Singer 1640 User manual

Other Singer Sewing Machine manuals

Singer

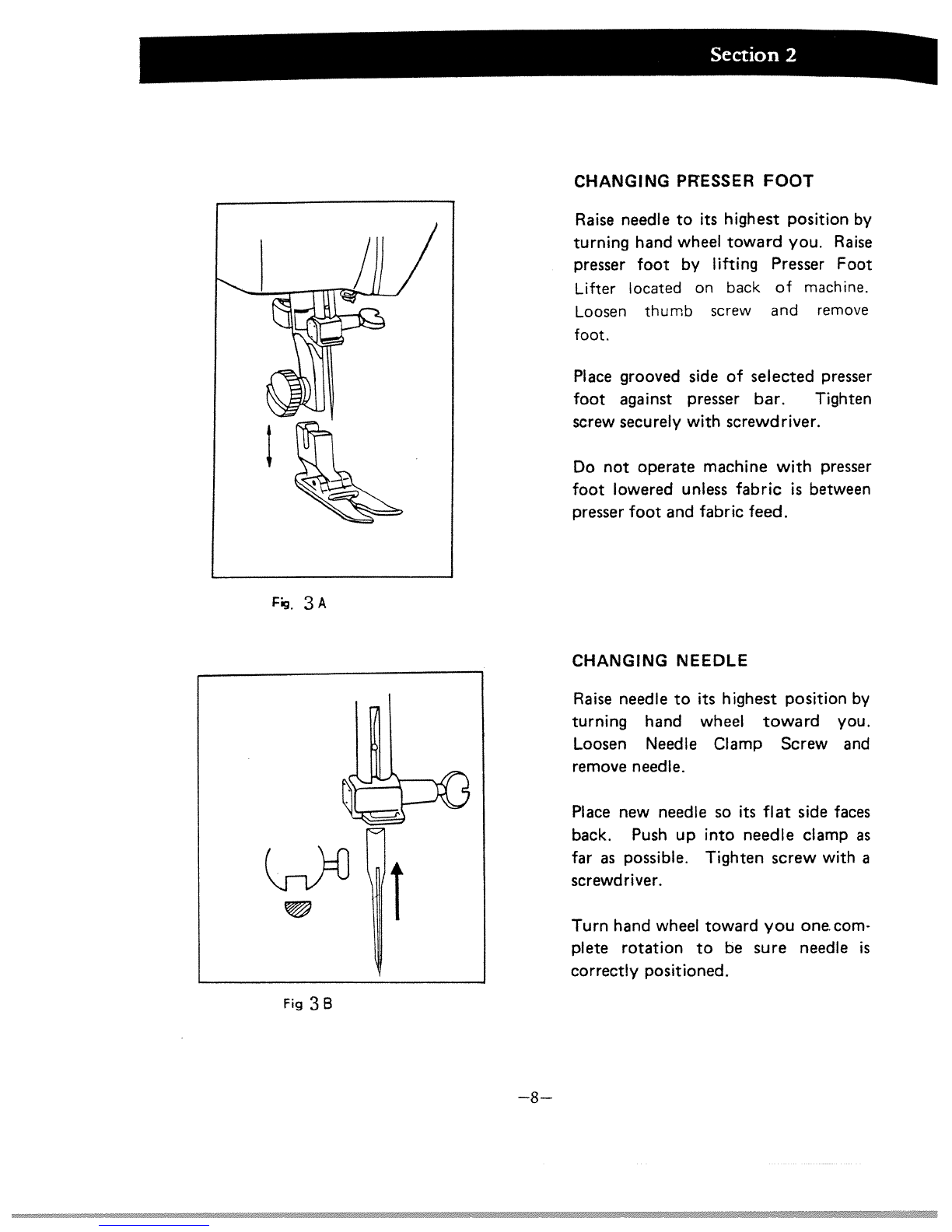

Singer 111W106 Setup guide

Singer

Singer Athena User manual

Singer

Singer 270-37 User manual

Singer

Singer 92-20 User manual

Singer

Singer 212 User manual

Singer

Singer Merritt 8834 User manual

Singer

Singer 431 D200A User manual

Singer

Singer 66-18 User manual

Singer

Singer Futura 1100 User manual

Singer

Singer FUTURA SES1000 User manual

Singer

Singer S0705 User manual

Singer

Singer JUNIOR MISS 67B User manual

Singer

Singer 15K80 Setup guide

Singer

Singer 135W1 Quick start guide

Singer

Singer 117-1 User manual

Singer

Singer HD 6800C User manual

Singer

Singer 591D200A User manual

Singer

Singer 8280 User manual

Singer

Singer 70 User manual

Singer

Singer 145W204 Quick start guide