DESCRIPTION

The 457 G 1 machine is a high speed, single needle,

lock

stitch,

zig-zag sewing machine for stitching light

and medium weignt fabrics.

^

The

machine

specifications

are as

follows:

-

1.

Needle

Bar

Stroke

1-5/16

inch =

33.40

mm

Presser

Bar

Lift

9/32

inch

=

7.15

mm

Maximum

Width

of

Zig-Zag Stitch

5/32

inch = 4.00 mm

Space at right of Needle 8-3/16 inch = 208.00 mm

Maximum

Length

of

Stitch

6 stitches per

inch

= 4.20 mm per stitch

Bed 15-11/16 inches long, 7 inches wide

= 398.50 mm long, 177.80 mm wide

MachinePulley(SafetyType) for

3/8

inch= 9.50 mm

V-Belt.

Outside diameter of belt groove 2.9 inches

=

73.65

mm.

Effective

diameter

for

5/16

inch

=

7.93

mm

round

leather

belt

2-3/8

inches

=

60.30

mm.

2. Automatic lubricating system for supplying oil to

all

moving

parts

which

can be observed through an

oil

flow

window

at

the

front

of

the

machine

arm.

3.

Transverse,

two

toone,

horizontal

axis

rotary

hook,

automatically pressure lubricated

and

with fine

ad

justment for the oil flow.

4. Single rotary take-up which controls thread at all

times to meet the requirements of the hook.

5. Thread pretension and rotary thread tension for

proper

regulation of the stitch formation.

6. Thewidth of the zig-zag

stitch

isset by turning the

bight control knob and the corresponding setting

is

indicated

at

the

front

of

the

machine.

7. The length of the

stitch

is

adjusted by changing the

feed driving eccentric on the bed shaft

and

the set

ting is indicated on the machine pulley.

8. Pendant

link

mechanism

with

eccentricfor adjusting

the feed dog to height and parallelism.

9. Low inertia presser

bar

mechanism.

10. The arm shaft, the needle vibrating shaft and the

belt

end

of

the

bed

shaft

are

mounted

in

double-

shielded ball bearings.

Needle bearings for the needle bar yoke connec

ting link

and

the feed driving eccentric connection;

super-oilite bushings for the feed driving eccentric

rockshaft, the needle bar yoke shaft and the needle

vibrating eccentric connection link.

11. The removable arm cover permits accessibility to

all parts in the arm.

12. Vibration absorbing location of the machine in the

machine base whioi is

firmly

mounted as oil pan

and

oil

reservoir

in

the

table.

SPEED

The maximum speed recommended for this machine

^

5000

R.P.M.

depending

on

materials

used

and

opera-

ons performed. It is

advisable

to run a new machine

-or a more moderate speed until an oil flow is visible in

the oil flow window and this speed should be maintain

ed for several minutes. When the machine is

In

operat

ion, the machine pulley must always turn over toward

the operator.

SETTING

UP

The machine rests on a cork gasket in the machine

base. The machine base also serves as drip pan, oil re

servoir and as housing for the knee lifter.

When using the SINGER-table the machine base rests

on

its

four cornersand

is

fastened by meansof rest

pins

(wooden) furnished

with

the machine.

Any

table-cut-out

into

which

the machine base cannot be inserted pro

perly must be reworked or adjusted by

shims

so that

the

machine

base

1.

does

not rock,

2. is level in both directions,

3. prevents the inserted machine from touching

the

table,

4. raises

the

inserted machine

above

the

table,

enough to open the bed slide

and

that the

bed hinge connections support the machine

only when it is tilted back.

When assembling the knee lifter make certain that

the knee lifter pin is properly inserted to connect the

knee

lifter

mechanism

of

the

machine

with

that

of

the

machine base. The lifting range of the knee lifting lever

sfc^n

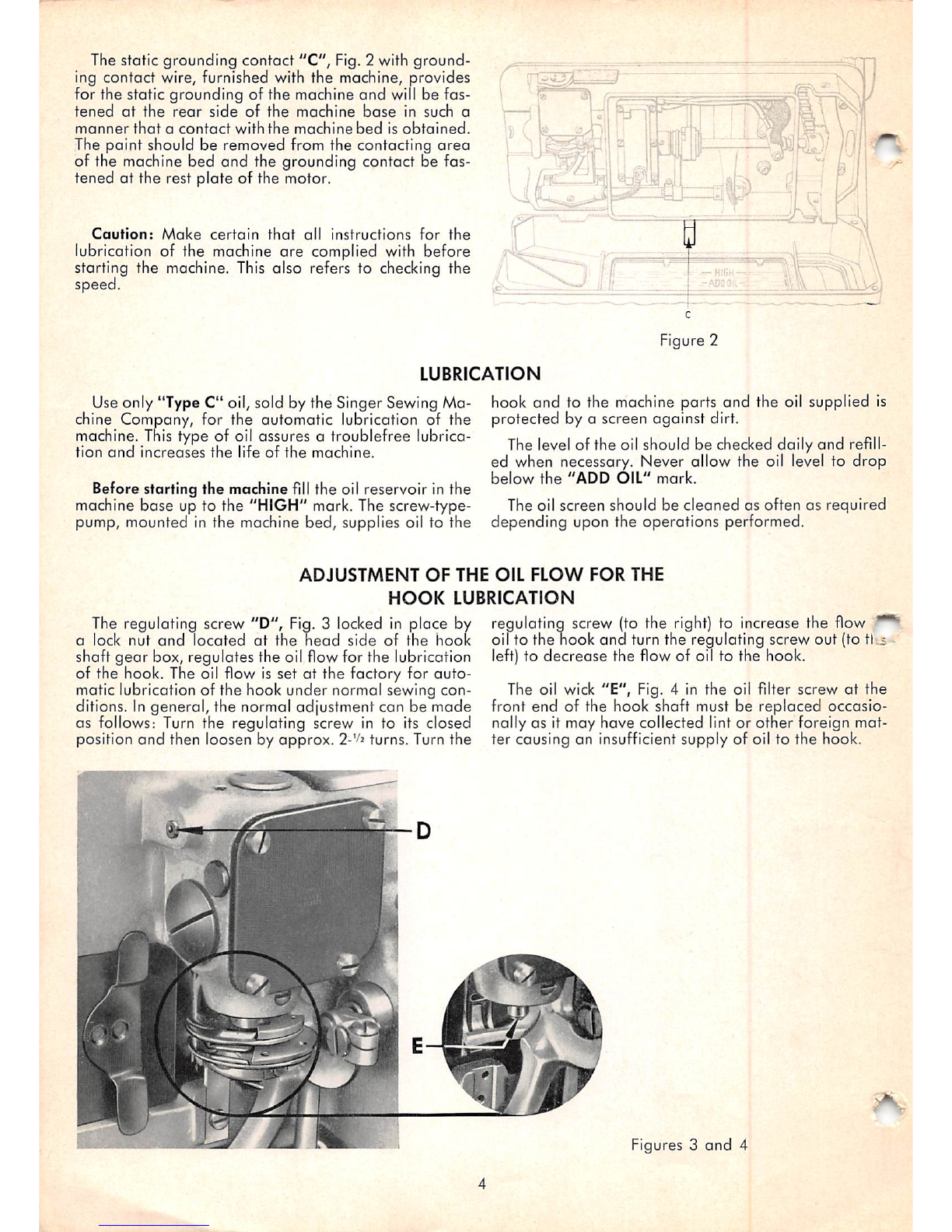

be adjusted by the screw"A",

Fig.

1 (no

lifting)

and

^ the screw "B", Fig. 1

(full

lifting). When using the

~-itill

lifting range, the lifted presser

bar

lifter must disen

gage.

itufr'"-'

Figure 1