CONTENTS

Page

1. Getting to Know Your Machine ............................................................................................................................ 1

Principal Parts and What The Do.................................................................................................................... 1

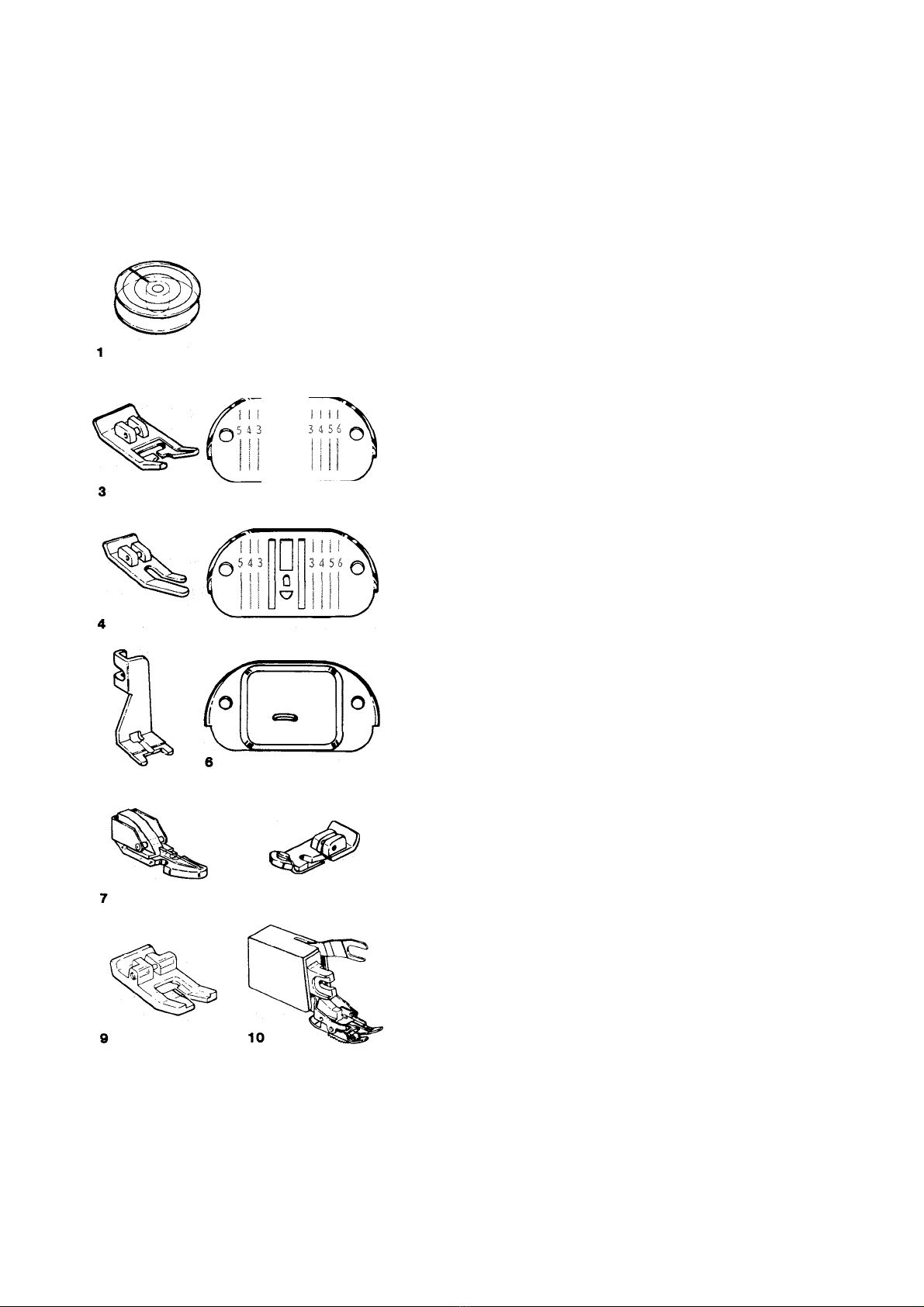

Accessories............................................................................................................................................................ 2

2. Getting Read to Sew............................................................................................................................................... 6

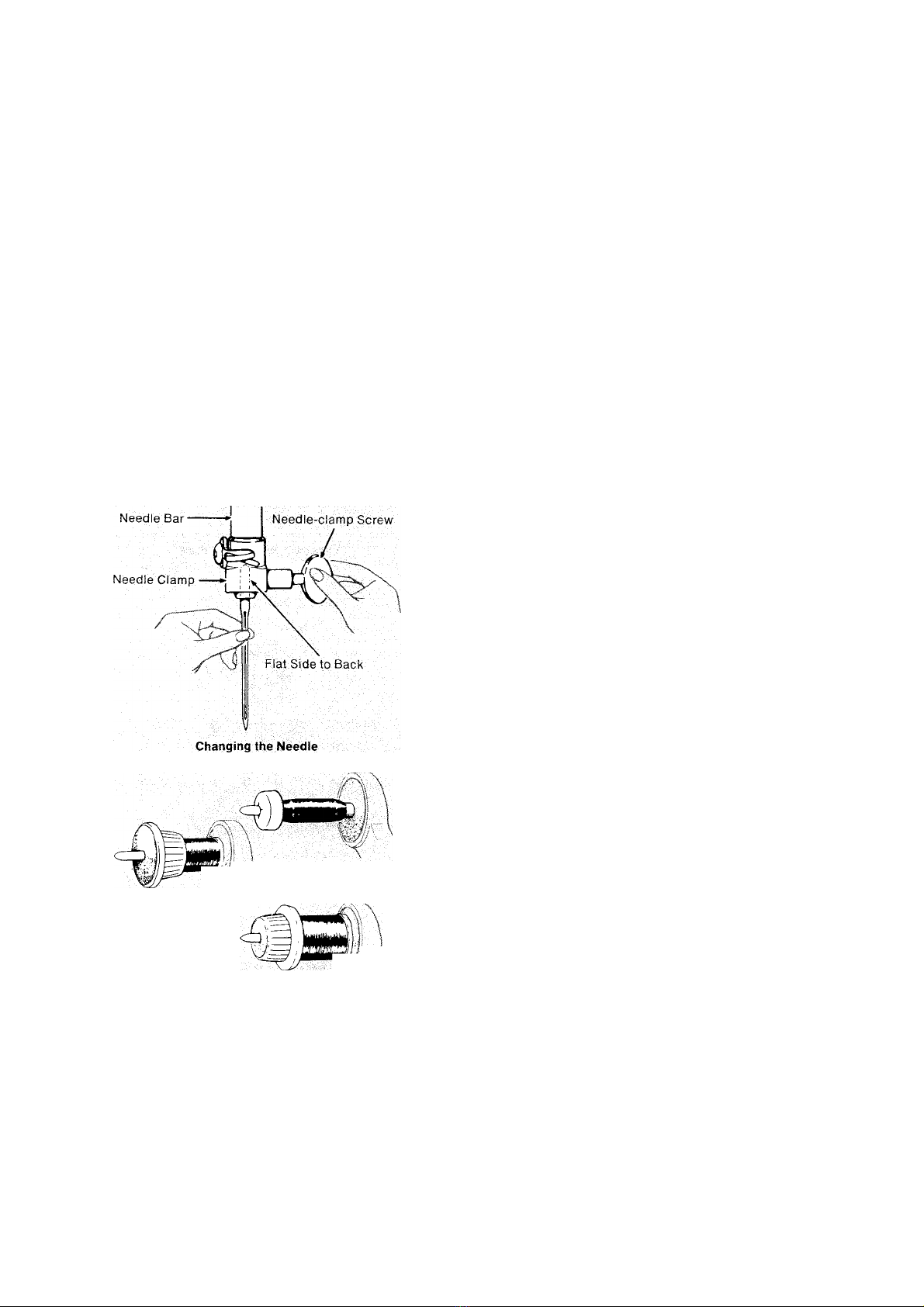

Needles .................................................................................................................................................................. 6

Operating Machine ............................................................................................................................................... 7

Choosing Needle and Thread............................................................................................................................... 8

Threading the Machine......................................................................................................................................... 9

Threading the Needle • Winding the Bobbin

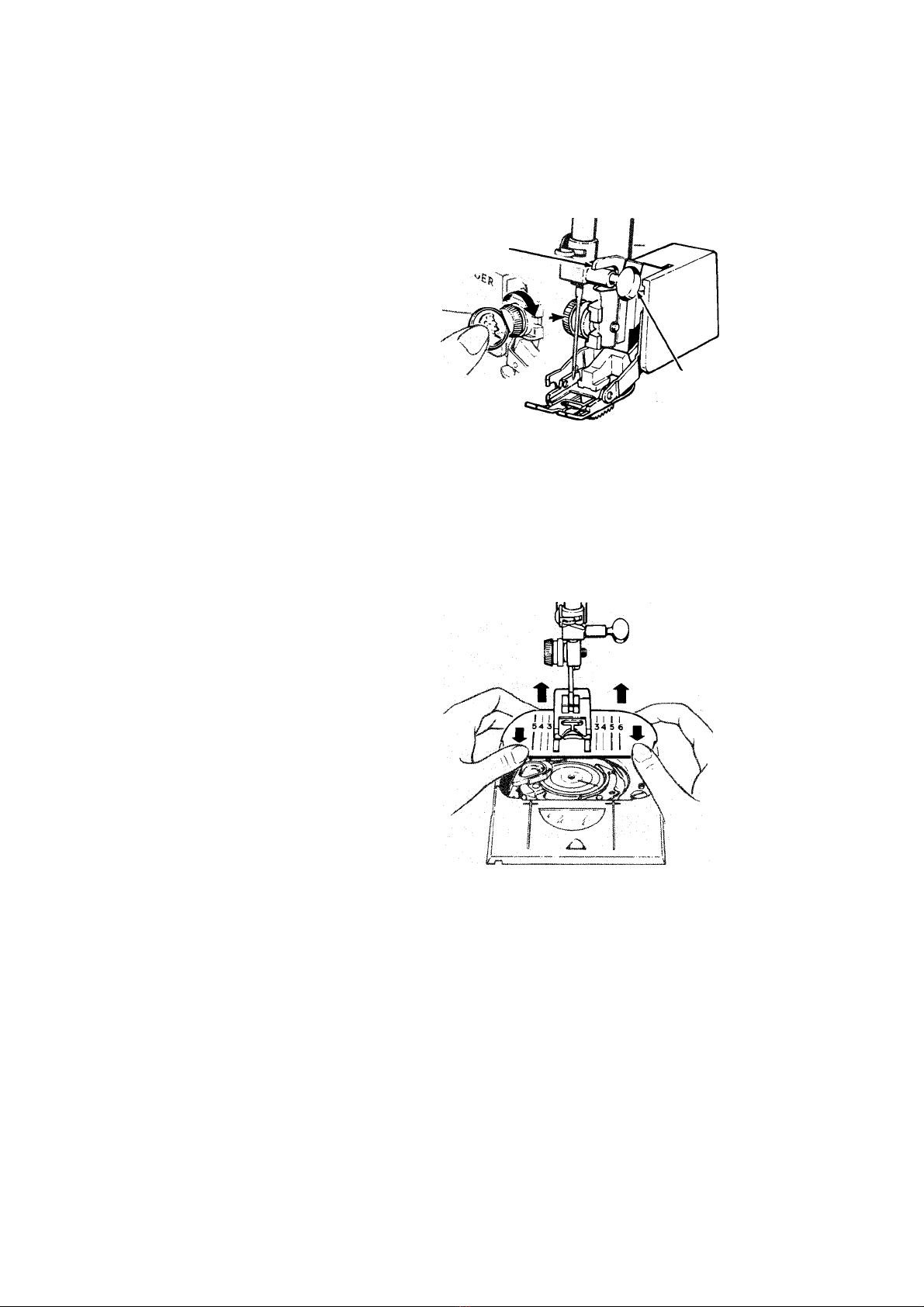

Changing the Bobbin.......................................................................................................................................... 12

3. Tips on Straight Stitching ..................................................................................................................................... 14

Adjusting Machine to Your Fabric .................................................................................................................... 14

Setting Controls • Regulating Pressure • Regulating Needle-thread Tension • Setting

Stitch Length

Sewing a Seam.................................................................................................................................................... 16

4. All About Zig-Zag Stitching................................................................................................................................... 20

How Stitches Are Produced .............................................................................................................................. 20

Setting Pattern Selector • Adjusting Stitch Placement • Adjusting Stitch Width • Adjusting

Needle-thread Tension • Adjusting Stitch Length

Finding the Beginning of a Pattern Unit .......................................................................................................... 23

Adjusting Stitch Balance When Using Flexi-Stitch Patterns

...........................................................................

23

Interchangeable Fash/on and F/ex/-Sf/fc/7 Discs .......................................................................................... 24

5. Twin-Needle Stitching............................................................................................................................................ 26

6. Temporar Stitching............................................................................................................................................... 28

7. Buttons and Buttonholes ..................................................................................................................................... 34

Buttons ................................................................................................................................................................ 34

Buttonholes .................................................................................................................................................... 35

8. Sewing the Professional Wa ............................................................................................................................... 41

Construction Details ......................................................................................................................................... 41

Zippers • Corded Seams • Blindstitch Hems • Darts

Sewing Knit and Stretch Fabric......................................................................................................................... 44

Stretch Stitch Chart • Starting to Sew Using a Flexi-Stitch Pattern • Guiding and Supporting

Fabric • Adjusting Pressure • Plain Stretch Seams • Maxi-Topstitching • Overedged

Seams • Mock Overedging • Finishes for Hems and Facings

Handling Special Fabrics................................................................................................................................... 50

Fabric-Handling Table • The Even Feed foot

Decorative Touches

..............

............................................................................................................................ 54

Satin Stitching • Applique • Free-Motion Embroider • Hesitation Embroider •

Topstitching

Keeping Up Appearances ................................................................................................................................. 58

Darning • Mending • Replacing Lingerie Elastic • Stitch Centering

9. Free-Arm Sewing .................................................................................................................................................. 61

Your Personal Measurements .......................................................................................................................... 65

10. Caring for Your Sewing Machine.......................................................................................................................... 66

11. Sewing Aids ........................................................................................................................................................... 69

Index................................................................................................................................................................................ 70

Instrukcje obsługi maszyn do szycia firm Polskich jak i zagranicznych np. Singer Toyota Pfaff Gritzner Łucznik rka

maszynykrawieckie.shophurt.pl