TABLE OF CONTENTS

INTRODUCTION............................................. 1

Intended Use .................................................................. 1

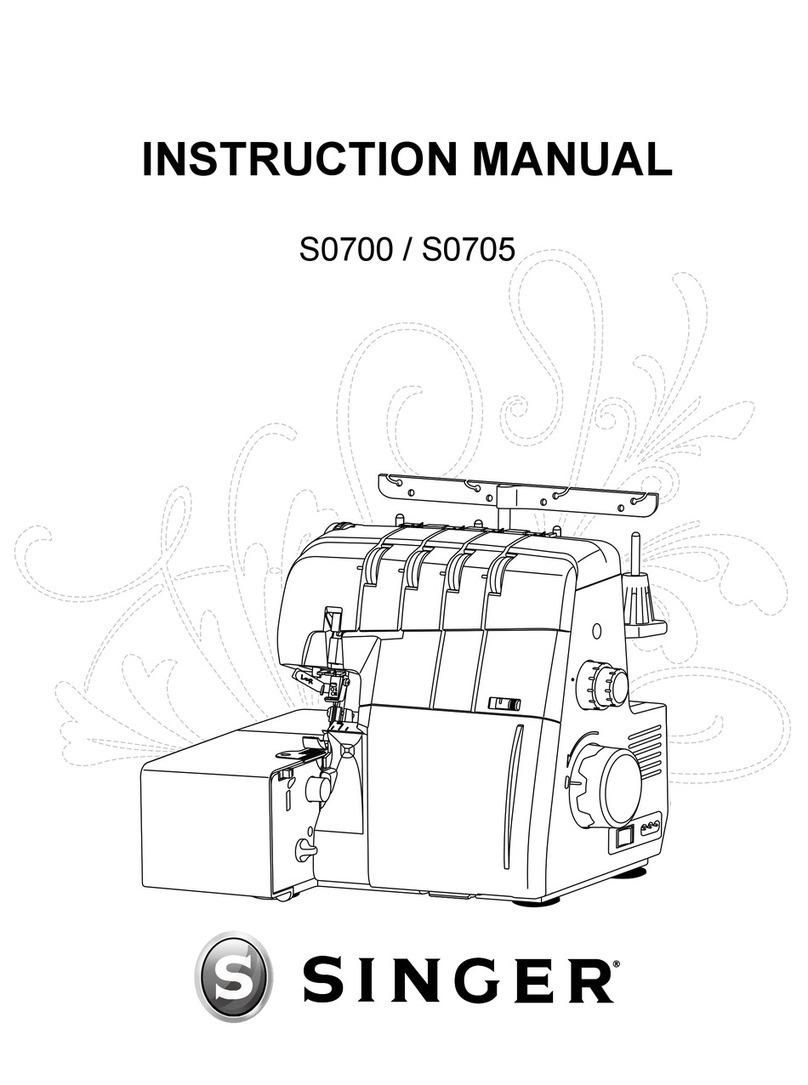

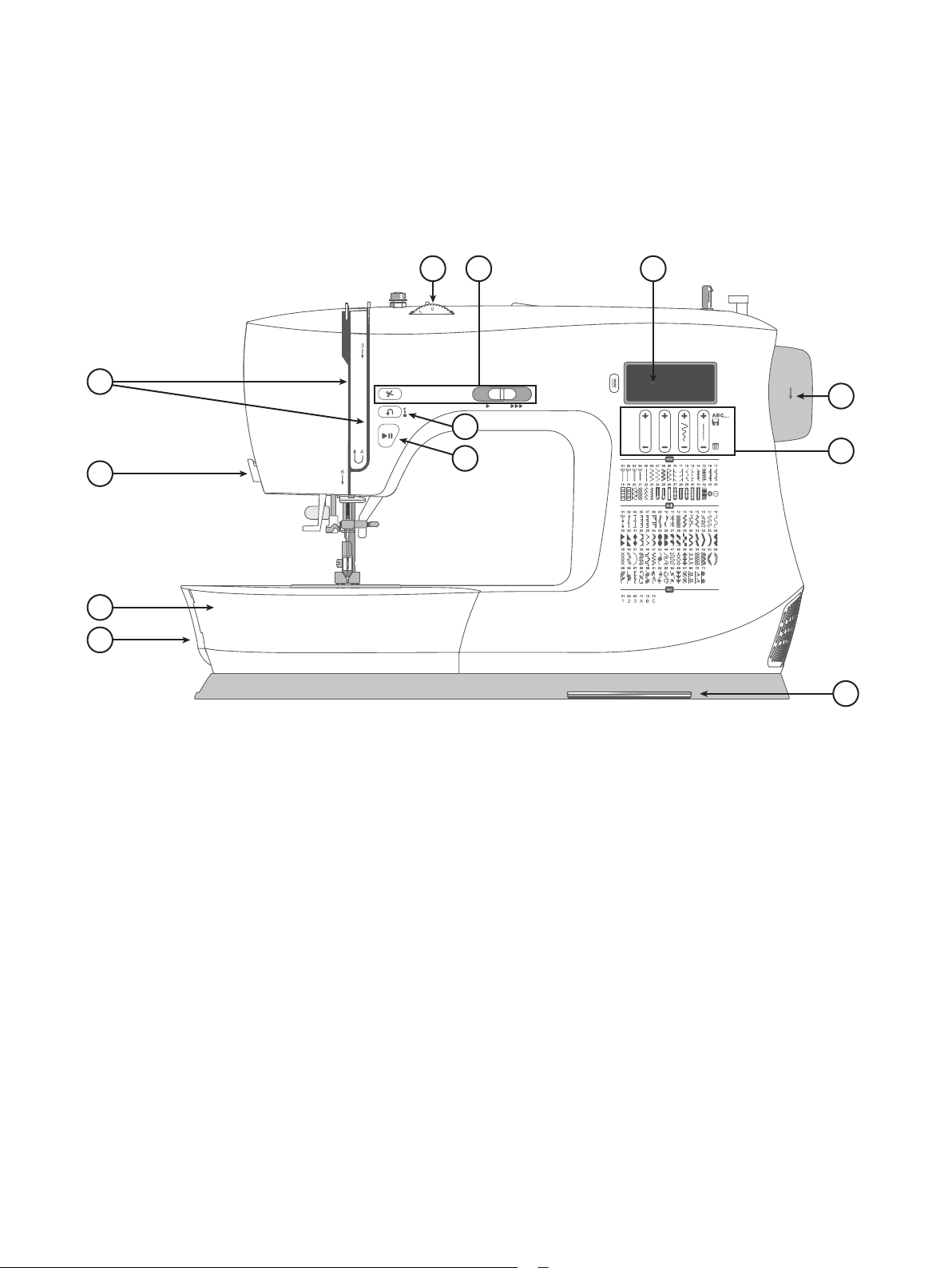

Machine Overview.......................................................... 1

Needle Area Overview.................................................... 2

Top of Machine ............................................................... 2

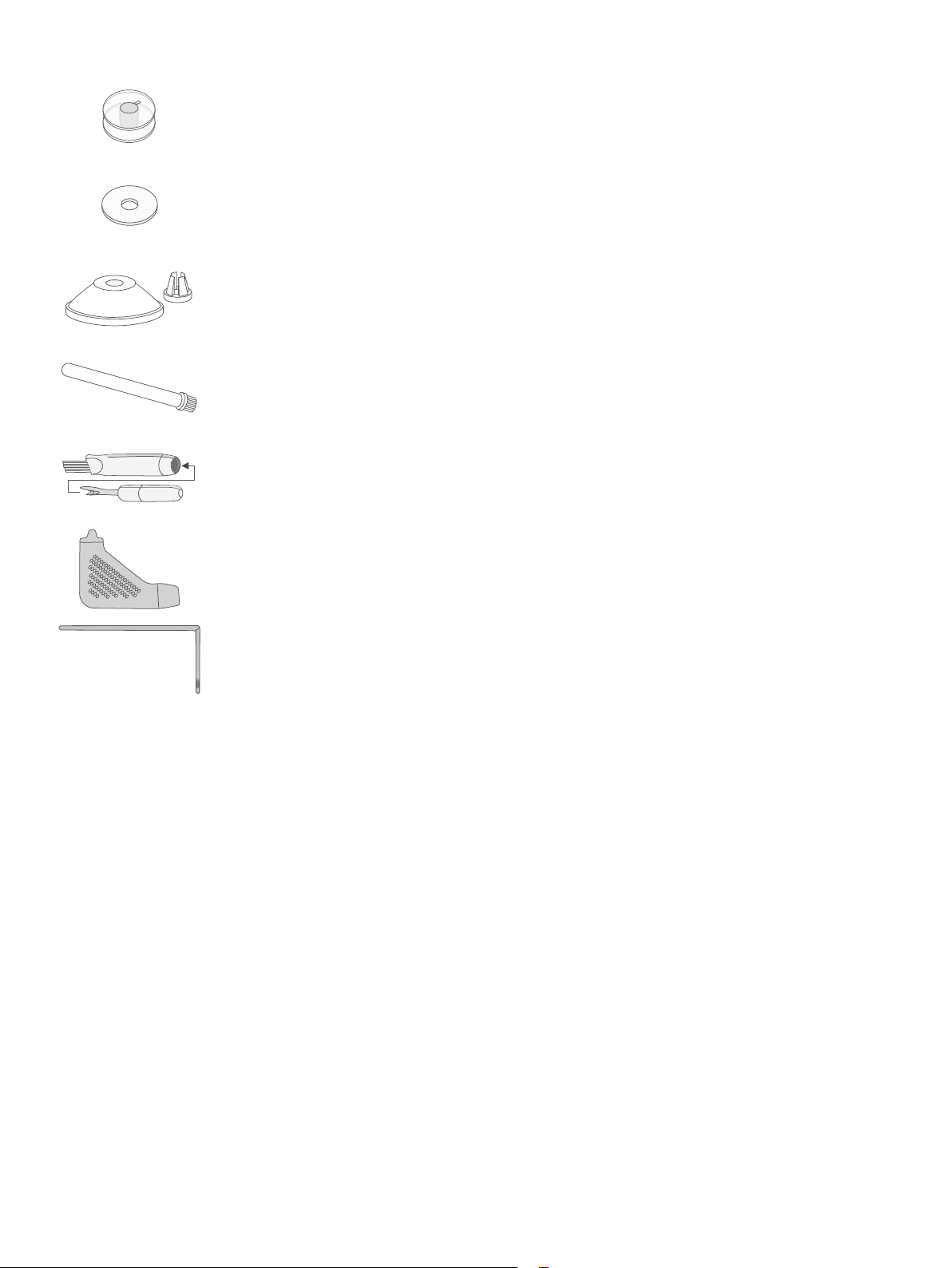

Overview Accessories .................................................... 3

Included Accessories (Not Pictured).................................... 3

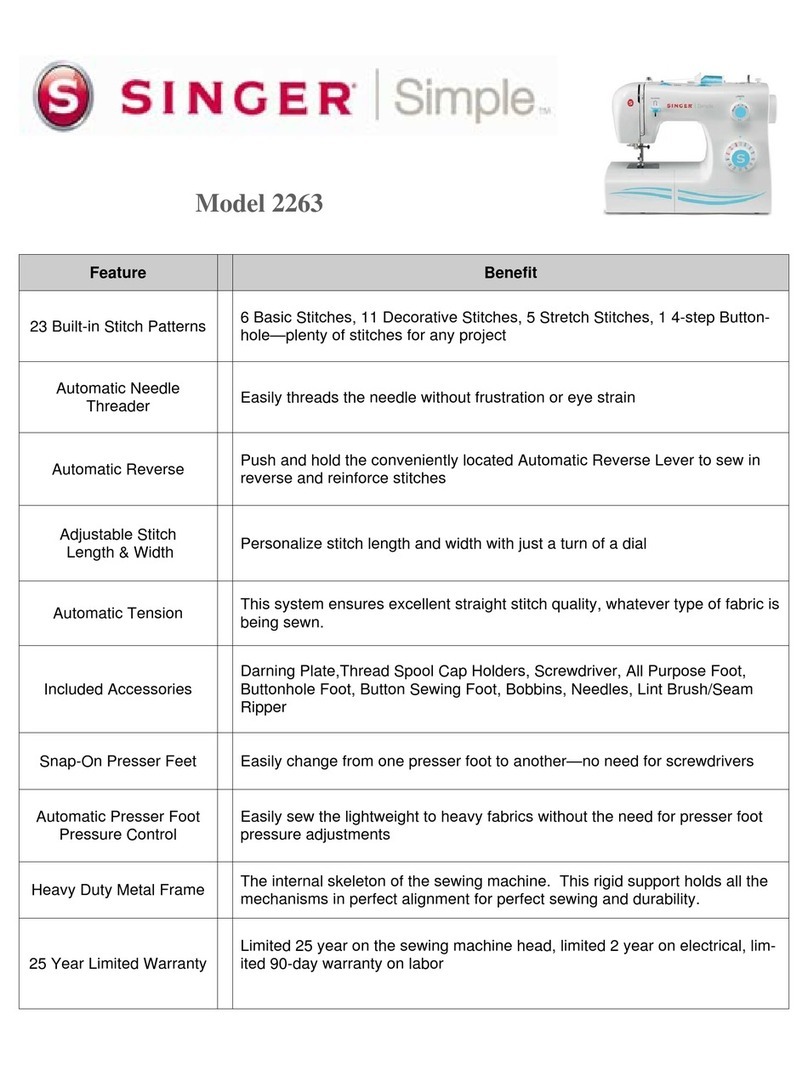

Presser Feet................................................................... 4

Included Presser Feet (Not Pictured) ................................... 5

Optional Accessories............................................................ 5

Stitch Overview............................................................... 6

Utility Stitches ..................................................................... 6

Decorative Stitches .............................................................. 8

All Stitches........................................................................... 8

PREPARATIONS............................................ 9

Unpacking the Machine.................................................. 9

Connect to the Power Supply......................................... 9

Packing Machine after Sewing ....................................... 9

Free Arm/Removable Accessory Tray .......................... 10

Presser Foot Lifter........................................................ 10

Thread Knife................................................................. 10

Spool Pin .......................................................................11

Wind the Bobbin ........................................................... 12

Insert the Bobbin .......................................................... 12

Thread the Machine...................................................... 13

Needle Threader........................................................... 14

Needles ........................................................................ 14

Important Needle Information ........................................... 15

Selection Guide — Needle Size, Fabric, Thread ............... 15

Change the Needle....................................................... 15

Thread Tension............................................................. 16

Sew without Feed Teeth ............................................... 16

Change the Presser Foot ............................................. 17

OPERATING YOUR MACHINE.................... 18

Machine Operation Controls......................................... 18

Reverse Button................................................................... 18

Tie-Off................................................................................ 18

Start/Stop............................................................................ 18

Needle Up/Down ............................................................... 18

Automatic Thread Cutter ................................................... 18

Speed Control Lever .......................................................... 18

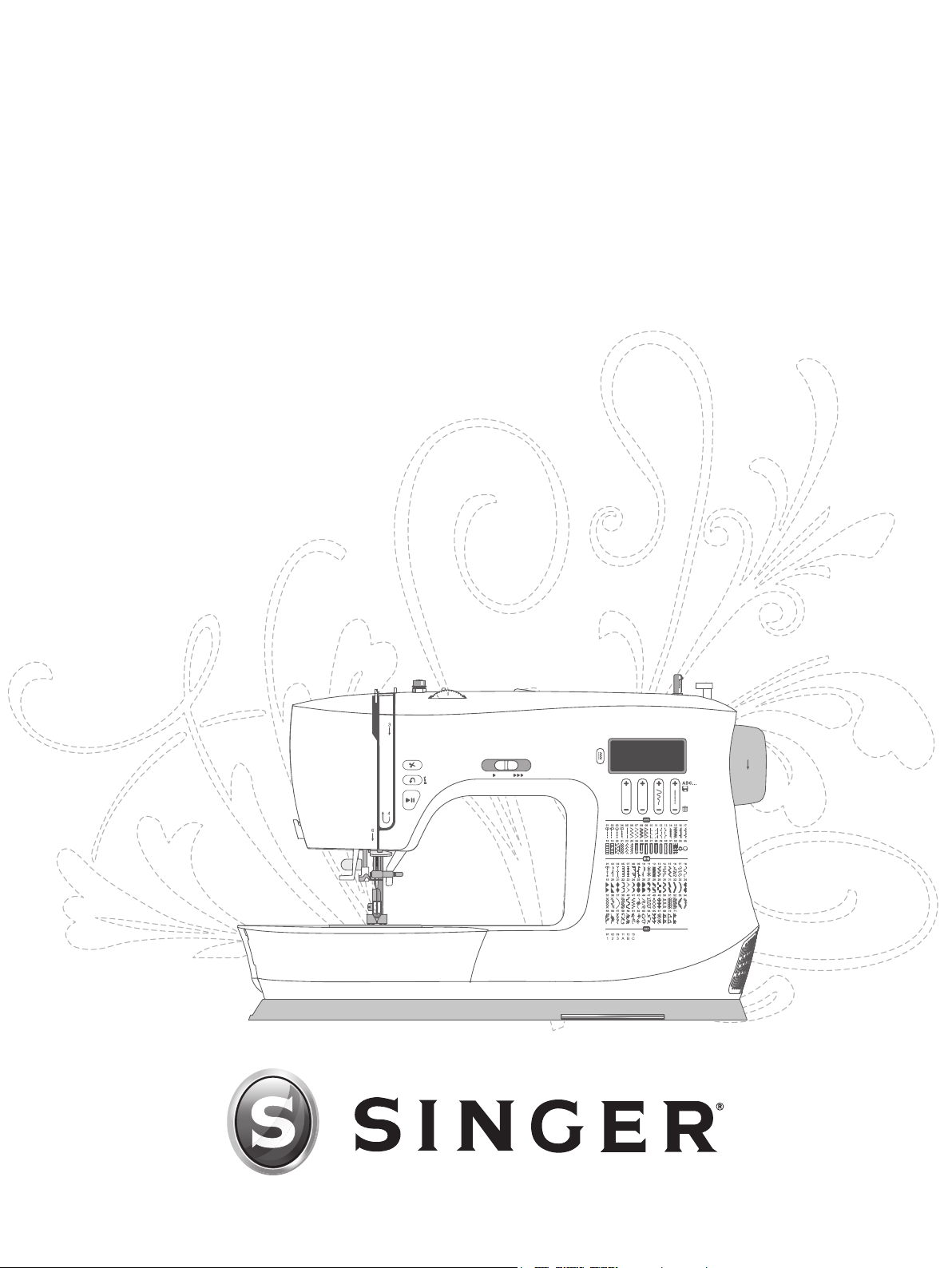

Stitch Control Panel...................................................... 19

Display ............................................................................... 19

Stitch Menu / Sound On/Off .............................................. 19

Stitch Width / Needle Position........................................... 19

Stitch Length...................................................................... 19

Stitch Selection Buttons..................................................... 19

Sewing Mode................................................................ 20

Display in Sewing Mode.................................................... 20

Select a Stitch..................................................................... 20

Create a Sequence .............................................................. 21

SEWING........................................................ 22

Sewing.......................................................................... 22

Start to Sew – Straight Stitch........................................ 22

Change Needle Position..................................................... 22

Change Sewing Direction............................................. 23

Finish Sewing ............................................................... 23

Straight Stretch Stitch................................................... 23

Multi-Step Zigzag Stitch................................................ 24

Slant Overedge Stitch................................................... 24

Closed Overlock Stitch ................................................. 25

Blind Hems ................................................................... 25

Darning and Mending ................................................... 26

Repair Large Holes ............................................................ 26

Repair Tears ....................................................................... 26

Repair Small Holes ............................................................ 27

One-Step Buttonhole.................................................... 28

Sew Zippers.................................................................. 29

Centered Zipper ................................................................. 29

Hand-Look Quilt Stitch.................................................. 30

Button Sewing .............................................................. 30

MAINTENANCE............................................ 31

Cleaning the Machine................................................... 31

Cleaning the Bobbin Area............................................. 31

Cleaning under the Bobbin Area................................... 31

Troubleshooting............................................................ 32

Technical Specication ................................................. 35