From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

DESCRIPTION

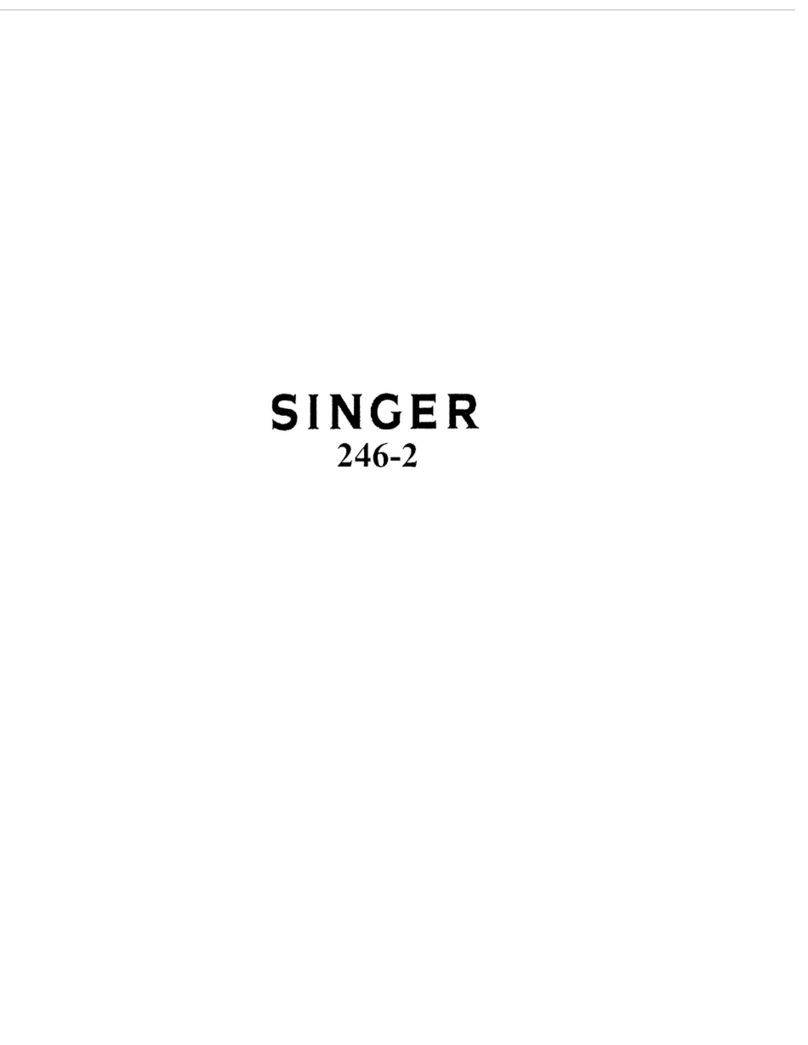

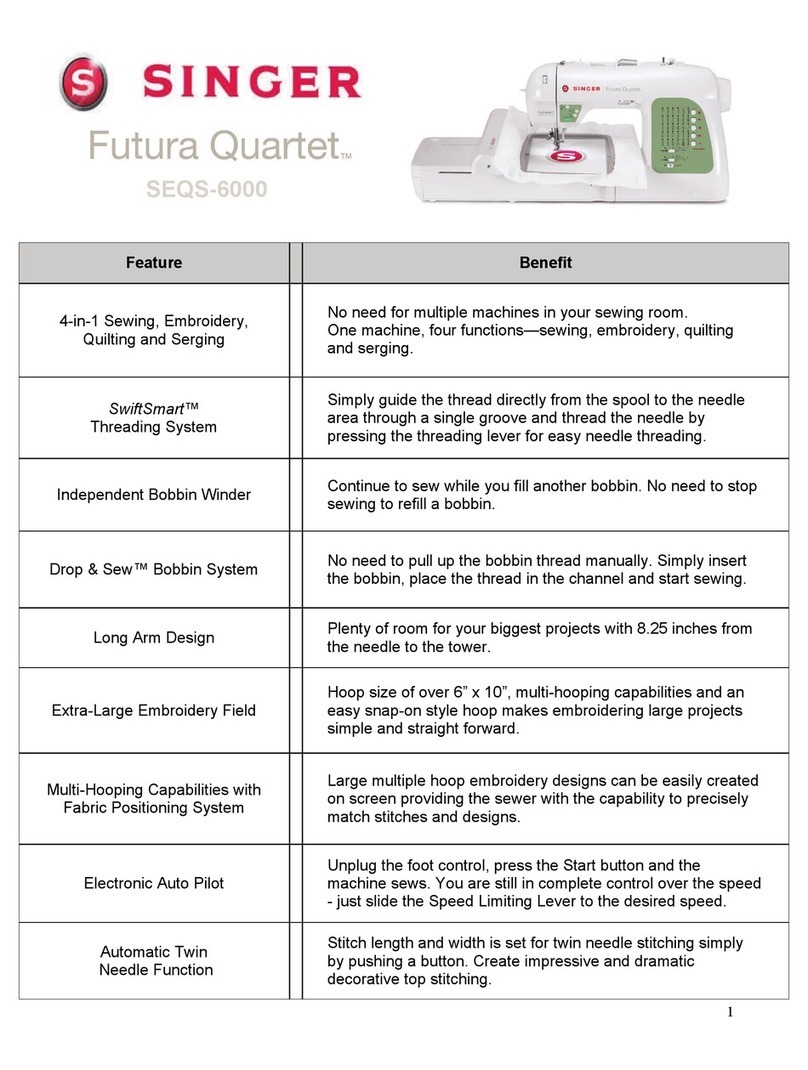

Fig. 2.

X-ray

View

of Class

246K

Machine

(Lubricating System Shown in Solid Black)

Machines

246K42,

246K43

and

246K45

pro-

duce

high

speed

overedging

and

simultaneous

trimming

on

materials

ranging

from

lace

to

canvas.

Available

for

single needle

operations,

these

powerful

but

compact

machines

are

capable

of

producing

three

different

overedge

stitches.

Stitch

Types

503,

504

and

505.

Adaptable

for

gathering,

stretching

or

feeding

the

work

uniformly,

these

machines

of

C:lass

246K

have

proven

themselves

in

an

almost

endless

list

of

overedge

operations

including

serging,

inter-

mittent

gathering,

ruffling,

binding,

scalloping,

cuffing,

side-seaming,

yoking,

closing,

cording,

welting

and

inserting.

GENERAL CHARACTERISTICS

Curved needles:

Catalogue

#

1265

(151 x 7)

regular,

Catalogue#l263

(151 x 3)

tapered

blade.

Loopers (or

looper

and

spreader)

independently

driven,

permitting

variations

in

their

adjustment

in

relation

to

each

other

and

to

the

needle,

to

suit

the

work

required.

Either left or right twist of thread

may

be

used

in

needle

and

in

loopers.

Adjustable trimmer

cuts

cleanly;

operating

in

advance

of

needles.

Trimmings

guided

into

chip

chute

to

avoid

interference

with

work

and

with

mechanism.

Presser

foot

can

be

swung

toward

left

to

facili-

tate

threading

or

replacement

of

needle.

3

Tubular operation

is

accommodated

by

a

small

"horn"

extension

of

the

throat

plate

support.

Cloth plate

can

be

swung

to

the

left

for

con-

venience,

when

stitching

tubular

pieces

or

when

making

machine

adjustments.

Fittings for Machine

246K42

are

designed

to

retain

control

of

thread-chain

as

long

as

presser

foot

is

engaged

with

feed

dog,

enabling

operator

to

break

the

thread

chain

manually,

without

losing

control

of

chain

or

distorting

the

thread

loops.

Splash lubricating system,

shown

in Fig. 2,

automatically

and

continuously

oils

principal

bear-

ings

during

operation.

Oil cooling reservoir

in

rear

of

machine.

Oil level indicator

gauge

in

direct

view

of

operator.

Oils

recommended,

see

inside

front

cover.

Machine pulley

164231

for

3/8

inch

Y-belt;

also

used

for

5/16

inch

round

belt.

Machine pulley should

always

turn over

away

from operator

when

machine

is

in

motion.

ACCESSORIES

AND

TOOLS

Foot

lifter.

Knee

lifter

supplied

instead,

when

specified

on

order

..

Threading

wire

164196.

Tweezers

164204.

Socket wrench

164197

(for

needle

clamping

nut).

Flat, open-end wrench l

0875

(for

feed

eccentric

nut).

Screwdriver

85318.

Wrench

164831

(for

right

looper

carrier

guide

bar

oil

plug

screw

nut).

Thread unwinder

15103

l

(for

two-

or

three-

thread).

Thread unwinder

228705

(two-thread)

or

228706

(three-thread)

for

nylon

threads

will

be

supplied

instead

of

regular

unwinder,

upon

spe-

cific

order.