Sinexcel PWS1-500K Series User manual

Operating Manual

PWS1-500K Series Energy Storage PCS

1

Sinexcel

PWS1-500KTL-EX-1M/2M/3M/4M/5M/6M/7M/8M

PWS1-500KTL-EX-M1/M2/M3/M4/M5/M6/M7/M8

Series Bi-direc ional Energy S orage PCS

Opera ing Manual

Version: V2.1

Shen hen Sinexcel Electric Co., Ltd.

All rights reserved. In case of any content change, it shall be without prior notice.

Shen hen Sinexcel Electric Co., Ltd.

Website: http://sinexcel.us/ or www.sinexcel.com

Add: Building 6, Area 2, Baiwangxin High-tech Industrial Park, No. 1002, Songbai Road, Nanshan District,

Shen hen

Postcode: 518055

Hotline: +86 0755-8651-1588

2

Table of Con en s

1 Information on this Document.................................................................................................................... 4

1.1 Validity ............................................................................................................................................... 4

1.2 Target Group ...................................................................................................................................... 4

1.3 Nomenclature Terms and abbreviations ................................................................................................ 5

2 Safety Precautions ..................................................................................................................................... 6

2.1 Symbols ............................................................................................................................................. 6

2.2 Important Safety instructions ............................................................................................................... 7

2.3 Additional Information ......................................................................................................................... 8

3 Product Introduction.................................................................................................................................. 9

3.1 System Introduction ............................................................................................................................ 9

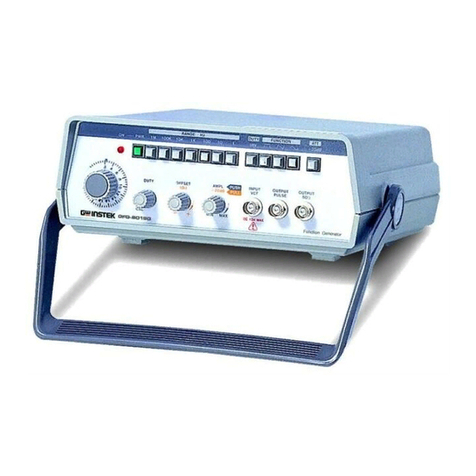

3.2 PCS Appearance ................................................................................................................................. 9

3.3 System Schematic Diagram ................................................................................................................. 9

3.4 PCS Composition ............................................................................................................................... 11

3.5 Operating Compositions .................................................................................................................... 12

3.5.1 Switches Introduction ................................................................................................................. 12

3.5.2 Touch Screen ............................................................................................................................. 13

3.5.3 LEDs of the System .................................................................................................................... 14

3.5.4 Labels ........................................................................................................................................ 15

4 Technical Data ........................................................................................................................................ 17

5 Storing, lifting and transporting ................................................................................................................ 23

5.1 Safety during Transport ..................................................................................................................... 23

5.2 Transporting the PCS ......................................................................................................................... 23

5.2.1 Transport and storage ................................................................................................................. 23

5.3 Unpacking the PCS ............................................................................................................................ 23

6 Installation ............................................................................................................................................. 24

6.1 Safety during Installation ................................................................................................................... 24

6.2 Mechanical Installation ...................................................................................................................... 25

6.2.1 Mounting preparation .................................................................................................................. 25

6.2.2 Preparation for Mounting on a Base ............................................................................................. 26

6.3 Electrical Connections ....................................................................................................................... 26

6.3.1 Input requirement ...................................................................................................................... 26

6.3.2 Output requirement .................................................................................................................... 27

6.3.3 Wiring mode .............................................................................................................................. 27

6.3.4 System grounding ....................................................................................................................... 34

6.3.5 DC port wiring ............................................................................................................................ 34

6.3.6 AC port wiring ............................................................................................................................ 35

6.3.7 Wiring of terminal strips .............................................................................................................. 35

6.4 Communication interface connection .................................................................................................. 38

6.4.1 Connecting the EMS over RS485 or Ethernet ................................................................................ 38

6.4.2 Connecting a BMS over CAN ........................................................................................................ 39

6.5 Check after installation ...................................................................................................................... 40

7 Function Description ................................................................................................................................ 41

7.1 Operating Status ............................................................................................................................... 41

7.1.1 Overview of the Operating Status ................................................................................................ 41

7.1.2 Operating States without STS ...................................................................................................... 42

8 Operation ............................................................................................................................................... 43

8.1 Safety during Operation .................................................................................................................... 43

8.2 Power On Procedure ......................................................................................................................... 43

3

8.3 Setting Procedure before startup ....................................................................................................... 44

8.3.1 Touch screen power on ............................................................................................................... 44

8.3.2 Log into the control Interface ...................................................................................................... 45

8.3.3 Select Control Mode .................................................................................................................... 45

8.3.4 General Settings ......................................................................................................................... 46

8.3.5 Communication setting ............................................................................................................... 46

8.4 Manual Startup Procedure ................................................................................................................. 46

8.5 Automatic Startup Procedure ............................................................................................................. 47

8.6 Remote Startup Procedure ................................................................................................................. 47

8.7 Shutdown Procedure ......................................................................................................................... 47

8.8 System Power Off ............................................................................................................................. 47

8.9 Emergency shutdown ........................................................................................................................ 47

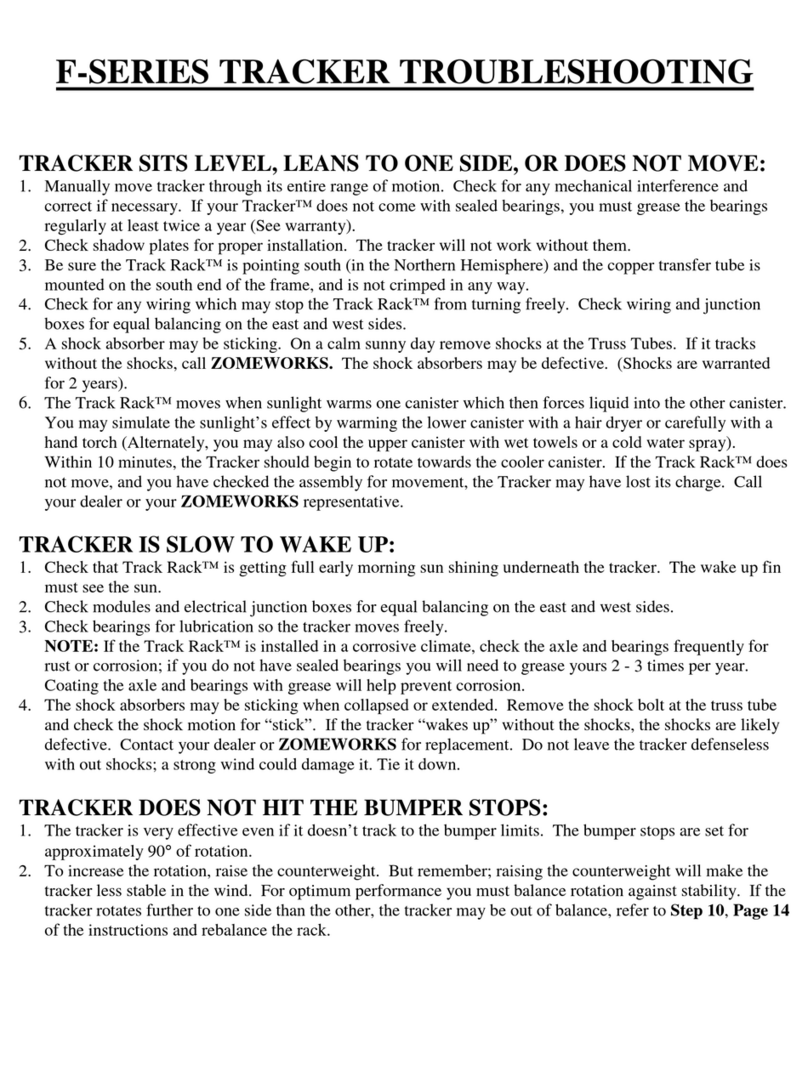

9 Troubleshooting ...................................................................................................................................... 48

9.1 Safety during Troubleshooting ........................................................................................................... 48

9.2 Export fault record ............................................................................................................................ 48

9.3 Faults caused by improper parameter settings .................................................................................... 48

9.4 Detailed Troubleshooting ................................................................................................................... 49

10 Maintenance ......................................................................................................................................... 50

10.1 Safety during Maintenance .............................................................................................................. 50

10.2 Maintenance Schedule and Consumables .......................................................................................... 50

10.2.1 Operation environment requirements ......................................................................................... 50

10.2.2 Electrical and fixed connection inspection ................................................................................... 51

10.2.3 Clearing and cleaning ................................................................................................................ 51

10.3 Maintenance Work .......................................................................................................................... 51

11 Contact ................................................................................................................................................. 52

Appendix 1 Settings on HMI (Touch Screen) ................................................................................................ 53

12.1 Touch Screen Startup ...................................................................................................................... 53

12.1.1 Main Menu Structure before log-in ............................................................................................. 53

12.1.2 Log into the control Interface .................................................................................................... 54

12.2 Main Menu Structure after log-in.................................................................................................... 55

12.3 Control Mode Setting ....................................................................................................................... 56

12.4 Parameter Setting ........................................................................................................................... 56

12.4.1 Settings Menu .......................................................................................................................... 56

12.5 Common Setting ............................................................................................................................. 62

12.5.1 Language Selecting ................................................................................................................... 62

12.5.2 Date and Time Selecting ........................................................................................................... 62

12.5.3 Communication setting .............................................................................................................. 62

12.5.4 AC settings ............................................................................................................................... 62

12.5.5 DC settings ............................................................................................................................... 64

12.5.6 Regulating the reactive power of the ESS AC port in on-grid mode .............................................. 65

12.6 System Setting ................................................................................................................................ 66

12.6.1 General Setting ......................................................................................................................... 67

12.7 Manual Startup ............................................................................................................................... 67

12.8 Automatic startup ........................................................................................................................... 68

12.9 Remote startup ............................................................................................................................... 68

12.10 Shutdown procedure ..................................................................................................................... 68

12.11 System Power Off .......................................................................................................................... 69

12.12 Emergency shutdown .................................................................................................................... 69

Appendix 2 Limited Warranty Policy ............................................................................................................. 70

4

1 Informa ion on his Documen

1.1 Validi y

This document is valid for the following device models with or without STS module:

• PWS1-500K

• PWS1-500KTL

• PWS1-500KTL-EX-1M/2M/3M/4M/5M/6M/7M/8M

• PWS1-500KTL-EX-M1/M2/M3/M4/M5/M6/M7/M8

Model defini ion

This section introduces product model definition in this operating manual, as shown in Fig. 1-1:

PWS

1

-

500

KTL

-

EX

-

XM

Rated Power

:

500K

500KTL: 500K Transformerless

500K: 500K with transformer

Bi-directional Energy Storage PCS

EX: For Europ and other country

XM: Module number

MX

:

DC input number

Fig.1-1 Product model definition

For example:

PWS1-500KTL: 500kW Bi-directional storage inverter without isolation transformer.

PWS1-500K: 500kW Bi-directional storage inverter with isolation transformer.

Check the type label for the production version of PCS.

The illustrations in this document have been reduced to be necessary and may differ from the real product.

1.2 Targe Group

The tasks described in this document can only be performed by professionals or other qualified persons.

Qualified persons must have the following skills

:

• Understand how the product works and how to operate the product

• Understand how the battery works and how to operate the battery

• Training on how to deal with the ha ards and risks associated with installing and using electrical

equipment installation

• Installation and commissioning of electrical equipment and installations

• Understand all applicable standards and directives

• Understand and follow this manual and all safety information

5

1.3 Nomencla ure Terms and abbrevia ions

Terms Definition

STS Static Transfer Switch

AC Alternative current.

DC Direct current.

BESS Battery energy storage system

ESS Energy storage system.

EMS Energy management system.

BMS Battery management system.

PCS Power conversion system.

SLD Single line diagram

SOH State of health (of battery), expressed in percentage.

SCR Silicon controlled rectifier

DOD Depth of discharge, the rest battery capacity, expressed in percentage.

EOD End of discharging.

SOC State of charge (of battery).

UI User Interface

EPO Emergency Power Off

SPD Surge Protecting Device

6

2 Safe y Precau ions

2.1 Symbols

NO.

Symbol Reference Standard Description

1

IEC 60417-5036

IEC 60417-5416

Note the shock ha ard,

energy storage time

release (discharge time

is marked next to the

symbol)

2

ISO 7000-0434 Watch out for danger

3

IEC 60417-5041 Watch out for hot

surface

4

ISO 7000-1641

Refer to the operation

manual

Symbol

Explanation

Indicates a dangerous situation that, if not avoided, will result

in death or serious injury

Indicates a dangerous situation that, if not avoided, will result

in death or serious injury

7

Indicates a dangerous situation that, if not avoided, may result

in minor or moderate injury

Indicates that if property damage is not avoided

Draw attention to important information, best practices and tips

NOTE is used to address information that is not related to pers

onal injury, equipment damage, and environmental degradation.

2.2 Impor an Safe y ins ruc ions

This user’s manual is about installation and operation of Sinexcel PWS1 series 500kW Bi-directional Energy

Storage Inverter (PCS).

Before installation, please read this user’s manual carefully.

The PCS must be commissioned and maintained by the engineers designated by the manufacturer or the

authori ed service partner. Otherwise, it might endanger personal safety and result in device fault. Any

damage against the device caused thereby shall not be within the warranty scope.

The PCS cannot be used for any circumstance or application related to life support device.

This manual contains important instruction for Models of PWS1 series that shall be followed during

installation and maintenance of the PCS.

Any contact with copper bar, contactor and terminal inside the device or connected with the loop of utility

grid might result in burning or fatal electric shock.

Don’t touch any terminal and conductor connected with the loop of utility grid.

Pay attention to any instruction and safety documents about power on-grid.

There might be an electric shock risk inside the device!

Any operation related to this device will be conducted by professionals.

Pay attention to the safety precautions listed in safety instruction and installation documents.

Pay attention to the safety precautions listed in operating and installation manual and other documents.

Large leakage current

Before connecting input power supply, please ensure that the grounding is reliable.

The device must be grounded complying with the local electric codes.

8

When storage battery is connected to PCS, there may be DC voltage at input port. Please pay attention to it

during operation or check the battery system user manual

Don’t touch electric parts within 15 minutes after power outage!

There is dangerous energy in capacitance storage. Don’t touch device terminal, contactor and cooper bar

and other electric parts within 15 minutes after disconnecting all device power supplies.

All maintenance and preservation inside the device require using tools and shall be conducted by trained

person. The components behind the protective cover plate and dam board which are opened by tools cannot

be maintained by users.

Please read this user’s manual before operation.

2.3 Addi ional Informa ion

Links to additional information can be found at http://sinexcel.us/ or www.sinexcel.com.

9

3 Produc In roduc ion

3.1 Sys em In roduc ion

The [PWS1-500K series Bi-directional Storage Inverter (PCS)] is a battery power conversion system that

converts the DC (direct current) supplied by a battery into grid-compliant AC (alternating current). An

[external] low voltage transformer fitted downstream feeds the AC (alternating current) into the utility grid.

This kind of PCS can be used in the on-grid mode and off-grid mode. The model with STS can get the faster

switching between on-grid and off-grid mode.

The [PWS1-500K series Bi-directional Storage Inverter (PCS)] can be used in off-grid systems based on

diesel generators (Gensets).

3.2 PCS Appearance

3

1

2

Figure3- 1: Design of the PCS

Position

Designat

ion

1 Indicator light

2 HMI(Touch Screen)

3 EPO (Emergency Power Off)

3.3 Sys em Schema ic Diagram

PWS1-500K Bi-directional Storage Inverter (PCS) is composed of 8 PCS-AC modules. The modules identify

master-slave systems through the DIP switch dial-up codes on the panel. #1 is a master system, while other

modules track the master system. The Bi-directional Storage Inverter (PCS) cabinet is equipped with SPD

protector, AC/DC breaker and distribution units. If on/off-grid switching is to be achieved, extra power

distribution unit needs to be added. Fig.3-2 is a topological graph for its composition and structure.

10

L1

L2

L3

N

AC SwitchDC Switch 1

AC SPD

Battery

-

PCS-AC, n=1~8

·······

PCS-AC 1

PCS-AC n

Grid

Fig. 3-2 Topological graph for Bi-directional Storage Inverter (PCS) with 1 branch input

DC Switch n

Battery

-

DC Switch

1

Battery

-

L

1

L

2

L

3

…

…

PCS-AC, n=1~8

…

…

PCS-AC 1

PCS-AC n

AC Switch

AC SPD

Grid

DC Switch, n=1~8

Fig. 3-3 Topological graph for Bi-directional Storage Inverter (PCS) with 1/2/3/4/5/6/7/8 branch input

Both models have identical mechanical and electrical construction except composed of different sets of

PCS-AC modules and rating:

For PWS1-500K series is composed of 8 sets of PCS-AC modules, the special model with different number of

DC branch switches from 1 to 8.

Main composition of PWS1-500K PCS rack is shown in Table.3-2.

Table 3-2 Main composition of the PCS rack

Serial No. Item Quantity Remark

1 Cabinet set The cabinet is equipped with distribution

11

components.

2 PCS-AC module 8 set(s)

3 Power Management Unit 1 set It is installed in the cabinet door.

3.4 PCS Composi ion

3

1

2

5

4

10

7

8

9

6

5

4

10

7

8

9

6

Figure3-3: Visible Components of the PCS without STS module with STS module

Position Designation Description

1 Indicator lights

2 Touch Screen

3 EPO (Emergency Power Off)

4 PCS-AC (1~8 module(s)) 62.5KW 1 set

5 Battery DC Branch Switch 1 to 8 set DC Branch Switch

6 U2 Main control board

7 AC Switch

8 Wiring terminal

9 SPD switch

10 AUX Power supply switch

Components position 8 Wiring Terminal, 9 SPD switch, 10 AUX power supply switch can be seen after unfold

the dam-board.

12

3.5 Opera ing Composi ions

3.5.1 Swi ches In roduc ion

3.5.1.1 AC swi ch

The AC disconnection unit disconnects the PCS from the Grid. The NA series PCS breaker is comply to the UL

certification.

I

O

▽

▽▽

▽

Figure 3-4: Switch positions of the AC disconnection unit

Position Designation Explanation

I Switch position In (On) The AC disconnection unit is closed.

▽

Central switch position The AC disconnection unit was tripped and is open.

O Switch position off The AC disconnection unit is open.

3.5.1.2 DC Swi ch

The DC disconnection unit disconnects the PCS from the Battery module arrays. The NA series PCS breaker

is comply to the UL certification.

I

O

▽

▽▽

▽

Figure 3-5: Indicators on the DC load-break switch

Position Designation Explanation

I Switch position In (On) The DC disconnection unit is closed.

▽

Central switch position The DC disconnection unit was tripped and is open.

O Switch position off The DC disconnection unit is open.

13

3.5.1.3 AUX power supply AC Swi ch

220Vac AUX power supply can be the redundancy power supply through the AC Switch inside the PCS

cabinet. These switches can be visible after opening the dam-board.

AUX power supply switch

SPD switch

Figure 3-6: AUX power supply AC Switch and SPD switch

3.5.2 Touch Screen

3.5.2.1 User In erface

The touch display is used to display instantaneous values and parameter settings. Click the touch screen

with fingernail. Tapping the symbols on the touch display activates the corresponding functions. If the touch

display has not been touched for

【

ten

】

minutes, the display is locked and the logged-in user will be logged

out. By tapping the screen unlock the display again.

The touch display is divided into two areas.

A

B

C

Figure 3-7 UI Design of the touch display

14

Position Designation Explanation

A Menu Menu can be different before/after log-in and other setting.

B System Topology

C Version and time

3.5.2.2 Symbols Explana ion

Symbol Designation

Grid

Load in AC side

DC side

STS Module

Transformer (Inside)

AC

DC

AC Module

Switch on DC or AC side open

Switch on DC or AC side closed

3.5.3 LEDs of he Sys em

The appearance of the PCS is shown in below. Front door body is mainly composed of touch screen, normal indicator light,

alarm indicator light and emergency shutdown button etc.

5

3

4

2

1

Figure 3-8 LEDs on the front panel

LED designation Description Explanation

1 Fault indicator light

2 Normal indicator light

3 Power indicator light

4 Touch screen

5 Emergency shutdown button

15

1

2

4

5

7

6

3

Figure 3-9 Front view for PCS-AC module

LED designation Description Explanation

1 Normal indicator light Green

2 Fault indicator light Red

3 DIP switch Address

4 Hanger

5 Power supply socket

6 Communication cable socket

7 Handle Can’t bearing too much weight

3.5.4 Labels

Figure 3-11 Warning label position

16

No. Label Explanation

1

Label-Dot label-A phase

2

Label-Dot label-B phase

3

Label-Dot label-C phase

4

Label-Dot label-Negative electrode

5

Label-Dot label-Negative electrode

6

Label-Dot label-Negative electrode

7

Label-Dot label-Neutral line

8

Label-Dot label-Grounding

9

Label-Warning label-Danger High Voltage

10

Label-Warning label-Danger large leak current

17

4 Technical Da a

Technical parameters for the models without transformer (500KTL series)

Specification

Model

PWS1-

500KTL

-EX-8M

PWS1-

500KTL-

EX-7M

PWS1-

500KTL

-EX-6M

PWS1-

500KTL

-EX-5M

PWS1-

500KTL-

EX-4M

PWS1-

500KTL-

EX-3M

PWS1-

500KTL-

EX-2M

PWS1-

500KTL-

EX-1M

Utility-interactive Mode

Battery voltage

range 600~900V

Battery Normal

voltage 750V

DC max current 873A 763A 654A 545A 436A 327A 218A 109A

AC voltage 400Vac (3P3W)

AC current(rms) 720A 630A 540A 450A 360A 270A 180A 90A

AC max

current(rms) 792A 693A 594A 495A 396A 297A 198A 99A

Current(inrush) 72A 63A 54A 45A 36A 27A 18A 9A

Maximum output

fault current 1080A 945A 810A 675A 540A 405A 270A 135A

Maximum output

overcurrent

protection

1080A 945A 810A 675A 540A 405A 270A 135A

Nominal power 500kVA 437.5kVA 375kVA 312.5kVA 250kVA 187.5kVA 125kVA 62.5kVA

AC max power 550kVA 481.2kVA 412.5kVA 343.8kVA 275kVA 205.2kVA 137.5kVA 68.7kVA

AC frequency 50/60Hz(±2.5Hz)

THDi ≤3%

AC PF Listed: 0.8~1 leading or lagging (Controllable)

Actual: 0.1~1 leading or lagging (Controllable)

Stand-alone Mode

Battery voltage

range 600~900V

Battery Normal

voltage 750V

DC Max Current 873A 763A 654A 545A 436A 327A 218A 109A

AC voltage 400Vac (3P3W)

AC voltage range 360~440V

AC current(rms) 720A 630A 540A 450A 360A 270A 180A 90A

AC max 792A 693A 594A 495A 396A 297A 198A 99A

18

current(rms)

Current(inrush) 72A 63A 54A 45A 36A 27A 18A 9A

Maximum output

fault current 1080A 945A 810A 675A 540A 405A 270A 135A

Maximum output

overcurrent

protection

1080A 945A 810A 675A 540A 405A 270A 135A

Nominal power 500kVA 437.5kVA 375kVA 312.5kVA 250kVA 187.5kVA 125kVA 62.5Kva

AC max power 550kVA 481.2kVA 412.5kVA 343.8kVA 275kVA 205.2kVA 137.5kVA 68.7kVA

Output THDU

≤

2%

(

Linear load

)

AC frequency 50/60Hz

AC PF Listed: 0.8~1 leading or lagging (Load-depend)

Actual: 0.1~1 leading or lagging (Load-depend)

Overload

Capability

105%~115% 10min;

115%~125% 1min;

125%~150% 200ms

Physical

Cooling Forced air cooling

Noise 70dB

Enclosure IP20

Max elevation 3000m/10000feet (> 2000m/6500feet derating)

Operating ambient

temperature -20°C to 50°C (De-rating over 45°C

)

Humidity 0~95% (No condensing)

Size (W

×

H

×

D) 1100

×

2160

×

800mm

Weight 600Kg 550Kg 500Kg 450Kg 400Kg 350Kg 300Kg 250Kg

Installation Floor standing

Other

Peak efficiency 98.20%

Protection OTP, AC OVP/UVP, OFP/UFP, EPO, AC Phase Reverse, Fan/Relay Failure, OLP, GFDI, Anti-islanding

Storage type Lithium iron phosphate battery

Configurable

protection limits Upper/Lower AC Voltage/Frequency limit, Battery EOD voltage.

AC connection 3-Phase 3-Wire

Display Touch Screen

Communication RS485, CAN, Ethernet

Isolation Non-isolated

Active anti-islanding

method AFD (

Active Frequency Disturbance)

19

Over voltage

category III

Specification

Model

PWS1-

500KTL-

EX-M8

PWS1-

500KTL-

EX-M7

PWS1-

500KTL-

EX-M6

PWS1-

500KTL-

EX-M5

PWS1-

500KTL

-EX-M4

PWS1-

500KTL-

EX-M3

PWS1-

500KTL-

EX-M2

PWS1-

500KTL-

EX-M1

Utility-interactive Mode

Battery voltage

range 600~900V

Battery Normal

voltage 750V

DC max current 873A 763A 654A 545A 436A 327A 218A 109A

AC voltage 400Vac (3P3W)

AC current 720A 630A 540A 450A 360A 270A 180A 90A

AC max current 792A 693A 594A 495A 396A 297A 198A 99A

Current(inrush) 72A 63A 54A 45A 36A 27A 18A 9A

Maximum output

fault current 1080A 945A 810A 675A 540A 405A 270A 135A

Maximum output

overcurrent

protection

1080A 945A 810A 675A 540A 405A 270A 135A

Nominal power 500kVA 437.5kVA

375kVA 312.5kVA 250kVA 187.5kVA

125kVA 62.5kVA

AC max power 550kVA 481.2kVA

412.5kVA

343.8kVA 275kVA 205.2kVA

137.5kVA

68.7kVA

AC frequency 50/60Hz(±2.5Hz)

THDi ≤3%

AC PF Listed: 0.8~1 leading or lagging (Controllable)

Actual: 0.1~1 leading or lagging (Controllable)

Stand-alone Mode

Battery voltage

range 600~900V

Battery Normal

voltage 750V

DC Max Current 873A 763A 654A 545A 436A 327A 218A 109A

AC voltage 400Vac (3P3W)

AC voltage

range 360~440V

AC current(rms) 720A 630A 540A 450A 360A 270A 180A 90A

AC max

current(rms) 792A 693A 594A 495A 396A 297A 198A 99A

This manual suits for next models

16

Table of contents

Other Sinexcel Inverter manuals

Popular Inverter manuals by other brands

Xantrex

Xantrex FREEDOM HW 1000 installation guide

Generac Power Systems

Generac Power Systems 004709-0 owner's manual

SMA

SMA 8000TL Replacement manual

Generac Power Systems

Generac Power Systems 004700-0 Installation and owner's manual

Studer

Studer variotrack quick guide

Ozone Solutions

Ozone Solutions OZV-20DG installation manual