in die Wege geleitet werden können.

Dieses Produkt sollte nur von geschulten und kompetenten

Personen bedient werden. Unter keinen Umständen sollte die

Integrität des Klettergurts durch Modikationen, Reparaturen oder

Anpassungen untergraben werden.

NICHTBEACHTUNG JEGLICHER DIESER FAKTOREN

KANN IN SCHWERWIEGENDEN VERLETZUNGEN

ODER SOGAR TOD RESULTIEREN.

20

DE

ACHTUNG

Obwohl jeder Klettergurt gleich ist, gibt es wichtige

Unterschiede.Vergewissern Sie sich bitte, dass Sie die richtige

Größe und Passform für Ihre Statur auswählen.

2. VERWENDUNG

2.1 GRÖSSEN 2.2 ZUORDNUNG DER EINZELTEILE

FUNKTIONEN

1Rückenpolster

2Beinschlaufen

3Einstellschließen für Beinschlaufen

4Beinauagen

5Einstellschließen für den Beckengurt

6Seilbrücke

7Ringe – Seiten-D-Ringe, 7a Vorder-D-Ringe, 7b Brückenringe

8Untere Mehrfachringe

9Einstellschließen für Hinterriemen

10 Schultergurtaufsatz

11 Zubehörschleifen

12 Zubehörringe

13 Kettensägenbefestigungspunkte

14 Schwimmende Brückenverstellungsschnallen

15 Schwimmende Brückenbügel

16 Beinaufsteigerschnallen

17 Etikett (unter dem Stretch-Panel)

18 Untergeschirr (nur weibliche GEMINI-Modelle)

19 19 Werkzeughakenpunkte

MODEL GRÖSSE

FÜHRUNG TAILLE SCHENKEL

SIMFIRE ARB-1 Small/

Medium

Min 27” (68cm)

/ Max 34” (86cm)

Min 17” (43cm)

/ Max 27” (68cm)

SIMFIRE ARB-2 Medium/

Large

Min 34” (86cm)

/ Max 42” (106cm)

Min 17” (43cm)

/ Max 27” (68cm)

SIMGEM ARB-3 Small/

Medium

Min 26” (66cm)

/ Max 34” (86cm)

Min 17” (43cm)

/ Max 27” (68cm)

This manual suits for next models

2

Table of contents

Languages: