Sinexcel PWD-100M User manual

PWD-100M

User Manual

Ver 1.00

Sinexcel PWD-100M Intelligent Switching Box

User's Manual

Data Version V1.0

Date of filing 2022-10-23

BOM code

Applicable to PWD-100M

Shenzhen Sinexcel Electric Co., LTD provides a full range of technical support to customers, users can

contact the nearest office or customer service center of Shenzhen Sinexcel Electric Co., LTD

Shenzhen Sinexcel Electric Co., LTD

All rights reserved. Contents are subject to change without notice.

Shenzhen Sinexcel Electric Co., LTD

Company website: www.sinexcel.com

Address:Block 6, Block 2, Nanshan Baiwangxin Hi-Tech Industrial Park, No.1002 Songbai Road,

Nanshan District, Shenzhen, China

Postcode:518055

Customer Service Hotline:0755-8651-1588

Company Fax:0755-8651-3100

E-mail: service@sinexcel.com

Contents

Chapter 1 Overview ................................................................................3

1.1 Model Definition................................................................................................................................................................3

1.2 Explanation of symbols ......................................................................................................................................................3

1.3 Safety Instructions .............................................................................................................................................................4

1.3.1 Safety instructions in mechanical installation.............................................................................................................5

1.3.2 Safety instructions in electrical connection ................................................................................................................5

1.3.3 Safety instructions for the switch box in operation ....................................................................................................5

1.3.4 Repair and Replacement Safety Instructions ..............................................................................................................6

1.3.5 Other ..........................................................................................................................................................................6

1.4 Precautions ........................................................................................................................................................................7

1.4.1 Personnel requirements .............................................................................................................................................7

1.4.2 Equipment use range..................................................................................................................................................7

1.4.3 Enclosure marking ......................................................................................................................................................7

1.4.4 Instructions.................................................................................................................................................................7

Chapter2 Product Introduction .....................................................................8

2.1 SystemApplication..............................................................................................................................................................8

2.2 Technical parameters .........................................................................................................................................................8

2.3 Dimension........................................................................................................................................................................10

2.4 Function Description........................................................................................................................................................13

Chapter 3 Equipment Installation .................................................................15

3.1 Transport and Storage......................................................................................................................................................15

3.2 Open Box Inspection........................................................................................................................................................15

3.2.1 Overview...................................................................................................................................................................15

3.2.2 Packing list ................................................................................................................................................................15

3.3 Installation requirements.................................................................................................................................................16

3.3.1 Environmental requirements....................................................................................................................................16

3.3.2 Carrier requirements ................................................................................................................................................16

3.3.3 Other requirements..................................................................................................................................................17

3.4 Equipment installation.....................................................................................................................................................17

3.5 Electrical connection........................................................................................................................................................18

3.5.1 System configuration ................................................................................................................................................18

3.5.2 System grounding .....................................................................................................................................................18

3.5.3 Cableconnection.......................................................................................................................................................18

3.5.4 Connecting communication lines..............................................................................................................................20

IITable of Contents

3.5.5 Dry node connection ................................................................................................................................................21

3.6 Post-installation check .....................................................................................................................................................22

Chapter 4 Commissioning Operation ................................................................23

4.1 Working State Description ...............................................................................................................................................23

4.2 Control method................................................................................................................................................................25

4.3 Backstage display description ..........................................................................................................................................26

4.3.1 Event logging interface display .................................................................................................................................26

4.4 Switching on and off ........................................................................................................................................................28

4.4.1 Pre-boot check..........................................................................................................................................................28

4.4.2 Grid connection procedure.......................................................................................................................................28

4.4.3 Off-grid steps ............................................................................................................................................................30

4.4.4 Shutdown procedure ................................................................................................................................................31

4.4.5 Emergency shutdown ...............................................................................................................................................31

4.4.6 Parallel operation......................................................................................................................................................31

Chapter 5 Communication mode .....................................................................32

5.1 EMS communication ........................................................................................................................................................32

5.1.1 Ethernet port ............................................................................................................................................................32

5.1.2 RS485 serial port.......................................................................................................................................................32

5.2 PWD-100M andPCS cascade networking.........................................................................................................................32

5.3 PWD-100M and multiple PCS are connected to the same network ................................................................................33

Chapter 6 Maintenance ............................................................................34

6.1 Maintenance....................................................................................................................................................................34

6.2 Power circuit connection maintenance............................................................................................................................34

6.3 System working condition maintenance..........................................................................................................................34

6.4 Cleaning and sanitation....................................................................................................................................................35

Appendix .........................................................................................36

Appendix I: Quality assurance and after-sales service.................................................................................................................36

Installation record ..............................................................................38

Chapter 1 Overview

1.1 Model Definition

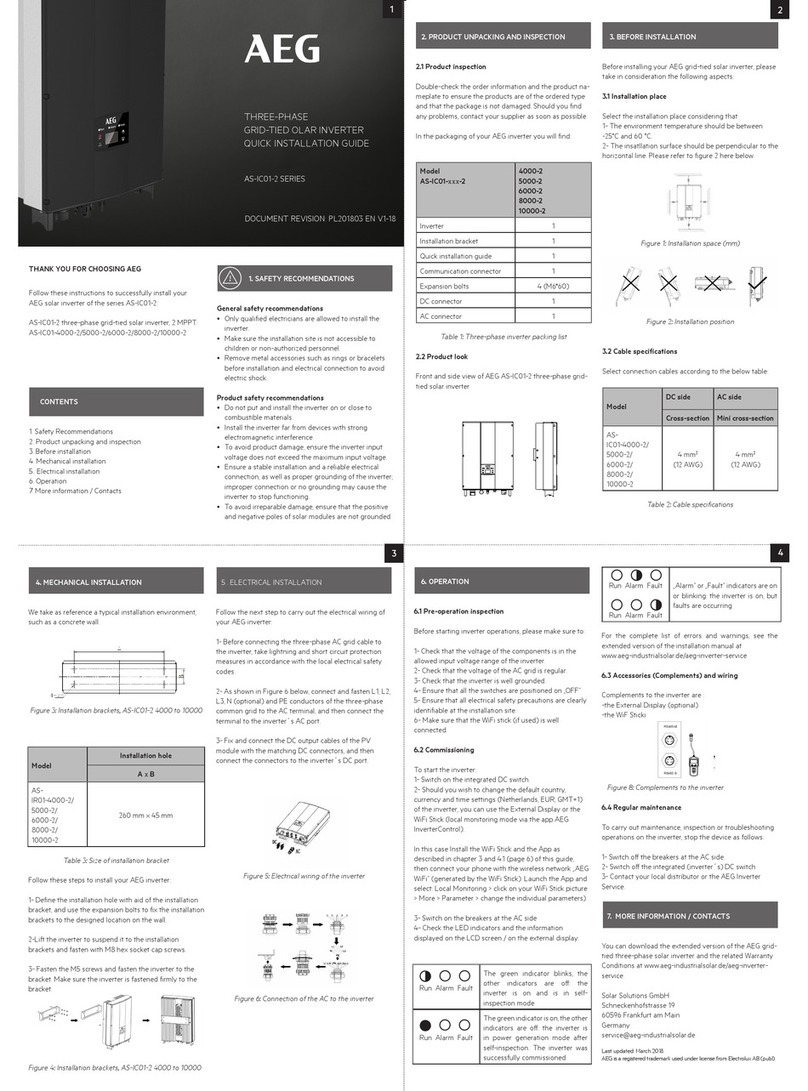

This section presents the product model definitions covered in the manual as shown in Figure 1-1.

PWD-100M-O

Power 100kW

Power Switch Device

Module

Outside

Figure 1-1 Model Number Definition

Description.

PWD-100M indicates power switching equipment with a module rated capacity of 100kW also known as PWD-100M

intelligent switching box.

PWD-100M-O indicates outdoor power switching equipment with a module rated capacity of 100kW.

The two models have some differences in appearance.

1.2 Explanation of symbols

The following is a list of the identifiers applied in this manual. Please read carefully and understand the meaning

represented by each symbol.

This instruction indicates that there are hazards during operation and that failure to comply

with such warning messages will directly result in serious personal injury or death.

This instruction indicates that there are potential hazards during operation and that failure to

comply with such warnings may result in personal injury or death.

This instruction indicates that there is a potential hazard during operation and that failure to

follow such warnings may result in equipment damage.

DANGER

WARNING

CAUTION

4Chapter 2Introduction to PCS-AC, STS modules

"Instructions" are additional information in the manual, highlighting and supplementing the

content, and may also provide tips or tricks to optimize the use of the product, helping you to

efficiently solve some of the problems in the application.

1.3 Safety Instructions

This manual covers the installation and use of the PWD-100M Intelligent Switching Box from Sinexcel Electric.

⚫The PWD-100M Smart Switch Box must be commissioned and maintained by an engineer appointed

by the manufacturer or its agent. Otherwise, it may endanger personal safety and cause equipment failure, and the

resulting damage to the equipment is not covered by the warranty.

⚫PWD-100M intelligent switching box is for commercial/industrial use only.

⚫The PWD-100M Smart SwitchBox is designed and tested in strict accordance with relevant

international safety standards, and its installation, commissioning, operation and maintenance processes must

comply with the Code of Practice for the Safety of Electrical and Electronic Equipment. Improper use or misuse may

endanger the personal safety of the operator or third parties, as well as damage the converter or other property

safety. To avoid this, the following safety precautions must be strictly observed during operation and maintenance,

which are described in detail in the respective sections.

All installation, commissioning and maintenance operations must be performed by

qualified personnel. Professional technicians must meet the following conditions.

⚫An engineer appointed by the manufacturer or its agent.

⚫Have received professional training.

⚫A complete reading of this manual and familiarity with safety matters in

the operation of electrical and electronic equipment.

⚫Be familiar with the relevant safety codes for electrical systems.

Misuse of the equipment poses a risk of injury!

⚫must always follow the instructions in the manual when moving and

placing the machine.

⚫Improper operation of the equipment may result in electric shock, burns,

contusions, etc.

⚫Damage to the equipment caused by any private modification and split

system (or equipment) operation without permission is not covered by the warranty.

CAUTION

CAUTION

1.3.1 Safety instructions in mechanical installation

⚫Damage to the equipment caused by any unauthorized modification and

disassembly of the system (or equipment) is not covered by the warranty.

⚫Always make sure that the converter is free of any electrical

connections before installing the Smart Switch Box!

⚫Poor ventilation of the installation environment will affect the performance of the system!

⚫Good ventilation needs to be ensured during the operation of the equipment. The unit

must be kept upright and the air ducts smooth, with no strong air currents blocking

the air flow near the air outlet to ensure adequate cooling inside the unit.

1.3.2 Safety instructions in electrical connection

⚫Before making electrical connections, it is important to be safe and not to touch the

metal terminals without adequate protection.

⚫The cables used in the electrical system must be securely connected, well insulated and

of proper gauge.

⚫All electrical installations must meet national/regional electrical standards.

⚫Permission must be obtained from the electricity authority of the country/region in which

the installation is located in order to be connected to the grid.

⚫Before connecting to the input power, be sure to ground it reliably and comply with local

electrical standards.

1.3.3 Safety instructions for the switch box in operation

⚫Any touching of the copper strip, contacts, terminals, etc. inside the equipment

connected to the grid circuit may result in a fatal burn or electric shock!

⚫Do not touch the terminals and conductors connected to the grid circuit.

⚫Pay attention to any instructions and safety instruction documents regarding connection

to the grid.

⚫There may be a risk of electric shock inside the device! Donot open theSmart Switch

Box housing while the Smart Switch Boxis in operationor under power.

⚫Only an intact and closed box enclosure protects the operator's personal property.

DANGER

CAUTION

DANGER

WARNING

CAUTION

DANGER

WARNING

6Chapter 2Introduction to PCS-AC, STS modules

⚫any operation of this equipment needs to be performed or directed by a professional.

⚫Please note the safety precautions listed in the user manual and other documents.

1.3.4 Repair and Replacement Safety Instructions

Improper maintenance of the equipment may result in injury or damage to the equipment.

Before performing any operation, the user must strictly follow the following steps.

⚫(a) First disconnect the disconnect switches on the grid side, PCS side and load

side of the intelligent switching box.

⚫Wait at least 5 minutes until the internal energy storage components are

discharged, during which time it is strictly forbidden to touch the equipment terminals,

contacts, copper row and other electrically charged parts with human body or any

conductor.

⚫Use testing equipment to verify that no voltage or current is present.

⚫Do not allow unrelated personnel to enter the maintenance site!

⚫Temporary warning signs must be posted or barriers erected during electrical

connection and maintenance work to prevent entry of unrelated persons into the

electrical connection or maintenance area.

⚫Restart the intelligentswitching boxonly after troubleshooting faults affecting the safety

performanceof theintelligent switching box.

⚫The Smart SwitchBox does not contain maintenance parts inside, so if you need any

maintenance service, please contact our after-sales service personnel.

⚫Please do not replacethe internal components ofthe Smart Switch Box without

permission. Our company will not be responsible for any warranty and joint and

several liability for the resulting damage.

⚫Contact or improper handling of printed circuit boards or other electrostatic sensitive

components can result in damage to the device.

⚫Avoid unnecessary contact with the circuit board.

⚫Observe electrostatic protection codes and wear anti-static bracelets.

1.3.5 Other

All safetymarkings, warning labels and nameplates on the Smart Switch Box.

⚫Must be clearly visible.

⚫Must not be removed or covered.

DANGER

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

1.4 Precautions

1.4.1 Personnel requirements

The PWD-100M intelligentswitching box must be commissioned and maintained by the manufacturer or its agent's

designated engineer. Otherwise, it may endanger personal safety and cause equipment failure, and the resulting damage to

the equipment is not covered by the warranty.

1.4.2 Equipment use range

The PWD-100M intelligent switchingbox is for commercial/industrial use only and may not be used as any energy saving

equipment associated with life support equipment.

1.4.3 Enclosure marking

Thechassis markings contain important information for safe operation of the cabinet and are strictly prohibited from being

torn or destroyed.

Makesurethe chassis marking is clearly readable and replace it immediately if it appears damaged or blurred.

1.4.4 Instructions

To facilitate the user to read this manual more easily, the manual is equipped with a large number of pictures. The

pictures are for illustration purposes only. The actual product shall prevail for specific information about the product.

Chapter2 Product Introduction

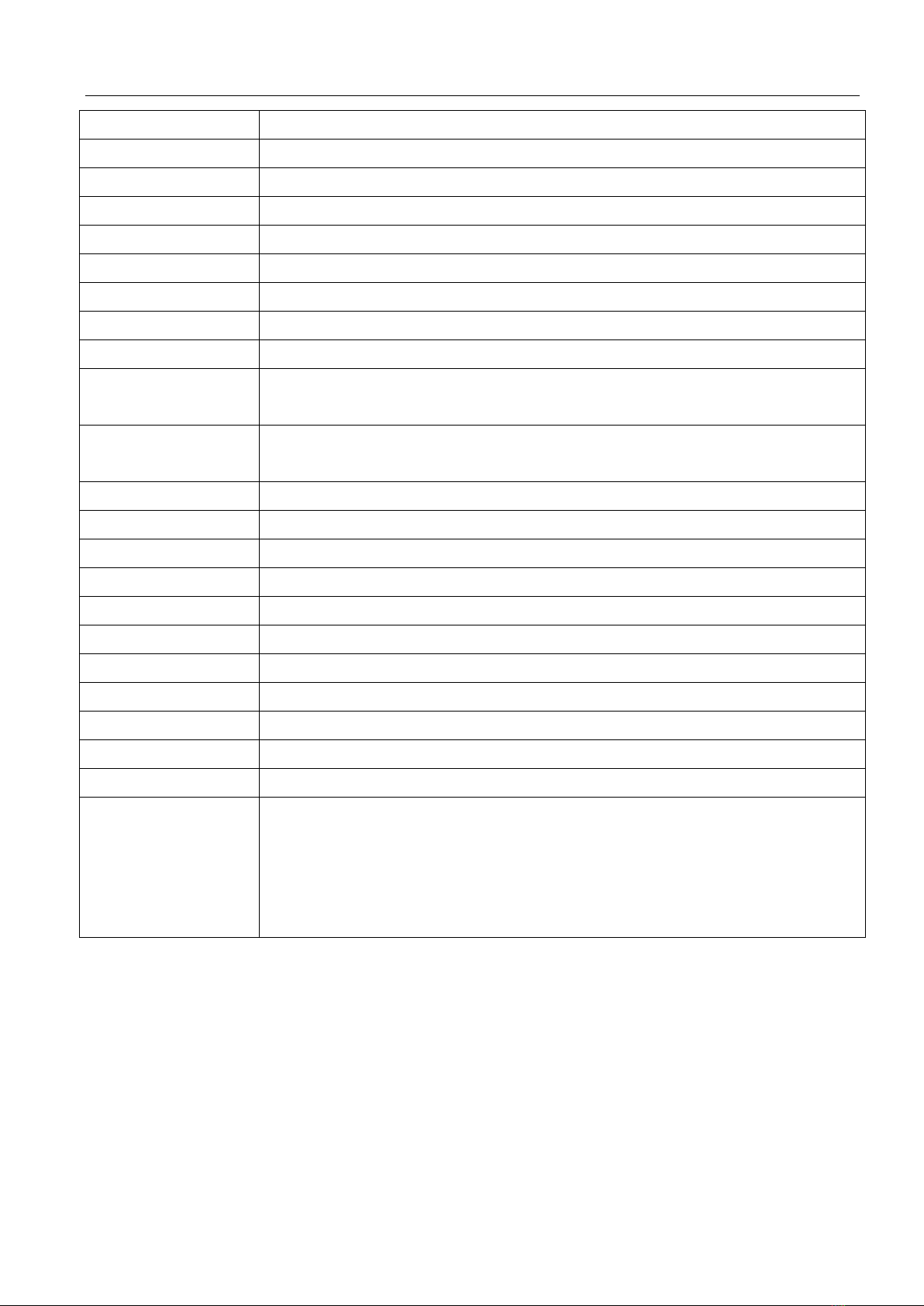

2.1 SystemApplication

Intelligent switching equipment is usually connected between grid, PCS and load at the same time, used to dispatch the

power configuration between the three, grid can be composed of low-voltage distribution network or a small range of oil

machine power supply network, the load is local load for industrial and commercial use, when there is a fault in the grid, it can

be switched off the grid through PCS to realize grid and load switching, when PCS has a fault, cut off the connection between

grid and PCS to ensure normal operation of the load.

Figure 2-1 Intelligent switching topology diagram

2.2 Technical parameters

Table 2-1 shows the detailed technical parameters of PWD-100M intelligent switching box.

Table 2-1 technical parameters table

Indicator Item \ Model

PWD-100M

System parameters

Rated power

100kVA

Rated voltage

Single-phase: 220VAC/230VAC/277VAC

Three-phase: 380VAC/400VAC/480VAC

Rated frequency

50Hz/60Hz

Rated input current

145A

Parallel and off-grid

switching time

<30ms

PWD100

Grid

Breaker

PCS

Breaker

PCS

Breaker

PCS

Aux1

MCU1

MCU2

Breaker

BI

load

CT

KM1 KM2

N1

N2

NPE

Breaker

Aux2

CT

Chapter 3System Introduction9

Protection grade

IP20

Design life

10 years

Cooling method

Air-cooled

Grid access

1 way (no more than 100kW)

PCS access

1 way (no more than 90kW)

Load access

1 way (no more than 90kW)

Number of inverters

3 unitsPWS2-(29M,30M)-EX

Wiring method

Three-phase four-wire system / Three-phase three-wire system

Communication

method of upper computer

ModBus, TCP/IP protocol

Communication

interface

CAN*2/RS485*4/WIFI*1/LAN*2

Dimension

440*580*175mm

Noise

70dB

Temperature range

-25℃~ +50℃

Altitude

3000m

Humidity

0~100%

Weight

25KG

Installation method

Wall/rack type

DI

6

DO

4

Indicators

Run, fault, power

Wiring terminals

DT terminal (M8)

Protection

System protection: over temperature, AC over-voltage, AC reverse sequence, emergency

stop, fan failure, output overload.

Safety protection conditions can be set, setting parameters include: AC voltage protection

upper limit, AC voltage protection lower limit, AC frequency protection upper limit, AC frequency

protection lower limit.

Indicator items \

Models

PWD-100M-O

System parameters

Rated power

100kVA

Rated voltage

Single-phase: 220VAC/230VAC/277VAC

Three-phase: 380VAC/400VAC/480VAC

Rated frequency

50Hz/60Hz

Rated input current

145A

Parallel and off-grid

<30ms

switching time

Protection class

IP65

Design Life

10 years

Cooling method

Air-cooled

Grid access

1 way (no more than 100kW)

PCS access

1 way (no more than 90kW)

Load access

1 way (no more than 90kW)

Number of inverters

3 unitsPWS2-(29M,30M)-EX

Wiring method

Three-phase four-wire system / Three-phase three-wire system

Communication

method of upper computer

ModBus, TCP/IP protocol

Communication

interface

CAN*2/RS485*4/WIFI*1/LAN*2

Dimension

440*580*175mm

Noise

70dB

Temperature range

-25℃~ +50℃

Altitude

3000m

Humidity

0~100%

Weight

31.5KG

Installation method

Wall/rack type

DI

6

DO

4

Indicators

Run, fault, power

Wiring terminals

DT terminal (M8)

Protection

System protection: over temperature, AC over-voltage, AC reverse sequence, emergency

stop, fan failure, output overload.

Safety protection conditions can be set, setting parameters include: AC voltage protection

upper limit, AC voltage protection lower limit, AC frequency protection upper limit, AC frequency

protection lower limit.

2.3 Dimension

PWD-100M intelligent switching box outline dimensions as shown in Figure 2-1, chassis length 580mm, width 440mm,

height 173. 8mm.

PWD-100M-O intelligent switching box outline dimensions as shown in Figure 2-3, chassis length 920mm, width 440mm,

height 205mm.

Chapter 3System Introduction11

Figure 2-1 PWD-100M intelligent switching box dimensions

1

234

5

Figure 2-2 PWD-100M front panel

Table 2-1 PWD-100M front panel description

Serial

number

Name

Description

1

Grounding

terminal

Grounding protection wire fixed point

2

Grid terminal

Connection to the grid

3

Load side terminal

Connects tothe load

4

PCS side terminal

ConnectPWS2-(29M,30M)-EX module

5

Signal interface

area

External communication port

Figure 2-3 PWD-100M-O Intelligent Switching Box External Dimensions

6

1

2 3 4

5

7

Chapter 3System Introduction13

Figure 2-4 PWD-100M-O front panel

Table 2-2 PWD-100M-O front panel description

Serial

number

Name

Description

1

Pneumatic

pressure reducing

valve

Prevents expansion when the internal temperature of the module is high

2

Grid terminal

Grid side inlet baffle (remove this baffle during installation)

3

Load side

terminals

Load side inlet baffle (remove this baffle during installation)

4

PCS side terminal

block

PCS side inlet baffle (remove this baffle during installation)

5

Signal line

waterproof terminal

External communication port

6

Grounding

terminal

Grounding protection wire fixed point

7

Handle

For chassis support

2.4 Function Description

The functions of the PWD-100M intelligent switching box can be basically summarized as follows.

On-grid active cut off-grid: When PCS module PWS2-(29M,30M)-EXwith PWD-100M intelligent switching box

systemworks in the on-grid state, if the user takes the initiative to set off-grid, the system switches off-grid operation, at which

time the load is carried by PCS alone.

Off-grid active cut to grid: When PCS module PWS2-(29M,30M)-EX modulewith PWD-100M intelligent switching box

systemis working in the grid-connected state, if the user actively set the grid-connected, the system switches to

grid-connected operation, and the load is driven by PCS and the grid together at this time.

When the PCS module PWS2-(29M,30M)-EX module with PWD-100M intelligentswitching box system is workingin

grid-connected state, if abnormal condition of the grid is detected, the system will automatically switch to off-grid operation,

and the load will be driven by PCS alone; if the grid is back to normal, the system will automatically return to grid-connected

operation, and the load will be driven by PCS and the grid together.

Data storage: PWD-100M intelligent switching box stores operation information, operation records, fault records and

other information.

Communication function.

⚫The standard RS485 interface can be connected with EMS and other monitoring equipment.

⚫The standard Ethernet interface is used to communicate with the host computer to achieve remote control,

remote software upgrade and other functions.

⚫Standard CAN interface can be used for parallel communication with PWS2-(29M,30M)-EX.

Protection functions.

⚫Overcurrent protection

⚫Overload protection

⚫Short circuit protection

⚫Simultaneous failure protection

⚫Environmental over-temperature protection

⚫Grid voltage monitoring

⚫Grid frequency monitoring

⚫Anti-islanding protection

⚫Redundant protection functions in accordance with VDE certification

Chapter 4 Equipment Installation15

Chapter 3 Equipment Installation

3.1 Transport and Storage

When transporting andstoring the SmartSwitch Box, please pay attention to the marking on the box. The following

requirements should be met during transport and storage.

⚫Do not removethe outer packagingof the Smart Switch Box.

⚫No corrosive gases in the surroundings.

⚫Storage temperature maintained at -40℃~65℃and relative humidity maintained at 0%RH~95%RH.

⚫Non-dusty environment.

⚫Periodic inspection is required during storage; if insects and rodents are found, the packaging

material needs to be replaced in time.

⚫Compliance with fire-fighting requirements.

⚫After long-term storage, the converter needs to be inspected and tested by professionals before it can

be put into use.

CAUTION

⚫Cabinets should not be stacked when transported and stored, and other items

are not allowed to be stacked on top.

⚫The cabinet should be placed upright, not upside down or flat.

3.2 Open Box Inspection

3.2.1 Overview

Beforethe PWD-100M intelligent switchingbox is ready for installation, an unpacking inspection should be conducted,

mainly checking the following contents.

⚫Check whether the quantity of each item in the packing list is consistent with the physical object.

⚫Check whether the nameplate data of the product and the ordering contract are consistent, such as the product

model, rated capacity, voltage level, etc..

⚫Check whether the factory documents and accessories are complete.

⚫Whether the chassis is deformed, off-painted and loose.

3.2.2 Packing list

PWD-100M intelligent switching box packinglist is shown in Table 3-1, PWD-100M-O outdoor intelligent switching box

packing list is shown in Table 3-2.

Table 3-1 PWD-100M intelligent switching box packing list

16Chapter 4 Equipment Installation

Seri

al

number

Name

Qua

ntity

Remarks

1

User manual

1

copy

2

External communication terminal

2

pcs

3

WIFI signal enhancement connector

1pc

4

Certificate of Conformity

1

copy

Table 3-2 PWD-100M-O intelligent switching box packing list

Seri

al

number

Name

Qua

ntity

Remarks

1

User manual

1

copy

2

External communication terminal

2

pcs

3

WIFI signal enhancement connector

1pc

4

Fireproof mud

1

copy

5

Certificate of Conformity

1

copy

3.3 Installation requirements

3.3.1 Environmental requirements

⚫Installation indoors, avoiding sunlight, rain and standing water.

⚫Clean installation environment, avoiding large amounts of dust in the air.

⚫Installation position without shaking.

⚫Ambient temperature guaranteed at: -20 to 50°C.

3.3.2 Carrier requirements

⚫Intelligent switching box installation carrier must have fireproof performance.

⚫Please do not install the equipment on flammable building materials.

⚫Please ensure that the installation surface is sturdy and meets the load-bearing requirements for the installation of

the smart switching box.

Table of contents

Other Sinexcel Inverter manuals

Popular Inverter manuals by other brands

Thermal Arc

Thermal Arc Dragster 80 owner's manual

Mitsubishi Electric

Mitsubishi Electric FR-E720-0.4K instruction manual

FoxESS

FoxESS H1 Series user manual

Mitsubishi Electric

Mitsubishi Electric FR-A700 Series Installation guidelines

Everpower Electronics

Everpower Electronics SD700 Programming and Software Manual

atecpool

atecpool SIROCCO AIHP115 user manual