Singer 1305 Installation instructions

Other Singer Sewing Machine manuals

Singer

Singer Professional 14U11 Manual

Singer

Singer 400W31 User manual

Singer

Singer 20U User manual

Singer

Singer 211G146 User manual

Singer

Singer Professional 5 User manual

Singer

Singer 107W13 User manual

Singer

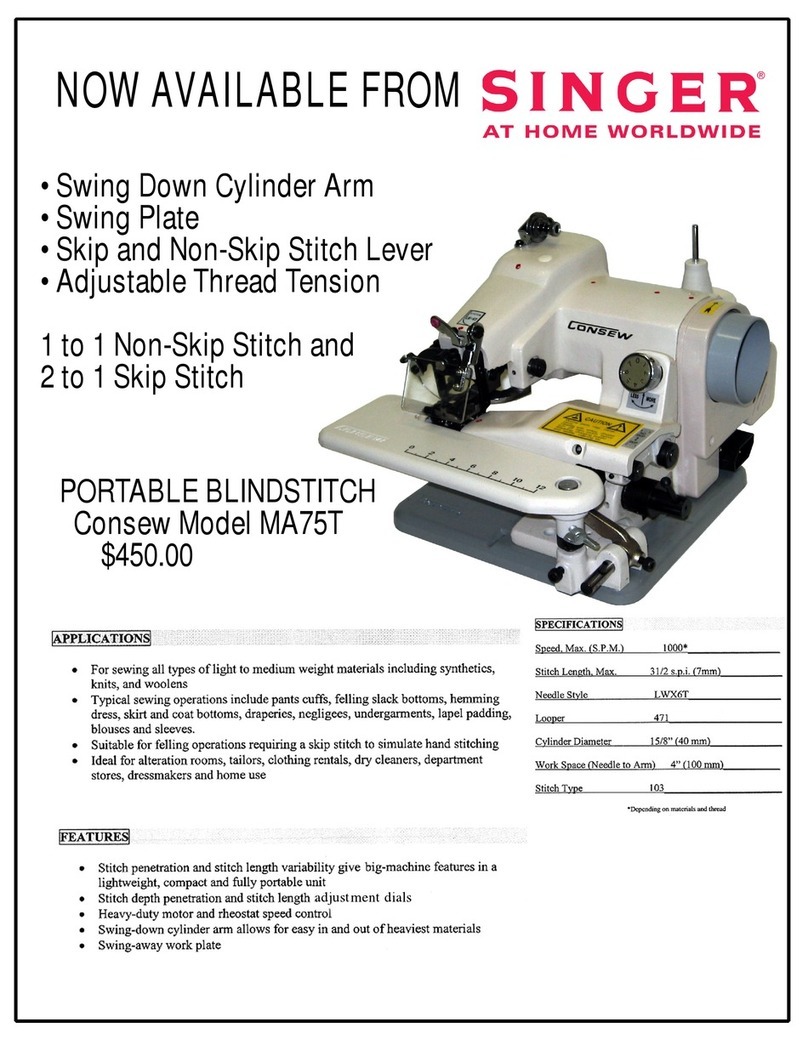

Singer MA75T User manual

Singer

Singer 281-20 User manual

Singer

Singer 271K11 User manual

Singer

Singer 7902 Specifications

Singer

Singer 2191D200A - 1 User manual

Singer

Singer 7-33 Quick start guide

Singer

Singer 6202 User manual

Singer

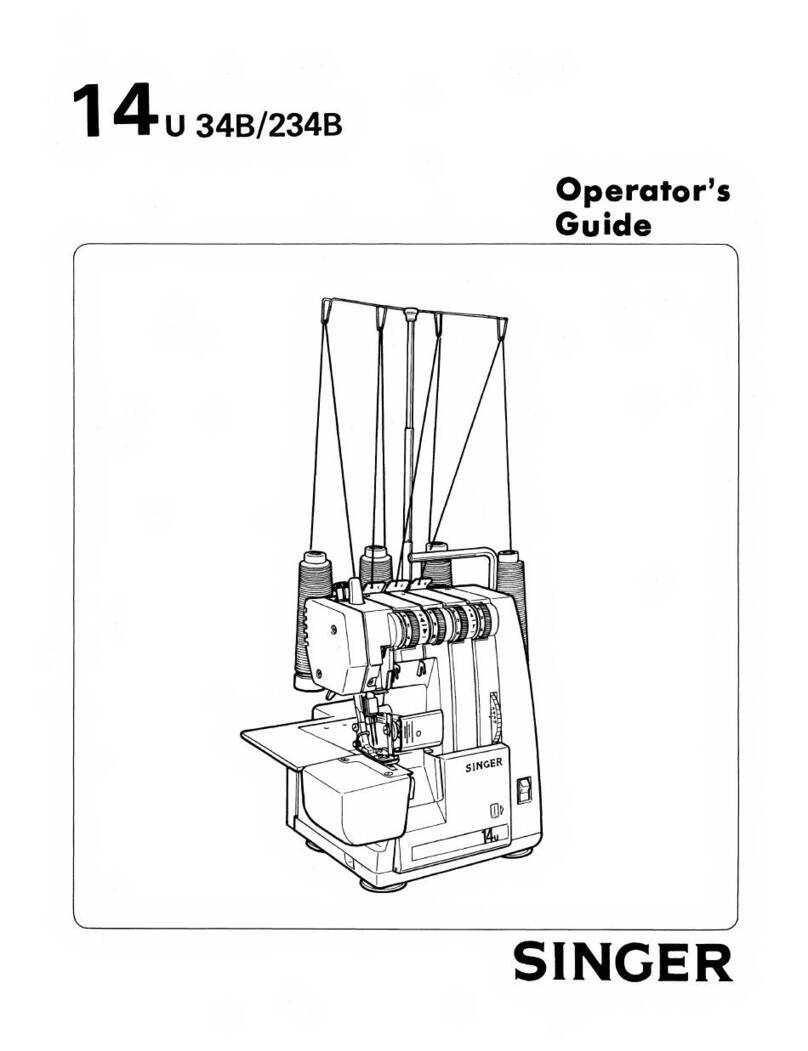

Singer 14U 34B Manual

Singer

Singer 251-12 Manual

Singer

Singer 107W35 User manual

Singer

Singer 153W100 Quick start guide

Singer

Singer HD6620C User manual

Singer

Singer Heavy Duty 14HD854 User manual

Singer

Singer Athena User manual