Simco minion2 Instruction Manual

INSTRUCTIONS

Operation/Maintenance

minION2™

Ionizing Air Blower

US Patents: 5,008,594,

6,717,792 B2, 6,785,114,

7,054,130

SIMCO's minION2 ionizing air blower is designed to control electrostatic

charges in semiconductor and electronics manufacturing equipment and

for benchtop applications requiring high performance in a small pack-

age. Using steady-state DC corona ion technology, the minION2 fea-

tures self-monitoring to ensure controlled, consistent ion output.

SECTION 1 Description

SECTION 2 Safety

SECTION 3 Features

SECTION 4 Specifications

SECTION 5 Installation

SECTION 6 Operation

SECTION 7 Maintenance

SECTION 8 Replacement Parts

SECTION 9 Warranty

2257 North Penn Road

Hatfield, PA 19440

(215) 997-0590

(800) 538-0750

Fax: (215) 997-3450

Publication 5200964

(Rev B, February 2007)

2257 North Penn Road

Hatfield, PA 19440

Phone: (215) 997-0590

(800) 538-0750

Fax: (215) 997-3450

http://www.simcoION.biz

e-mail: [email protected]

®

®

SECTION 1 Description

SIMCO’s minION2 ionizing air blower is designed to control electrostatic

charges in semiconductor and electronics manufacturing equipment and for

benchtop applications requiring high performance in a compact package. The

minION2’s small size also makes it easily portable for field service applications

where static control is necessary.

Using steady state DC corona ion technology, the minION2 features self-moni-

toring to ensure controlled, consistent ion output. Performance is enhanced by

SIMCO’s patented radial emitter array and ion balance maintained with the

patented ionizing circuitry. Structured airflow from the patented air outlet

ensures maximum delivery of ionized air to the target. These features in the

design of the minION2 enable it to meet the demands of critical semiconductor

equipment manufacturers with corona ionization.

The minION2 uses modular wiring to enable “daisy chaining” of units, up to

three units may be daisy chained on a standard power supply. A plug-type ter-

minal block is included for easy wiring if the user desires to hard-wire the unit

in place. There is the option of supplying power to the unit through the terminal

block where the user wishes to supply power from a 24 VDC machine bus. The

terminal block also features relay contact output of the unit’s fault alarm for

remote fault sensing.

An optional clamp-on spring arm stand is available for benchtop applications

requiring elevated positioning, or for locations with a restricted mounting surface

area.

SECTION 2 Safety

CAUTION!

1. Read the complete Operation Manual before operating. Failure to follow

instructions may result in damage to the ionizer and/or personal injury.

2. The AC adapter is supplied with a 2- or 3-prong inlet plug, which must be

inserted into an appropriate, properly wired wall outlet.

3. A factory-qualified service technician must perform component service and

repairs. Please contact SIMCO Customer Service for information.

WARNING!

4. Keep the unit dry. Do not operate the unit in flammable or explosive

atmospheres.

5. Do not insert objects through the unit's intake or outlet grilles while in

operation. Damage to the ionizer and/or personal injury may result.

SECTION 9 Warranty

SIMCO warrants its products to be free of defects in components, workmanship,

or materials for a period of one year from date of purchase. This warranty does

not apply to any physical or electrical damage caused by misuse, abuse or negli-

gence (such as any modifications made to the unit or service work done by any

other than SIMCO authorized technicians). Any unit with altered or removed

serial number is ineligible for warranty.

SIMCO will not be liable for loss or damage due directly or indirectly to an

occurrence or use for which the product is not designed or intended. In no event

shall SIMCO be liable for incidental or consequential damages except where

state or regional laws override.

This warranty extends to the original purchaser and is not transferable. No per-

son, agent, distributor, dealer or company is authorized to change, modify, or

amend the terms of this warranty in any manner whatsoever.

All products returned must have an “RA” (Return Authorization) number regard-

less of warranty status. Call SIMCO for an assigned RA number.

Information in this document is subject to change without notice and does not

represent a commitment on the part of SIMCO. No part of this manual may be

reproduced or transmitted in any form or by any means, electronic or mechani-

cal, including photocopying and recording, for any purpose other than the pur-

chaser’s personal use without written permission of SIMCO.

29

SECTION 8 Replacement Parts/Part Numbers

Part Number Description

4011424 minION2 (no power supply)

4011425 minION2 (with 100/120VAC Japan / North America power

supply)

4011426 minION2 (with 230VAC Continental Europe power supply)

4011427 minION2 (with 230VAC United Kingdom power supply)

5051406 minION2 power supply only (100/120VAC Japan / North

America)

5051407 minION2 power supply only (230VAC Continental Europe)

5051408 minION2 power supply only (230VAC United Kingdom)

4371099 emitter, standard stainless steel (6 required)

4370760 emitter, long life tungsten (6 required)

4520764 modular cable, 4P4C, 3’ long

4520767 modular cable, 4P4C, 6’ long

5051141 articulated arm kit

SECTION 3 Features

• Small and compact

• Closed –loop balance control

• Simple to install and operate

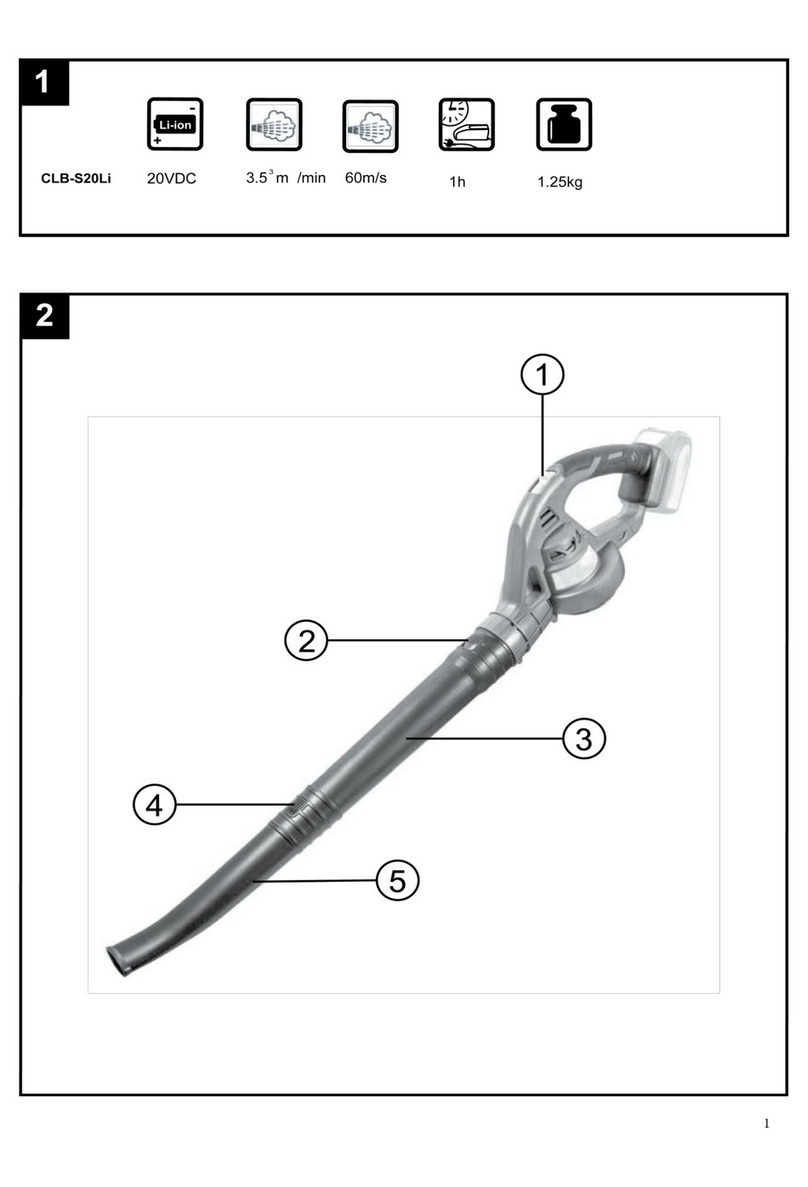

SECTION 4 Specifications

OPERATING SPECIFICATIONS

(Balance) Offset Voltage: 0+/-10 V

Discharge time in seconds:

Distance 305 mm 460 mm 610 mm 760 mm 915 mm

(12 in.) (18 in.) (24 in.) (30 in.) (36 in.)

Fan - High 2 sec. 3 sec. 5 sec. 7 sec. 9 sec.

Fan - Low 3 sec. 4 sec. 7 sec. 9 sec. 12 sec.

Offset voltage and discharge time determined as per ANSI/ESD STM3.1 using 6”

x 6”, 20 pF plate (charged plate monitor). Discharge times are in seconds from

1000 volts to 100 volts.

Input Power: 24 VDC, 250 mA, 6W

Power Supply: Universal 100-240 Vac input (IEC320) / 24 Vdc, 750

mA output, suitable to power up to 3 units.

Operating Temperature: 0˚C to 50˚C (32˚F - 122˚F)

Airflow Volume: Fan - High: 42 CFM (1.2 m3/min)

Fan – Low: 21 CFM (0.6 m3/min)

Audible Noise: 52 dB(A) at 610mm (24 in.)

48 dB(A) at 1m (39 in.)

High fan speed, measured perpendicular to air outlet.

ON/OFF: Switch

Fan Speed: Variable, recessed adjustment.

Indicators: Power: green LED, Fault: red LED.

Connectors: Two 4-position, 4-contact (4P4C) modular “handset”

connectors for power, may also be used for daisy

chaining units. Modular cable is included with unit.

Modular connector part numbers: (Amp 5-641334-3,

Hirose TM3P-44P, Kobiconn, 154-UL6164)

3 8

Connectors: Plug type terminal block may be used for power

and/or faultoutput connection. Terminal block is

included with unit. Terminal block part numbers:

(Weidmuller 1792890000, Phoenix 1803604,

Altech 36.305)

MECHANICAL SPECIFICATIONS

Emitter Material: Polished stainless steel

Enclosure Material: Reinforced polycarbonate, color: white

Enclosure Dimensions: (98mm W x 136mm H x 60mm D)

3 7/8” W x 5 3/8” H x 2 3/8” D

Unit Weight: (0.5 kg) 1.1 lb

Stand Material: Nickel plated stainless steel

SECTION 5 Installation

5.1 Unpacking

Carefully remove the equipment from the carton and inspect the contents.

NOTE: If any damage has occurred during shipment, notify the local carri-

er at once. A report should also be forwarded to SIMCO, 2257 North Penn

Road, Hatfield PA 19440. See Section 9 (Warranty) for Return Shipment

information.

5.2 Installing

The minION2 ionizer is designed for portable or permanent operation. Typically,

the unit should be positioned such that there is good airflow provided to the crit-

ical area. Generally this requires that the unit be within 36” inches of the intend-

ed target. The stand provided can be used in a permanent operation by bolting it

to a sturdy flat surface such as a wall or shelf. The unit can be mounted hori-

zontally if required.

CAUTION!

5.3 Electrical Connections

The standard AC adapter provided with the minION2 is a universal input AC

type adapter with a line cord suitable for the region of operation. This AC

adapter may be used to power up to three minION2 ionized air blowers by wiring

them in series (daisy chain fashion) with the modular cords included. The con-

nectors used on the minION2 are 4P4C modular “handset” style connectors. For

reference, the modular cable carries +24 VDC on the inner two conductors and

7.3 Ion Output and Balance Check

To test the unit for ion output, the use of a charged plate monitor is recommend-

ed. Prior to performing these checks, clean the emitters as described above and

allow the unit to run for 10 minutes to allow the ion balance to stabilize. Offset

voltage and discharge times can be measured and checked against the Ion

Balance and Ion Output tables in Section 4, Specifications. If a charged plate

monitor is not available, periodic verification instrumentation may be used but if

periodic verification instruments are used it will be necessary to get “baseline”

data using the chosen periodic verification instrument.

7.4 Emitter Replacement

To replace emitters, turn off the minION2 and unplug it from the power supply

at the rear panel connector. Lay unit face down on a soft surface. Remove the

four Philips head screws at the air inlet on the rear panel. Lift the rear panel out

of the enclosure and set to one side (Note how the black plastic divider fits

between the ionizer and circuit boards during disassembly). The ionizing hub

contains sockets for the ion emitting pins. Carefully remove the ion emitters by

pulling them straight out from the ionizer hub. Push new ion emitters into the

sockets, make sure all sockets have emitters and all emitters are fully inserted

into their sockets. Replace the rear panel on the enclosure while guiding the

black plastic divider back into place. Ensure that the power switch and power

jacks are properly fitted through the openings on the rear panel. Secure the rear

panel with the four Philips head screws, do not over tighten the screws. Test unit

and return to service.

7.5 Troubleshooting / Diagnostics

This information provides a quick troubleshooting reference for the minION2

ionizing air blower. Should any of these possible solutions not solve the problem,

contact SIMCO.

47

PROBLEM CAUSE SOLUTION

UNIT FAILS TO OPERATE AC ADAPTER NOT CONNECTED CHECK ALL ELECTRICAL

(NO GREEN INDICATOR CONNECTIONS

LIGHT) FAULTY AC ADAPTER REPLACE AC ADAPTER

UNIT FAILS TO OPERATE INTERNAL FAULT RETURN UNIT FOR REPAIR

(GREEN INDICATOR

LIGHT ON)

RED FAULT INDICATOR DIRTY EMITTER HUB CLEAN EMITTER HUB AS

ILLUMINATES DESCRIBED ABOVE

INTERNAL HV FAULT RETURN UNIT FOR REPAIR

EXCESSIVELY LONG DIRTY EMITTERS CLEAN EMITTERS AS

STATIC DISCHARGE TIMES DESCRIBED ABOVE

WORN EMITTERS REPLACE ION EMITTERS

ION BALANCE OUT OF DIRTY EMITTERS CLEAN EMITTERS AS

SPECIFICATION DESCRIBED ABOVE

WORN EMITTERS REPLACE ION EMITTERS

GROUNDED METAL NEAR MOVE METAL AWAY FROM

IONIZED AIR OUTLET OUTLET OR MOVE OUTLET

AWAY FROM METAL

ground/return is on the outer two conductors.

The minION2 may also be powered through the plug type terminal block locat-

ed on the rear panel; +24 VDC goes to pin 1 and the ground/return goes to pin 2.

This allows powering of minION2 ionized air blowers from a 24 volt machine

bus. Each minION2 draws 250 milliamps so adequate current must be provided.

A unit powered through the plug type terminal block may power other minION2

units wired in series (daisy chain fashion) with the 4P4C modular cords includ-

ed. Power distributed through the modular cable must be limited to a maximum

of 2 amps for safety purposes. Wired in this fashion, the recommended maxi-

mum number of units wired in series is 5.

The plug type terminal block also provides relay contact output for the fault

alarm. Pin 4 is Common. Pin 5 is Normally Open. Pin 3 is Normally Closed.

The relay contacts are rated for a maximum of 1 A at 30 Vdc resistive with a

maximum switching voltage of 220 VDC.

A terminal block plug is supplied with the minION2.

SECTION 6 Operation

The minION2 power switch is located on the rear panel of the unit, above the

modular cable jacks. The rear panel also has a small hole next to the modular

cable jacks that provides access to the recessed fan speed control adjustment.

The fan speed may be adjusted with a small screwdriver or trim pot tool.

Clockwise rotation provides maximum fan speed, counterclockwise provides

minimum fan speed.

The front panel of the minION2 has two LED indicator lights. The green LED

indicates the unit is powered. The red LED is a fault indicator for the high volt-

age power supply monitoring circuit. The high voltage power supply monitor-

ing circuit also drives the fault alarm relay.

The minION2 produces an ionized air stream that covers a targeted area. The

time required to neutralize a static charge on an item in the target area depends

on several factors. Two important factors are; distance to ionizer and air veloci-

ty. Set the fan speed as high as acceptable to provide more rapid static neutral-

ization. For fast neutralizing, the minION2 should be as close to the target area

as practical.

SECTION 7 Maintenance

7.1 Emitter Cleaning

To clean emitters, turn off the minION2 and unplug it from the power supply.

Visually inspect the emitter array for particle or dust accumulation. Moisten a lint

free swab with deionized water or isopropyl alcohol and insert it through the inlet

grille. Wipe each emitter clean and clean the emitter hub as necessary to remove

accumulation. Allow to evaporate completely before returning the minION2 to

service.

7.2 Air Inlet and Outlet Cleaning

The air inlet grille on the rear of the unit and the ionized air outlet should remain

clean to prevent restriction of air flow. They can be cleaned with a soft brush or

vacuum.

5 6

Table of contents

Other Simco Blower manuals