Simtronics TLU 600 User manual

Qualité de détection

L’efficacité des détecteurs de flamme IMRAD

Optronics ICARE : haute sensibilité, temps

de réponse très court, fiabilité, immunité face

aux interférents (sources chaudes, rayonnement

solaire, sources lumineuses…) garantit une

protection parfaite contre les risques de feu

dans les environnements industriels et permet

la commande de moyens d’extinction.

Les boîtiers bénéficient d’un traitement spécifique

pour une résistance aux agents corrosifs

(boîtier INOX 316L ou aluminium).

Des performances élevées

La cartouche de détection interchangeable (3xIR

ou UV / 2xIR) optimise la détection, grâce à son

microprocesseur et ses algorithmes, et gère les

logiques d’alarme. Les détecteurs TV63 disposent

d’un très grand champs de vision (> à 80 m pour le

3xIR avec un angle d’ouverture de 110°).

Les relais intégrés complétés par la sortie 4-20mA

permettent l’exploitation du TV63 par les centrales

(gaz ou incendie) ou directement par les automates

industriels.

Fiabilité

Les détecteurs sont équipés d’un test de contrôle

automatique qui vérifie, à intervalles réguliers, le bon

fonctionnement de la détection UV / IR, ainsi que

l’intégrité optique et électronique de l’ensemble.

Simplicité

La cartouche interchangeable débrochable permettant

de changer de technologie (3xIR ou UV / 2xIR) ainsi

que le support de fixation et d’orientation indépendant

du boîtier électronique rendent ce détecteur

particulièrement simple à installer et à maintenir.

Applications

tockage et utilisation de matières inflammables,

pétrole, GNL/GPL, on shore / off shore, chimie,

industrie, aéronautique, automobile, etc.

The remote detectors

ive the optimum

solution for

maintenance

operations

by remote

control.

The remote control

Our range of

remote detectors

constitutes an

important advance

in gas and fire

detection technology.

All configurations, tests and

readouts are remotely accessible using

the infrared remote controller. his tool,

common to all SIMRAD Optronics ICARE

remote detectors, allows test detection

without using a test lamp

and facilitates maintenance.

• Maintenance and configuration

by a single operator

•

Ease of use and reduced maintenance costs

• No need to use a test lamp

• Readout of status, settings and alarms

• Inhibition remote control

• Compatible with all remote detectors

• Certified intrinsically safe for use in

restricted areas II 2 G/EEx ia II C 6

• Safety in use

Les télecapteurs

apportent la solution

la plus performante

aux opérations

de maintenance

en permettant

le contrôle

à distance.

L’accès à distance

Les télécapteurs représentent

une évolution majeure dans le domaine

de la détection de gaz et de flamme.

La télécommande infrarouge pilote à distance

et en toute sécurité les opérations de réglage,

de test ou de visualisation.

Cet outil, commun à tous les télécapteurs

IMRAD Optronics ICARE, permet la réalisation

d’essais de détection sans utiliser de lampe test

et rend aisée la maintenance.

• Opération de maintenance et

de paramétrage par un seul opérateur

• implicité d’utilisation et réduction

des coûts de maintenance

• Dispense de l’utilisation d’une lampe test

• Lecture des états, paramètres et alarmes

• Commande d’inhibition à distance

• Universelle avec la totalité des télécapteurs

• Agrément de sécurité intrinsèque pour une

utilisation en zone classée II 2 G/EEx ia II C 6

• écurité d’intervention

detection and processes the alarm logic.

hese V63 detectors have a wide viewing

angle (> 80 m for the 3xIR with an angle

of 110°). he integrated relays and a

4-20mA output enable the control of the

V63 by the central units (fire or gas)

or by PLC.

Reliability

he detectors are equipped with an

automatic test control, which regularly

checks the functionality of the UV and

the IR detection, as well as the optical

and electronic integrity of the system.

Simplicity

he removable and interchangeable

cartridge (3xIR or UV / 2xIR) along with

the wall mounting independent from

the electronic box, makes this detector

particularly simple to use.

Applications

Storage and use of flammable materials,

petroleum, GNL/GPL, on shore / off shore,

chemicals, industrial, aeronautic,

automobile industry,…

Detection quality

he efficiency of SIMRAD Optronics ICARE

flame detectors offers : high sensitivity,

a very short response time, reliability,

immunity from interferences (hot sources,

solar radiation, light sources…).

It also guarantees protection against fire

risks in industrial environments and

enables the control of fire-fighting facilities.

he housings are treated specifically to

resist corrosive factors (316L stainless

steel or aluminium housings).

High performances

hanks to its microprocessor and

algorithms, the removable detection

cartridge (3xIR or UV/ 2xIR) optimises IR

Without eneratin false alarms

these detectors offer exceptional

metrolo ical performances

The desi n of this new eneration of detectors provides 3 main features :

Performances / Guaranteed detection / Easy installation, use and maintenance.

With its interchan eable cartrid e, this detector offers the choice of multi IR detection

technolo ies (3xIR) or combined UV/IR (UV/2xIR).

Ne énérant pas d’alarmes intempestives

ces détecteurs offrent des performances

métrolo iques exceptionnelles

La conception de cette nouvelle énération de

détecteurs repose sur 3 axes essentiels :

Performances / Garantie de détection / Facilité de

mise en œuvre, d’exploitation et de maintenance.

Ce détecteur offre, par sa cartouche interchan eable,

le choix des technolo ies de détection multi IR (3xIR)

ou combinées UV/IR (UV/2xIR).

Detection distance on a normalized fire / Distances de détection sur feu normalisé

(Box / Bac : 0.3 x 0.3m) UV 2xiR : 45m • 3xiR : 80m

Manual

NOSP 14540-04 (JULY 2011)

Remote controller TLU 600/610

TLU 600/610

Page 2/20

NOSP 14540-04 (JULY 2011)

CONTENTS

1.

INTRODUCTION .............................................................................................................3

1.1.

1.1.

I

DENTIFICATION AND ARKING

....................................................................................3

1.2.

1.2.

F

UNCTIONS

.............................................................................................................4

1.3.

1.3.

R

E OTE CONTROLLER CONSTRUCTION

.........................................................................5

2.

CERTIFICATION .............................................................................................................7

3.

OPERATION ...................................................................................................................8

1.4.

3.1.

S

WITCHING ON

........................................................................................................8

1.5.

3.2.

PASS WORD

.............................................................................................................8

1.6.

3.3.

ENU

....................................................................................................................9

1.7.

3.4.

PICTOGRA S

.........................................................................................................11

4.

TECHNICAL SPECIFICATIONS .....................................................................................15

5.

AINTENANCE............................................................................................................15

1.8.

5.1.

C

LEANING

............................................................................................................15

1.9.

5.2.

C

HANGING A BATTERY UNIT

......................................................................................15

6.

PACKAGING AND TRANSPORT....................................................................................15

7.

STORAGE .....................................................................................................................15

8.

Contact details.............................................................................................................19

INDEX OF FIGURES

Figure 1: TLU Label .............................................................................................................3

Figure 2: the remote controller............................................................................................5

Figure 3: the remote controller key pad...............................................................................6

Figure 4: connection established screen...........................................................................10

Figure 5: connection to multiple sensors screen ...............................................................10

Figure 6: battery charging indicator...................................................................................11

Figure 7: low battery level indicator...................................................................................11

Figure 8: connection indicator ...........................................................................................12

Figure 9: good communication indicator............................................................................12

Figure 10: poor communication indicator ..........................................................................13

Figure 11: charging connection..........................................................................................13

APPENDICES

APPENDIX 1 : EC conformity declaration for TLU600.........................................................16

TLU 600/610

Page 3/20

NOSP 14540-04 (JULY 2011)

1.

1.1.

1. INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

The TLU 600/610 remote controller is a portable terminal communicating with the

SI TRONICS D iTT, D ITO, D TX, D TK, D TT, D TV of the series 60, 61, 62, 63, 64 and 65,

TI 40 (IREX) and TV 50 (UVIR) family of remote sensors and the D IRT, D IRO, D RX, D RK,

D RT et D RV family of SI TRONICS network remote sensors of the series 60, 61, 62, 63, 64

and 65.

The remote controller is intrinsically safe for use in explosive areas.

1.1.

1.1.1.1.

1.1. I

II

I

DENTIFICATION AND A

DENTIFICATION AND ADENTIFICATION AND A

DENTIFICATION AND ARKING

RKINGRKING

RKING

odel TLU 600 displays European (ASCII) characters, whilst model TLU 610 displays the

Cyrillic alphabet.

The manufacturer’s label, located at the back of the battery compartment, carries the

following information:

-anufacturer: SI TRONICS

-odel: TLU 600 (European) or TLU 610 (Cyrillic display)

Figure

Figure Figure

Figure 1

11

1: TLU Label

: TLU Label: TLU Label

: TLU Label

TLU 600/610

Page 4/20

NOSP 14540-04 (JULY 2011)

1.2.

1.2.1.2.

1.2. F

FF

F

UNCTIONS

UNCTIONSUNCTIONS

UNCTIONS

The TLU 600/610 universal remote controller is used to exchange data with the remote

sensor. This dialogue is based on a tree of on-screen menus and the use of function

keys.

It simplifies every operation connected with maintenance, calibration, etc. The amount of

usable functions will depend upon the remote sensor involved. For example, with the

D ITT, D ITO, D TT, D TX and D TK family of remote sensors, the remote controller

can be used to calibrate, read current status, measure current, etc. For the flame

detector, the remote controller can be used to stimulate a flame detection.

Similarly, the language used in these exchanges (French, English, etc.) will be that used

by the remote sensor (except for the welcome screens).

From the Serie 63 of remote sensor, functions are password protected through various

levels. The pass word used for the switching on of remote controller gives access to

authorized functions.

The remote sensor and remote controller communicate by an infra-red link.

Communication is therefore always by “line of sight”, i.e. there must be no obstacle

between the remote sensor and the remote controller.

The average communication distance is about 6 meters.

TLU 600/610

Page 5/20

NOSP 14540-04 (JULY 2011)

1.3.

1.3.1.3.

1.3. R

RR

R

E O

E OE O

E OTE CONTROLLER CONSTR

TE CONTROLLER CONSTRTE CONTROLLER CONSTR

TE CONTROLLER CONSTRUCTION

UCTIONUCTION

UCTION

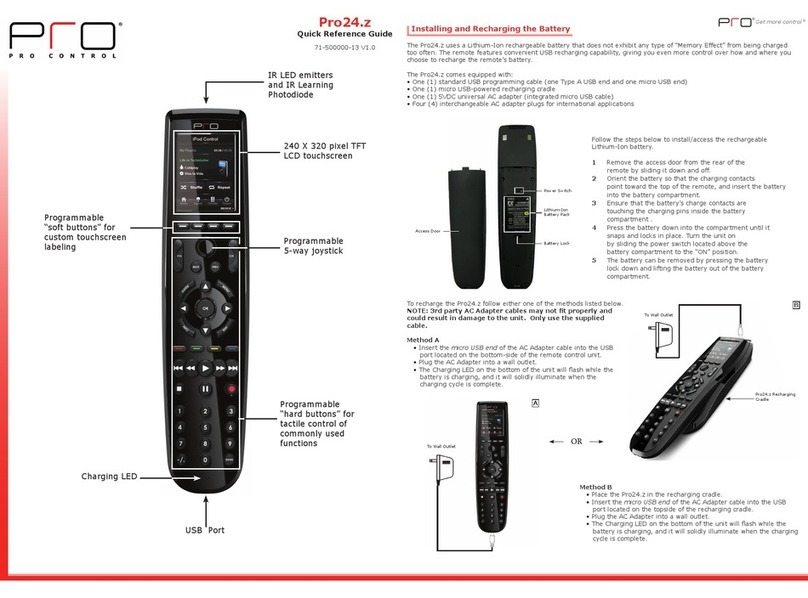

The remote controller includes:

-a case,

-a back-lit LCD screen displaying 4 lines of 20 characters,

-internal electronics,

-a buzzer,

-a battery unit compartment,

-a keypad with 18 keys including four function keys.

A charger is supplied with the remote controller.

Back-lit

LCD screen

4 lignes X

20 characters

case

4 function

keys

Central matrix

of 12 keys

Screen back-light

Control button

and ON/OFF

écran

button

Figure

Figure Figure

Figure 2

22

2:

: :

: the remote controller

the remote controllerthe remote controller

the remote controller

TLU 600/610

Page 6/20

NOSP 14540-04 (JULY 2011)

The case is made up of two parts: the cover which carries the keypad, the main body

which carries the LCD screen, electronics and charger connector, and the battery

compartment.

The case has an infra-red communication window at the front and a charger connector

socket on the left-hand side.

The parts are assembled using cross-head self-tapping screws and the waterproofness

is assured by charged seals graphite.

Figure

Figure Figure

Figure 3

33

3:

::

:

the remote controller key pad

the remote controller key padthe remote controller key pad

the remote controller key pad

The lower left button controls the backlighting of the LCD screen.

The lower right button is the remote controller ON/OFF.

The four functions keys are labelled

F1

,

F2

,

F3

and

F4

.

120

227

TLU 600/610

Page 7/20

NOSP 14540-04 (JULY 2011)

The central matrix comprises 12 keys: 0 to 9, comma and enter. Keys 2, 4, 6 and 8 are

dual-function, acting also as up, down, right and left arrows.

2.

2.2.

2. CERTIFICATION

CERTIFICATIONCERTIFICATION

CERTIFICATION

The equipment was designed and built to comply with the European directive 94/9/CE for

products able to work in explosive atmosphere (usually called ATEX directive) which, for the

certified devices is shown on the label by the symbol , the class of protection and the

approval number obtained by a certified laboratory.

The compliance with this directive was obtained by the application of the following harmonized

standards:

EN 60079-0 / IEC 60079-0

EN 60079-11 / IEC 60079-11

The equipment is also IEC Ex certified on the basis of the following standards:

IEC 60079-0

IEC 60079-11

TLU 600/610

Page 8/20

NOSP 14540-04 (JULY 2011)

3.

3.3.

3. OPERATION

OPERATIONOPERATION

OPERATION

3.1.

3.1.3.1.

3.1. S

SS

S

WITCHING ON

WITCHING ONWITCHING ON

WITCHING ON

The remote controller is switched ON by pressing the ON/OFF key at the bottom right of

the key pad (see Figure 2). The remote controller then runs a self-test routine. The

character set is then displayed on the LCD screen, then gives access to the menus.

3.2.

3.2.3.2.

3.2.

PASS WORD

PASS WORDPASS WORD

PASS WORD

From the Serie 63 (A type in the new references system), two safety levels protect the

remote sensor functions:

-Level 1 called "USER"

-Level 2 called " AINTENANCE"

The remote controller are despatched with the following pass words :

-Level 1 "USER" : one press at the bottom "enter"

-Level 2 " AINTENANCE" "012345"

You can change the pass words. Their length is possible between 0 and 6 characters. You

can valid the pass word pressing the bottom "enter" (the only one bottom to press in the

case of 0 character).

3.2.1.

3.2.1.3.2.1.

3.2.1. C

CC

C

O PATIBILITY WITH TH

O PATIBILITY WITH THO PATIBILITY WITH TH

O PATIBILITY WITH THE OLD FA ILY BEFORE

E OLD FA ILY BEFORE E OLD FA ILY BEFORE

E OLD FA ILY BEFORE THE

THE THE

THE

S

SS

S

ERIE

ERIE ERIE

ERIE

63

6363

63

Remote sensors before the Serie 63 are not protected with the safety levels.

Whatever the pass word entered in the remote controller, the remote sensor gives

access to the menus.

TLU 600/610

Page 9/20

NOSP 14540-04 (JULY 2011)

3.3.

3.3.3.3.

3.3.

ENU

ENUENU

ENU

To go to menus of the remote controller, a pass word has to be entered. Then it is

possible to go to all or a part of the following menus.

The following figure gives an overview of the various menus:

Autotest Screen

ICARE TLU600 r3.0

Code :______ ENTER

Autotest OK

SCAN | ADJT | |

ICARE TLU600 v3.0

>>>>>>>>>>>>>

Access level

| | |

CONNEXION

1 :SENSOR 1 ZONE 1

2 :SENSOR 2 ZONE 1

SELEC:1..9|FORW|SCAN

In case of

Sensor Answer

In case of 1,2,….

MODE REMOTE

ADJUSTMENT

CODE | LANG| << | ESC

LANGUAGE SELECTION

Current Language

English

FRAN|ENGL| << | ESC

CODE CHANGEMENT

LEV1 | LEV2 | << | ESC

CODE CHANGEMENT

New code

:

>Confirm :

VAL | | << | ESC

CODE CHANGEMENT

Wrong code

| | << | ESC

In case of

correct code

TLU 600/610

Page 10/20

NOSP 14540-04 (JULY 2011)

3.3.1.

3.3.1.3.3.1.

3.3.1. L

LL

L

ANGUAGE CHOICE

ANGUAGE CHOICEANGUAGE CHOICE

ANGUAGE CHOICE

To change the language of the remote controller :

-Go to the menu Setting/Language

-Choose English or French, then go out the menu pressing at the bottom "Esc" or

"«". The remote sensor will recognize automatically the language from the Serie

63.

3.3.2.

3.3.2.3.3.2.

3.3.2. P

PP

P

ASS WORD ODIFICATIO

ASS WORD ODIFICATIOASS WORD ODIFICATIO

ASS WORD ODIFICATION

NN

N

To change the pass word :

-Go to the Setting/Code

-Choose the access level to modify

-To be valid the pass word has to be entered twice

3.3.3.

3.3.3.3.3.3.

3.3.3. C

CC

C

ONNECTION TO SENSOR

ONNECTION TO SENSORONNECTION TO SENSOR

ONNECTION TO SENSOR

To connect to a sensor :

-Go to Scan enu

-After the questioning phase, the remote controller displays the sensor list which

answered

-Select a sensor with its number or launch again a Scan

When a sensor is selected, the remote control goes in RE OTE mode. The menus

which appear are those of the selected télécapteur.

C O N N E X I O N

1 G D 0 0 1

S E L : 1 . . 9 | F O R W

| S C A N

Figure

Figure Figure

Figure 4

44

4:

: :

:

connection established screen

connection established screenconnection established screen

connection established screen

In this example, the remote sensor carrying the label GD001 has been recognised by the

remote controller.

The label is an 8 character identity chosen by the customer and allocated to the remote

sensor during its manufacture in the SI TRONICS factory.

Press key 1 to begin the dialogue with this remote sensor.

It may be that there is more than one sensor in the remote controller’s field of view. A

list of them will then appear on the screen as shown below:

C O N N E X I O N

1 : G D 0 0 1

2 : D M T V 6 5

S E L : 1 . . 9 | F O R W

| S C A N

Figure

Figure Figure

Figure 5

55

5:

: :

: connection to multiple sensors screen

connection to multiple sensors screenconnection to multiple sensors screen

connection to multiple sensors screen

TLU 600/610

Page 11/20

NOSP 14540-04 (JULY 2011)

Press function key F3 (FORW) to view the next remote sensor.

Each line is numbered. Press the key for that line number (1 to 9) to communicate with

the corresponding remote sensor.

Up to this point, the menus have been in French. From this point onwards, the language

used will be that programmed into the remote sensor (French, English, etc.).

A green LED in the remote sensor’s infra-red head will, until this point, have been

flashing at a frequency of about 0.5 Hz. From the moment you select this remote sensor,

the flashing rate will increase to 1 Hz to indicate that communication has been

established and will remain at this frequency throughout the dialogue. This makes it

easier to identify the selected sensor, and shows that communication is taking place.

3.4.

3.4.3.4.

3.4.

PICTOGRA S

PICTOGRA SPICTOGRA S

PICTOGRA S

A number of symbols called pictograms are used to simplify TLU 600/610 operation.

These pictograms appear in the right-hand column (20

th

column of the screen).

3.4.1.

3.4.1.3.4.1.

3.4.1. C

CC

C

HARGE INDICATOR

HARGE INDICATORHARGE INDICATOR

HARGE INDICATOR

:

::

:

"

""

"

"

""

"

When the battery is charging, the " " pictogram appears on the right of the screen

as shown below:

Figure

Figure Figure

Figure 6

66

6:

: :

: battery charging indicator

battery charging indicatorbattery charging indicator

battery charging indicator

3.4.2.

3.4.2.3.4.2.

3.4.2. L

LL

L

OW BATTERY LEVEL IND

OW BATTERY LEVEL INDOW BATTERY LEVEL IND

OW BATTERY LEVEL INDICATOR

ICATORICATOR

ICATOR

:

::

:

"

""

"

"

""

"

When battery voltage falls to its lower limit, the " " pictogram appears on the

right of the screen as shown below:

Figure

Figure Figure

Figure 7

77

7:

: :

: low battery level indicator

low battery level indicatorlow battery level indicator

low battery level indicator

The battery must then be recharged using the charger supplied. (see chapter 3.4.5:

Battery recharging, page 13).

Do not continue to use the remote controller longer than half an hour after this

symbol first appears without recharging the battery. To do so could damage the

battery unit.

TLU 600/610

Page 12/20

NOSP 14540-04 (JULY 2011)

3.4.3.

3.4.3.3.4.3.

3.4.3. C

CC

C

ONNECTION INDICATOR

ONNECTION INDICATORONNECTION INDICATOR

ONNECTION INDICATOR

:

::

:

"

""

"

"

""

"

Once dialogue with the sensor has been established, the " " pictogram appears on

the right of the screen. It remains on-screen until the connection is broken.

Figure

Figure Figure

Figure 8

88

8:

: :

: connection

indicator

indicatorindicator

indicator

The connection may be broken in two ways:

∗Using the

FCNX

(End connection) menu. This is the normal way to end

communication with a remote sensor.

∗You have moved your remote controller away from the sensor for more than 3

minutes. The remote sensor has closed the connection because it assumes that

you have forgotten to use the

FCNX

menu to end the dialogue.

Once the connection is broken, the green LED on the remote sensor returns to

flashing at around 0.5 Hz.

3.4.4.

3.4.4.3.4.4.

3.4.4. T

TT

T

ARGETING INDICATOR

ARGETING INDICATORARGETING INDICATOR

ARGETING INDICATOR

:

::

:

"

""

"

",

",",

",

"

""

"

"

""

"

Once dialogue is established with the remote sensor (connection indicator " " is

displayed), the targeting indicator lets you know the quality of communication with

the remote sensor.

When the " " symbol is displayed, the quality of communication is excellent.

Figure

Figure Figure

Figure 9

99

9:

: :

: good communication indicator

good communication indicatorgood communication indicator

good communication indicator

When the " " symbol replaces the one referred to above, communication is

becoming difficult. If there is no indication, communication has been lost. If this

happens, move closer to the remote sensor and make sure you are pointing the

remote controller directly at it. If the sun is shining directly at the remote controller,

you may need to shade the infra-red communication window at the front of the

controller.

TLU 600/610

Page 13/20

NOSP 14540-04 (JULY 2011)

Figure

Figure Figure

Figure 10

1010

10:

::

:

poor communication indicator

poor communication indicatorpoor communication indicator

poor communication indicator

3.4.5.

3.4.5.3.4.5.

3.4.5. B

BB

B

ATTERY RECHARGING

ATTERY RECHARGINGATTERY RECHARGING

ATTERY RECHARGING

Only the charger supplied with the remote controller is to be used to recharge the

battery; using any other charger risks permanent damage to the remote controller.

It carries the label TLU600.

NEVER CHARGE THE BATTERY IN AN EXPLOSION RISK AREA.

The charger must never be used in an explosion risk area, nor must the remote

controller when it is on charge.

To ensure optimum battery life, you should wait until the low battery charge

indicator ( ) appears and then recharge completely over.

The charger of the TLU600 is an automatic charger with fast load adapted specially.

CHARGER

MAINS

220 Vac

Figure

Figure Figure

Figure 11

1111

11:

::

:

charging connection

charging connectioncharging connection

charging connection

∗Connect the charger with the main 100-240V AC 50-60Hz. The LED gets clearer

in yellow (not connected battery)

∗Connect the charger with the remote controller. The LED remains yellow

during some seconds during the initialization and test phase.

∗The LED gets clearer in orange during the fast charge which can last till two

hours.

∗Switching in compensation charge, green/yellow blinking

∗Switching in slow charge, the LED gets clearer in green when the battery is

charged.

In case of emergency, it’s possible to interrupt the fast load to use the remote

controller, but with a reduced battery capacity.

TLU 600/610

Page 14/20

NOSP 14540-04 (JULY 2011)

The battery can be subjected at some hours of slow load, without damage, but the

permanent charge is not advised.

The energy source of the remote controller is a moulded block Ni H 7.2V nominal,

1800 mAh, joining safety elements and carrying the label bellow

In case of failure of the block battery, it’s necessary to replace the block by a same

block battery, only supplied by Simtronics, to keep the ATEX protection

3.4.6.

3.4.6.3.4.6.

3.4.6. B

BB

B

ACK

ACKACK

ACK

-

--

-

LIGHTING

LIGHTINGLIGHTING

LIGHTING

The remote controller is fitted with a screen back-lighting system which provides

excellent legibility regardless of ambient lighting conditions.

Back-lighting can be turned on and off using the button at the bottom left of the

remote controller (see Figure 2, page 5).

3.4.7.

3.4.7.3.4.7.

3.4.7. A

AA

A

UTO ATIC CUT

UTO ATIC CUTUTO ATIC CUT

UTO ATIC CUT

-

--

-

OFF

OFFOFF

OFF

The remote controller has an automatic cut-off system to conserve battery life.

This system is activated 3 minutes after the last key press or whenever the

connection to a remote sensor has been broken for over 3 minutes.

TLU 600/610

Page 15/20

NOSP 14540-04 (JULY 2011)

4.

4.4.

4. TECHNI

TECHNITECHNI

TECHNICAL SP

CAL SPCAL SP

CAL SPECIFICATIONS

ECIFICATIONSECIFICATIONS

ECIFICATIONS

•Operating temperature: -20°C to 50°C,

•Self-powered operation: 4 hours,

•Power supply: Rechargeable Ni H batteries,

•Dimensions (maxima): 230 Long x 120 Wide x 70 Deep,

•Weight: 0.85 kg.

5.

5.5.

5.

AINTENANCE

AINTENANCEAINTENANCE

AINTENANCE

To be done out of ATEX area

5.1.

5.1.5.1.

5.1. C

CC

C

LEANING

LEANINGLEANING

LEANING

Take care not to scratch the infra-red communication window.

5.2.

5.2.5.2.

5.2. C

CC

C

HANGING A BATTERY UN

HANGING A BATTERY UNHANGING A BATTERY UN

HANGING A BATTERY UNIT

ITIT

IT

To change the battery unit:

-remove the battery compartment by undoing the 6 cross-head screws.

-Disconnect the link connector.

-Change the unit.

-Reconnect the link cord making sure the connector is the right way round.

-Coil the cord into the space between the body and the battery unit.

-Refit the compartment using the 6 screws, taking care to avoid pinching the wires or

damaging the waterproof seals.

6.

6.6.

6. PACKAGING AND

PACKAGING AND PACKAGING AND

PACKAGING AND TRANSPORT

TRANSPORTTRANSPORT

TRANSPORT

Whenever the equipment is to be transported (for repair, etc.), it is advisable to pack the

remote controller and its accessories in their original packaging.

7.

7.7.

7. S

SS

STORAGE

TORAGETORAGE

TORAGE

Store the remote controller in a dry, dust-free area at a temperature in the range -25 to

+50°C.

TLU 600/610

Page 16/20

NOSP 14540-04 (JULY 2011)

APPENDIX

APPENDIX APPENDIX

APPENDIX 1

11

1

: EC conformity declaration for TLU600

: EC conformity declaration for TLU600: EC conformity declaration for TLU600

: EC conformity declaration for TLU600

TLU 600/610

Page 17/20

NOSP 14540-04 (JULY 2011)

TLU 600/610

Page 18/20

NOSP 14540-04 (JULY 2011)

TLU 600/610

Page 19/20

NOSP 14540-04 (JULY 2011)

8.

8.8.

8. CONTACT DETAILS

CONTACT DETAILSCONTACT DETAILS

CONTACT DETAILS

You will find an updated list of distributors on our web pages:

www.simtronics.eu

Email address for general enquiries: mail@simtronics.no

Simtronics ASA

Kabelgaten 8, Økern Næringspark

PO Box 314, Økern, NO-0511 Oslo, Norway

Tel: +47 2264 5055

Simtronics SAS

792, av de la Fleuride

BP 11016, 13781 AUBAGNE CEDEX – FRANCE

Tel: +33 (0) 442 180 600

This manual suits for next models

1

Table of contents

Popular Remote Control manuals by other brands

Danfoss

Danfoss Ikompact user manual

Remote Control Systems

Remote Control Systems ARGYLE C38 manual

Evolve Communications

Evolve Communications GUIDE Remote RD5000 user manual

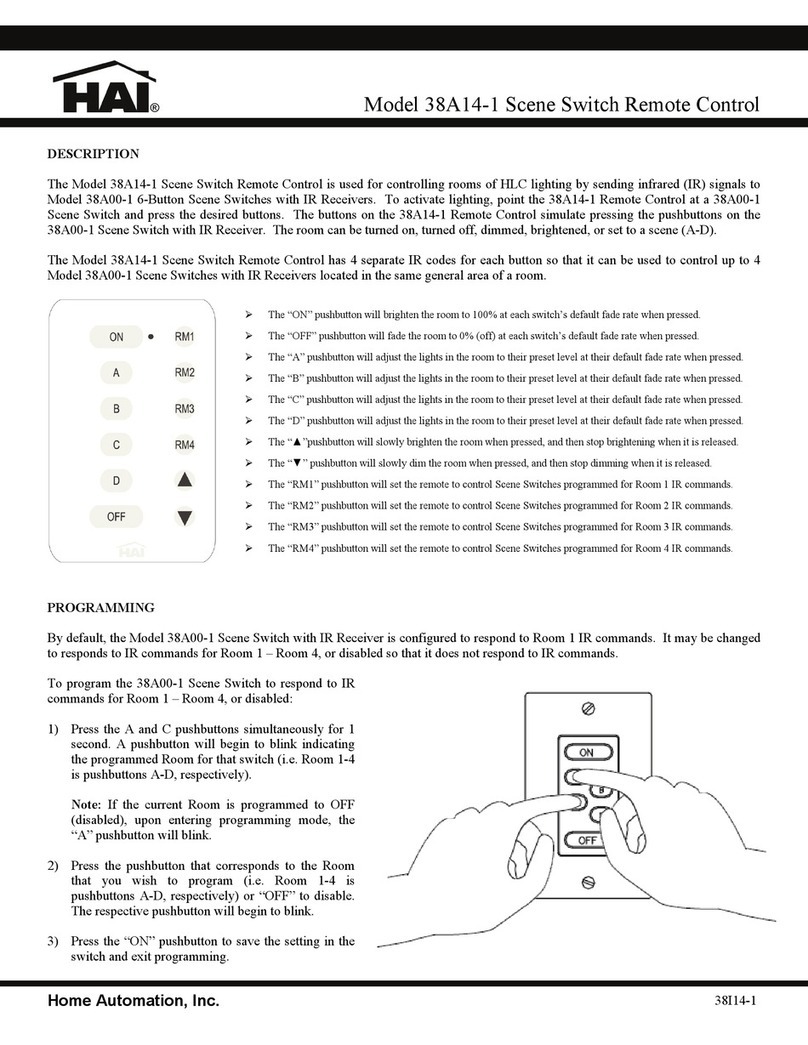

Home Automation

Home Automation 38A14-1 manual

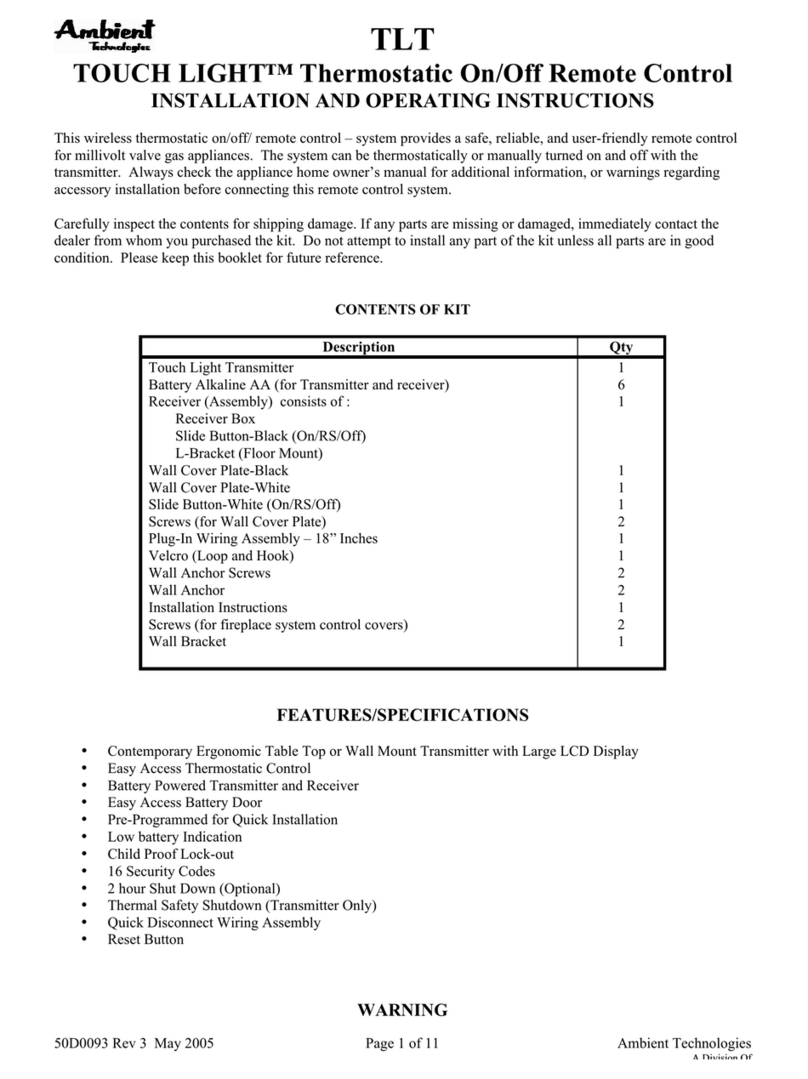

Ambient

Ambient TOUCH LIGHT Nstallation and operating instructions

Philips

Philips SBCRU631/87 user manual