Singer 4166 User manual

Other Singer Sewing Machine manuals

Singer

Singer 211A165AA Setup guide

Singer

Singer 457G 133 Setup guide

Singer

Singer 144W102 Installation and operation manual

Singer

Singer LITTLE TOUCH & SEW 67A User manual

Singer

Singer 7442 User manual

Singer

Singer QUANTUM XL-5000 Operation instructions

Singer

Singer 240W User manual

Singer

Singer 31K User manual

Singer

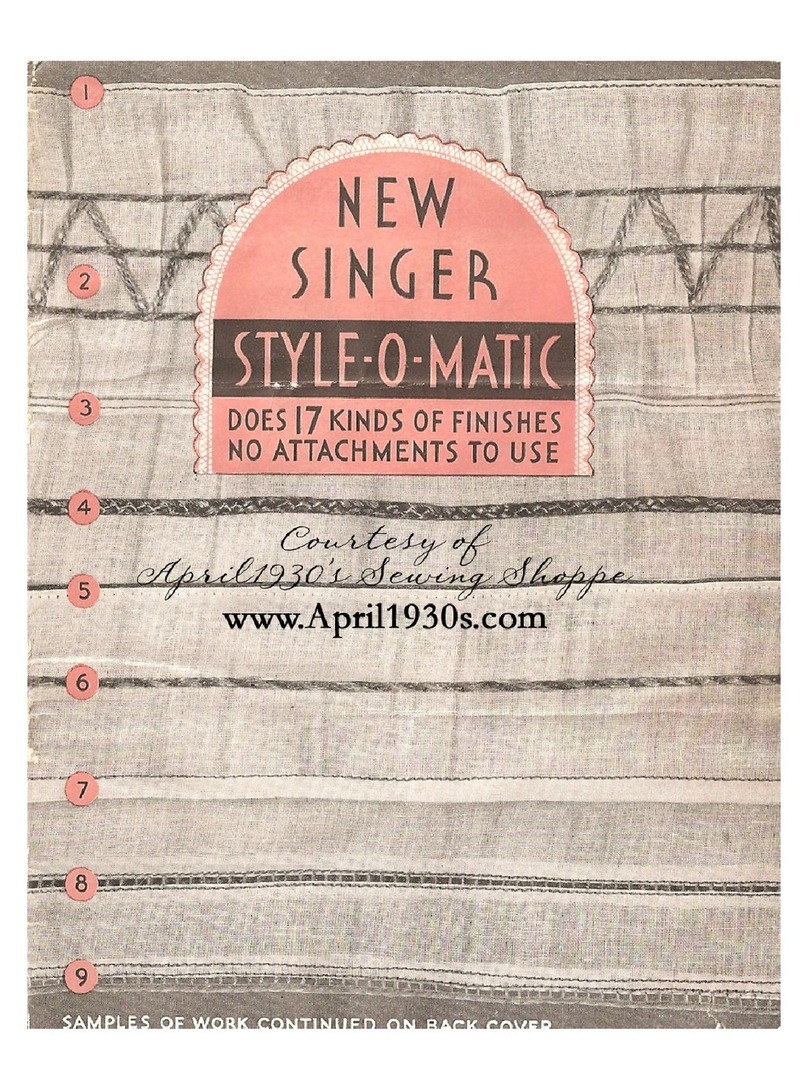

Singer Style-O-Matic User manual

Singer

Singer 281-5 User manual

Singer

Singer 591D200A User manual

Singer

Singer TINY TAYLOR TT600 User manual

Singer

Singer 6105 User manual

Singer

Singer 248-2 User manual

Singer

Singer SERGER 14U64A User manual

Singer

Singer 246-12 User manual

Singer

Singer Stilist II Owner's manual

Singer

Singer 97-7 User manual

Singer

Singer 221K User manual

Singer

Singer 144W305 Quick start guide