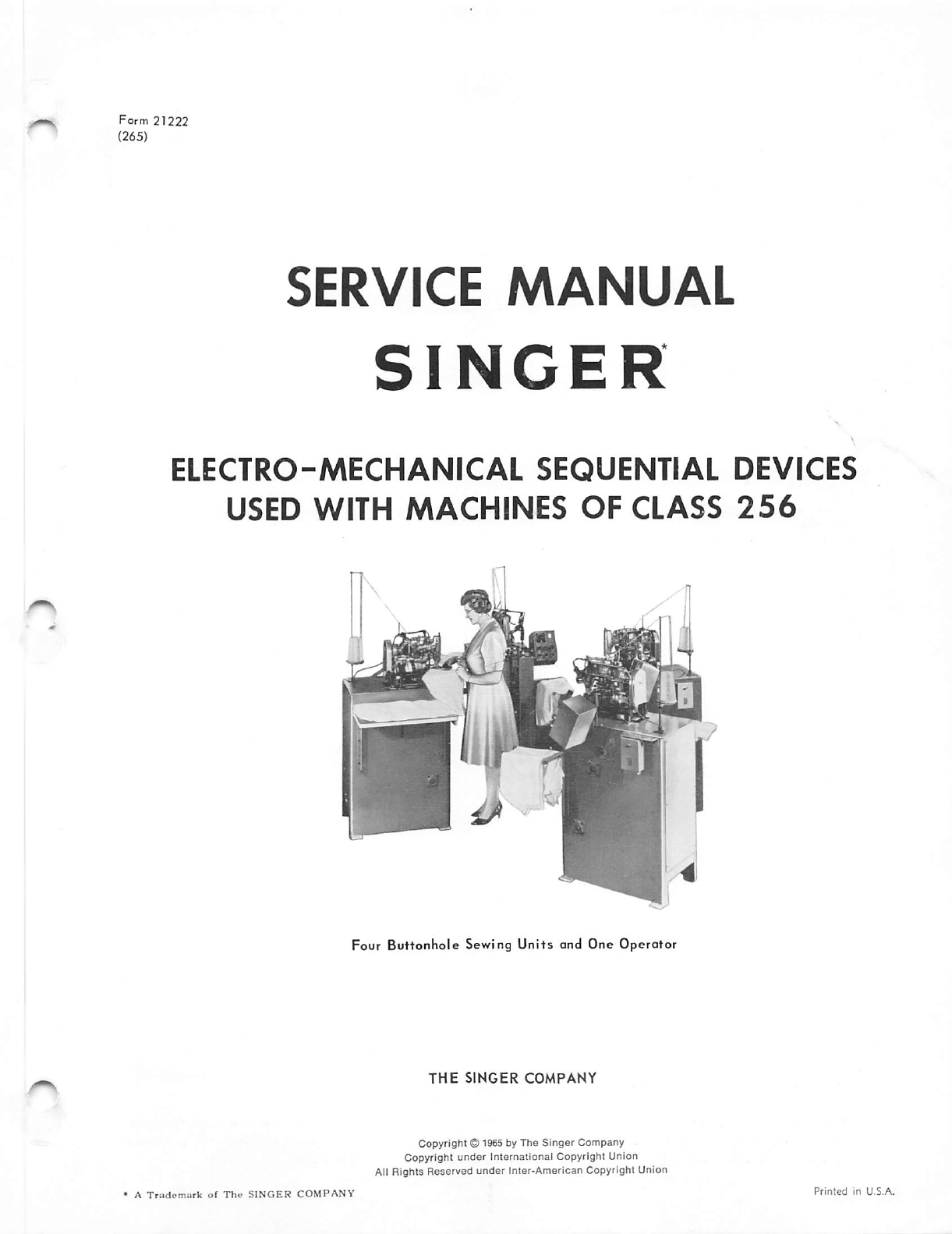

Electro-Mechanical

Sequential

Devices

are

designed

to

automatically

space

buttonhole

sewing

in

a

garment.

The spacing governs the

number

of buttonholes

which

can

be

sewn

in

one

cycling

ofthe

unit.

A complete unit consists of a steel cabinet

which

houses the

mechanism

required

for

the

automatic

move

ment of the garment. Top surface of cabinet

forms

a

table

which

supports

a

sewing

machine

and

a

control

panel.

GENERAL

FEATURES

Com

actuated

mechanism

controls operation of

sewing machine.

Electrical switches control operation of entire

device.

G>ntrol panel

contains

electrical

equipment

neces

sary to coordinate control circuits. Panel is equipped

with thermal-overload

protection.

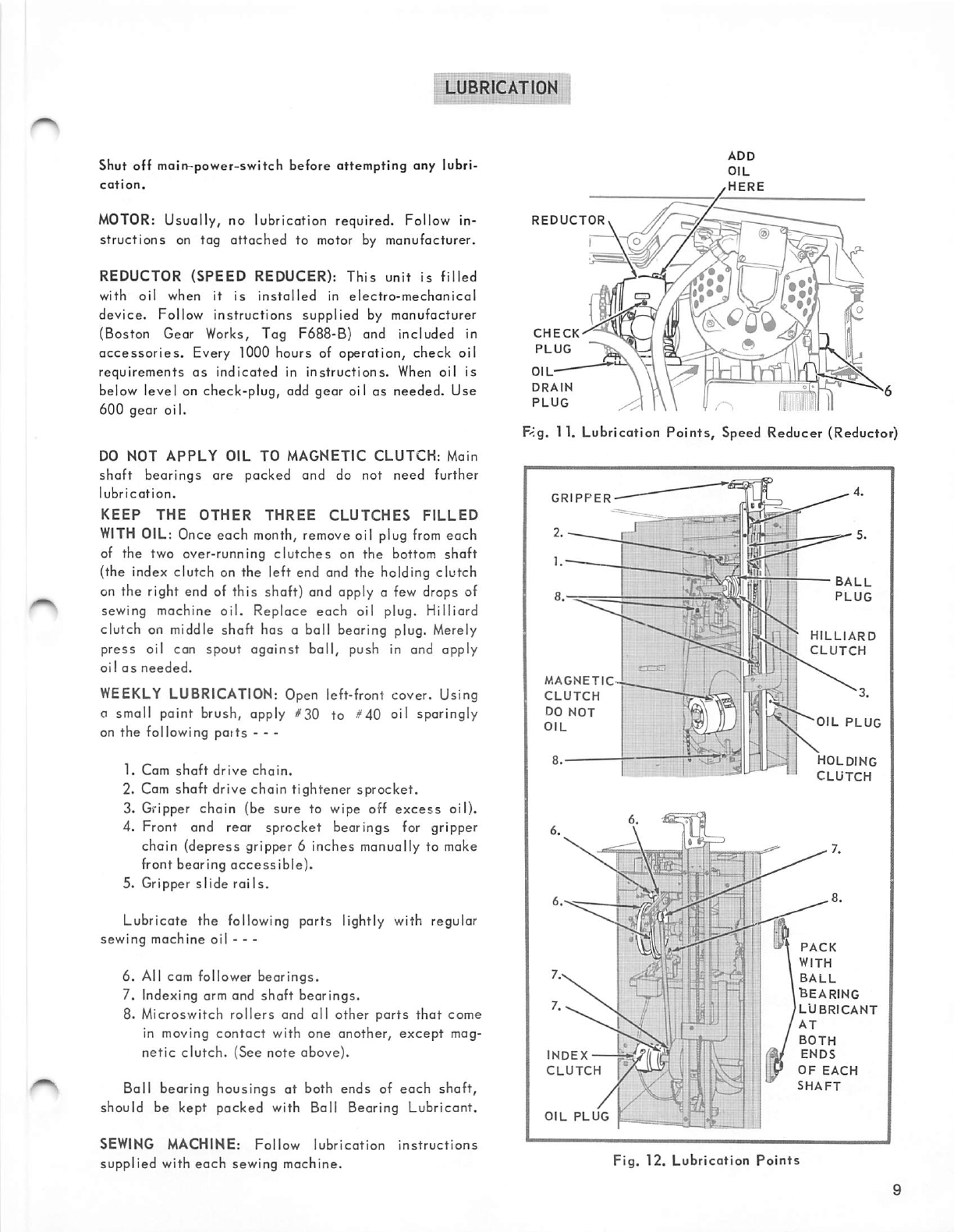

ASeries 38 Motor drives sewing machine. Indexing

Unit is

also

driven by this motor through Speed-Re-

ducer. Orders for motor must specify correct voltage,

cycles

and

phase

required.

SPECIAL

FEATURES

ELECTRO-MECHANICAL

SEQUENTIAL

DEVICE

257000 is designed for

use

with Buttonhole Sewing

Machine

71-201.

Entire automatic buttonholing unit is

known

as

Machine

256W1.

Machine

256W1

sequentially positions buttonholes

parallel to edge of garment in accordance with a pre

determined spacing. Buttonholes con be aligned

from

3/8

inch to 1 inch from edge of facing.

The

machine

positions

and feeds

the

garment so

that buttonholes are located vertically. From 3 to 7

buttonholes con be sewn in one

cycle,

depending upon

the desired spacing within the machine's travel limit

of

19

inches.

Spacing between buttonholes is adjustable

from

2)4

inches

to 5)4

inches

opart.

Feed

wheels

available

for 100, 120, 150

and

180

stitches per buttonhole. Machine regularly supplied

with feed wheel for 120

stitches

per buttonhole.

j:.

'j • '

L,

With equal

ease,

machine

handles

resin-finished

cottons, cotton and synthetic blends, 100%

synthetics

and

silks.

Acounter automatically

stops

machine before bob

bin thread runs out. Red Indicator Light informs opera

tor of

reason

for

stoppage.

If

needle

thread

breaks,

buttonhole knife is auto

matically prevented

from

cutting buttonhole and opera

tion is automatically stopped.

Knives available will cut buttonholes

3/8",

1/2",

5/8"

and

3/4"

long. Machine regularly fitted to cut

buttonholes

5/8"

long.

At completion of each buttonholing

cycle,

indexing

clomp is automatically returned to open

"start"

posi

tion (ready to accept new work).

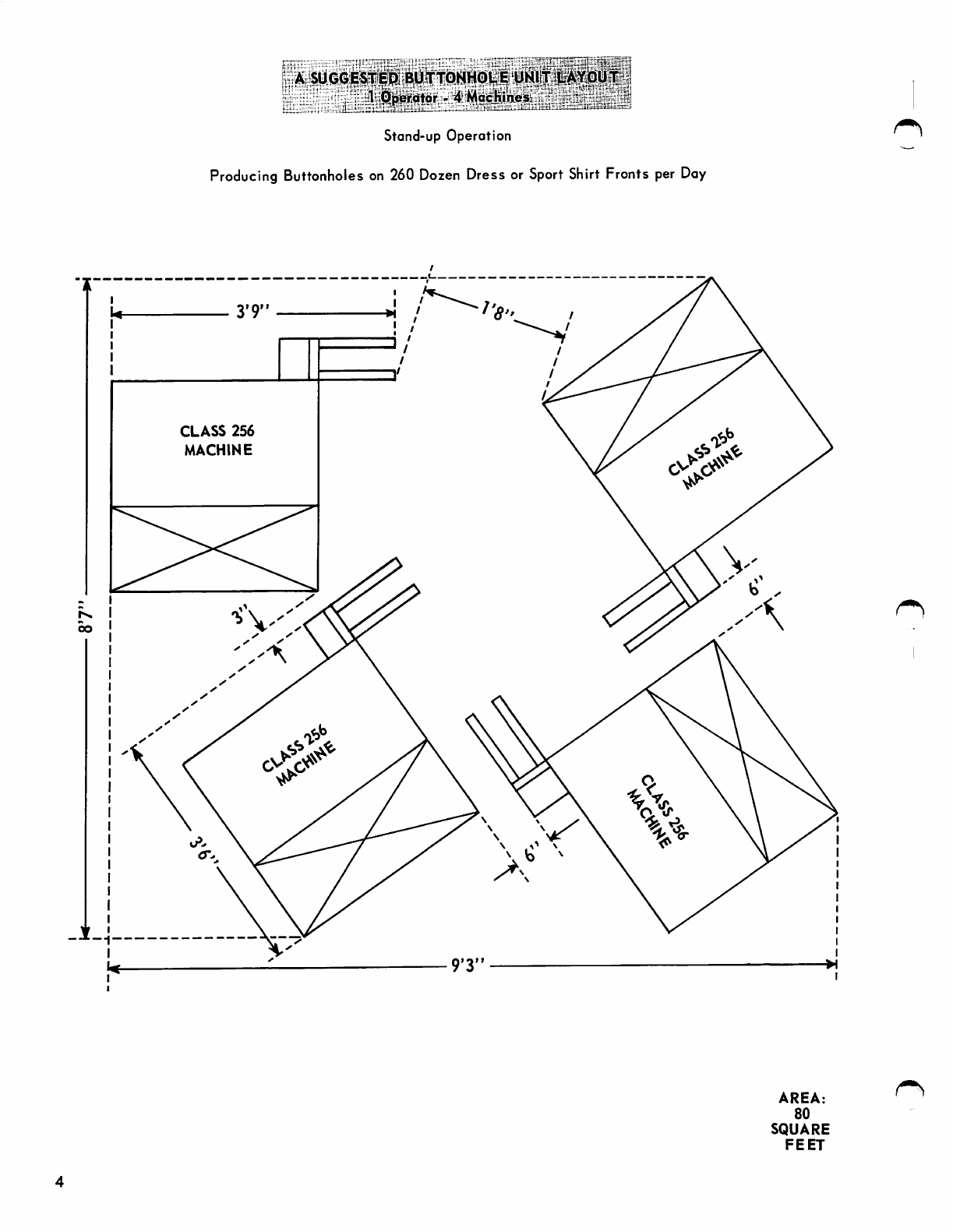

Convenient feeding and receiving racks simplify

loading and unloading of work.

Operation of each unit requires little more than

placing

work

under clamp, pressing starting button and

removing

work

when cycle is completed.

The sewing head. Machine 71-201, has an oscil

lating shuttle and a

maximum

speed of 2000 R. P.

M.

Instructions for servicing Machine 71-201

are

contained

in

Form

2174W.

In addition to the sequential device, the sewing

head and other units already mentioned. Machine

256W1

includes

an

adjustable

upper cloth

plate,

athread un

winder and a light fixture.

ELECTRO-MECHANICAL

SEQUENTIAL

DEVICE

257464 is designed for use with Buttonhole Sewing

Machine 271K201.

Entire

automatic buttonholing unit

is

known

as

Machine

256-5.

Machine 256-5 is

essentially

the same as Machine

256W1,

except

for sewing head in

use.

The sewing head.

Machine

271K201,

has a lubri

cated rotary sewing

hook

and a two-speed drive. Its

maximum

speed is 3000 R. P.

M.

Instructions for ser

vicing

Machine

271K201

are contained in

Forms

21303

and K6640,

available

upon

request.

From the library of: Superior Sewing Machine & Supply LLC