Singer 160 User manual

Other Singer Sewing Machine manuals

Singer

Singer 114K103 Installation and operation manual

Singer

Singer 150W4 Quick start guide

Singer

Singer 142W102 Installation and operation manual

Singer

Singer SM024 User manual

Singer

Singer 4443 User manual

Singer

Singer 153W104 User manual

Singer

Singer 11W2 Installation and operation manual

Singer

Singer 2282 User manual

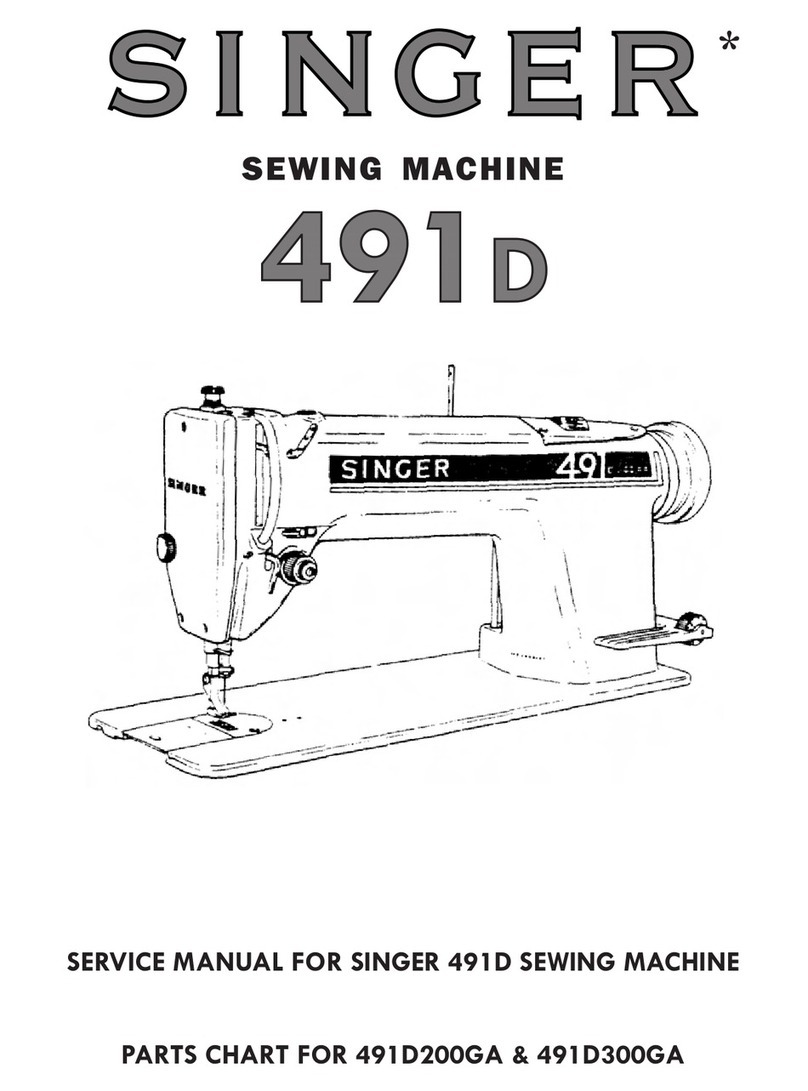

Singer

Singer 491D User manual

Singer

Singer HD-110 User manual

Singer

Singer 700 series User manual

Singer

Singer 154W100 User manual

Singer

Singer Imperial 7005 User manual

Singer

Singer Futura CE-250 User manual

Singer

Singer 591UX260 User manual

Singer

Singer 136W105 User manual

Singer

Singer 99-31 User manual

Singer

Singer 71-108 User manual

Singer

Singer 160 User manual

Singer

Singer CONFIDENCE 7470 User manual