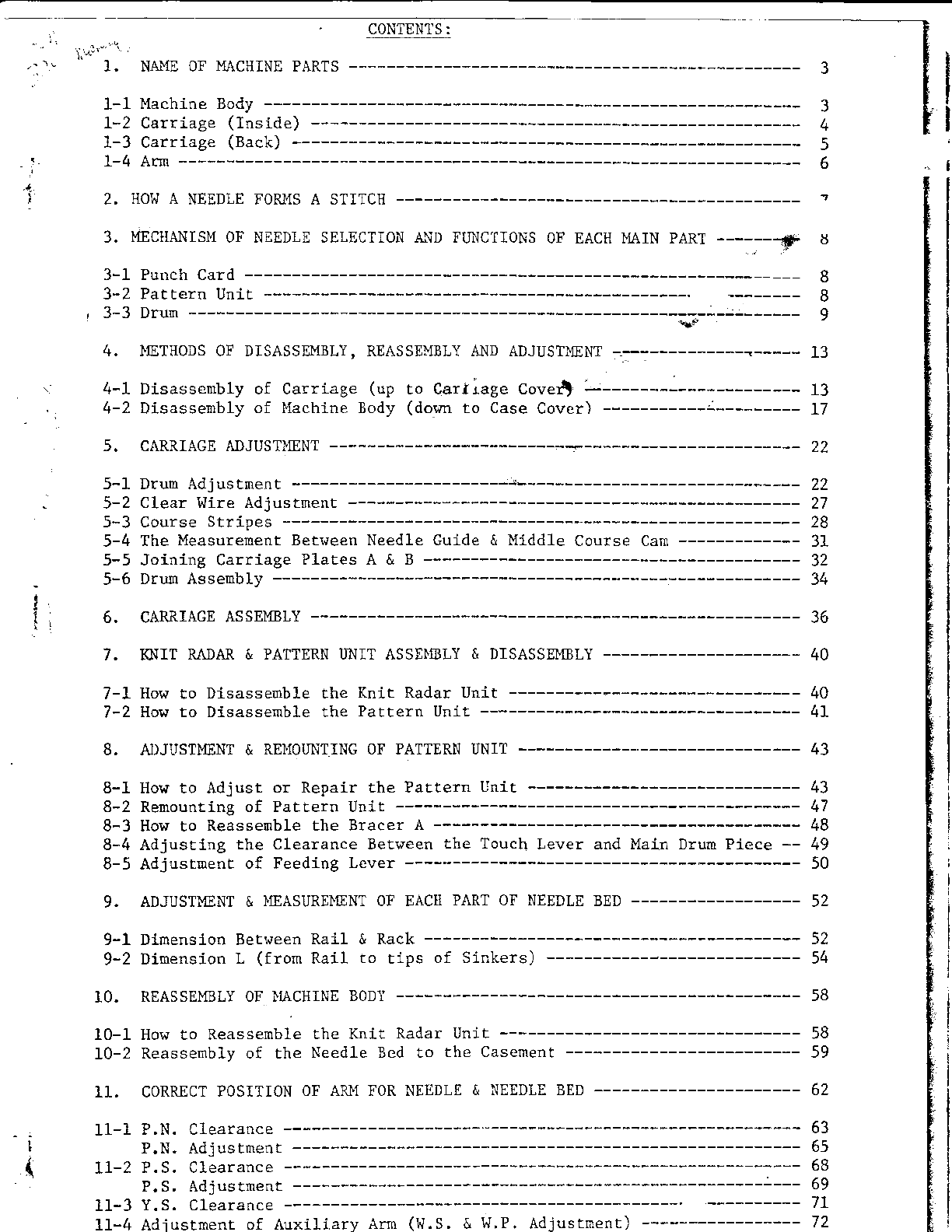

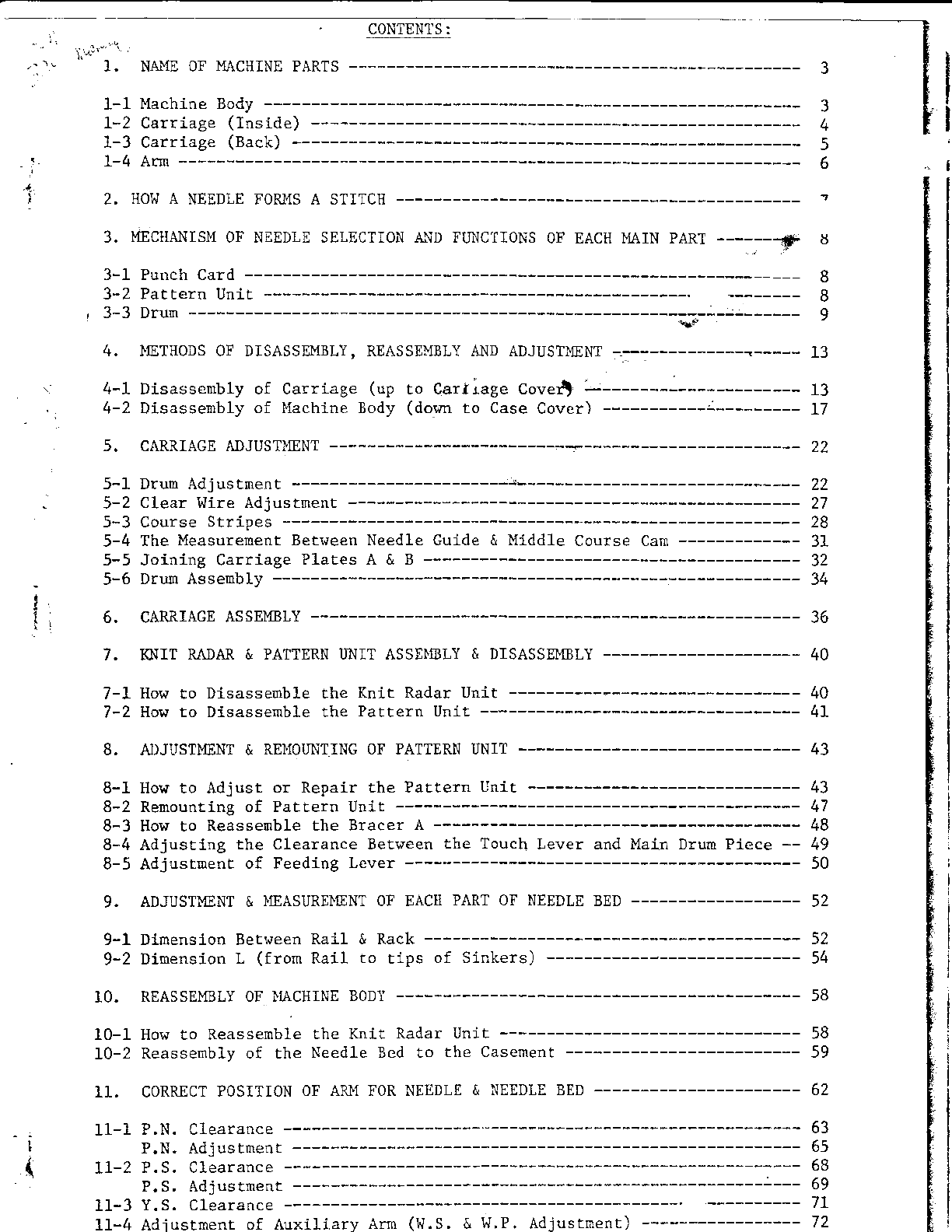

coNrfNTs:

1-I MaLh Lne Bodv ------------

l-2 Csrridge (1ns ide) --

1-3 Carriage (Back) -----------

1-4 Arn ---'-r----

2. liOW A NEEDIE FOR.]'{S A STITCH

3. IfECIIANISM OF NEEDLE SELECTION A.liD FUNCTIONS OF EACH I{AIN PART -------tli- E

3-1 Punch Card ------------ 8

3-2 Pattern Unit --*-^------- -------- 8

3-3 Drun ---*---- ------ 9

4. IIETIIODS 0F DISASSIMBLY, REASSEIIBLY AND ADJUSTITENT -:-:---------------- 13

4-1 Disassenbly of Carriage (up to Carlrage coverf ---------------------- 13

4-2 Disassembly of Machine Body (down to Case Cover) --------------------- 17

5. CARRTAGE ADJUSTIIENT ---------------- 22

5-1 Drum Adjuslnent -------------- ------ 22

5-2 Clear Wire Adjustnent -------------- 27

5-3 Course Stripes --------- ------------ 28

5-4 The Measurement Betr'reen Needle Guide & Middle Course Carn ------------- 31

5-5 Joining Carriage PlaEes A & B ----------- ---------- 32

5-6 Dru$ Assenbly ---------------------- 34

6. CARRTACE ASSEMBLY -------- ---------- 36

3

6

t

1, 7. KNIT RADAR & ?ATTERN UNIT ASSN}ELY & DISASSEMBLY -__------_--_-_----.. 40

7-1 How to Dlsasseoble the Knit Radar Unit -------'----

7-2 How to Disassenble the Patter:n Unit ------------

B. AI)JITSTMENT 6 RElIol,'liTING 0F PATTERN UNIT ------------------------------ 43

40

41

I

i

8-1 Ho\r to Adjust or Repair the ?atlein Unit ------------ 43

8-2 Remounring of Pattern Unit ------------ ------------- 47

8-3 ltow to Reassenble lhe Bracer A --------------- ------- 48

8-4 Adjustlng the Clearance Belween the Touch Lever and Mai.n Drum Piece -- 49

8-5 Adjostnent of Feeding Lever ----------- -------------- 50

9. ADJUSTMENT & }IEASURE}ANT OI EACI1 PART OF NEEDLE BED ------._-_-_--_-_- 52

9-1 Dlnenslon Betueen Rail & Rack ---------- ------------- 52

9-2 Dir0ension L (fron Rail to tips of Sinkers) -------- ----------- 54

10. REASSEMBLY OF ITACHTNE BoDY ------------ ------------- 58

t0-1 How to Reassemble the Knit Radar Unit ------------ ------------- 58

10-2 Reassenbly of the Needle Bed to the casemen! ------------------------- 59

11. CORRECT ?OSITION OF AR}f TOR NEI1DLE & NEEDLE BED ---------------------- 62