TABLE OF CONTENTS

INTRODUCTION .................................................. 1

Intended Use...............................................................1

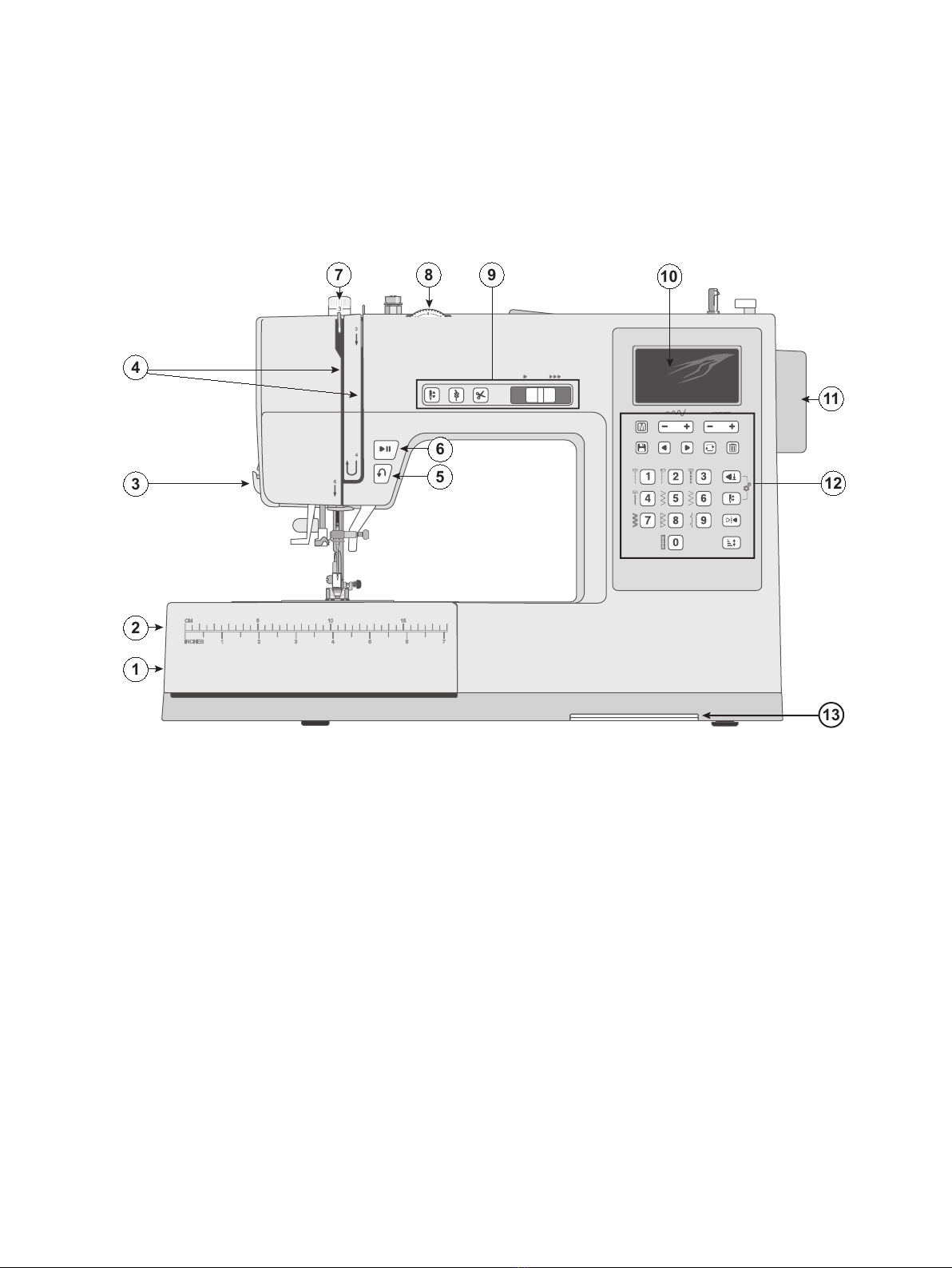

Machine Overview .......................................................1

Needle Area Overview .................................................2

Top of Machine............................................................2

Overview Accessories..................................................3

Included Accessories (Not Pictured)...............................3

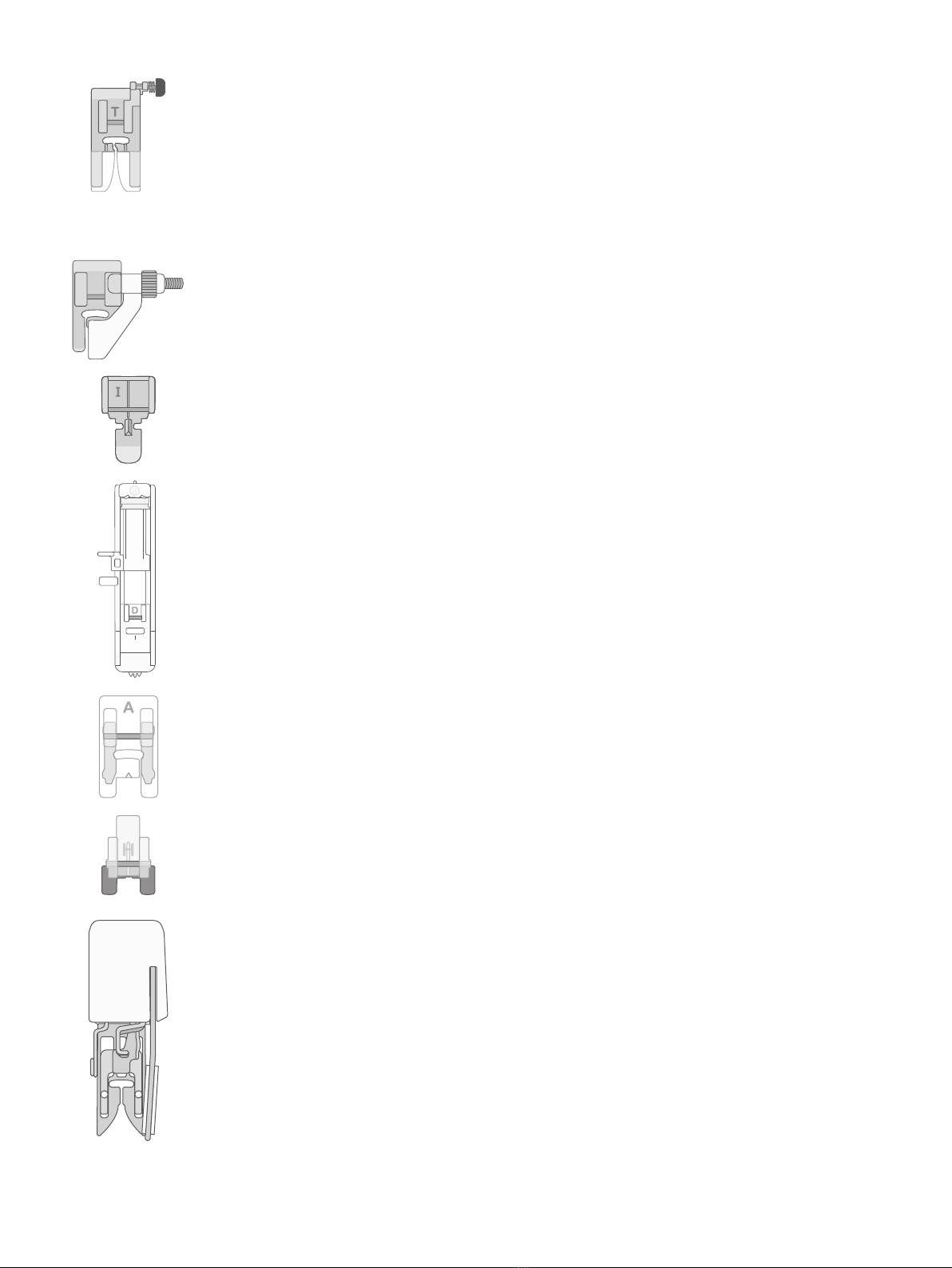

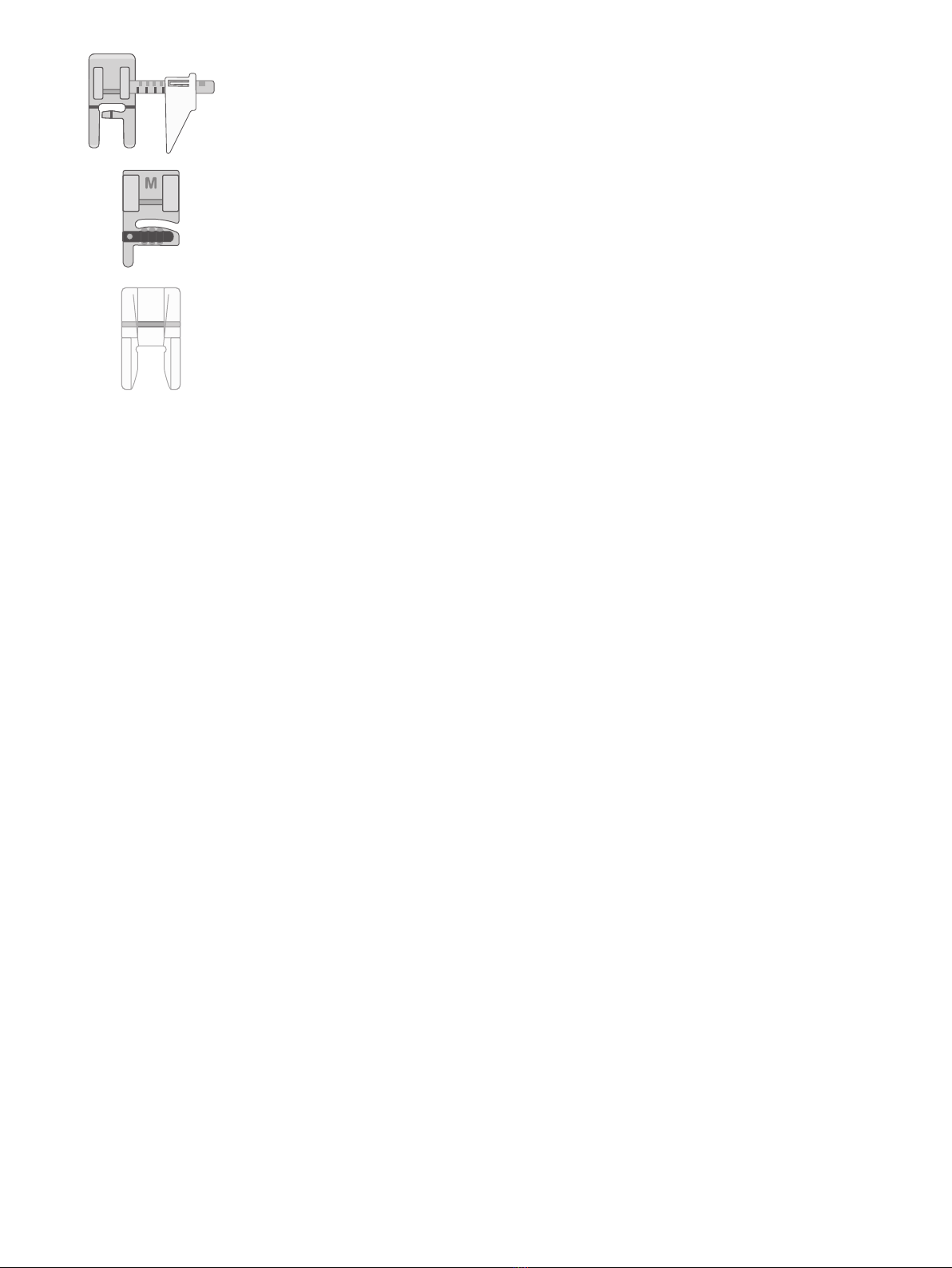

Presser Feet ...............................................................4

Optional Accessories...................................................5

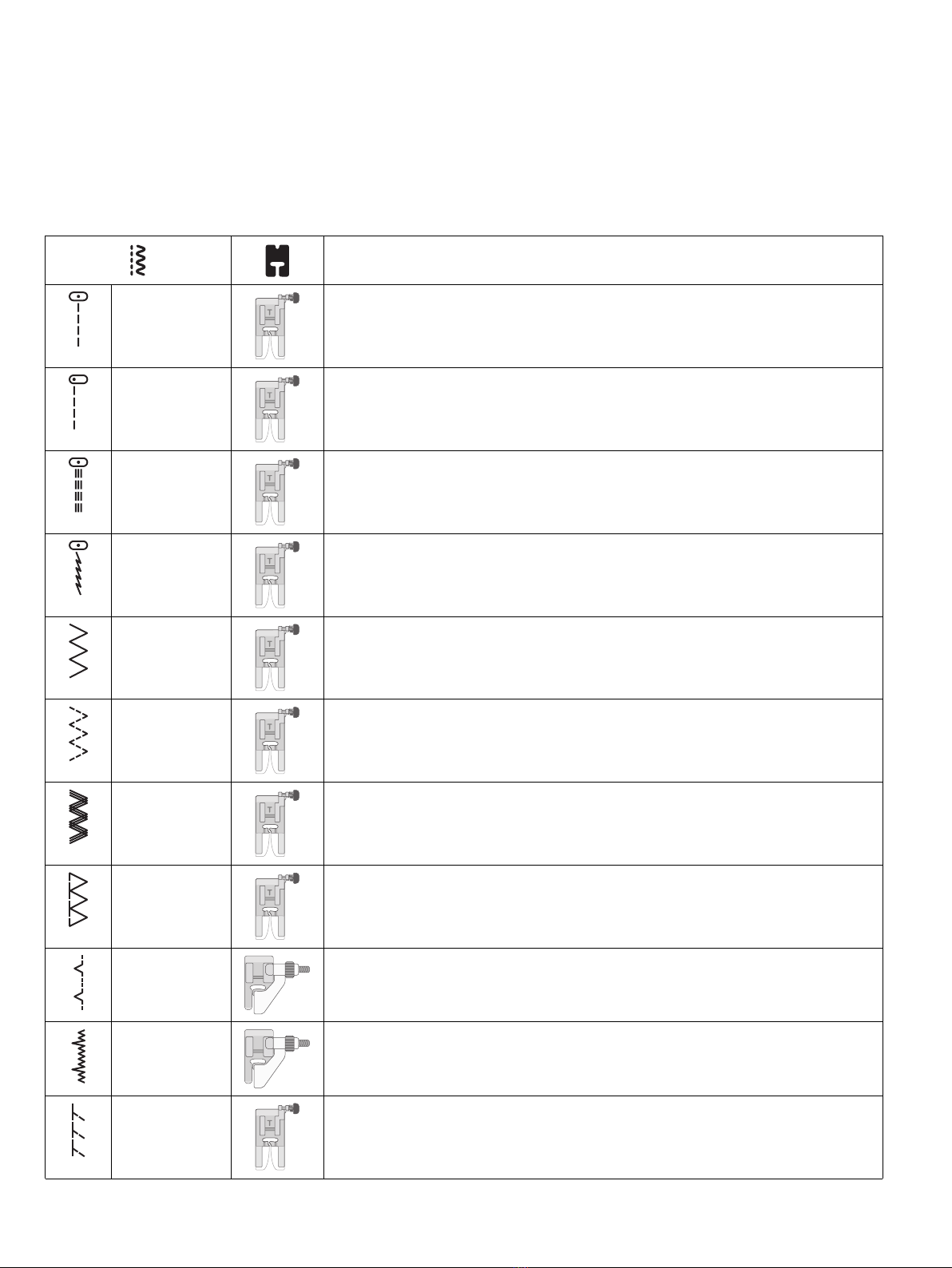

Stitch Overview ...........................................................6

Utility Stitches...........................................................6

Decorative Stitches .....................................................8

PREPARATIONS .................................................. 9

Unpacking the Machine................................................9

Connect to the Power Supply .......................................9

Packing Machine after Sewing......................................9

Free Arm/Removable Accessory Tray .........................10

Presser Foot Lifter .....................................................10

Thread Knife .............................................................10

Spool Pin .................................................................. 11

Wind the Bobbin ........................................................12

Insert the Bobbin .......................................................12

Thread the Machine...................................................13

Needle Threader .......................................................14

Needles ....................................................................14

Important Needle Information ..................................... 15

Selection Guide — Needle Size, Fabric, Thread ............. 15

Change the Needle....................................................15

Thread Tension .........................................................16

Sew without Feed Teeth .............................................16

Presser Foot Pressure ...............................................16

Change the Presser Foot ...........................................17

OPERATING YOUR MACHINE ....................... 18

Machine Operation Controls .......................................18

Reverse Button ........................................................ 18

Start/Stop................................................................ 18

Needle Up/Down...................................................... 18

Tie-Off................................................................... 18

Automatic Thread Cutter............................................ 18

Speed Control Lever ................................................. 18

Stitch Control Panel ...................................................19

Display................................................................... 19

Stitch Menu / Sound On/Off ....................................... 19

Stitch Width / Needle Position .................................... 19

Stitch Length........................................................... 19

Stitch Selection Buttons............................................. 19

Sequence Controls.................................................... 20

Automatic Stop Setting.............................................. 20

Needle Up/Down Setting ........................................... 20

Mirror Side to Side ................................................... 20

Elongation .............................................................. 20

Sewing Mode ............................................................20

Display — Sewing Mode ........................................... 20

Select a Stitch .......................................................... 21

Sequence Mode ........................................................22

Display in Sequence Mode ......................................... 22

Create a Sequence .................................................... 22

Sew Out a Sequence.................................................. 23

SEWING............................................................... 24

Sewing .....................................................................24

Start to Sew – Straight Stitch ......................................24

Change Needle Position............................................. 24

Change Sewing Direction...........................................25

Finish Sewing............................................................25

Straight Stretch Stitch ................................................25

Multi-Step Zigzag Stitch .............................................26

Slant Overedge Stitch ................................................26

Closed Overlock Stitch...............................................27

Blind Hems ...............................................................27

Darning and Mending.................................................28

Repair Large Holes ................................................... 28

Repair Tears ............................................................ 28

Repair Small Holes................................................... 29

Jeans Hem................................................................29

Button Sewing...........................................................30

One-Step Buttonhole .................................................31

Sew Zippers..............................................................32

Centered Zipper ....................................................... 32

Hand-Look Quilt Stitch ...............................................33

MAINTENANCE.................................................. 34

Cleaning the Machine ................................................34

Cleaning the Bobbin Area...........................................34

Cleaning under the Bobbin Area .................................34

Troubleshooting.........................................................35

Technical Specification...............................................38