Simco scorpION3 User manual

INSTRUCTIONS

Operation/Maintenance

Simco Ionization for Electronics Manufacture

Publication 5200943, June 2007

2257 N Penn Rd - Hatfield , PA 19440

215-997-0590 - 1-800-538-0750 (in USA)

Email: [email protected]

Simco Ionization for Electronics Manufacture 1 Publication 5200943

Simco Ionization for Electronics Manufacture Publication 5200943

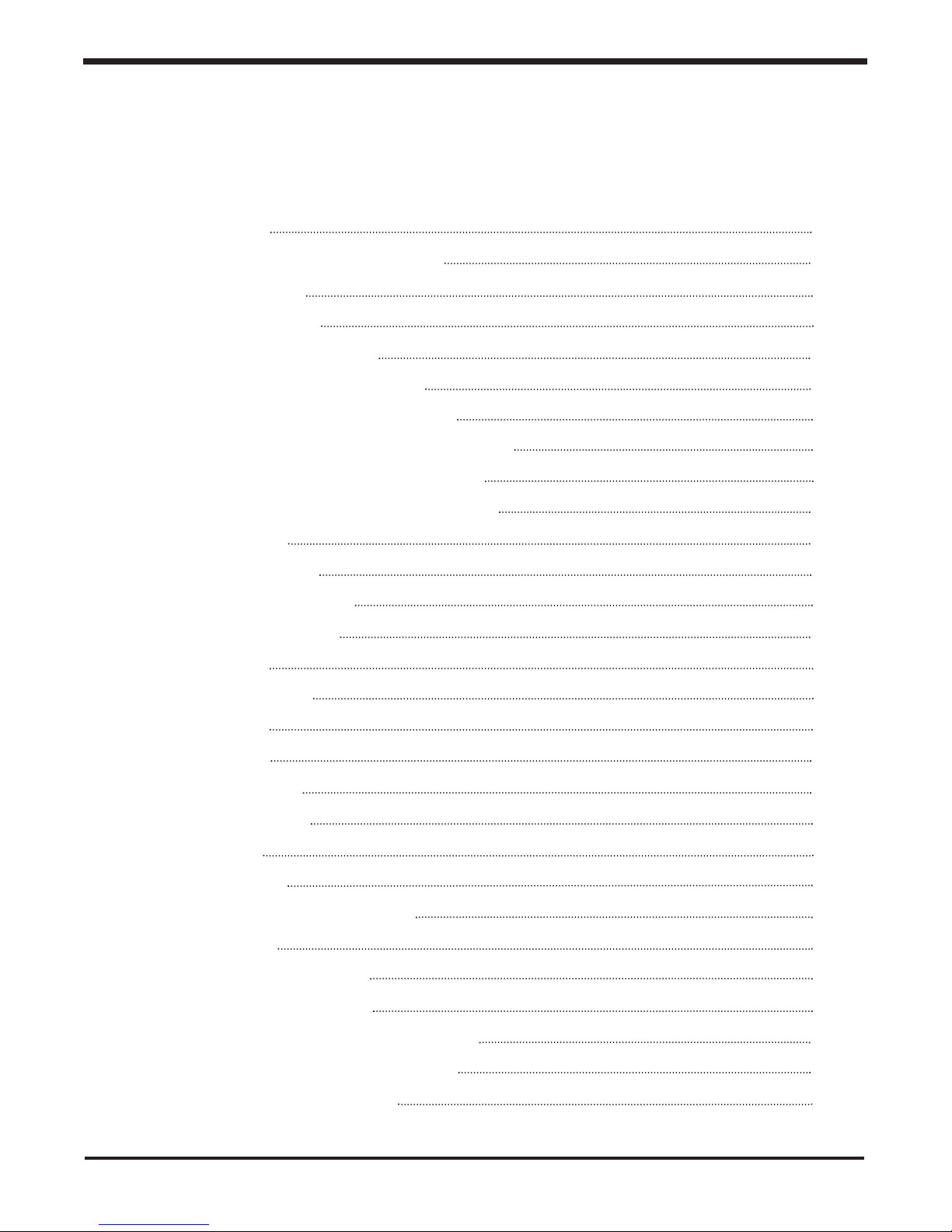

Section

1 Introduction 4

Section

2 scorpION3

CI

Computer

Interface 6

2.1 Description 6

2.2 Specifications 6

2.3 Systems Connections 7

2.4 Ethernet Equipped Models 8

2.5 Internal Address Configuration 8

2.6 The scorpION3 Bus and Connections 9

2.7 The RS-485 Bus and Connections 10

2.8 The User Interface and Connections 10

Section

3 Account

Types 12

3.1 User Account 12

3.2 Manager Account 12

3.3 Interface Layout 13

Section

4 Status

Panel 14

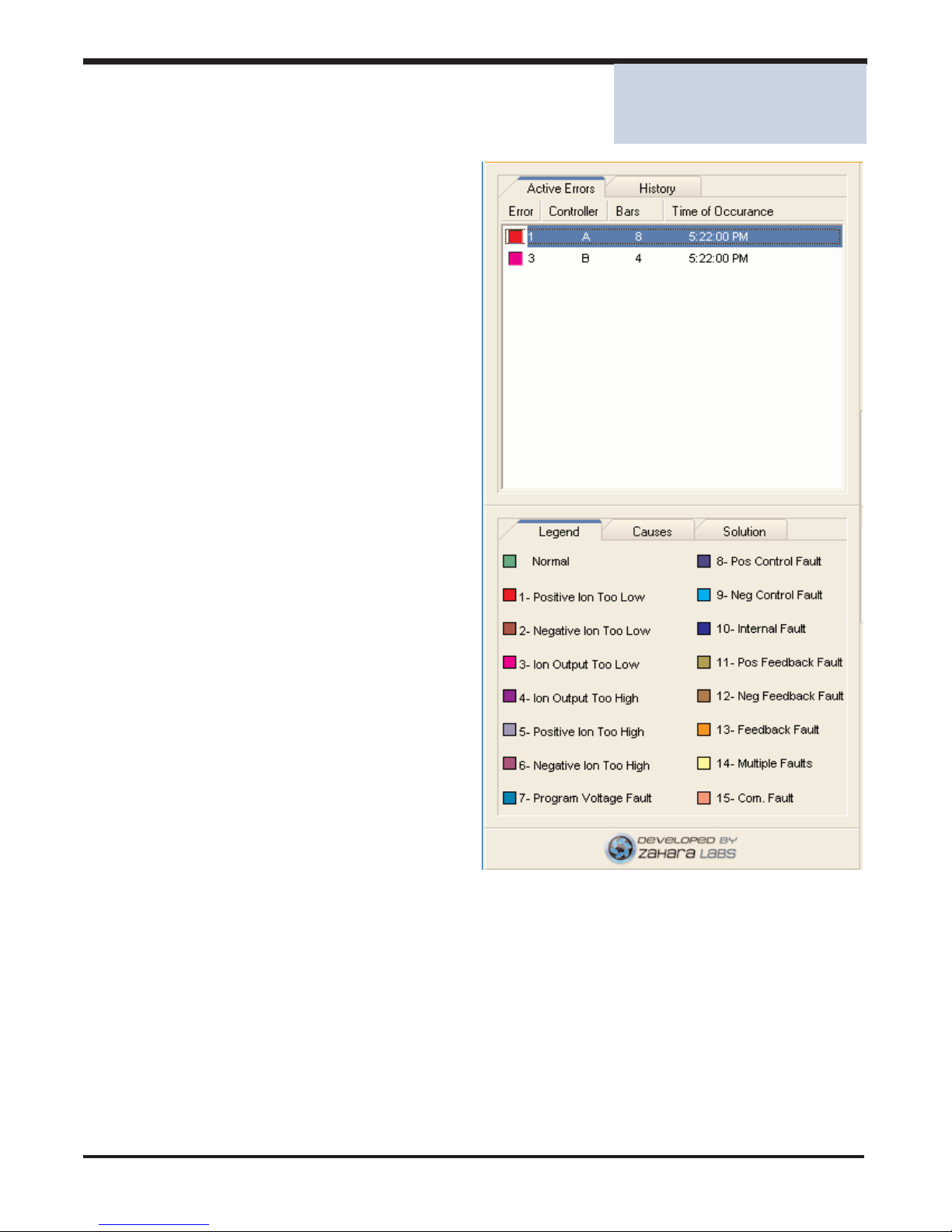

4.1 Active Errors 14

4.2 History 14

4.3 Legend 14

4.4 Causes Tab 15

4.5 Solution Tab 15

Section

5 History

Tab 16

Section

6 Graphic

Panel 18

6.1 Full Screen Graphic View 18

Section

7 Error

Logging 20

7.1 Daily Error Logging 20

7.2 Active Error Logging 20

7.3 An Example with Error Conditions 21

7.4 Context Sensitive Error Analysis 22

7.5 Expanded Historic View 23

Table

of

Content

2

Section

8

Bar

Modification 24

8.1 Custom Grouping History 24

8.2 Modifying a Controller 25

8.3 Programming a Bar 26

8.4 Diagnosing a Bar 28

8.5 Changing the Role of Bar 29

8.6 Changing the Address of Bar 30

Notes

Data Log

Simco Ionization for Electronics Manufacture Publication 5200943

3

32

33

Simco Ionization for Electronics Manufacture Publication 5200943

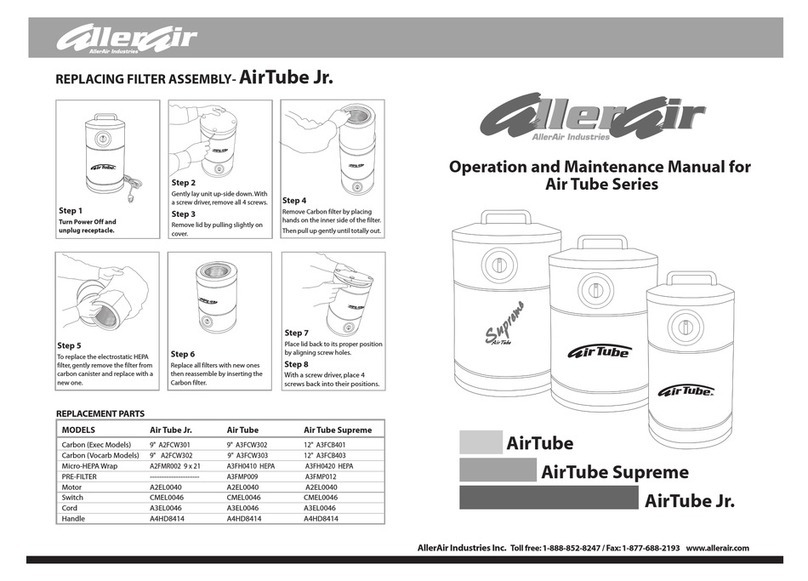

Features Include:

• Tool Interface Integration

• "Peak Reduction" Technology

• Bi-directional Intelligent MMI

• Full Digital Platform

• Active Monitor and Control

• SiC Emitters (US and International patents pending)

The scorpION3 ionizing bar utilizes SIMCO's innovative and

effective microcontroller intelligent ionization technology.

The system provides rapid neutralization of static charges

over a localized work area or in a mini environment. It is the

most flexible and efficient system available, capable of elim-

inating electrostatic discharge (ESD) and preventing electro-

static attraction (ESA) of particles to surfaces.

Section 1

Introduction

Introduction

4

SECTION 1- Introduction

Simco Ionization for Electronics Manufacture Publication 5200943

5

Simco Ionization for Electronics Manufacture Publication 5200943

SSCCOORRPPION3 CI

Computer

Interface

2.1

Description

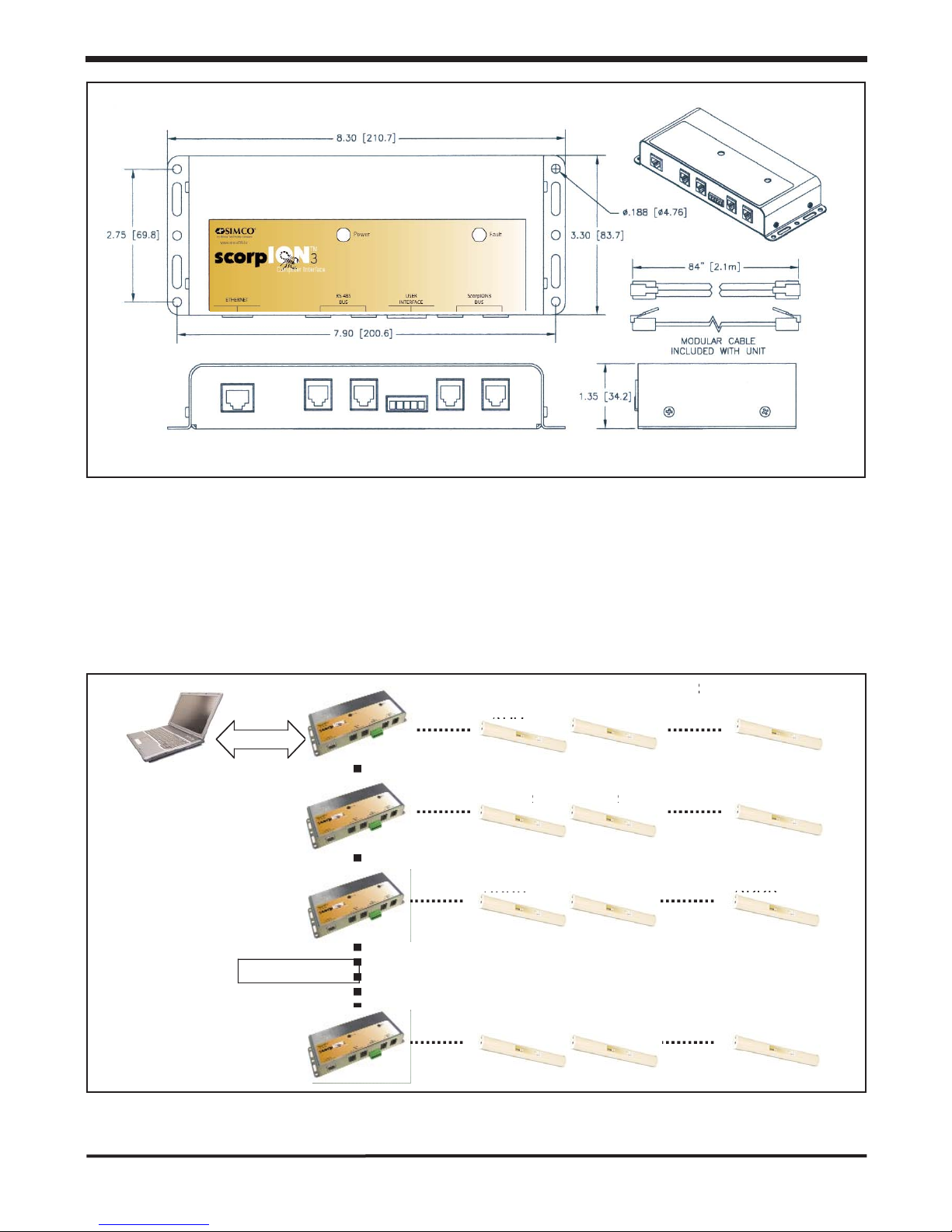

The scorpION3 CI (Computer Interface) was designed to allow multiple ion bar systems to be connected

and controlled from a single personal computer through dedicated hardware. This connection allows ion

bar performance and settings to be monitored, configured and diagnosed. The computer interface contin-

uously polls the condition, settings and diagnostic information of connected ion bars. Using this device

allows the construction of a scorpION3 network consisting of multiple CI units each with multiple ion bars

connected.

Each CI supports up to 10 connected ion bars on a dedicated scorpION3 communication / power distri-

bution bus. Multiple CI's can be 'networked' via a true RS-485 communication bus used to supplying data

to a PC. Ethernet capable models convert the RS-485 bus to Ethernet allowing

connection of multiple systems via a single IP address. This architecture allows calibration and monitoring

of scorpION3 based systems. The computer interface also provides a user interface, which provides an

auxiliary power input and relay contacts for system level fault detection.

scorpION3

CI

Features:

- Ethernet option

- Two RS485 interconnect bus connections

- 24VDC input, with power indicator

- Two scorpION3 bus connections

- Stainless steel case with mounting options

6

SECTION 2

scorpION3 CI

Computer Interface

SECTION 2- scorpION2 CI Computer Interface

2.2

Specifications:

Unit Part Number: without Ethernet with Ethernet

without Software 5051411 5051412

with Software 5051413 5051414

Power: 24 VDC, 100 mA

Power may be input at the scorpION3 BUS connector (from the scorpION3

bar system) or at the USER INTERFACE connector (see connections sections

of instructions).

scorpION3

Bus: RJ-11 modular connector x 2

User

Interface: Terminal socket block. Plug-in connector supplied with unit. (Weidmuller P.N.

1792890000)

RS-4485

Bus RJ-11 modular connector x 2

Ethernet:

(optional) RJ-45 modular connector x 1

Indicators: Power - green LED

Fault - red LED

Enclosure: Stainless Steel

Weight: 0.64 kg (1.4 lbs)

Mounting: User supplied M3 or M4 screws (#6 or #8)

Ethernet

RS485 BUS

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

scorpION2 BUS

2.3

System

Connections

The following figure depicts connections typical to a system with multiple CI units and multiple ion

bars. Connections of scorpION3 bars to the CI are made using the scorpION3 bus. Connections

between scorpION3 CI units are made using the RS-485 bus. Connection to the PC is via

Ethernet.

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR ADDR ADDR

scorpION2 Computer Interface

Simco Ionization for Electronics Manufacture Publication 5200943

7

SECTION 2- scorpION2 CI Computer Interface

3

Simco Ionization for Electronics Manufacture Publication 5200943

2.4

Ethernet

Equipped

Models

Ethernet equipped models of the scorpION3 CI convert RS-485 to Ethernet directly by using an

embedded device server (EDS). The EDS reliably converts the RS-485 to Ethernet using a single IP

address. Utilities from the EDS configure the PC to use a directly assigned virtual COM port that

remaps the serial port drive to the IP address. In most cases this configuration can be easily

achieved following the quick installation guide. This information as well as detailed user guides can

be located on the CD provided with the hardware.

The Network Enable Administrator runs on Windows based systems, allowing a broadcast search

for EDS devices to be performed. This utility finds EDS's based on their MAC addresses and allows

the assignment of IP addresses. It may be necessary to obtain an IP address for this assignment

from administrators of the network. Options for the COM assignment allow a 'virtual' COM port to

be configured using the mapping functions. After configuration the PC based hardware will use this

virtual COM port to communicate with the scorpION3 system and the PC will automatically retain

this configuration.

By entering the IP address of the EDS directly into the address line of a web browser such as

Internet Explorer, the EDS Web console can be accessed. Many of the same parameters can be

adjusted from the Web console. COM port configuration must have the following settings:

The Ethernet connection on the computer interface is clearly label and follows standard pin out

configurations for Ethernet.

2.5

Internal

Address

Configuration

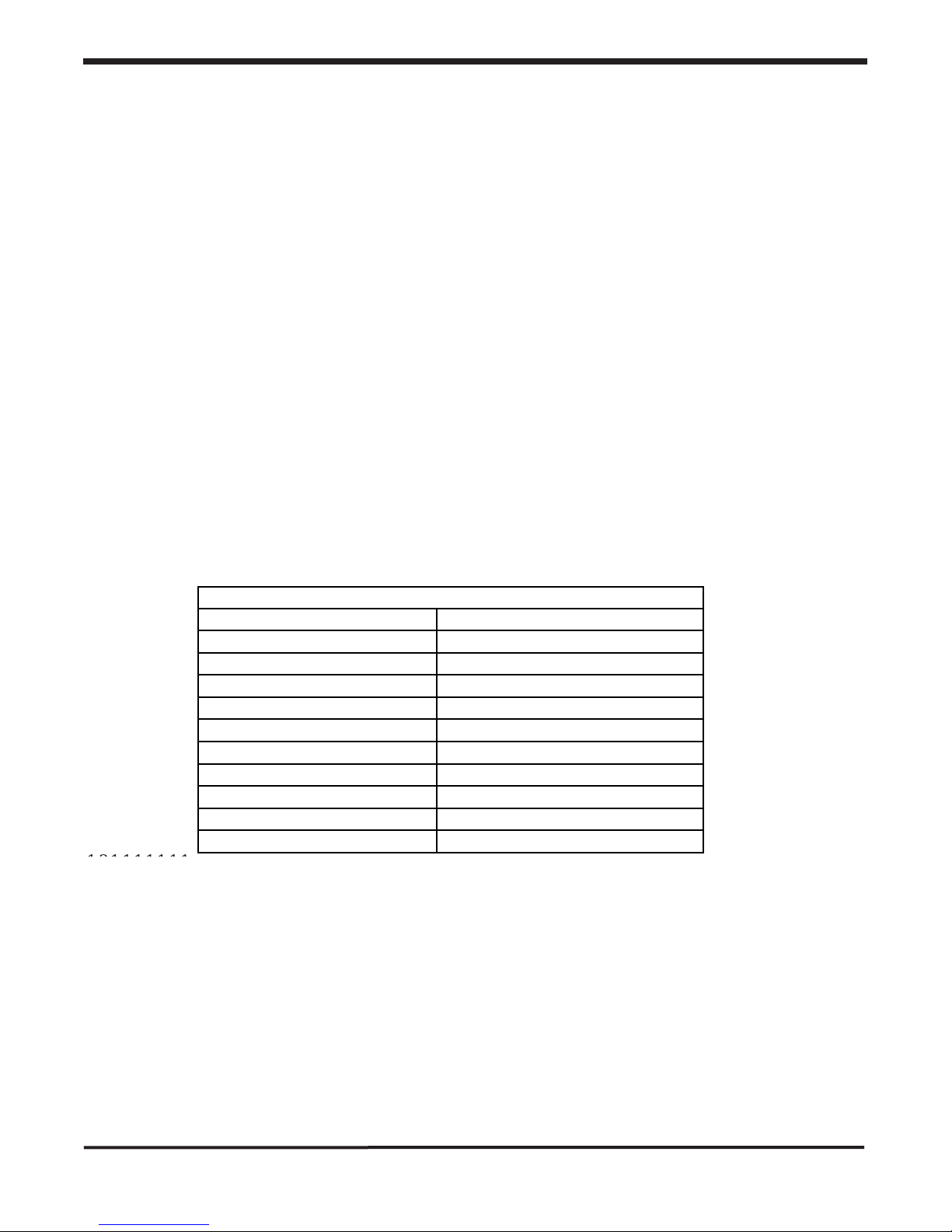

A dipswitch internal to the scorpION3 CI is used to configure the address. In installations where

multiple CI units will be connected back to a single PC, each CI must have a unique address. The

dipswitch has 8 positions but switch 1-4 only are used to configure the address. The address equals

the binary number configured by the switches. The following table explains the configuration of

switches 1-4, where 0=off and 1=on, the PC based software subsequently refers to the CI units by

letter.

MOXA NE-4110A CONFIGURATION

PARAMETER

SETTING

Baud Rate

9600

Data Bits

8

Stop Bits

1

Parity

None

Flow Control

None

FIFO

Enable

Interface

RS485 4 Wire

Operation Mode

Real COM Mode

TCP Alive Check Time

99

Max Connection

4

131111111

8

SECTION 2- scorpION2 CI Computer Interface

Simco Ionization for Electronics Manufacture Publication 5200943

SWITCH SETTINGS (1-4)

ADDRESS

SOFTWARE LABEL

0000

0

A

0001

1

B

0010

2

C

0011

3

D

0100

4

E

ETC….

2.6

The

scorpION3

Bus

and

Connections

The scorpION3 bus provides power and communication lines to connected scorpION3 bars. Two

RJ-11 style connectors on the CI provide the ability to connect and power ion bars with this bus.

For some installations 24 VDC power can be supplied via the RJ-11 modular connector. Connect

pins 1 & 6 to the +24 volt supply voltage and connect pins 3 & 4 to ground (ground serving as the

return for the supply voltage), see table below. Users connecting to the scorpION3 in this way

should be ready to supply 200mA per ion bar connected and about 100mA for the CI. Note that

the scorpION3 CI is internally fused to protect the user's power supply during this type of setup.

Connections or grounding of the other pins (2 & 4) on the modular connector is not permitted and

may result in malfunction or damage to the system.

scorpION2 bus (N.C. = no connection permitted)

PIN NUMBER 1 2 3 4 5 6

CONNECTION +24VDC N.C. GND GND N.C. +24VDC

+/-10%

Because of the connection scheme used on the scorpION3 bus there is no need to be concerned

with the orientation of interconnection wiring. Cables that are 'flipped' or 'straight' will function iden-

tically.

For installations of up to 3 ion bars and a CI, Simco's AC adapter can be utilized. Install all ion

bars and interconnect wiring before applying power. Plug the adapter power cord into a grounded

electrical outlet of 100 to 240 VAC, 50 or 60 HZ. Connect the adapter to the scorpION3 CI and

to the ion bars with modular cables, power will automatically be distributed to the other ion bars

on the 'chain'. The scorpION3 bar has no on/off switch so application of the 24VDC to the unit

will turn it on, and ionization will begin. The adapter and wiring can be located as desired by the

user.

9

SECTION 2- scorpION2 CI Computer Interface

Simco Ionization for Electronics Manufacture Publication 5200943

Note: a CI that is powered this way will provide power to ion bars that are connected to it via the

modular connector, and in this configuration the SIMCO adapter can power a maximum of 3 ion

bars.

2.7

The

RS-4485

Bus

and

Connections

The RS-485 bus is a 4 wire, full duplex RS-485 connection. Two connections on the CI are provid-

ed for connections to this bus. This bus is used specifically for interconnection of multiple CI units

back to an Ethernet enabled CI. With this construction a single IP address can collect data from

multiple scorpION3 systems. Note that there is no power distribution via these bus connections, so

each CI in the systems must be powered independently.

RS-485 bus

PIN NUMBER 1 2 3 4 5 6

CONNECTION TX+ TX- GND GND RX+ RX-

Cabling that interconnects multiple CI units must be of the 'flipped' or 'parallel' construction, where

by pin 1 is connected to pin 1 on the next connection, etc. This configuration connects all wires in

parallel with one another.

2.8

The

User

Interface

and

Connections

The User Interface provides a terminal strip for supplying power to a scorpION3 system. Wiring

connections are made to stripped wires, using clamping screw. This permits direct connection of

the CI and ion bars to existing power in tool or mini-environment applications. The specific pin

outs are provided below. Power supplied to pins 1 and 2 should conform to the following: pin 1

must be earth ground; pin 2 should be 24VDC+/10%. Users who provide power to the system in

this way should budget 200mA per scorpION3 bar and 100mA for the CI itself. The CI has an

internal fuse in series with the power distribution to the ion bars; this protects the power supply due

to wiring (24V) short circuits.

User Interface

PIN NUMBER 1 2 3 4 5

CONNECTION GND +24VDC NC COM NO

+/-10%

10

1 2 3 4 5

SECTION 2- scorpION2 CI Computer Interface

Simco Ionization for Electronics Manufacture Publication 5200943

The User Interface also provides a relay contact output that toggles based on fault conditions. The

normal relay positions are indicated in the table above. The CI detects status and conditions from

all connected ion bars. On a fault condition from any ion bar in the system the relay is activated,

changing the state of the relay relative to the common. The fault relay has a contact rating of 30V

at 1A maximum; this should not be exceeded as damage to the unit may result.

11

SECTION 2- scorpION2 CI Computer Interface

Account

Types

Before an operator can use the

scorpION3 Monitoring System they

need to login. You may login to the

GEMINI Profile Monitoring System in

two ways, as a User or Manager.

3.1

User

Account

As a User an operator can:

Monitor the scorpION3 system.

Review both active and corrected

error conditions.

Login without using a password.

3.2

Manager

Account

As a Manager an operator can:

• Do everything a User can.

• Edit a Controller's location.

• Modify the frequency of

Preventive Maintenance.

• Update the date of last

Preventive Maintenance.

• Modify the frequency of

System Calibration.

• Update the date of last

System Calibration.

• Change the manager login

password.

Simco Ionization for Electronics Manufacture 12 Publication 5200943

SECTION 3

Account Types

SECTION 3 - Account Types

Simco Ionization for Electronics Manufacture Publication 5200943

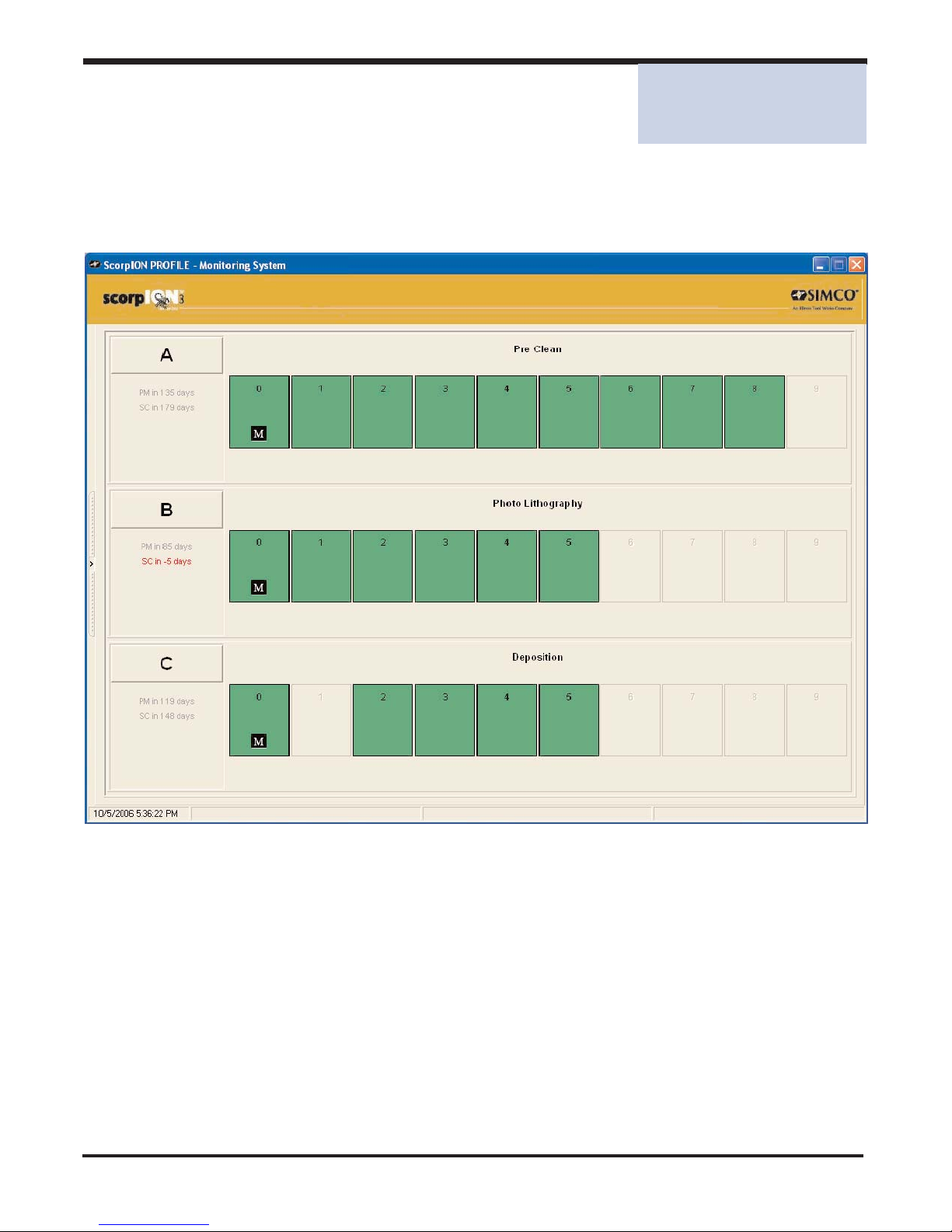

3.3

Interface

Layout

The scorpION3 monitor software is laid out in two primary areas:

Status

Panel and the Graphic

Panel; separated by a Horizontal divider. A status bar at the bottom

of the screen displays the current date and time, two status areas display the time the Historic Error

log was written to, and when the Active Error log was written to.

The above system is composed of 3 controllers A, B, and C correspondingly having 9, 6, and 5

emitters each. Preventive Maintenance for controller A is due in 135 days and System Calibration is

due in 179 days.

Currently there are two active errors in the Active Errors list. The ErrorLog.csv was last updated at

5:23:30 PM.

13

SECTION 3 - Account Types

Simco Ionization for Electronics Manufacture Publication 5200943

Status

Panel

4.1

Active

Errors

The top part of the Status Panel shows all

active error conditions. Each error is color

coded, identifies the Controller and the

Emitter experiencing the error, and the time

the error occurred.

4.2

History

A History tab next to the Active Tab lists all

corrected errors that have transpired.

4.3

Legend

In the lower part of the panel there is a

Legend that identifies error codes by ID

and by color.

14

SECTION 4 - Status Panel

SECTION 4

Status Panel

Simco Ionization for Electronics Manufacture Publication 5200943

4.5 Solution Tab

The Solution Tab displays possible

Solutions/corrective measures that can be

taken to eliminate an Error. The information

displayed is updated based on the error

selected in the Active Error list.

15

4.4

Causes

Tab

The Causes Tab displays possible Causes of

an Error. The information displayed is updat-

ed based on the error selected in the Active

Error list.

SECTION 4 - Status Panel

Simco Ionization for Electronics Manufacture Publication 5200943

History

Tab

The History tab displays a detailed history of corrected errors including the time of occurrence,

where they occurred (Controller / emitter), what type of error occurred and the duration of the error.

By including information regarding the next preventative maintenance and next system calibration

we can gauge the need for servicing the system. Notice that controller B's System Calibration indi-

cator is red. This happens because controller B should have had a System Calibration 5 days ago.

16

SECTION 5 - History Tab

SECTION 5

History Tab

Simco Ionization for Electronics Manufacture Publication 5200943

17

Simco Ionization for Electronics Manufacture Publication 5200943

Graphic

Panel

6.1

Full

Screen

Graphic

View

By maximizing the Horizontal Divider or by dragging the divider to the left you can get a full screen

This view takes full advantage of the graphical capabilities of the application.

18

SECTION 6 - Graphic Panel

SECTION 6

Graphic Panel

Simco Ionization for Electronics Manufacture Publication 5200943

19

Table of contents