TABLE OF CONTENTS

INTRODUCTION............................................. 1

Intended Use .................................................................. 1

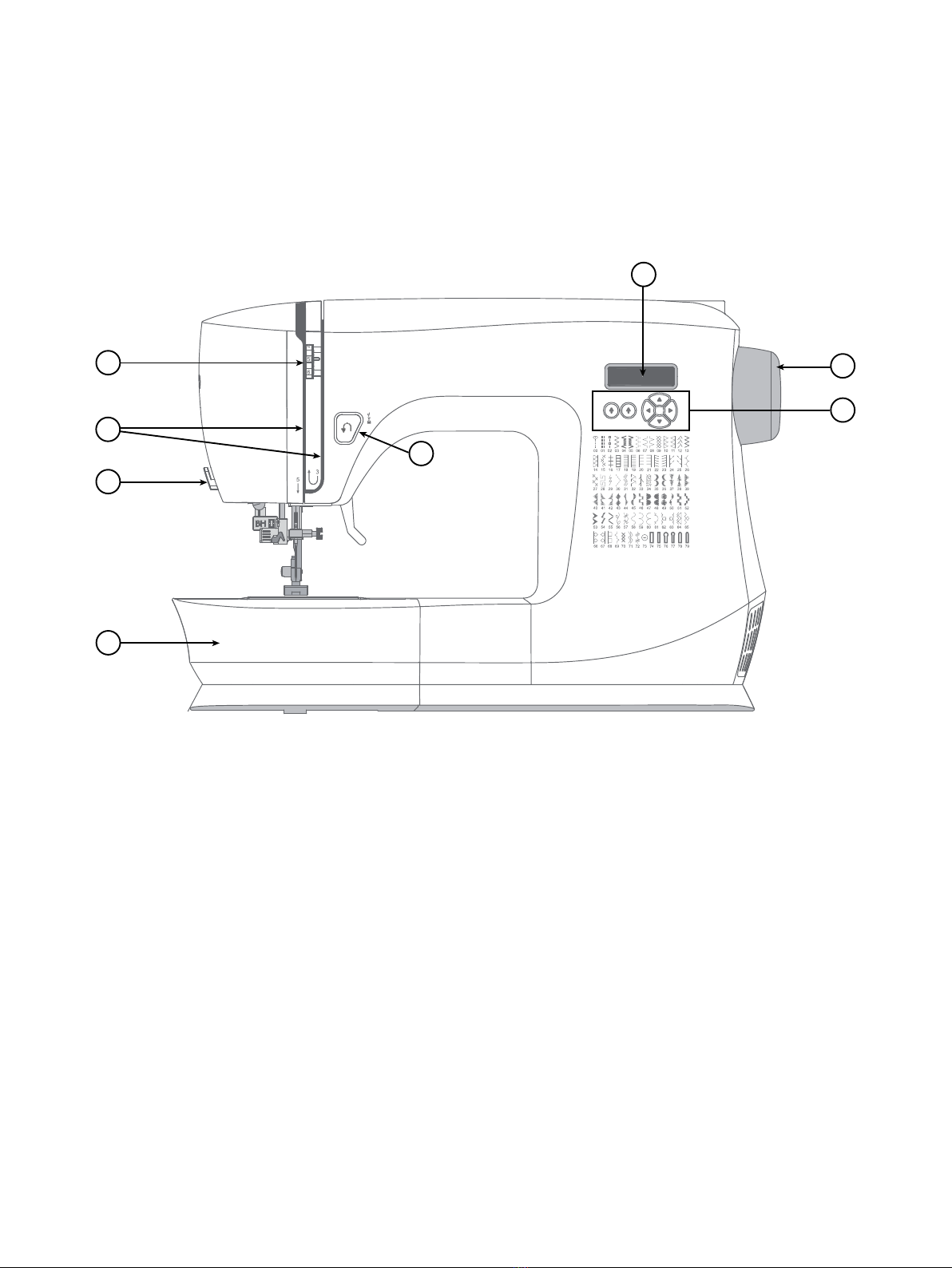

Machine Overview.......................................................... 1

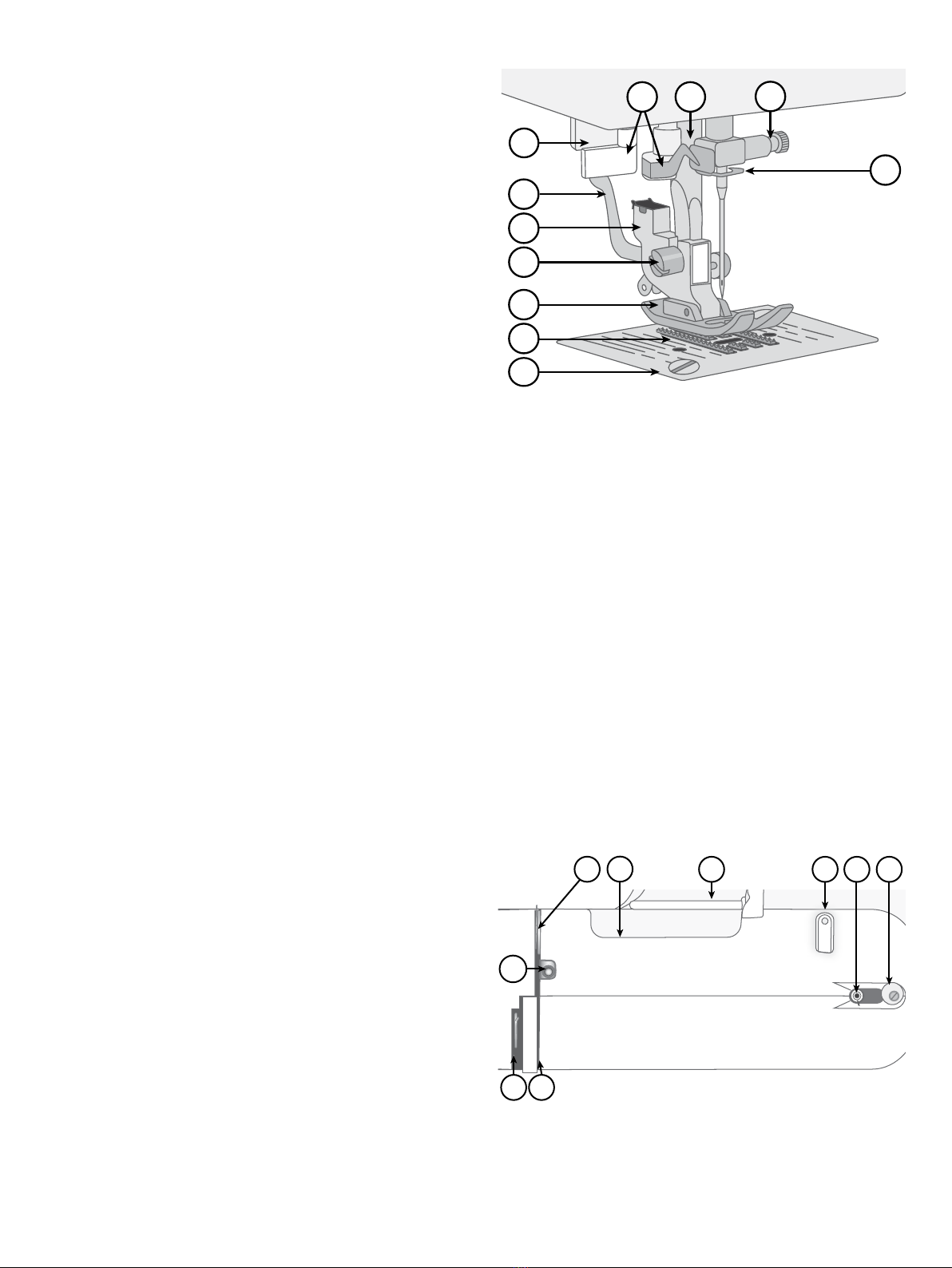

Needle Area Overview.................................................... 2

Top of Machine ............................................................... 2

Overview Accessories .................................................... 3

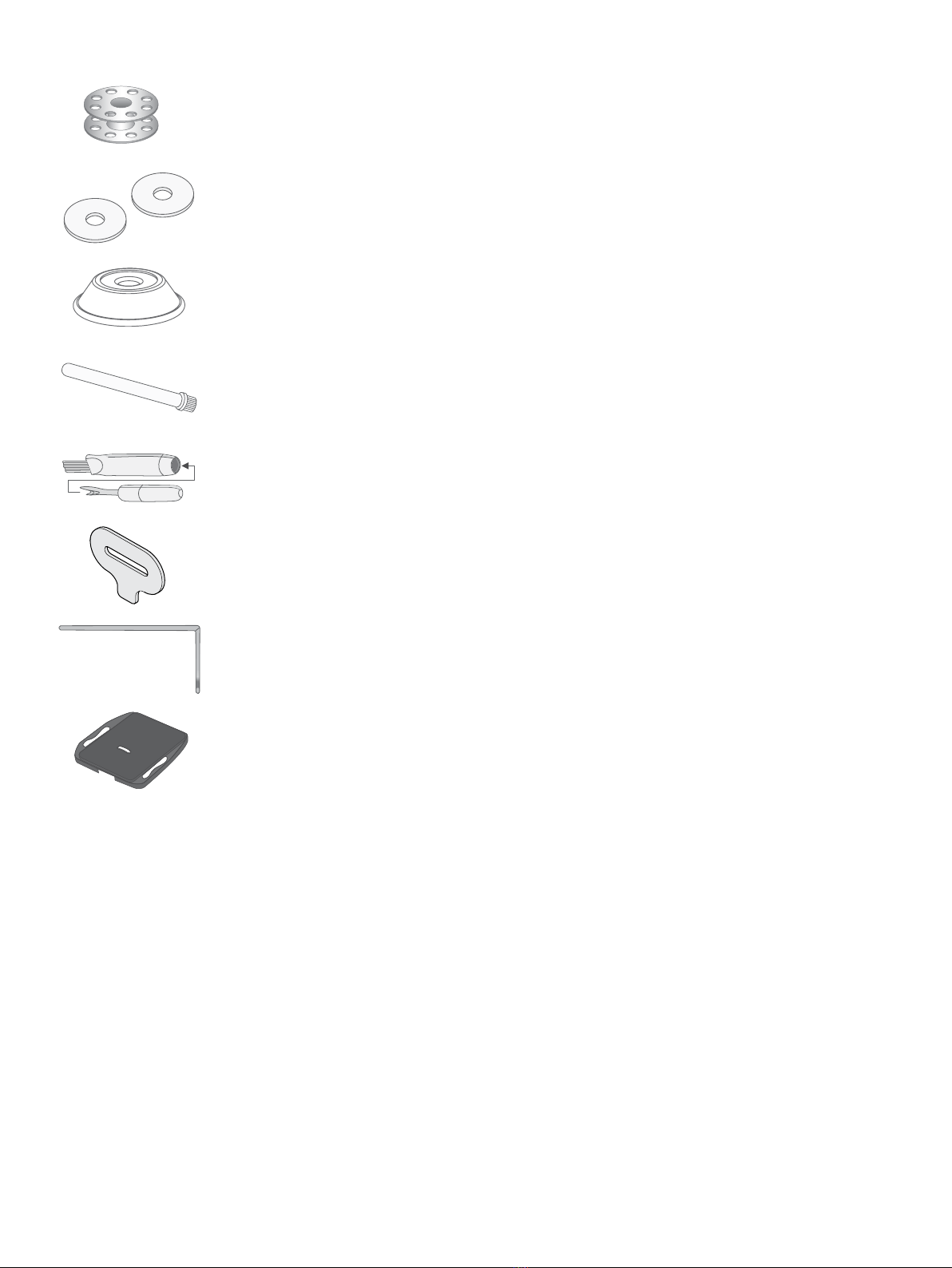

Included Accessories ................................................. 3

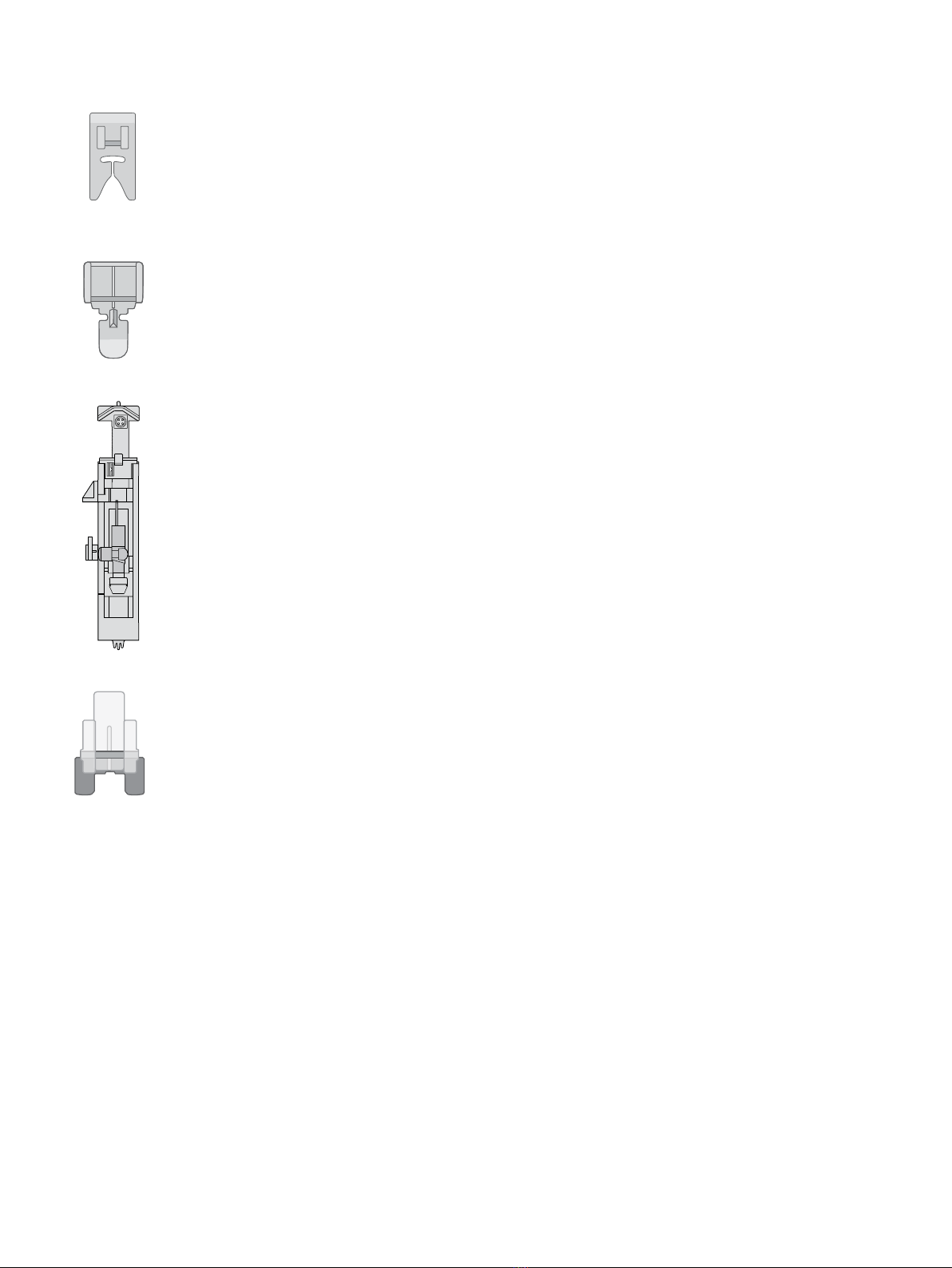

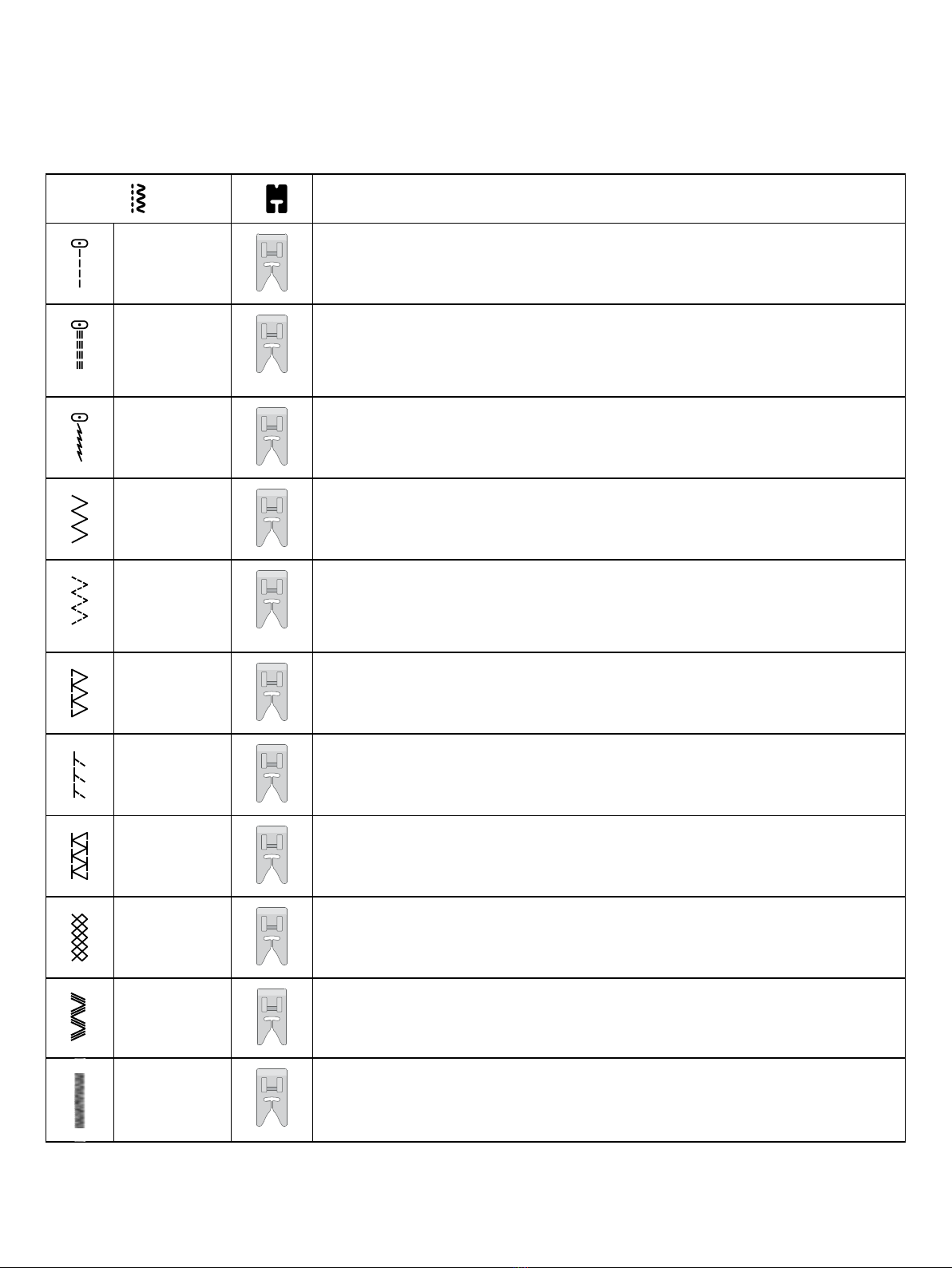

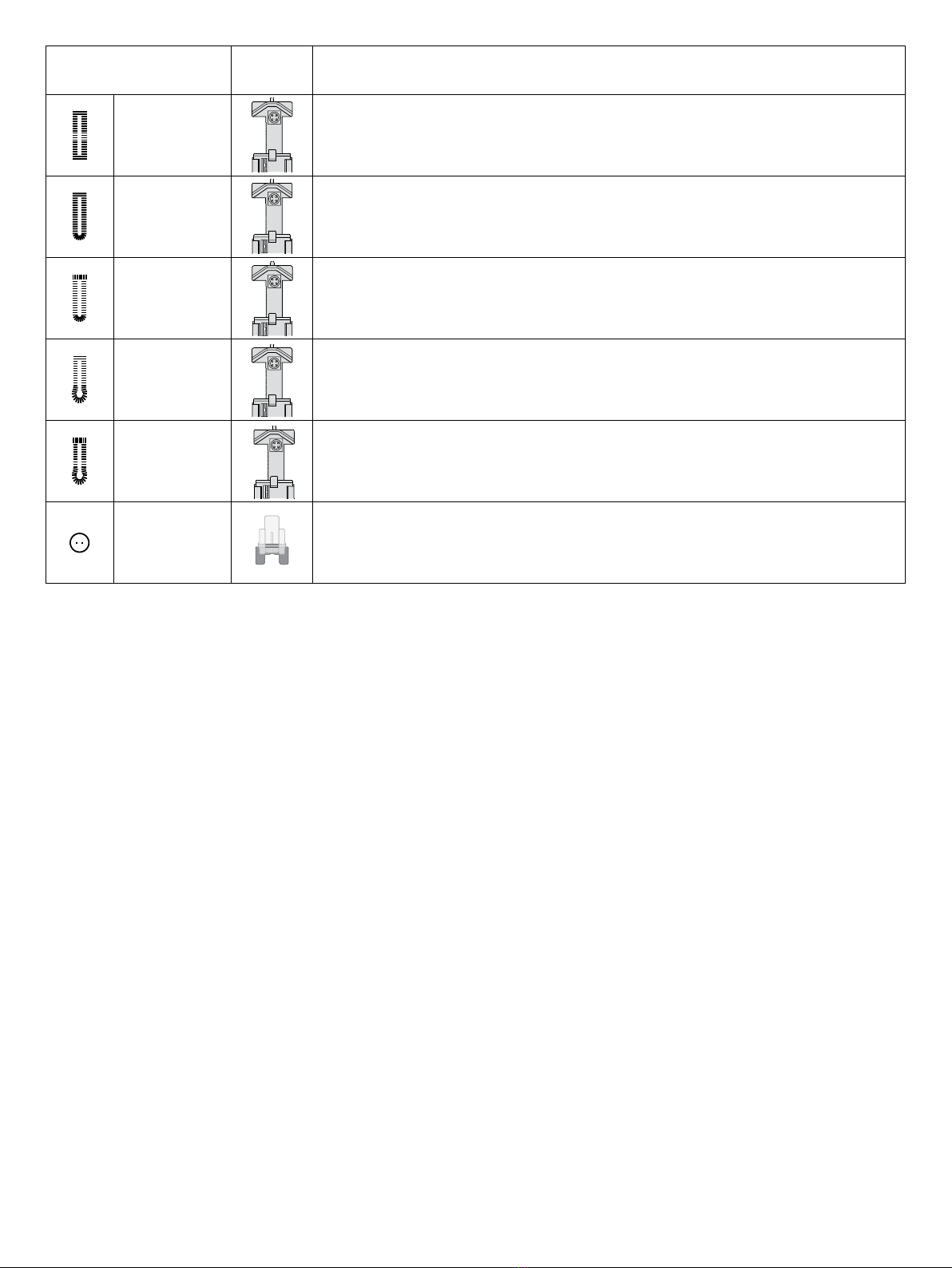

Presser Feet................................................................... 4

Optional Accessories .................................................. 4

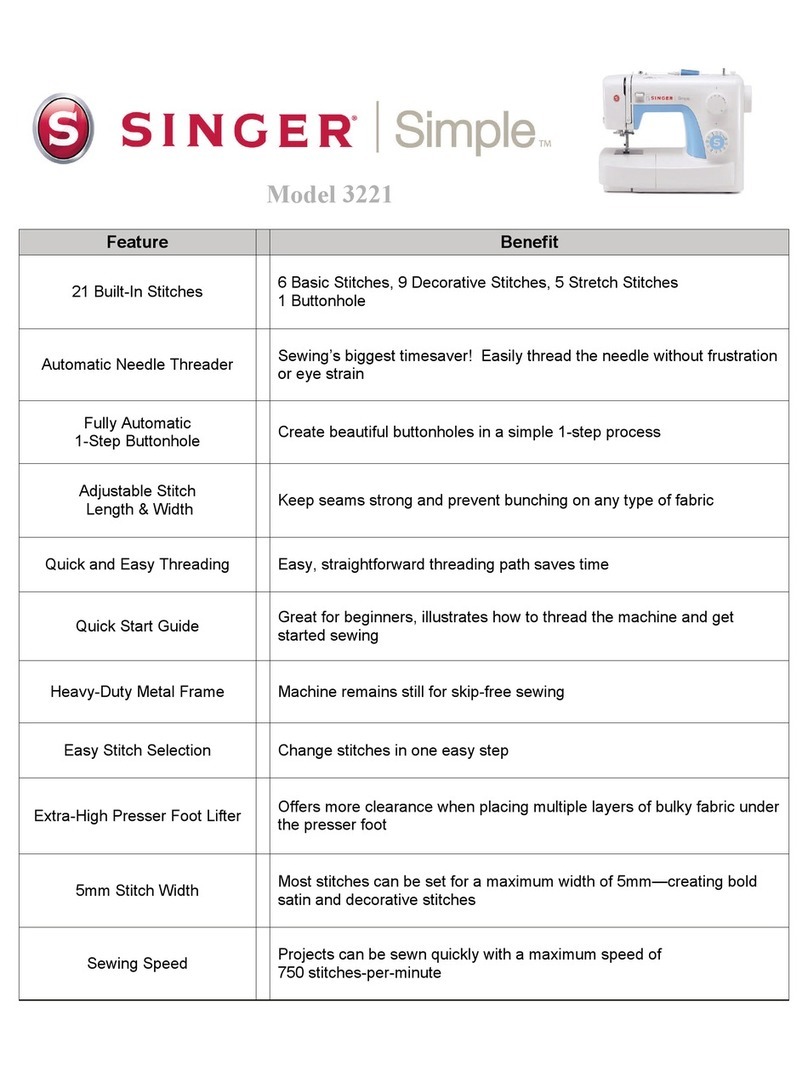

Stitch Overview............................................................... 5

Choosing Utility and Decorative Stitch Patterns ......... 5

PREPARATIONS............................................ 7

Unpacking the Machine.................................................. 7

Connect to the Power Supply......................................... 7

Packing Machine after Sewing ....................................... 7

Free Arm/Removable Accessory Tray ............................ 8

Presser Foot Lifter.......................................................... 8

Thread Knife................................................................... 8

Spool Pin ........................................................................ 9

Wind the Bobbin ........................................................... 10

Removing Bobbin Case from Shuttle ........................... 10

Inserting Bobbin Into Bobbin Case................................11

Inserting Bobbin Case Into Shuttle................................11

Picking Up Bobbin Thread.............................................11

Thread the Machine...................................................... 12

Needle Threader........................................................... 13

Needles ........................................................................ 13

Important Needle Information ................................... 14

Selection Guide — Needle Size, Fabric, Thread ...... 14

Change the Needle....................................................... 14

Thread Tension............................................................. 15

Change the Presser Foot ............................................. 15

OPERATING YOUR MACHINE.................... 16

Machine Operation Controls......................................... 16

Reverse Button ......................................................... 16

Tie-O ....................................................................... 16

Functions of Control Panel ........................................... 16

Stitch Number Selection Buttons .............................. 17

Stitch Length and Stitch Width / Needle Position...... 17

Helpful Messages......................................................... 18

SEWING........................................................ 19

Sewing.......................................................................... 19

Start to Sew – Straight Stitch........................................ 19

Change Needle Position ........................................... 19

Change Sewing Direction............................................. 20

Finish Sewing ............................................................... 20

Straight Stretch Stitch................................................... 20

Zigzag Stitching............................................................ 21

Multi-Step Zigzag Stitch................................................ 21

Slant Overedge Stitch................................................... 21

Overedge Stitch............................................................ 22

Feather Stitch ............................................................... 22

Shell Stitch.................................................................... 23

Double Overlock Stitch ................................................ 23

Ladder Stitch ................................................................ 23

More Decorative Stitches &

Ideas For Decorative Machine Stitching....................... 24

Darning and Mending ................................................... 24

Repair Large Holes ................................................... 24

Repair Tears.............................................................. 24

One-Step Buttonhole.................................................... 25

Sew Zippers.................................................................. 26

Centered Zipper ........................................................ 26

Hand-Look Quilt Stitch.................................................. 27

Button Sewing .............................................................. 27

MAINTENANCE............................................ 28

Cleaning the Machine................................................... 28

Cleaning the Feed Teeth and Shuttle Area................... 28

Cleaning the Sewing Machine

and Foot Control........................................................... 28

Troubleshooting............................................................ 29

Technical Specication ................................................. 32