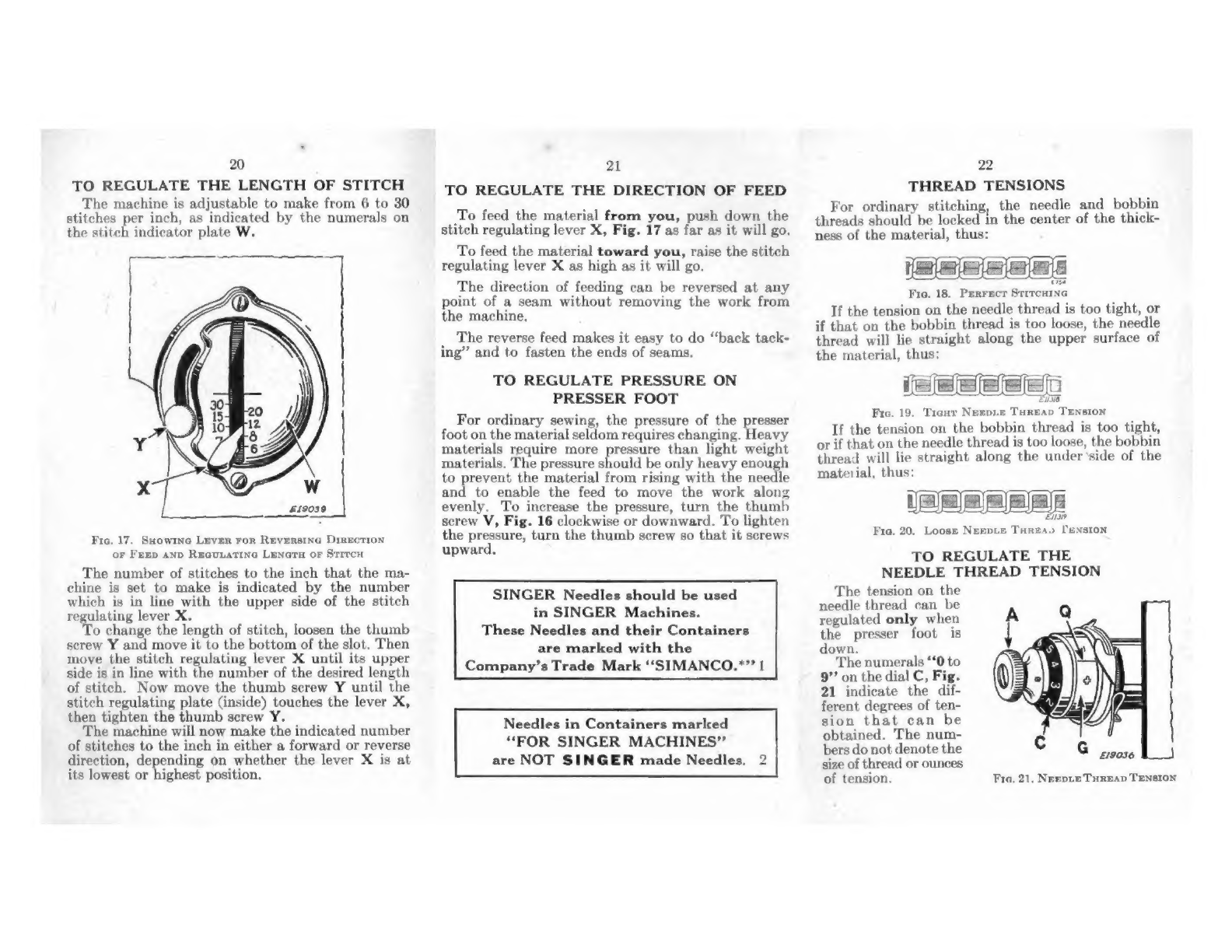

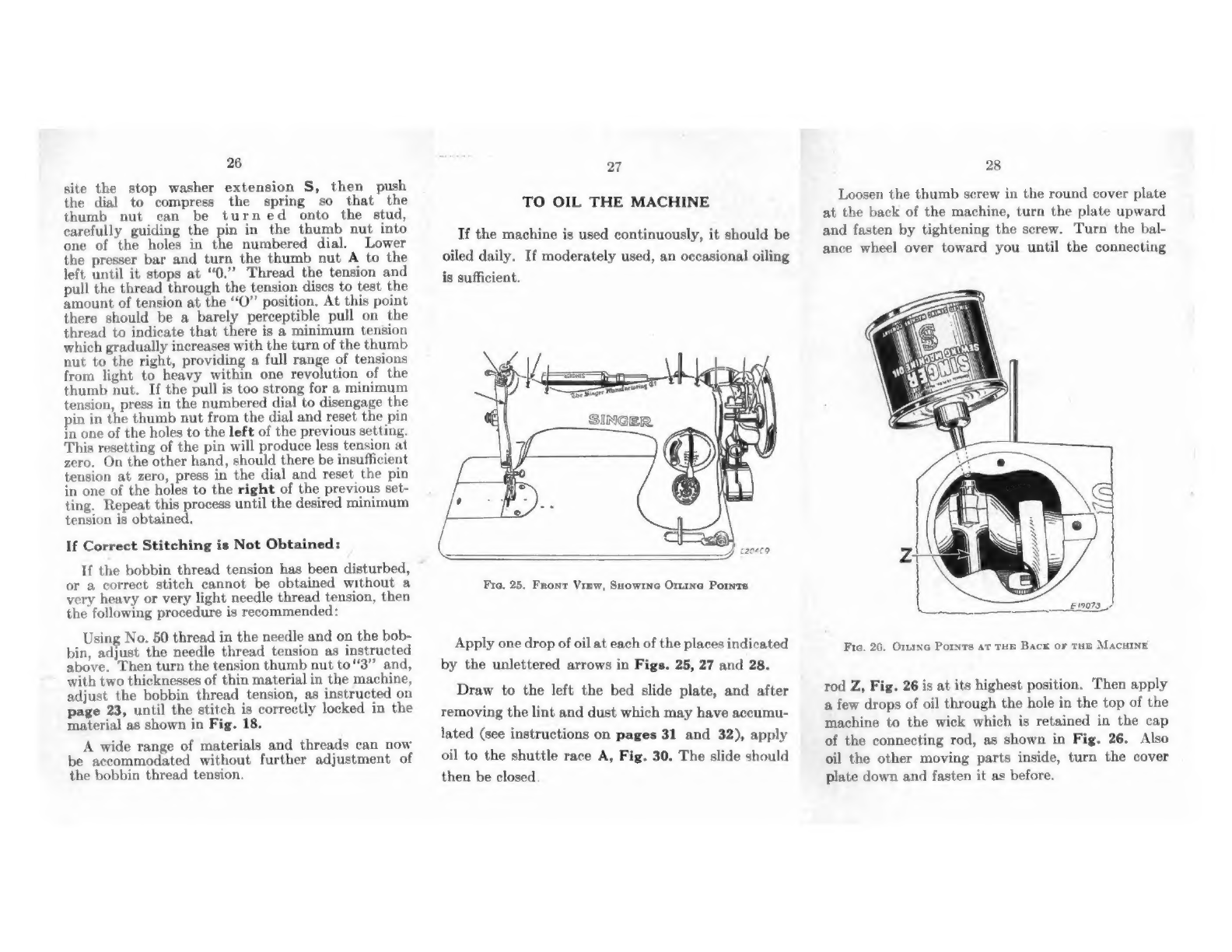

Singer 15-91 Installation and operation manual

Other Singer Sewing Machine manuals

Singer

Singer 246K42 Troubleshooting guide

Singer

Singer 5107 User manual

Singer

Singer 77-2 Installation and operation manual

Singer

Singer Inspiration 4220 User manual

Singer

Singer Sewing Machine User manual

Singer

Singer 71-53 User manual

Singer

Singer 66-16 User manual

Singer

Singer 71W1 Installation and operation manual

Singer

Singer 84-1 User manual

Singer

Singer 72W13 User manual

Singer

Singer Stylist 7258 User manual

Singer

Singer 29U 171A User manual

Singer

Singer Fashion Mate 3333 User manual

Singer

Singer 176-11 User manual

Singer

Singer Slant-O-Matic 403 Special Installation and operation manual

Singer

Singer 1288 User manual

Singer

Singer 3851 User manual

Singer

Singer 457 G 115 User manual

Singer

Singer XL-420 User manual

Singer

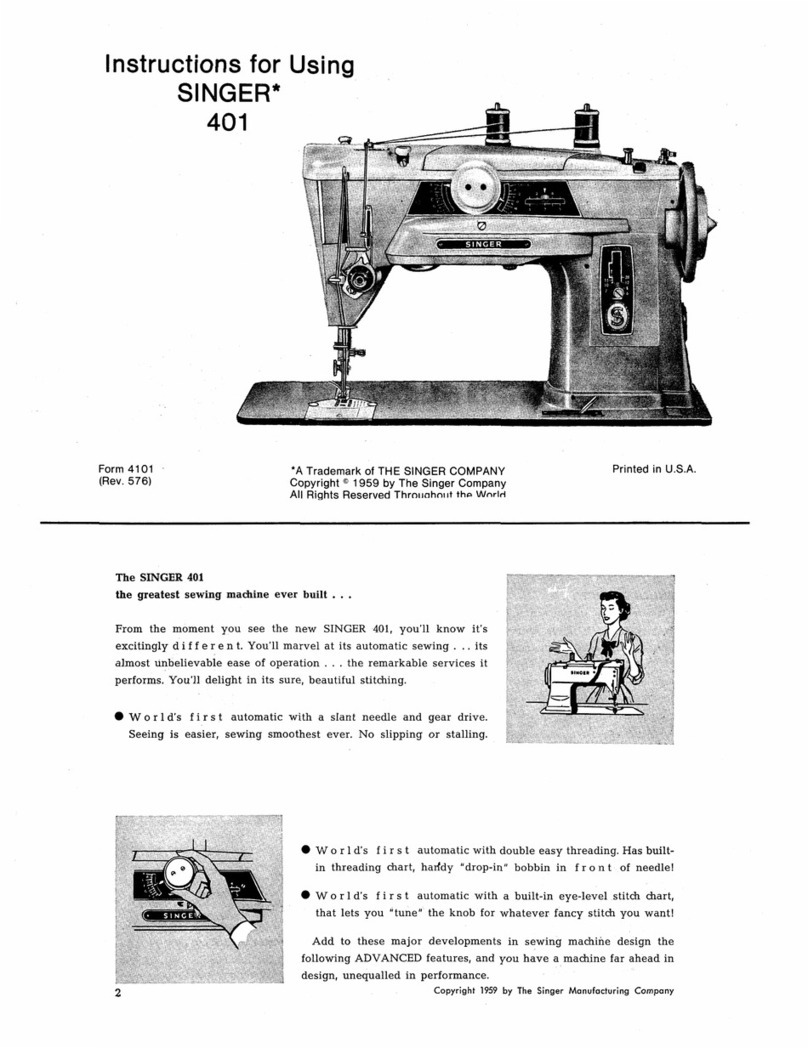

Singer 401 Mounting instructions