From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

8

MOVE TO

HIGHEST POINT

,.,,LOOSEN

SCREW

~

INSERT

NEEDLE

UP

FAR

AS

POSSIBLE

ND TIGHTEN SCREW

1 LONG

GROOVE

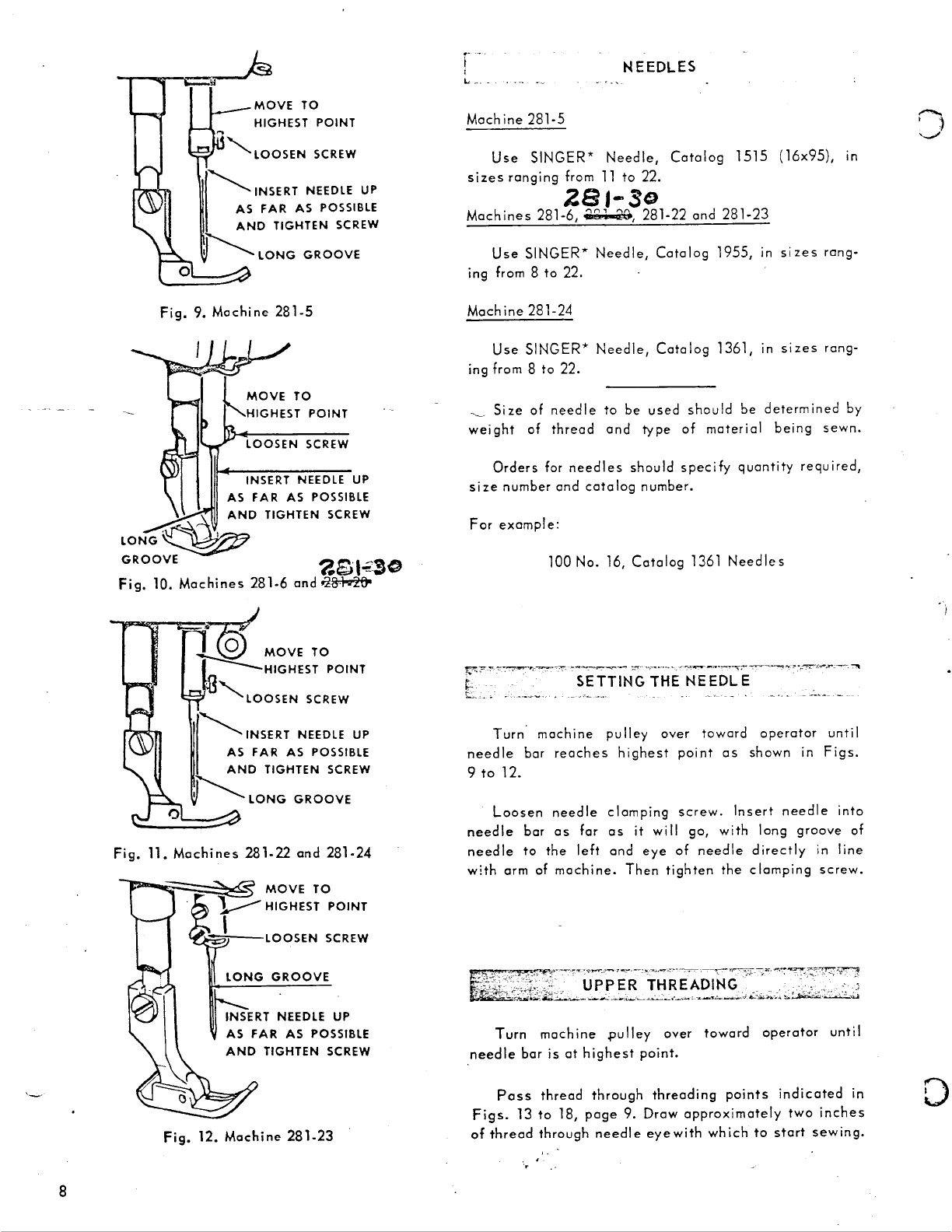

Fig.

9.

Machine

281-5

MOVE TO

HIGHEST POINT

LOOSEN SCREW

INSERT

NEEDLE

UP

AS FAR AS POSSIBLE

ND TIGHTEN SCREW

LONG.

~

I

GROOVE

2s,~so

Fig.

10.

Machines

281-6

and

,z&mt,o

7d

MOVE

TO

~HIGHEST

POINT

.

'LOOSEN

SCREW

~INSERT

NEEDLE

UP

FAR AS POSSIBLE

ND TIGHTEN SCREW

1 LONG

GROOVE

Fig.

11.

Machines

281-22

and

281-24

MOVE

TO

HIGHEST

POINT

AS

FAR

AS POSSIBLE

AND

TIGHTEN

SCREW

Fig. 12. Machine 281-23

NEEDLES

Machine

281-5

Use

SINGER*

Needle,

Catalog

1515

(16x95),

in

sizes

ranging

from

11

to

22.

2e,-so

Machines

281-6,

.'.,,1-20,

281-22

and

281-23

Use

SINGER*

Needle,

Catalog

1955,

in

sizes

rang-

ing from 8

to

22.

Machine

281-24

Use

SINGER*

Needle,

Catalog

1361,

1n

sizes

rang-

ing from 8

to

22.

Size

of

needle

to

be

used

should

be

determined

by

weight

of

thread

and

type

of

material

being

sewn.

Orders

for

needles

should

specify

quantity

required,

size

number

and

catalog

number.

For

example:

100

No. 16,

Catalog

1361

Needles

~.~-,-,,""'"7'!!1"'1'P;-~~------._..,..,...

~.-·

,•~~---~-="'

~

•.

--.,-._"-~'-'-,-"

-:'II

i -

SETTING THE

NEEDLE

L,

..

~ ~

--~---...-

. --

--·~

-

....

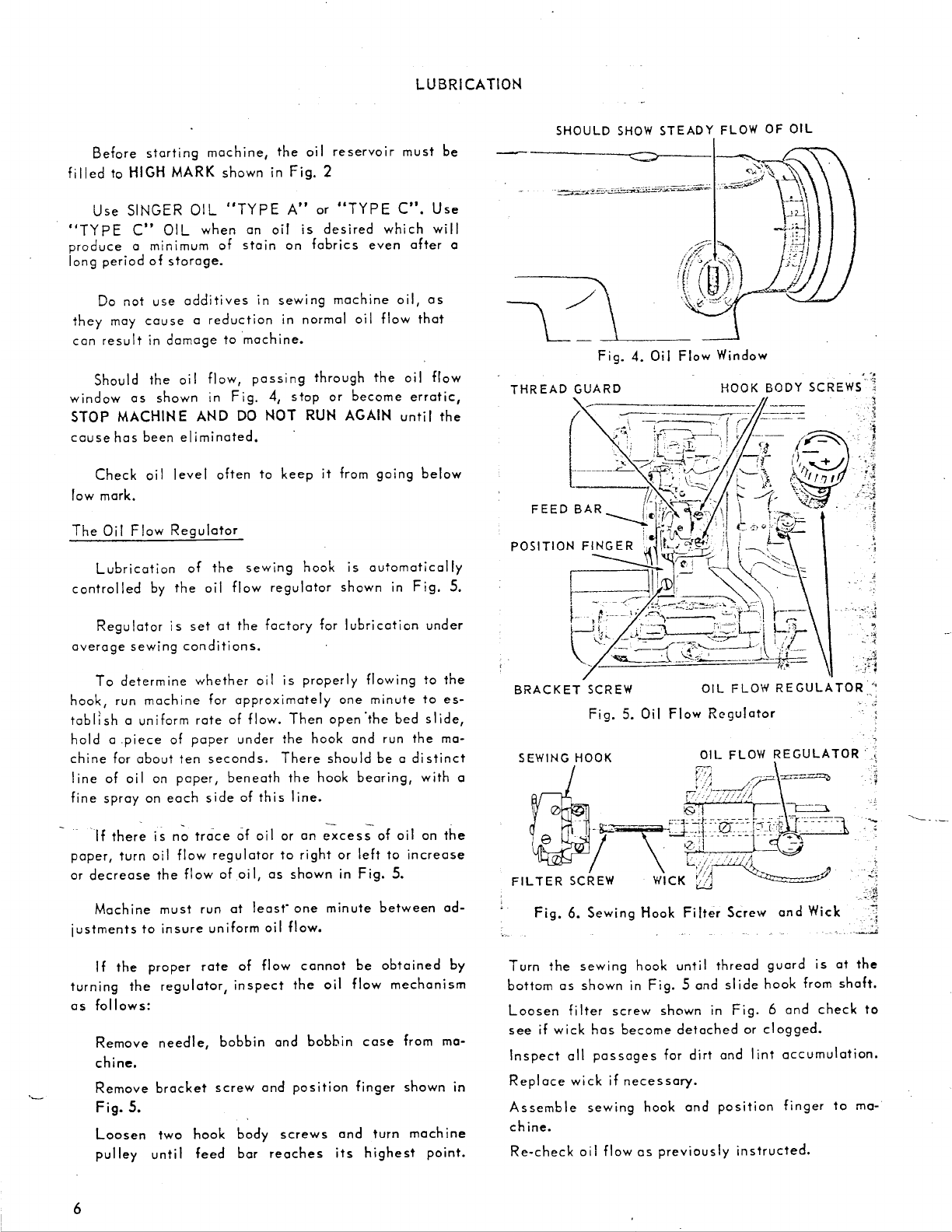

Turn·

machine

pulley

over

toward

operator

until

needle

bar

reaches

highest

point

as

shown

in

Figs.

9

to

12.

Loosen

needle

clomping

screw.

Insert

needle

into

needle

bar

as

for

as

it

will

go,

with

long

groove

of

need

le

to

the

I

eft

and

eye

of

need

le

directly

in

Ii

ne

with

arm

of

machine.

Then

tighten

the

clomping

screw.

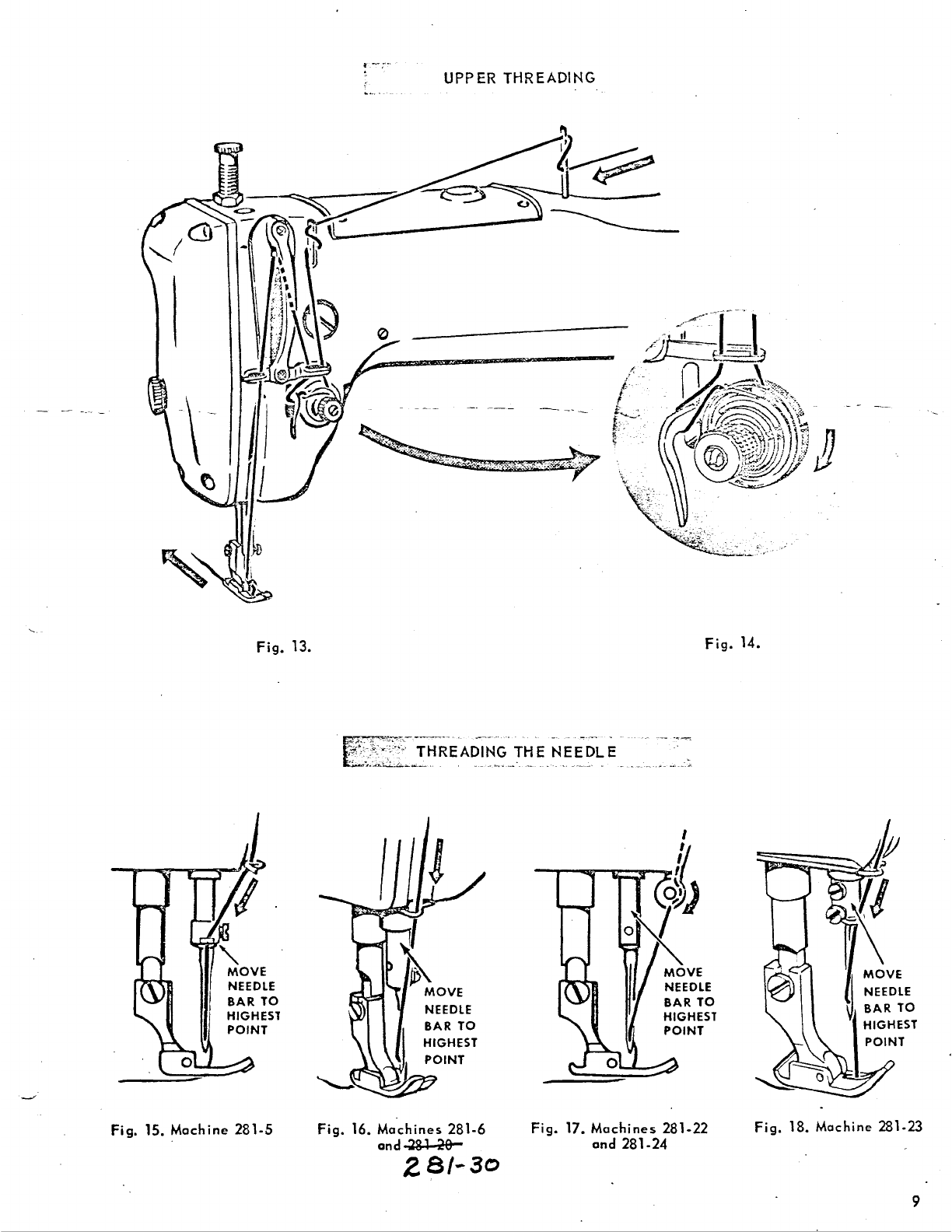

Turn

machine

.pulley

over

toward

operator

until

needle

bar

is

at

highest

point.

Poss

thread

through

threading

points

indicated

in

Figs.

13

to

18,

page

9.

Drow

approximately

two

inches

of

thread

through

needle

eyewith

which

to

start

sewing.

0