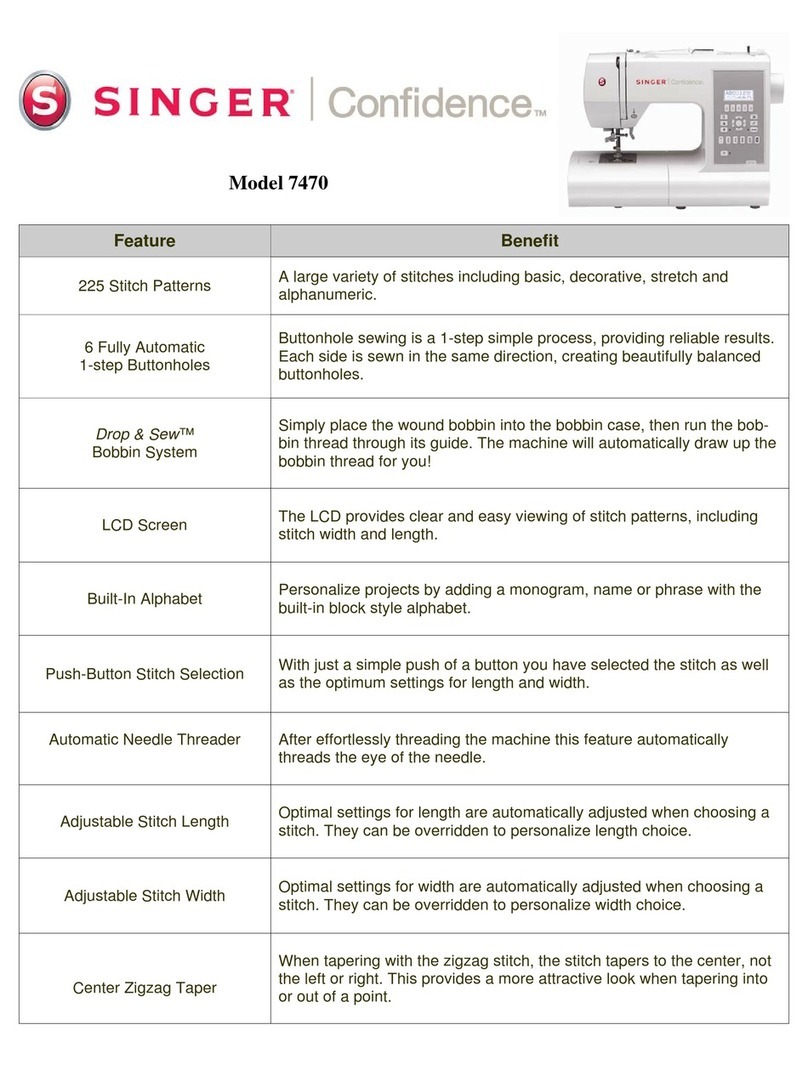

Singer 211G165 User manual

Other Singer Sewing Machine manuals

Singer

Singer 2282 User manual

Singer

Singer 176-21 User manual

Singer

Singer 6201; 6211 User manual

Singer

Singer 591V User manual

Singer

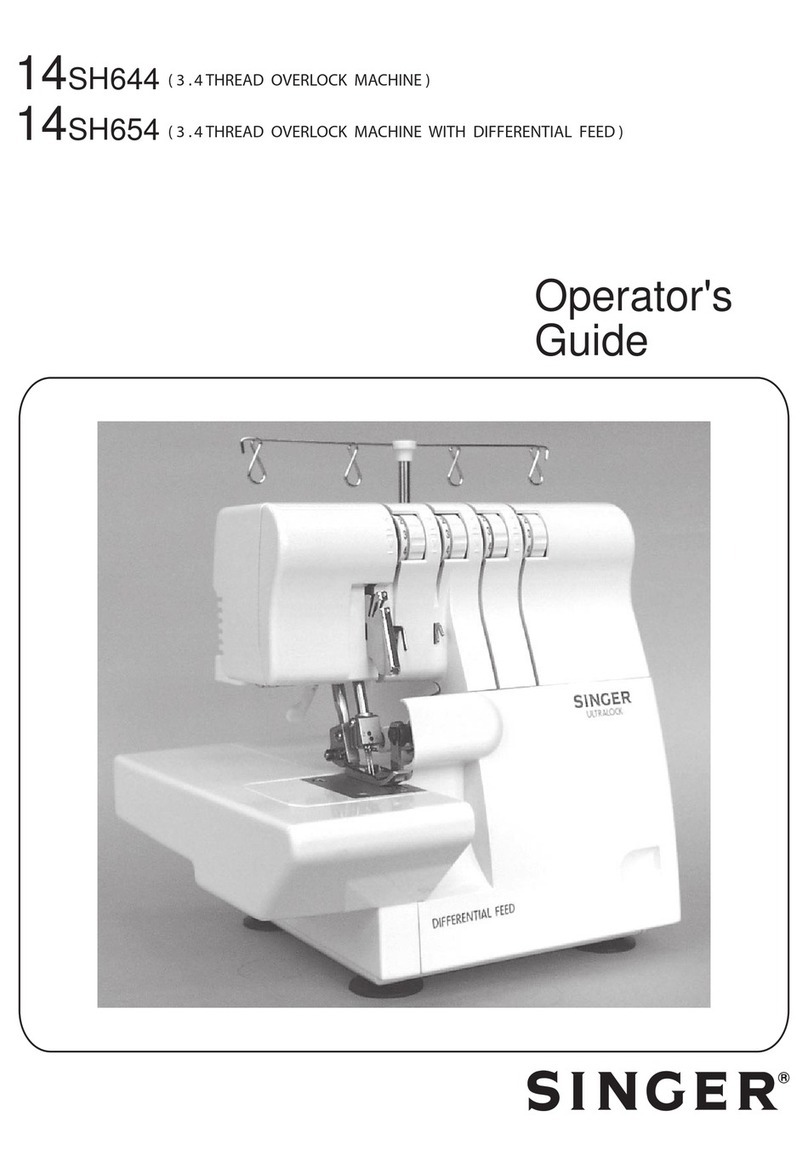

Singer 14SH644 Manual

Singer

Singer 300W103 User manual

Singer

Singer 471U User manual

Singer

Singer 2591 series Setup guide

Singer

Singer 15-210 User manual

Singer

Singer 457 G 115 User manual

Singer

Singer 6660 User manual

Singer

Singer 132W100 Installation and operation manual

Singer

Singer 1411 User manual

Singer

Singer 02; 22 User manual

Singer

Singer Futura 4300 User manual

Singer

Singer 7-33 User manual

Singer

Singer 114-55 User manual

Singer

Singer Simple 2263 User manual

Singer

Singer 300W class User manual

Singer

Singer 71-113 User manual