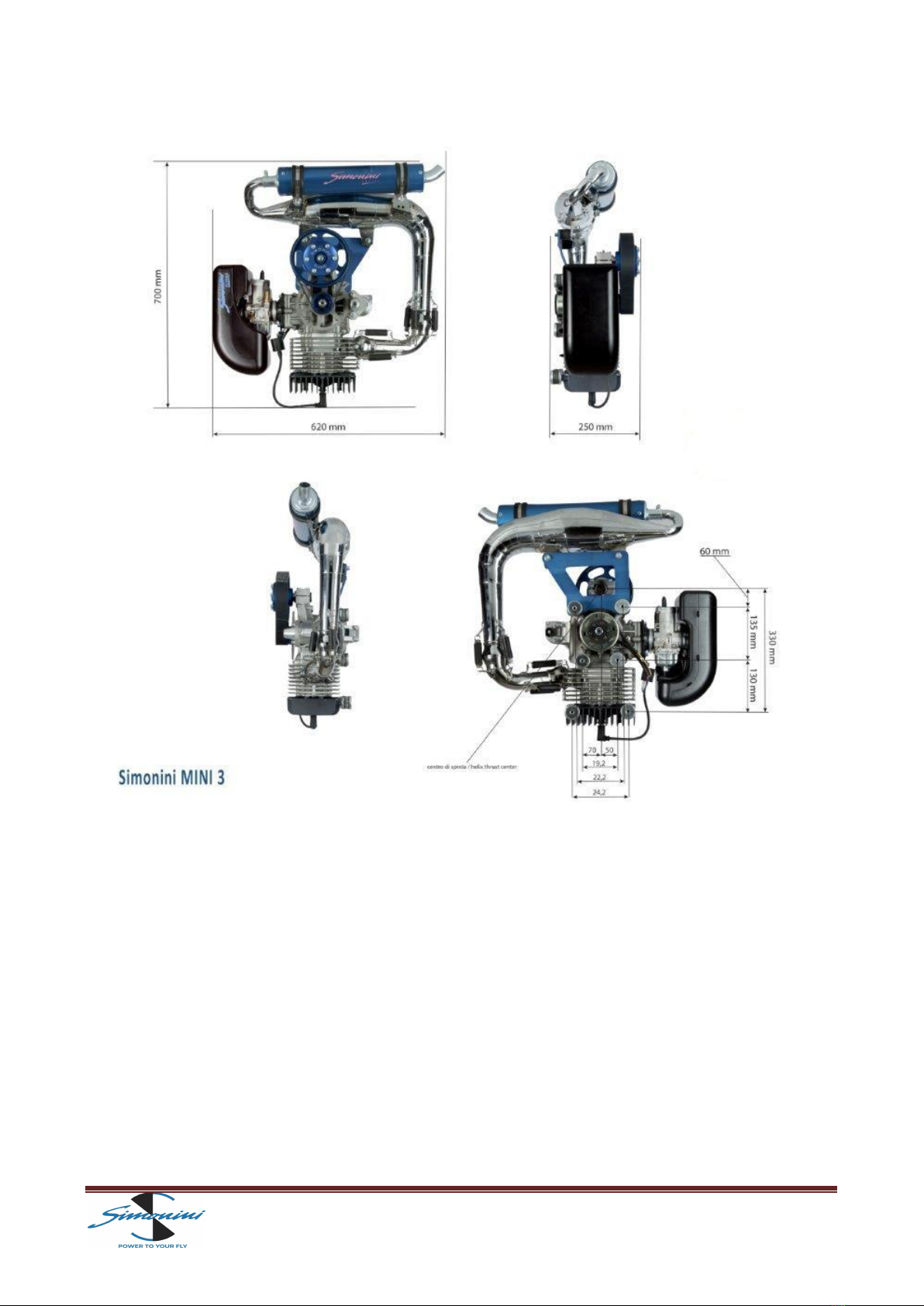

SIMONINI Racing MINI 3 User manual

page 1

MINI 3

This handbook aims to bring to the attention of key technical, functional and maintenance of your motor MINI 3. Read carefully the following pages, will be synonymous

with safety, reliability and great satisfaction durable.

This manual is considered part of the motor MINI 3, in case of transfer, will be delivered to the new owner.

About this manual lists all of the information available at time of printing. The SIMONINI RACING srl reserves the right to modify or change without notice.

page 2

TECHNICAL DATA

BORE 72,8mm

STROKE 65mm

DISPLACEMENT 270cc

COMPRESSION RATIO 10.1 / 1

Weight ready to fly 22 kg

CONSUMPTION A 5400 rpm 3,2litres/hour

POWER 7000 rpm 36hp

STATIC THRUST Over 100Kg

Lamellar intake with Bing 36mm carburetor

Aluminum cylinder with ceramic coating magnesium,

Exhaust resonance

Poly-V belt reduction

Electronic ignition

Electric start

Alternator battery charger in flight

Airbox

Lubrication premix: 2.5% with premium-grade gasoline

3.0% with unleaded fuel

REDUCTION RATIOS AVAILABLE:

1:249 crown 159 mm / Pinion 64 mm

1:258 crown 159 mm / Pinion 62 mm

1:276 crown 159 mm / Pinion 58 mm

page 3

page 4

MINI 3/01

KIT ENGINE SCREWS

MINI 3/29

WASHER-PRESSURE OUTLET

MINI 3/64

COMPLETE SET OF BEARINGS

MINI 3/02

COMPLETE EXHAUST SYSTEM

MINI 3/31A

REED VALVE NEW MODEL

MINI 3/65

COMPLETE ROD

MINI 3/03

COMPLETE SET OF GASKETS

MINI 3/33

AIR FILTER

MINI 3/66

ROD CAGE

MINI 3/04

COMPLETE SET OF ENGINE SCREWS

MINI 3/35

BING 54 CARBURETTOR

MINI 3/69

COMPLETE PISTON AND RINGS

MINI 3/05

CYLINDER HEAD GASKET

MINI 3/39A

RUBBER MANIFOLD NEW MODEL

MINI 3/69A

TWO RINGS MM. 72,80

MINI 3/06

KIT SCREWS FOR HEAD ( 4 )

MINI 3/41

CRANK-CASE

MINI 3/70

RECTIFIER RECHARGE BATTERY

MINI 3/07

CYLINDER HEAD

MINI 3/46

ECCENTRIC PINION

MINI 3/71

SPARK PLUG BR 10 ES

MINI 3/08

KIT SILENT-BLOCK (6)

MINI 3/47

SEEGER REDUCTION

MINI 3/72

PLATE FOR FIXING EXHAUST

MINI 3/09

KIT SCREWS FOR CYLINDER

MINI 3/48

SET OF REDUCTION BEARINGS

MINI 3/73

EXHAUST MANIFOLD AND

SPRINGS

MINI 3/10

CYLINDER

MINI 3/52

POLY-V BELT

MINI 3/74

EXHAUST GASKET

MINI 3/11

CYLINDER GASKET

MINI 3/53

REDUCTION PULLEY

MINI 3/75

RUBBER FOR SPARK PLUG

MINI 3/16

STATOR

MINI 3/54

ALUMINIUM PLATE FOR PROP

MINI 3/76

NUT AND WASHER FOR FLYWHEEL

MINI 3/17

FLY WHEEL

MINI 3/58

REDUCTION PINION

A72

COMPLETE AIRBOX

MINI 3/19

SCREW AND WASHER FOR PINION

MINI 3/59

CROWN WHEEL

A73

SPONGE FOR AIRBOX

MINI 3/23

ALUMINIUM PLATE FOR COIL

MINI 3/61

COMPLETE ELECTRIC STARTER

A74

RUBBER FOR AIRBOX

MINI 3/25

COMPLETE COIL

MINI 3/62

COMPLETE CRANKSHAFT AND ROD

A75

CLAMP FOR AIRBOX

MINI 3/28

ALUMINIUM PLATE FOR STATOR

MINI 3/63

COMPLETE SET OF SEALS

page 5

TIGHTENING TORQUES

Description

Special number in table

NM

Kgf.m

Head Nut

6x40 Screws

Connector

6x30 Screws

6x25 Screws

Nut 12

12x30 Screws

8x40 Screws

Spark Plug

6

44

29

37

44

19/76

51

42

71

22

12

10

12

10

54

60

24

18

2.2

1.2

1.0

1.2

1.0

5.4

6.0

2.4

1.8

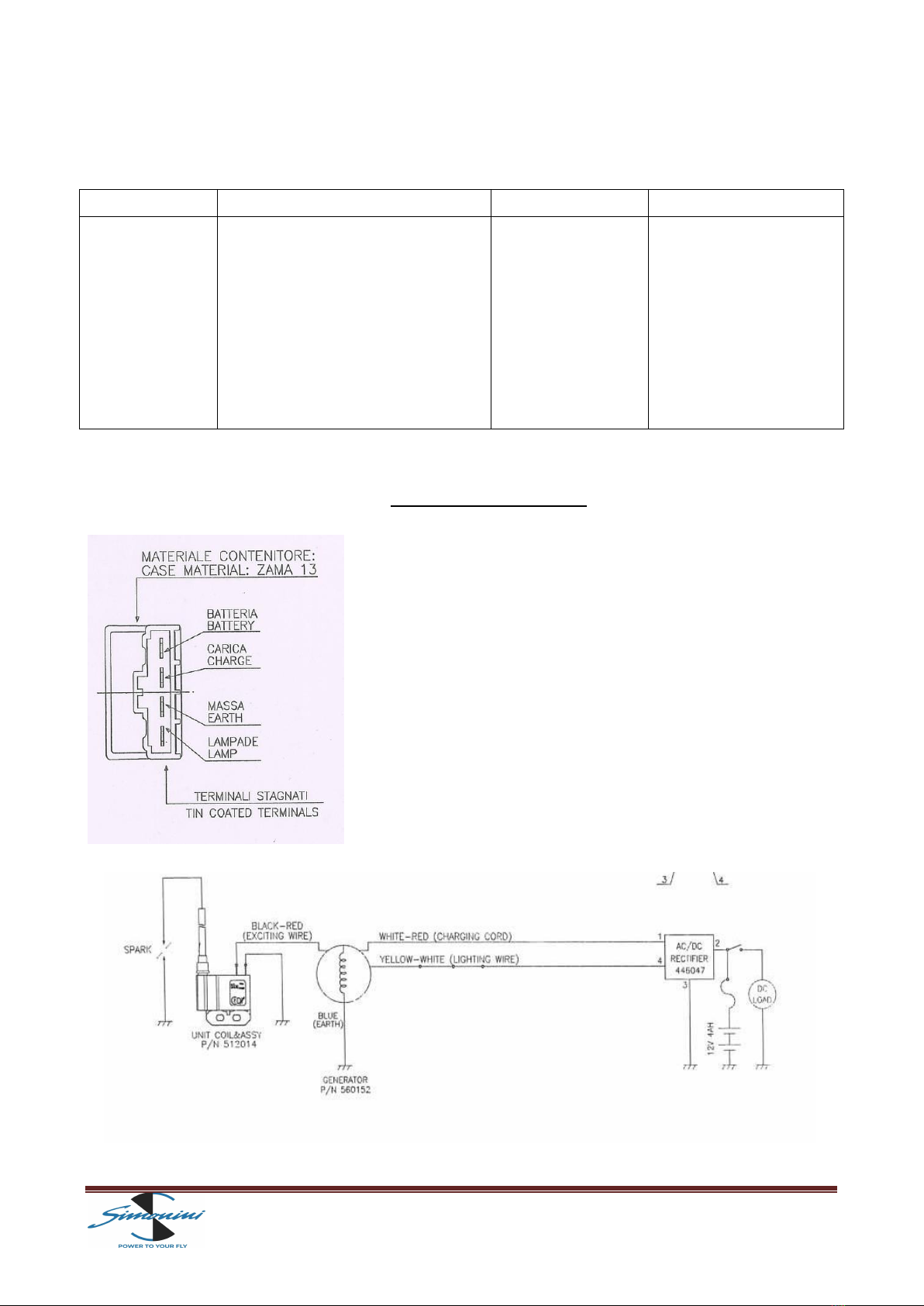

ELECTRICAL DIAGRAM

page 6

INSTALLATION

The MINI 3 engine must be fitted to the frame using its six elastic supports "silent

blocks", radially mounted: two placed on the head and four on the back of the

engine.

During the installation, some safety precautions must be made: remember that an

engine generates vibrations, even if very few, which can cause the loosening and/or

removal of screws or any other object. Therefore, to prevent any engine

components may cause damage to persons and/or property, make sure the engine

through a small steel cable. Components normally "made safe" are:

• The filter and the carburetor to the engine

• The springs and exhaust to the engine

• The engine itself to the frame, bypassing the silent blocks. In this case we will

use the "webbing" of synthetic fiber is particularly resistant to traction and tearing.

•The silent blocks and the silencer.

The mouth of the spherical muffler should be lubricated with grease resistant to

high temperatures (e.g. copper grease) before being implanted in the exhaust

manifold.

We recommend taking maximum care when carrying out these operations: in any

case, during the assembly phase the proper choices must be made by expert and

qualified personnel.

FUEL

The MINI 3 engine is designed to operate with a gasoline/oil mixture.

We recommend using oil-based semi-synthetic (for example, BARDAHL with API TC

specification) that, although inferior to a pure synthetic, remains mixed with

gasoline in the tank for a longer period. It grants good lubrication and longer life to

engine components.

During the running-in stage, use an oil percentage of 3.5% and then move to 3%

once the stage has been completed.

The gasoline must have an octane number that is not lower than 95, in order to

avoid pre-ignition phenomena.

Carefully mix the fuel oil in a tank is appropriate and it is better, once mixed, to use

it within a week. Do not use vegetable or animal oil. DO NOT MIX DIFFERENT TYPES

OF OIL. We do never recommend using Castrol TTS Oil. No guarantees by using this

oil will be applied.

page 7

CARBURETOR and FUEL PUMP

The carburetor BING 54/36, if used properly, provides good performances requiring

few tuning intervention. However, changes in weather conditions, altitude and a

possible change of the propeller (both in size and pitch) can affect its functioning.

The carburetor is adjusted during the testing phase with a standard setting. To

adjust the carburetor on the basis of these different situations, smaller or larger jets

are available.

The MINI 3 is equipped with a depression pump that draws fuel directly from the

tank. The draft tube has to no longer than 80 cm.

CARBURATION

Warning: in this paragraph the words "MIXTURE" indicates the union of the two elements (AIR) + (OIL /GASOLINE)

which takes place inside the carburetor

Weather conditions or altitude changes have influence to the operation of the

engine as it varies the air density and, consequently, changes the mix ratio between

the element AIR and the element OIL /GASOLINE.

In general, we can say that at high altitude, high humidity or high temperatures, less

air enters and therefore the mixture is richer in oil/gasoline: you will have to re-

establish the proper relationship by replacing the main jet with a lower measure.

In contrast, with low temperatures and low humidity, the air will become denser

than the lean-burn oil / gasoline, and consequently you will have to install a bigger

main jet.

WARNING: A mixture that is too low in oil/gasoline causes considerable damage to

the engine, which can cause it to break down and/or stop suddenly. It is

recommended to carry out the carburetion operations with the ENGINE SWITCHED

OFF!

page 8

RUNNING-IN

WARNING

• Before starting the engine, make sure that there are no loosened screws or

improperly attached parts;

• Ensure that any persons are at a distance of absolute safety and never in range of

the propeller;

•Do not start the engine where there are rocks or other objects that the force

generated by the propeller can lift and throw even at a considerable distance;

• Do not start the engine without propeller and without exhaust;

• Do not start the engine indoors: the exhaust gases contain poisonous carbon

monoxide which is toxic and can cause loss of consciousness and death.

The engine, before being sold, was subjected to a pre-running-in to verify the proper

operation and a test that confirms all the features advertised.

Once you require a MINI 3, you should pay particular attention to the first hour of

operation, in order to ensure all the engine’s qualities over time.

DURING THE RUNNING-IN PHASE, KEEP PARTICULAR ATTENTION TO THE EXHAUST GAS

TEMPERATURE AND HEAD TEMPERATURE UNDER CONTINUOUS OBSERVATION.

After having selected a suitable place and above all free from gravel or other

materials that may damage the moving parts, start the engine and let it warm up for

10 minutes at 2500 rpm, then slowly bring the engine to an higher system ,

decreasing and increasing the speed at intervals of 1 minute, thus going to affect

various "range" of use, but without exceeding the 4500 rpm. Absolutely avoid the

constant and repeated closing/opening the gas valve. After about 20 minutes from

start-up, shut down the engine and let cool completely.

WARNING! When the engine is running and even after its shutdown, it can cause

burns: so make sure it is completely cooled before working on it.

Proceed with a thorough visual inspection of any anomalies or loose parts. Once you

make sure everything is working properly and there are no problems of any kind,

you must repeat the previous operation for another 20 minutes of running,

respecting the same indications.

Last running-in phase: warm up the engine again for 10 minutes at 2500 rpm and

then, as in the two previous operations, gradually increasing the RPM. Now you can

wander over the entire range of use of the engine, bringing it several times to the

maximum speed at intervals of 1 minute.

After 20 minutes you can turn off the engine and, once cooled, you will proceed to a

page 9

full-tightening the screws on the MINI 3. Now the engine MINI 3 will be ready for

use for which it was designed by continuing to use a percentage of oil by 3% for the

next 10 hours.

WARNING! DURING THE RUNNING-IN PHASE, KEEP PARTICULAR ATTENTION TO THE EXHAUST GAS

TEMPERATURE AND HEAD TEMPERATURE UNDER CONTINUOUS OBSERVATION.

MAINTENANCE

Each time you use the engine, remember to perform routine checks pre-start-up:

• Check the silent block condition in complete integrity

• Make sure the exhaust does not present any cracks

• Ensure that the propeller does not present cracks or dents

• Make sure you have enough fuel, according to the duration of intended use of the

engine.

• Check that the electrical system and cables do not show abrasions or disruption.

• Check that there are no screws or parts loosened.

BELT TENSION

WARNING: CARRY OUT THE OPERATIONS WITH THE ENGINE SWITCHED OFF AND COOLED DOWN

During operation, the belt is under strain and wear and as result, lengthening

occurs, which could lead to sliding on the pulleys, with a subsequent decrease in

the general engine performance.

To restore the proper tension, loosen the screw M8 (No. 42) on the foot of the

engine which fastens the pulley can, turn screw M12 (n°51) anti-clock wise using

force of 1.8 Kgm and then re-tighten screw M8 (n°42)

INTERVENTIONS EVERY 20 HOURS

• Clean filter carburetor

• Clean fuel filter

• Check the belt tension and condition

• Lubricate the ball joint of the muffler

INTERVENTIONS EVERY 60 HOURS

• Replace the engine and exhaust silent blocks

page 10

• Replace the transmission belt

• Check the status of the intake manifold rubber

• Replace the exhaust pipe sound-absorbent material

• Check the electrode gap spark-plug: if it is over 0.6 mm, change the spark plug

• Rubber components such as belt transmission, silent block, intake manifold and

depression tube may be damaged by atmospheric agents. Their durability can

therefore be different from what is reported, you should therefore check their

condition and provide a possible replacement even outside the agreed time.

INTERVENTIONS EVERY 200 HOURS

• Replace all the bearings (N°64 + N°48)

• Replace all oil seals (N°63)

• Check the internal parts of the engine and carry out their replacement in case

the height limit confirm it is necessary.

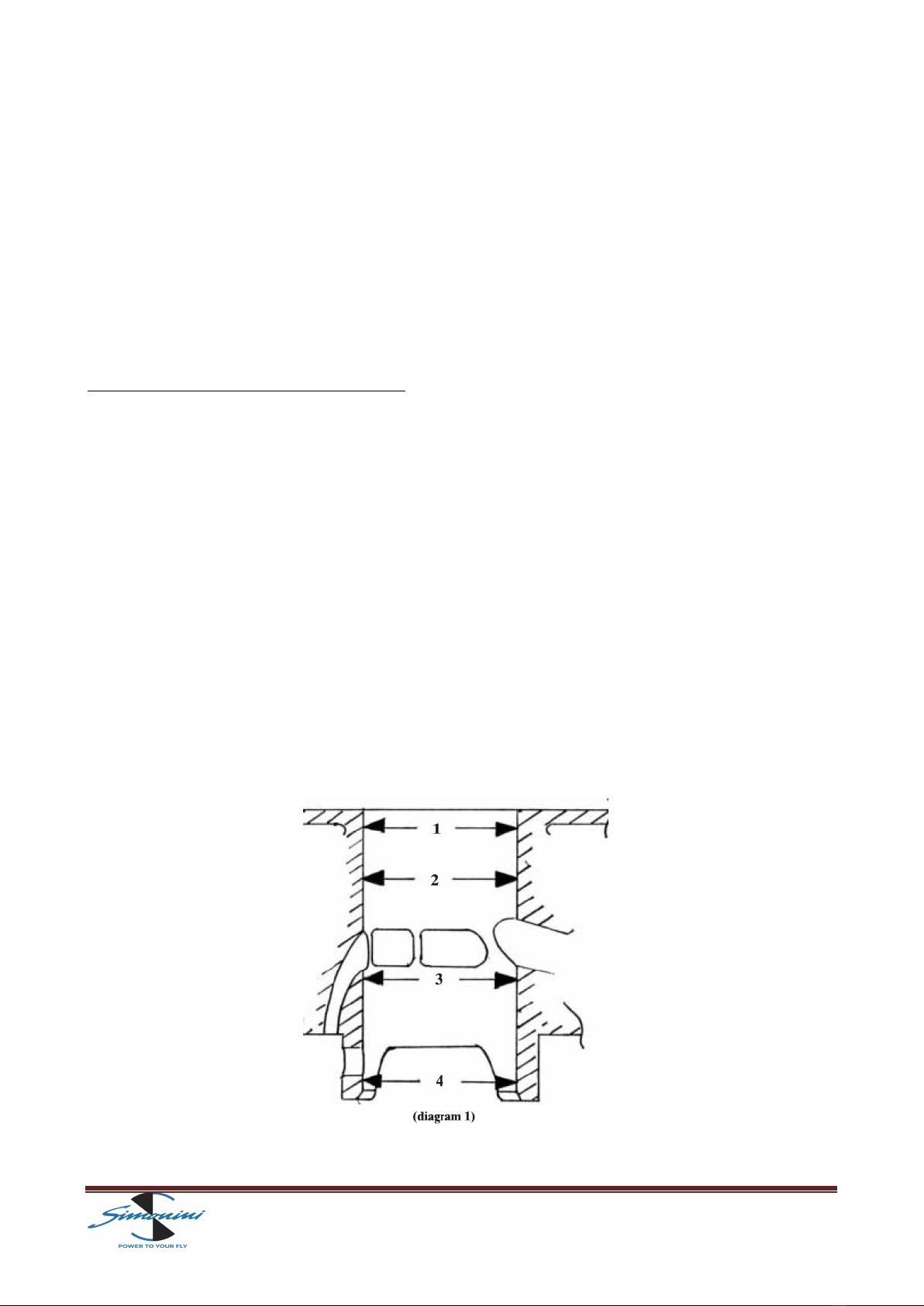

• Cylinder:

-must not show signs of seizure or scratches on the filling material (nickel

silicon);

-check the wear of the cylinder in the four points (shown in diagram 1) on X

and Y axles, none of the heights obtained must exceed the height limits:

SELECTION A: 72.830mm

SELECTION B: 72.840mm

SELECTION C: 72.850mm

SELECTION D: 72.860mm

The selection is shown with a letter at the bottom of the cylinder

• piston:

page 11

-There must not be any signs of seizure or deep cracks.

-Check the wear by measuring the piston at 18.5mm from the bottom keeping

the measuring instrument at a right angles to the axis pin.

Height limits:

SELECTION A: 72.690mm

SELECTION B: 72.700mm

SELECTION C: 72.710mm

SELECTION D: 72.720mm

• The pin must not be blue because that indicates a high working temperature and

the external diameter must not be less than 17.990mm.

• Measure the slack between the piston ring and its seat: slack height limit 0.1mm.

• Piston ring: insert a piston ring in the cylinder one by one, by using the piston, so

it is a square, measure the gap that is created between the two ends of piston ring

using feeler gauge. Height limit: 0.7mm

• Crankshaft: supporting the crankshaft at the two working points of oil seals, with

two comparators, measure the centering at the two working points of the bearings,

marked on diagram 2 with the letter A. Height limit: 0.05mm

• Measure the bearing seating, which must not be lower than the height limit:

24.98mm

•Check with a feeler gauge that the axle slack of the connecting-rod between the

two semi shaft, which must not exceed the height limit: 0.7mm

• Check the radial slack of the connecting rod on the coupling axle which must not

exceed the height limit: 0.05mm. This is detected by placing a comparator (B), as

page 12

shown in diagram 2, and moving the connecting rod vertically. The slack shown by

the comparator is assessed. Measure the diameter of the hole in the connecting-rod

foot. Height limit: 20.00mm

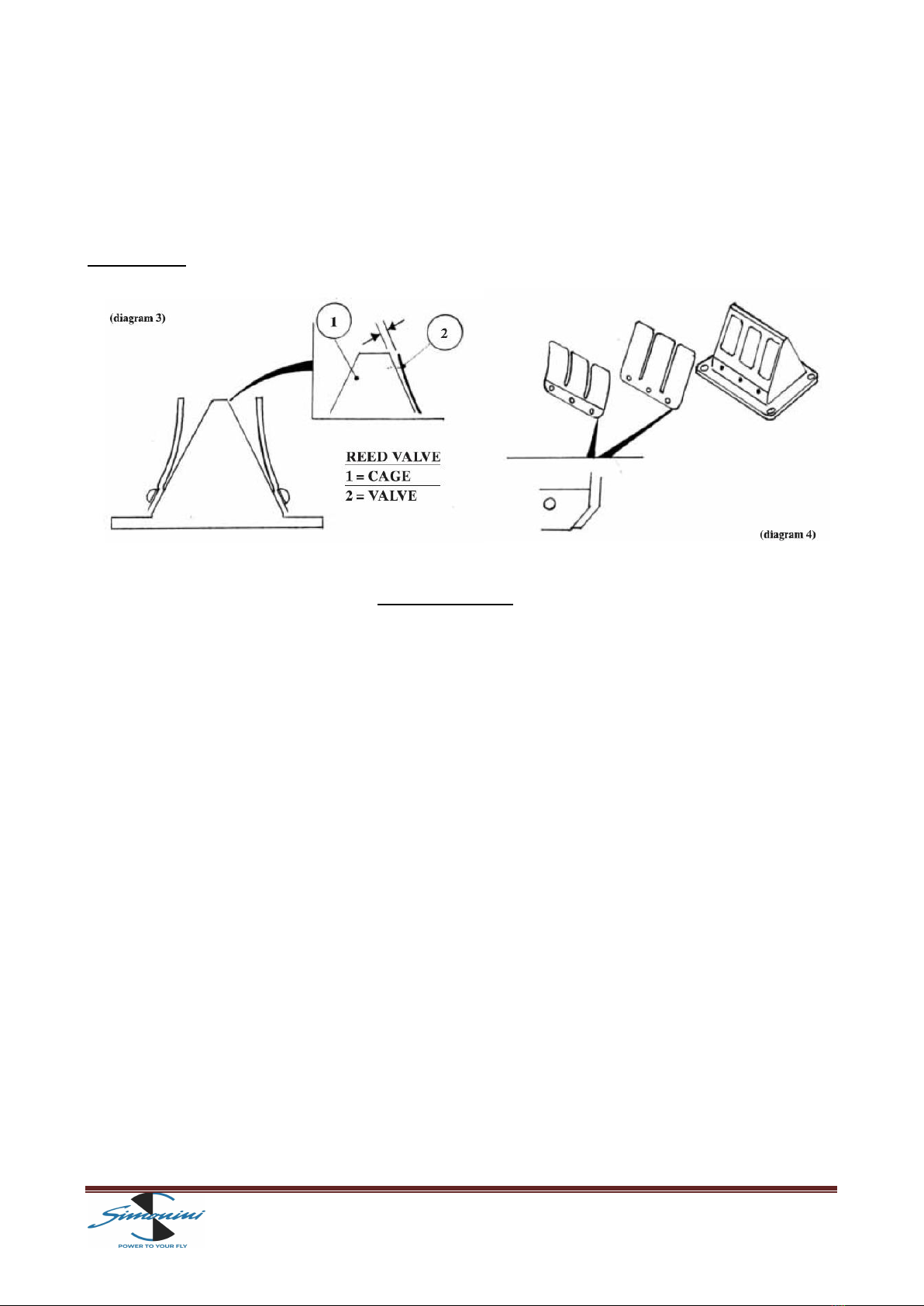

• Reed valve: Verify that between the frame and the reeds there is no space

(diagram 3). Height limit: 0.2mm.

WARNING: The reeds should not and cannot be turned (diagram 4)

TEMPERATURE

The MINI 3has been designed to work under certain operating temperatures: so

please stick strictly as written.

Temperatures that must not be exceeded when cruising or when the engine is at a

fixed rpm for a long time:

• Exhaust gas temperature 580 ° C.

• Temperature under spark plug 170 ° C.

Temperatures that must not be exceeded when taking off or when all the power is

required to the engine:

• Exhaust gas temperature 673 ° C.

•Temperature under spark plug 240 ° C.

WARNING engine will NEVER, at any time and condition, exceed:

• 670 ° C temperature of the exhaust gas.

• 240 ° C temperature under spark plug

It therefore makes it appropriate to adopt an instrument that detects these

temperatures for the protection of the engine, but especially for your and others'

safety.

page 13

We also inform you that high exhaust gas temperatures, in many cases, are a

symptom of poor carburetion. While high temperatures under the spark plugs,

usually, are due to poor ventilation (heat dissipation) of the engine, caused by the

presence of bodies and / or materials that prevent the passage of air cooling.

COMPONENTS AND TOOLS ON REQUEST

To have the possibility to customize the engine and then adapt it to different needs

and methods of use, SIMONINI offers a range of components on request:

▪PINION

In three different diameters (58/62/64) as well as providing the proper

reduction ratio, can be used to soften or make more rapid rise in engine

speed or to move, maintaining the propeller revolutions, any points of the

torque curve that does not meet your needs at a specified "range" of use, as

when cruising.

Code MINI3/53 mm. 58

Code MINI3/53 mm. 62

Code MINI3/53 mm. 64

▪PROPELLERS

We propose a two-blades wooden propeller, tractor or pushing configuration

Code E03 cm. 145

▪MAINTENANCE TOOLS

To facilitate maintenance operations, we propose two distinct tools with the

aim of extracting the ignitions flywheel and engine pulley:

Code U01 Pinion extractor

Code U02 Fly-wheel extractor

page 14

REQUEST FOR REPAIR OR REPLACEMENT OF WARRANTED

ATTENTION

The warranty is valid for 12 months from date of purchase and it covers all the

engine parts. It does not include the parts subject to wear: cylinder Nikasil, piston

and drive belts. There is NO warranty if the engine is tampered or if any not original

parts has been fitted without our approval.

In the case you need, please send the engine to

SIMONINI RACING srl

indicating:

• name

• address

• number the engine

• date of first start

• hours of operation

• any previous repairs

• carburetion setting

• complete description of the problem

Thank you for your trust and we remind you that the staff of SIMONINI RACING srl will be at your

disposal for any questions.

SIMONINI RACING SRL

Via per Marano 4303, Loc. San Dalmazio - 41028 Serramazzoni (Mo)

Tel 0536/953005 Fax 0536/953006.

Http: www.Simonini-flying.com E-mail: [email protected]

Table of contents

Other SIMONINI Racing Engine manuals

Popular Engine manuals by other brands

Desert Aircraft

Desert Aircraft DA170 owner's manual

GEIGER

GEIGER GB45MR Series Original assembly and operating instructions

THUNDER TIGER

THUNDER TIGER PRO-39H(R) instructions

Briggs & Stratton

Briggs & Stratton PROFESSIONAL SERIES 110000 Operator's manual

woodmizer

woodmizer LT28 G19 Safety, Operation, Maintenance & Parts Manual

Detroit Diesel

Detroit Diesel MBE4000 Service manual