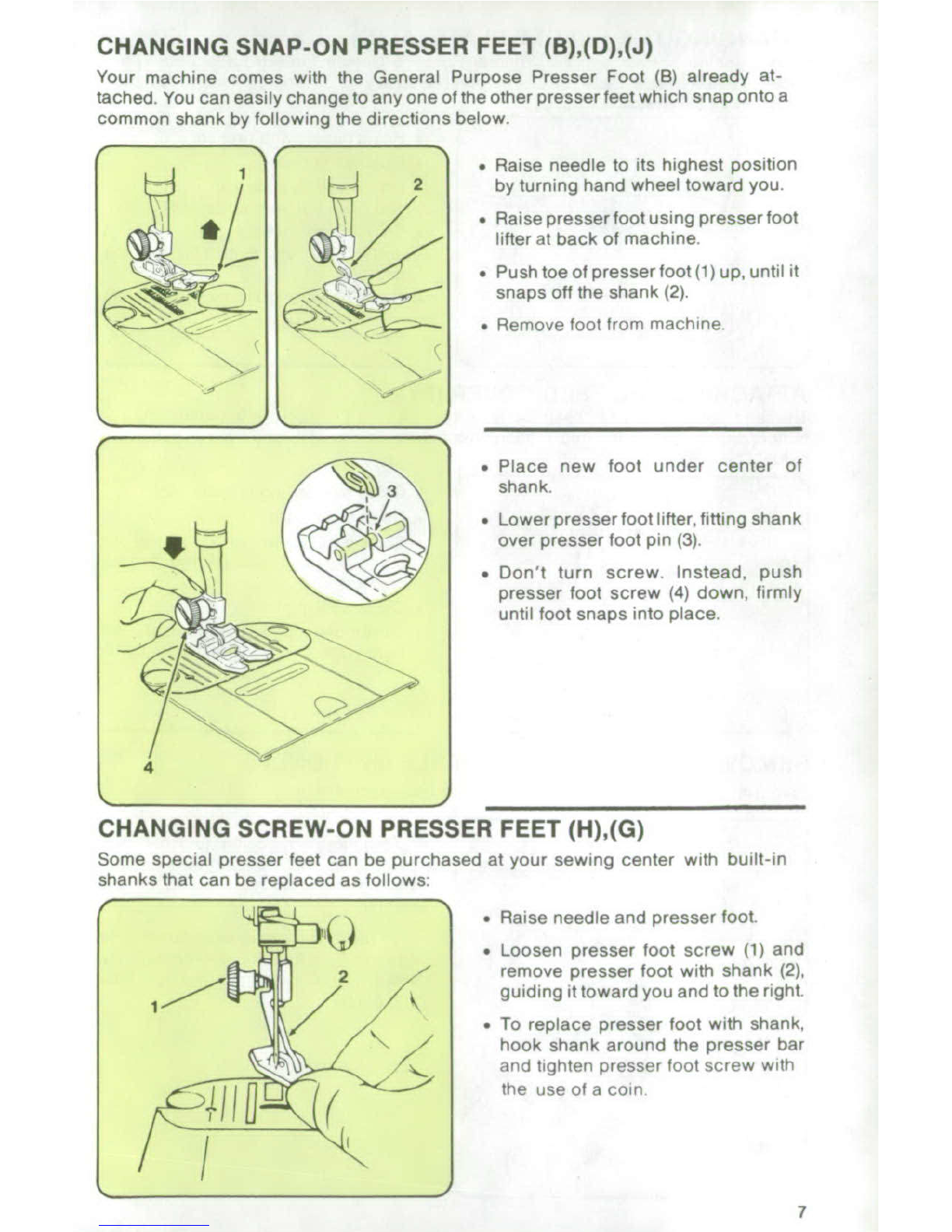

Singer 6201; 6211 User manual

Other Singer Sewing Machine manuals

Singer

Singer 212U141 User manual

Singer

Singer 185 Installation and operation manual

Singer

Singer 251-1 User manual

Singer

Singer 107W15 User manual

Singer

Singer 5532 User manual

Singer

Singer C5900 User manual

Singer

Singer 119-2 Installation and operation manual

Singer

Singer 81K70 Quick start guide

Singer

Singer 135W1 Quick start guide

Singer

Singer 451K125 User manual

Singer

Singer 46W61 Quick start guide

Singer

Singer 44-14 User manual

Singer

Singer 384.18024000 User manual

Singer

Singer S010L User manual

Singer

Singer 92-1 User manual

Singer

Singer 124-1 Quick start guide

Singer

Singer 127-3 & 128-3 User manual

Singer

Singer 70 User manual

Singer

Singer CONFIDENCE 7470 User manual

Singer

Singer 3337 User manual