DESCRIPTION

OF

MACHINES

Machines of

Class

281- are high

speed,

single

needle, lockstitch machines designed for sewing ma

terials ranging

from

light weight to heavy weight.

Among

the

varieties

covered

in

this

manual

are

puller-feed and needle-feed machines, top-gripper

machines and machines that perform simultaneous

trimming and

stitching.

All of these machines produce outstanding straight

line stitching in a wide range of wash-and-wear, syn

thetic

and

natural

fabrics.

Generol

Features

Federal stitch type 301.

Balanced, air cooled, rotating hook. Horizontal

Lint

wiper

keeps

lint and

abrasive

matter from ac

cumulating on hook.

Drop feed

consists

of pendant link feed with feed

leveling hinge pin.

Pendant link feed mechanism maintains longer feed

ing

cycle.

Three plain superfinished bearings support the

arm

shaft.

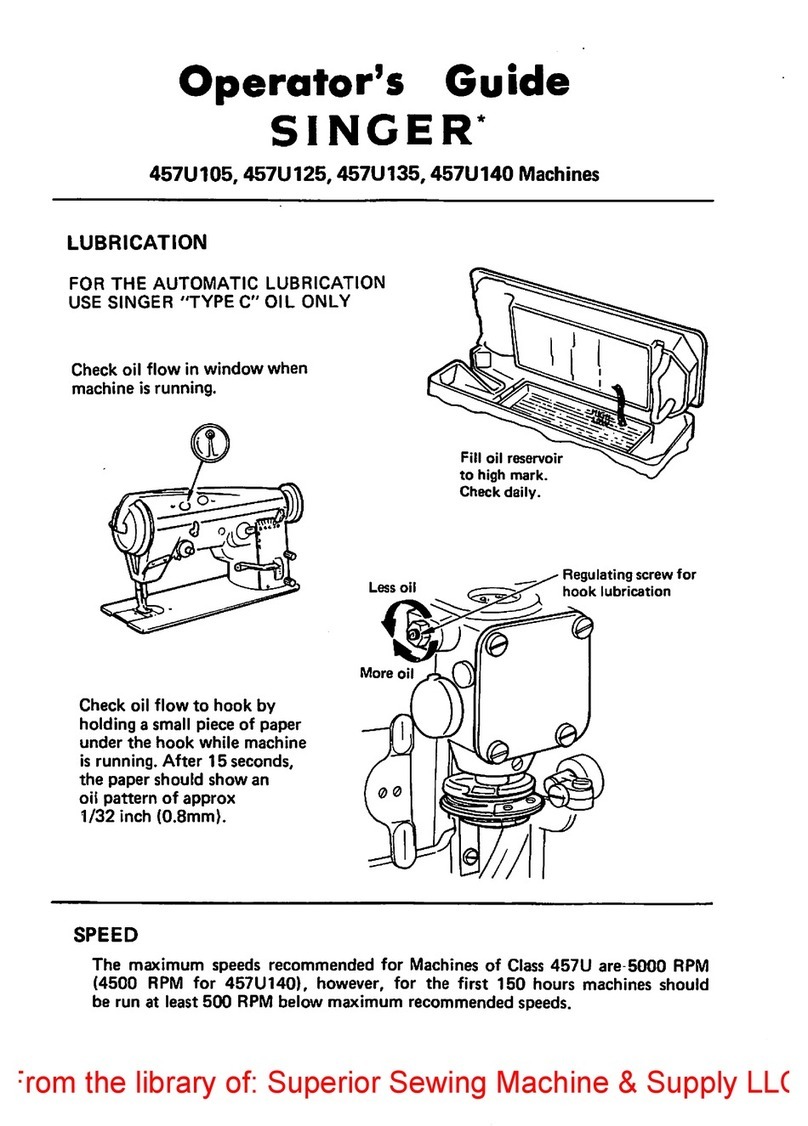

Fully automatic lubricating system with oil flow

window in

direct

view of

operator.

Knee lifter mechanism integral with machine base

and

oil

reservoir.

Independent light fixture mount.

Improved

needle

thread

guard

and

other

thread

hand

ling

ports.

Disc

tension.

Machinepulley 147139 for

3/8

inch V-belt.

Space

at right of

needle,

11

inches.

Machine

Varieties

Machine

281-5,

Vertical

Trimmer

Medium weight and heavy weight

fabrics.

Needle

bar

stroke,

1-13/64

inches

Presser

bar lift,

5/16

inch.

Knife bar

stroke,

5/16

inch.

Maximum

stitch

length, with regular

fittings,

5-1/2

stitches

per

inch.

Needle,

Catalog

1515 {16x95).

Bed-raising

plate

sets

flush

with

top

of

throat

plate.

Regularly fitted to trim

1/8

inch from line of

stitch

ing. Extra cutting bar and

presser

foot supplied for

3/16

inch.

When

specified

on order,

machines

can be

fitted

for

1/16, 3/32, 5/32, 3/16 or 1/4 inch

trim

margin.

Extra cutting bar and

presser

foot furnished in

each

instance

will be next

size

larger than

that

ordered.

When

1/4 inch (widest trim

margin)

is requested,

two

sets

of

this

size

will be supplied with machine.

Speed, 5000

stitches

per minute.

Mochine 281-6, Top Gripper

Collar and cuff operations on light weight to

medium

weight

fabrics.

Top driven gripper feed. Top feed intermittently

driven by linkage actuated through countershaft.

Countershaft driven by eccentric on arm shaft.

Eccentric

adjustable

to obtain optimum

relationship

between top and bottom feed. Top feed designed to

grip fabric

at

same

moment

that

bottom feed

rises

to

moke

contact

and

to

travel

with

bottom

feed

during

its entire

front

to rear feeding

motion.

Top

feed then returns (in

raised

position

above ma

terial) to beginning of next grip-feeding movement.

Needle

bar

stroke,

1-3/16

inches.

Presser

bar lift,

3/16

inch.

Maximum

stitch length, with regular fittings,

5-1/2

stitches

per

inch.

Needle,

Catalog

1955

Speed, 5000

stitches

per minute.