Singer 3851 User manual

Other Singer Sewing Machine manuals

Singer

Singer 150W161 Quick start guide

Singer

Singer 99W124 User manual

Singer

Singer 147-82 User manual

Singer

Singer 117-3 User manual

Singer

Singer 337 User manual

Singer

Singer 112W130 Quick start guide

Singer

Singer 15-91 User manual

Singer

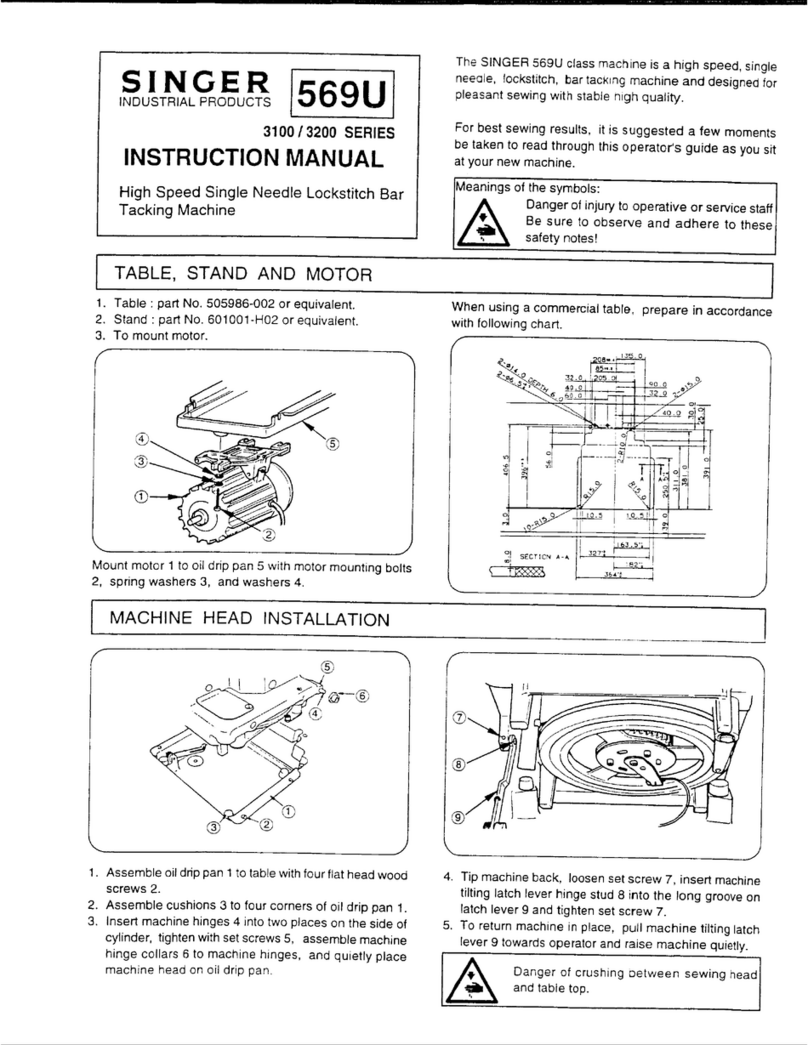

Singer 3100 User manual

Singer

Singer QUANTUM STYLIST 9960 User manual

Singer

Singer FEATHERWEIGHT II 118 User manual

Singer

Singer SE9150 User manual

Singer

Singer 521C User manual

Singer

Singer 831U User manual

Singer

Singer MC 1507 User manual

Singer

Singer TINY TAYLOR TT600 User manual

Singer

Singer 66 Series User manual

Singer

Singer 11W3 Installation and operation manual

Singer

Singer 812U User manual

Singer

Singer 20-2 User manual

Singer

Singer 144B8L20 User manual